Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sapphire Metrics That Matter FAQ PDF

Caricato da

mikecostantiniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sapphire Metrics That Matter FAQ PDF

Caricato da

mikecostantiniCopyright:

Formati disponibili

Frequently Asked Questions

Sapphire Quality Metrics that Matter

What are the metrics that do matter when evaluating sapphire quality? There are several potential defects in bulk sapphire cores that can have a significant impact on important downstream LED processes including epitaxial growth and wafering yields. These defects include the presence of bubbles (exclusion zones) and low angle grain boundaries. GTs ASF growth process dramatically minimizes these defects during crystal growth. GT developed a method called OHT, or Optical Homogeneity Technique, which is proven to detect these critical defects, bubbles and low angle grain boundaries. GTs ASF customers can adopt this method for grading ASF material. This ensures that GT and its ASF customers ship only the highest quality cores, maximizing our customers yields. A true measure of the quality of sapphire is how sapphire performs on key LED wafering parameters such as surface roughness (Ra), total thickness variation (TTV), warp and bow. The rate of wafer rejections and ultimately wafer yields are critical measures for wafer manufacturers as wafer yields directly impact their economics. GT recently completed a blind study to evaluate the impact of sapphire material on LED wafering. This study demonstrated that the quality and characteristics of the sapphire material source has a direct impact on LED wafer yields and that, of the materials from four suppliers that were blindly tested by an independent LED wafering manufacturer, GT ASF grown sapphire material delivers the highest wafer yields. GT ASF sapphire also ranked the best on overall performance, which was based on Rejected Wafer Ratio, EPD results and wafering geometry. (See Yields Matter: A Case Study on the Impact of Sapphire Material on LED Wafering Yields http://www.gtat.com/resources-casestudies.htm) This LED wafering analysis is part of a larger comprehensive material characterization project initiated by GT to study the effects of sapphire material properties on the entire High Brightness (HB) LED value chain and identify a comprehensive set of the metrics that matter in assessing sapphire quality and yields at each step of the LED supply chain. GT intends to publish additional papers reporting the findings from its ongoing and future studies.

Is color a metric that matters in determining the quality of GT ASF sapphire? No, there is no evidence that the pink color of GT ASF sapphire is a relevant measure of quality nor that the color in GT ASF sapphire negatively impacts any manufacturing processes or HB LED device performance. Although color has been correlated to contamination in some sapphire, GT has conducted extensive GDMS research that proves that the pink hue of ASF sapphire is not indicative of any contamination or impurities. GT ASF sapphire is also proven to meet and exceed the wafer standards for 99.9995% purity. In addition, the color in GT ASF sapphire is proven to be annealed out during the standard epi-wafer manufacturing process which calls for postannealing of sapphire at the wafer level for any and all sapphire wafers because of the stress induced by the polishing and lapping processes this step eliminates any traces of color from sapphire wafers, regardless of the sapphire source. GT has conducted extensive research to evaluate the impact of sapphire color on LED manufacturing and has published the results of this color analyses in a case study titled The Impact of Sapphire Color on HB LED Manufacturing (http://www.gtat.com/resources-casestudies.htm). GT has performed a transmission analysis called PCI, or Photo-thermal Common Path Interferometry developed to study absorption for high end LIGO optics (Laser Interferometric Gravitational Observatory), at Stamford University. The study had shown that the absorption of GT ASF pink material was the lowest, meaning that transmission of light was higher as compared to two suppliers of KY and one of HEM-like grown sapphire.

Is GT sapphire pink? What is the pink caused by? Yes, sapphire grown using GTs ASF technology can have a pink hue. The pink hue in ASF sapphire is a result of an engineered growth process that optimizes material for LED applications, improving the yield of high quality

LED sapphire. The pink hue is not an indication of impurities or contamination in GT ASF. It is with the knowledge that GTs sapphire color does not matter, that GT has chosen to grow boules with this high yield process that optimizes production costs. GT ASF material was found to have more red hue intensity, correlating to the pink appearance of the ASF grown boules. While GT ASF sapphire has a pink hue, all sapphire from other suppliers has color and as measured during our material characterization efforts. Other growth technologies material was shown to have more yellow hue, which is less apparent under typical lighting conditions.

If the pink color is not caused by impurities, what then causes the distinctive pink hue? No crystal is perfect. Thermodynamics dictates that a certain amount of crystal imperfections, even at extremely small levels, will occur in all crystals including sapphire. Imperfections such as vacancies (where an atom is missing from the lattice) or interstitials (where an extra atom occurs in the wrong location) are known to cause color, and it has been suggested in the literature that this may be the cause of pink in sapphire. As the findings of our recent case studies have shown, the pink hue observed in our ASF-grown material causes no downstream issues with HB LED wafer manufacturing.

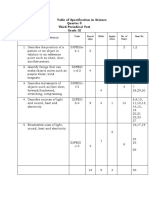

How do you know that all sapphire has color? GT has performed extensive studies evaluating wafer samples from GT and other sapphire suppliers using a Hunter UltrascanPro tool, which is a leading metrology tool for measuring color and color intensity. As illustrated in the chart below, this evaluation has shown that all sapphire has color. GT ASF material was found to have more red hue intensity, correlating to the pink appearance of the ASF grown boules. Material from other suppliers was tested and measured a yellow hue. Yellow color under typical lighting conditions is less noticeable to the human eye than red.

SapphireCoreColorMeasurement

b+

6

HunterUltraScan ProData

HunterScale b* value,(a+ yellow, a blue)

GTASF KYSupplier2

HEMLike KYSupplier1

0 0 1 2 3 4 5 6

a+ HunterScale a* value,(a+ red, a green)

Is the pink color in ASF sapphire an indication of poor quality or contamination? No. The pink of GT ASF sapphire is not indicative of impurities, contamination or poor quality. This is demonstrated by third party analyses as well as direct feedback from long standing LED customers, and their customers many of who are the leading wafer manufacturers and players in MOCVD growth, as well as leaders in industrial markets where very high quality sapphire material is required. This includes:

GDMS analysis has proven that pink-hued ASF sapphire is not indicative of impurities or contamination. Working with an independent laboratory, GDMS analysis of GTs ASF sapphire material has shown that it is as pure as or more pure than competitors sapphire. ASF crystal growth has very low concentrations of V, Cr, Mo, Fe, Ti, and Mg, elements that have been linked to color in sapphire. This analysis has shown that the level of elements in the raw aluminum oxide are the same as the levels of contamination after the sapphire growth process proving that the ASF process does not add any contamination. (See The Impact of Sapphire Color on HB LED Manufacturing - http://www.gtat.com/resources-casestudies.htm). Blind studies have demonstrated that GT ASF sapphire is a leader in quality and yields. GT has conducted a blind study with an independent wafering house to analyze the performance of sapphire from various sapphire suppliers in the critical epi-ready wafering step. Of the material tested from four suppliers, GT ASF grown sapphire material was shown to deliver the highest wafer yields and ranked best on overall performance, which was based on Rejected Wafer Ratio, EPD results and wafer geometry. (See Yields Matter: A Case Study on the Impact of Sapphire Material on LED Wafering Yields http://www.gtat.com/resources-casestudies.htm) Customer feedback has validated that GT ASF sapphire is of the highest quality. GTs proprietary ASF process builds on the 40-year legacy of innovation and quality pioneered by Crystal Systems, which was acquired by GT in July 2010. For over 12 years GT has supplied sapphire to the LED industry, today supplies sapphire material to six of the top 10 LED wafer makers and GT ASF material has been qualified by a leading high brightness device maker. In addition, GT supplies sapphire materials to other industrial markets including the optical market that has much higher quality standards than the LED market. GTs customers across all markets have consistently provided positive observations on the superior quality of the ASF grown sapphire material.

Are there incremental steps or costs associated with removing the pink from GT sapphire? Does sapphire with color like GTs require special treatment to retain the original purity chemicals or costs? No. GT ASF sapphire gets treated exactly the same as any other sapphire source through the entire LED manufacturing process and no extra steps or incremental costs are required to treat GT ASF material. We have received direct confirmation of this from our LED wafering customers as well as their customers.

Could GTs pink sapphire have an impact on optical transparency in chip designs that do not remove the sapphire such as Flip-Chip with sapphire? GT supplies sapphire to and is qualified at a majority of the top wafer manufacturers in the world. GT is confident that there is no negative impact on Flip-Chip and other device architectures that transmit light through GT ASF sapphire. In addition, GT has demonstrated that the color in ASF sapphire gets annealed out during the standard epi-wafer manufacturing process and that post-anneal light transmission reaches theoretical maximums. GT has performed a transmission analysis called PCI, or Photo-thermal Common Path Interferometry developed to study absorption for high end LIGO optics (Laser Interferometric Gravitational Observatory), at Stamford University. The study had shown that the absorption of GT ASF pink material was the lowest, meaning that transmission of light was higher as compared to two suppliers of KY and one of HEM-like grown sapphire.

How does the pink in GT ASF sapphire impact absorption rates and transmission? A study conducted by a third-party using Photo-thermal Common-path Interferometry or PCI recently demonstrated that wafers produced using GT ASF material do not negatively impact absorption rates or impact light transmission on devices that transmit through sapphire substrate. In fact, GT ASF material had the lowest absorption levels and the pinkest of the GT material tested actually had the lowest absorption level of all material tested.

PCI is a method developed at Stanford University for measuring the absorption of optical components. The PCI method was developed specifically for extreme sensitivity for the measurement of low absorbance materials and is a highly accurate method for measurement of the absorption of light at wavelengths from 400nm to 700nm. The study demonstrated that wafers produced using GT material had an absorption measurement of 0.2 %/cm, significantly less than the HEM-like sample which had the highest absorption measurement at 1.6 %/cm, or 8X that of the GT material. Absorption at 455nm was calculated to be <0.1 %/cm, which is far too small to have any negative effect on devices that transmit the LED light through the sapphire substrate. This absorption is far below the 3-5% absorption levels feared by the Flip-chip HB LED industry. (The Impact of Sapphire Color on HB LED Manufacturing - http://www.gtat.com/resources-casestudies.htm).

Theoretically, what could a reduction in optical transparency mean in terms of loss of lumens per wafer? GT has performed extensive analysis of transmission of light to ensure that ASF material does not impact any LED device performance. The effects of optical transparency become insignificant and are not differentiable from that of other suppliers. There is no loss of lumens for HB LED devices manufactured with GT ASF. GT material was measured using PCI (Photothermal Common-path Interferometry) to have an absorption of less than 0.1%/cm, which was lower than other suppliers tested, including KY and HEM-like sapphire. This absorption is too low to have any negative impact on optical transparency.

What is OHT? OHT is GTs non-destructive method for grading the quality of boule or core level sapphire. OHT is designed to detect bubbles and crystal lattice defects at the boule and core level, before the start of any downstream manufacturing. OHT includes a visual inspection under a polarized light to detect low angle grain boundaries (lineages), twins, and bulk sapphire lattice distortion. Also, the sapphire is inspected under a high intensity white light for gas or bubble content in the core material.

What are the differences between ASF and Kyropolous? GTs ASF method is based on the Heat Exchanger Method or HEM obtained by GT in the Crystal Systems acquisition. This method uses a crucible, with a seed placed in the bottom, to melt the sapphire feedstock while using a heat exchanger to cool the seed. The ASF method has the advantage of growing the sapphire crystal from the bottom, meaning the seed and crystal growth begins from the bottom of the crucible and the crystal grows up. The advantage of the ASF approach is that any defects such as bubbles in the melt are allowed to float up and away from the crystal growth front and escape out the top of the melt. This approach is different than Kyropolous (Ky) and Czochralski (Cz), which both seed and grow from the top of the liquid sapphire capturing defects and bubbles in the sapphire crystal. Additionally the ASF method has no moving parts and a low cost heat. Both Ky and Cz have moving parts in the growth and use higher cost shorter lifetime heaters. What are the advantages C-axis vs. A-axis growth? GT ASF makes use of A-axis for growth as it has proven to be higher yielding and more economical. A-axis grows much faster than C-axis therefore choosing larger area A-axis growth planes have proven to be an advantage of the ASF. The fact that sapphire is recyclable adds to the advantage of A-axis growth for C-axis applications leading to the Value Metric for sapphire crystal growth being defined as $/mm unlike other process where the material is not recyclable leading to a Value Metric of Mass Ingot Yield.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Table of Specification in Science Quarter 3 Third Periodical Test Grade IIIDocumento72 pagineTable of Specification in Science Quarter 3 Third Periodical Test Grade IIIMihatsu Taki100% (3)

- Science 5: Quarter 3 - Week 3 Title: Interaction of Objects CompetencyDocumento6 pagineScience 5: Quarter 3 - Week 3 Title: Interaction of Objects CompetencyJane BiebsNessuna valutazione finora

- Plate Heat Exchanger: ApplicationsDocumento2 paginePlate Heat Exchanger: ApplicationsmikecostantiniNessuna valutazione finora

- 2014 Adult Volleyball RegistrationDocumento1 pagina2014 Adult Volleyball RegistrationmikecostantiniNessuna valutazione finora

- File12992 0 m10Documento2 pagineFile12992 0 m10mikecostantiniNessuna valutazione finora

- Introduction To Physical System Modelling WellsteadDocumento256 pagineIntroduction To Physical System Modelling WellsteadErick Manuel CruzNessuna valutazione finora

- TP-20124 Anodizing Acid PDFDocumento8 pagineTP-20124 Anodizing Acid PDFmikecostantiniNessuna valutazione finora

- Guidelines On Sampling Strategy and Submission of Air Monitoring Sample Analysis Report PDFDocumento0 pagineGuidelines On Sampling Strategy and Submission of Air Monitoring Sample Analysis Report PDFmikecostantiniNessuna valutazione finora

- Chemistry 101 Solutions To In-Class Assignment 10 (Due by Nov. 12th) Acids and BasesDocumento3 pagineChemistry 101 Solutions To In-Class Assignment 10 (Due by Nov. 12th) Acids and BasesmikecostantiniNessuna valutazione finora

- Vacuum Coating 21 - 1 PDFDocumento9 pagineVacuum Coating 21 - 1 PDFmikecostantiniNessuna valutazione finora

- Adv Tips and Tricks 16Documento4 pagineAdv Tips and Tricks 16philippe.duque8031Nessuna valutazione finora

- Semi1098tab2 1a PDFDocumento5 pagineSemi1098tab2 1a PDFmikecostantiniNessuna valutazione finora

- Coupled Tanks SystemsDocumento8 pagineCoupled Tanks SystemsNamrajit DeyNessuna valutazione finora

- Vacuum Coating 13 - 1 PDFDocumento8 pagineVacuum Coating 13 - 1 PDFmikecostantiniNessuna valutazione finora

- Vacuum Coating 1 - 1 PDFDocumento5 pagineVacuum Coating 1 - 1 PDFmikecostantiniNessuna valutazione finora

- Adhesion Improvement of Plasma-Deposited Silica Thin Films On Stainless Steel Substrate Studied by X-Ray Photoemission Spectroscopy and in Situ Infrared Ellipsometry PDFDocumento7 pagineAdhesion Improvement of Plasma-Deposited Silica Thin Films On Stainless Steel Substrate Studied by X-Ray Photoemission Spectroscopy and in Situ Infrared Ellipsometry PDFmikecostantiniNessuna valutazione finora

- P&IDsDocumento4 pagineP&IDsRamadhan PrasetyaNessuna valutazione finora

- Getting Started Guide: Blackberry 8830 World Edition SmartphoneDocumento48 pagineGetting Started Guide: Blackberry 8830 World Edition SmartphonevrataryaNessuna valutazione finora

- Uniformity Control in Reactive Magnetron Sputtering - enDocumento4 pagineUniformity Control in Reactive Magnetron Sputtering - enmikecostantiniNessuna valutazione finora

- Nashua Poolsked TermA1Documento1 paginaNashua Poolsked TermA1mikecostantiniNessuna valutazione finora

- CFX Mod RadiationDocumento14 pagineCFX Mod Radiationramy86Nessuna valutazione finora

- Ronald Mark Associates v. StonhardDocumento21 pagineRonald Mark Associates v. StonhardPriorSmartNessuna valutazione finora

- Pep Science Curriculum WorkupDocumento18 paginePep Science Curriculum WorkupAnrewNessuna valutazione finora

- Glass IndustriesDocumento31 pagineGlass IndustriesSandeep Badarla0% (1)

- MC Science - Revision WS - Stage 5 - C05Documento7 pagineMC Science - Revision WS - Stage 5 - C05Camille HugoNessuna valutazione finora

- Oltia Cintec Scenography Crossroads BetDocumento19 pagineOltia Cintec Scenography Crossroads BetTudor SicomasNessuna valutazione finora

- Foc NotesDocumento10 pagineFoc NotesSourabh BiswasNessuna valutazione finora

- Lecture 4 - Microscopic Study of Minerals Under The MicroscopeDocumento23 pagineLecture 4 - Microscopic Study of Minerals Under The MicroscopeAnonymous 8KPGnFtB4100% (1)

- 52 Graphene Photonics Plasmonics and OptoelecctronicsDocumento12 pagine52 Graphene Photonics Plasmonics and OptoelecctronicsHabibe DurmazNessuna valutazione finora

- IPS Empress Direct PDFDocumento8 pagineIPS Empress Direct PDFartecmkNessuna valutazione finora

- Chaos Group - MaterialDocumento22 pagineChaos Group - MaterialonaaaaangNessuna valutazione finora

- 110 Manual Rev 04-15Documento82 pagine110 Manual Rev 04-15Reymundo ChanNessuna valutazione finora

- Kodak Copper Micro Wire Transparent RF Applications White PaperDocumento4 pagineKodak Copper Micro Wire Transparent RF Applications White PaperZypno ZypnoNessuna valutazione finora

- Plastic Materials 1Documento12 paginePlastic Materials 1Anbu M S TNessuna valutazione finora

- Samples Description": The Caving May Subdivided Into Two Main GroupsDocumento11 pagineSamples Description": The Caving May Subdivided Into Two Main GroupsLouisaMjjNessuna valutazione finora

- Light and Shadow FormationDocumento13 pagineLight and Shadow FormationNikil J.PNessuna valutazione finora

- Tubing Selection GuideDocumento4 pagineTubing Selection Guidejoaquim quintanaNessuna valutazione finora

- Revised - Transparent Solar PanelsDocumento5 pagineRevised - Transparent Solar PanelsalirezaNessuna valutazione finora

- 3D Hormigon TDocumento14 pagine3D Hormigon TDiego CorreaNessuna valutazione finora

- Cbse Questions On LightDocumento5 pagineCbse Questions On Lightjoydeep_d3232100% (1)

- Konica-Minolta EP 1054,1085,2030 Service ManualDocumento339 pagineKonica-Minolta EP 1054,1085,2030 Service ManualStefan LaurentiuNessuna valutazione finora

- Experimental Investigation and Cost Analysis of Light Transmitting ConcreteDocumento5 pagineExperimental Investigation and Cost Analysis of Light Transmitting ConcreteTECH MACNessuna valutazione finora

- Super Porcelain Ex 3Documento40 pagineSuper Porcelain Ex 3icepascuNessuna valutazione finora

- Pigments For PlasticsDocumento26 paginePigments For PlasticsFazlul HoqueNessuna valutazione finora

- Near Infrared Qualitative Analysis: Standard Practice ForDocumento8 pagineNear Infrared Qualitative Analysis: Standard Practice ForEric GozzerNessuna valutazione finora

- Ceramic-Applications Transparentkeramik 2016 WernerDocumento6 pagineCeramic-Applications Transparentkeramik 2016 WernerSyiera MujibNessuna valutazione finora

- Near-Infrared Reflectance Analysis Sleeper Among Spectroscopic TechniquesDocumento12 pagineNear-Infrared Reflectance Analysis Sleeper Among Spectroscopic TechniquesFabio OliveiraNessuna valutazione finora

- Factsheet Opaqueness and Opacity enDocumento2 pagineFactsheet Opaqueness and Opacity enNAEEM KHANNessuna valutazione finora