Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ggeothermal Closed Loop Pressure Drop

Caricato da

adammzjinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ggeothermal Closed Loop Pressure Drop

Caricato da

adammzjinCopyright:

Formati disponibili

Version 8.

1

rev. 081809

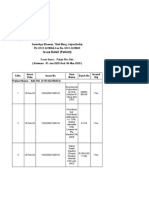

Geothermal Closed Loop Pressure Drop Calculation Worksheet

Customer: Example Address: Address:

1 2

Antifreeze (M,P,E or W)

P 25 5

Propylene Glycol

% Antifreeze by vol.: Number of circuits:

2

Note: M = Methanol; P = Propylene Glycol; E = Ethanol; W = Water Pump combinaton: B (2) UP26-99 Note: Pump combo A = 1-UP26-99; pump combo B = 2-UP26-99; pump combo C = 2-UP26-116; pump combo D = 3-UP26-99 (enter code from below)

1. Unit #1: 4 Unit 1" Hose kit 1-1/4" Inside Piping

(Unit to Flow Contoller)

TT_064

11.1 10 60

ft. of head x ft. of hose* x ft. of pipe* x

1.13 16.45 5.07

TT_026

5 tons Antifreeze corr. fact. = ft. of hd/100 ft. 100 = ft. of hd/100 ft. 100 =

Total Unit #1:

(enter code from below)

gpm 12.57 1.64 3.04 17.25 gpm 8.12 0.33 0.20 8.65 17.25

15

ft. of hd. ft. of hd. ft. of hd. ft. of hd.

2. Unit #2: 1 Unit 1" Hose kit 1-1/4" Inside Piping

(Unit to Flow Contoller)

7.2 10 20

ft. of head x ft. of hose* x ft. of pipe* x

1.13 3.31 1.02

2 tons Antifreeze corr. fact. = ft. of hd/100 ft. 100 = ft. of hd/100 ft. 100 =

6

ft. of hd. ft. of hd. ft. of hd. ft. of hd. ft. of hd.

Total Unit #2:

Unit total (largest of total Unit #1 and Unit #2 -- Units must be piped in parallel): 3. Inside Supply & Return Piping (Flow Controller to wall penetration): Pipe size: 1.25 in. Total gpm: 21 (Design flow rate) ft. of hd/100 ft. 100 = ft. of pipe* x 100 9.13 4. Outside Supply & Return Piping (Wall penetration to header): Pipe size: 1.25 in. Total gpm: 21 ft. of hd/100 ft. 100 = ft. of pipe* x 100 9.13

9.13

ft. of hd.

9.13

ft. of hd.

5. Circuit Piping (Use only one circuit if piped using parallel header system; use total pipe if series loop): Pipe size: 0.75 in. Design GPM/ckt: 4.2 Actual GPM/ckt = 3.4 gpm ft. of hd/100 ft. 100 = ft. of pipe* x 480 5.16 24.78 ft. of hd. 6. Fittings (Add 2 ft. of hd.for every 10 fittings): 7. Total Pressure Drop (A + B + C + D + E):

Minimum system flow rate should be 16 gpm.

100

1-Grundfos 26-99

D E

10

(number of fittings)

2 62.3

ft. of hd.

ft. of hd.** F

8. Determine Pump Sizing Curve Coordinates: Tot. gpm (3 gpm/ton) = Q1 21.0 x Tot. pres. drop (Ft hd)= h1 62.3 y point A Tot. gpm x 2/3 = Q2 14.0 x point B PD=(Q2^2)(h1)/(Q1^2) h2 27.7 y Tot. gpm x 4/3 = Q3 28.0 x point C PD=(Q3^2)(h1)/(Q1^2) h3 110.7 y 9. Plot system curve & determine which Flow Controller will produce the desired flow rate. Pump Sys B = 17 gpm (to the nearest gpm) 10. Verify circuit Reynolds number: 2171

CHECK REYNOLDS NUMBER -- TOO LOW!

90 Ft. of Hd. 80 70 60 50 40 30 20 10 Flow Rate (US gpm) 0

2-Grundfos 26-99 System curve--> 2-Grundfoss 26-116 3-Grundfos 26-99

21

14

10

12

14

16

18

20

22

24

26

28

(Pipe size: (Pipe size: (Pipe size: (Pipe size:

) ) ) )

tot. feet* x tot. feet* x tot. feet* x tot. feet* x

volume/100 ft. 100 = volume/100 ft. 100 = volume/100 ft. 100 = volume/100 ft. 100 = Total fluid in loop: % antifreeze x Total antifreeze req.:

Notes: 1) Use decimal number for pipe size (e.g. 3/4" = 0.75) 2) Volume/100 ft. is shown for PE pipe only. 3) Use 1" pipe for rubber hose.

11.0 -

gallons gallons gallons gallons gallons** by vol. gallons

12. Determine Flushing Requirements.

Flushing requirements: 20 gpm @ 57 ft. hd.

30

11. Calculate the amount of antifreeze needed:

*Enter ft. of pipe in both directions. **Includes coax & flush cart.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 6005 Servo Tank GaugeDocumento10 pagine6005 Servo Tank GaugeadammzjinNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- TDS 8127-Eng PDFDocumento2 pagineTDS 8127-Eng PDFadammzjinNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Approved List of Standards 30th March 2017Documento13 pagineApproved List of Standards 30th March 2017adammzjinNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Report On South Sudan Market Survey PDFDocumento29 pagineReport On South Sudan Market Survey PDFadammzjinNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Analytical Comparative Transport Cost Study On The Northern Corridor PDFDocumento15 pagineAnalytical Comparative Transport Cost Study On The Northern Corridor PDFadammzjinNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- 3LPE Coating SpecificationDocumento20 pagine3LPE Coating SpecificationadammzjinNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Saturday, April 6, 2013 1330-1400 Hrs 1400-1600 Hrs. 1600-1630 Hrs. Venue: GTU Campus, Gandhinagar CampusDocumento1 paginaSaturday, April 6, 2013 1330-1400 Hrs 1400-1600 Hrs. 1600-1630 Hrs. Venue: GTU Campus, Gandhinagar CampusadammzjinNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Product Data Sheet: Argon (Ar)Documento2 pagineProduct Data Sheet: Argon (Ar)adammzjin100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Clemco Clemvak III Owners ManualDocumento4 pagineClemco Clemvak III Owners ManualadammzjinNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Hajj Umrah ChecklistDocumento5 pagineHajj Umrah ChecklistadammzjinNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Wasilatus ShafiDocumento16 pagineWasilatus Shafiadammzjin100% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- E194-837 - 842 Gases Conversion ChartDocumento3 pagineE194-837 - 842 Gases Conversion ChartadammzjinNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Argon Liquid: Specification/gradeDocumento1 paginaArgon Liquid: Specification/gradeadammzjinNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ConversionDocumento2 pagineConversionadammzjinNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Tankguard SF Type: Tank Coating: Add To ListDocumento2 pagineTankguard SF Type: Tank Coating: Add To ListadammzjinNessuna valutazione finora

- Pipe SwabsDocumento2 paginePipe SwabsadammzjinNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sect6 - Chapt2 - Mobile Internal Combustion EnginesDocumento7 pagineSect6 - Chapt2 - Mobile Internal Combustion EnginesadammzjinNessuna valutazione finora

- High-Energy Cathode Materials (Li Mno Limo) For Lithium-Ion BatteriesDocumento13 pagineHigh-Energy Cathode Materials (Li Mno Limo) For Lithium-Ion BatteriesEYERUSALEM TADESSENessuna valutazione finora

- Openstax - Chemistry - Answer Key (Odds)Documento75 pagineOpenstax - Chemistry - Answer Key (Odds)Windel AventuradoNessuna valutazione finora

- Activated Carbon From Corn CobDocumento7 pagineActivated Carbon From Corn CobJhen DangatNessuna valutazione finora

- Sist Iso 293 1996Documento8 pagineSist Iso 293 1996rtplemat lemat100% (1)

- Basic Theory of Klor Brom IodDocumento8 pagineBasic Theory of Klor Brom IodAstri Nurul HidayahNessuna valutazione finora

- Persediaan 2017, 2018Documento1.061 paginePersediaan 2017, 2018Selly RianiNessuna valutazione finora

- Topic: Insects Pests Of: Cotton and Their IPMDocumento15 pagineTopic: Insects Pests Of: Cotton and Their IPMG Janardana ReddyNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- What Is Translocation in PlantsDocumento9 pagineWhat Is Translocation in PlantsZakia BariNessuna valutazione finora

- Dynamic Shaft SealDocumento1 paginaDynamic Shaft SealSathishkumarNessuna valutazione finora

- Paints Pigments and Industrial CoatingsDocumento10 paginePaints Pigments and Industrial CoatingsRaymond FuentesNessuna valutazione finora

- SCK SeriesDocumento17 pagineSCK SeriestahirianNessuna valutazione finora

- Material Price ListDocumento43 pagineMaterial Price ListSathish RagavanNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- KS3 Science 2009 L3 6 1Documento32 pagineKS3 Science 2009 L3 6 1Beamerglitz0% (1)

- Alloy-Steel Turbine-Type Bolting Material Specially Heat Treated For High-Temperature ServiceDocumento3 pagineAlloy-Steel Turbine-Type Bolting Material Specially Heat Treated For High-Temperature ServiceRoland CepedaNessuna valutazione finora

- 03.-Pulse Oximetry NotesDocumento8 pagine03.-Pulse Oximetry NotesAlexander Martínez PasekNessuna valutazione finora

- Lesson Plan ME-220 Engineering MaterialsDocumento2 pagineLesson Plan ME-220 Engineering MaterialsHajiasifAliNessuna valutazione finora

- Websitecompanies NewDocumento33 pagineWebsitecompanies NewRajiv JulakantiNessuna valutazione finora

- Questionbank AS5640Documento9 pagineQuestionbank AS5640Saurav KumarNessuna valutazione finora

- Safety Data Sheet PropanDocumento9 pagineSafety Data Sheet PropanFahri SofianNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pub Breaking Out of Beginners SpanishDocumento2 paginePub Breaking Out of Beginners SpanishTuan TuanNessuna valutazione finora

- Ancient and Modern Paper CharacterizatioDocumento20 pagineAncient and Modern Paper CharacterizatioVornicu NicoletaNessuna valutazione finora

- Mndy ParchiDocumento858 pagineMndy ParchiPAN SERVICESNessuna valutazione finora

- Volume: 04 Issue: 04 - Jul-Aug 2023Documento13 pagineVolume: 04 Issue: 04 - Jul-Aug 2023Central Asian StudiesNessuna valutazione finora

- Cambridge O Level: Chemistry 5070/41 October/November 2020Documento9 pagineCambridge O Level: Chemistry 5070/41 October/November 2020Islamabad ALMA SchoolNessuna valutazione finora

- Alexbook - Divadjac Joe Cell PDFDocumento29 pagineAlexbook - Divadjac Joe Cell PDFstella8880% (1)

- APECCalculations QADocumento275 pagineAPECCalculations QAshasha111 shasha1110% (1)

- Phyto-Mediated Synthesis of Zinc Oxide Nanoparticles of BerberisDocumento31 paginePhyto-Mediated Synthesis of Zinc Oxide Nanoparticles of BerberisRabeea NasirNessuna valutazione finora

- Soda Escamas - Modificado VeterquimicaDocumento1 paginaSoda Escamas - Modificado Veterquimicajuan aguileraNessuna valutazione finora

- Doosan Mitsubishi 2.4L - Product Overview Training PDFDocumento105 pagineDoosan Mitsubishi 2.4L - Product Overview Training PDFkhairul100% (1)

- MasoneilanDocumento20 pagineMasoneilanJohn MarshalNessuna valutazione finora