Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bitustop PVC Edge Tie Waterstops: Description

Caricato da

Tuntun TatTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bitustop PVC Edge Tie Waterstops: Description

Caricato da

Tuntun TatCopyright:

Formati disponibili

BITUSTOP PVC EDGE TIE WATERSTOPS

DESCRIPTION

BITUSTOP PVC WATERSTOPS are produced by melting and shaping mixtures been obtained from Polyvinylchloride (PVC) resin, stabilizer, plasticizer and anti oxidant dyestuff in suitable temperature and pressure in Extruders. for sealing joints in concrete structures subject to water pressure Being cast into the centre of the concrete member, PVC Edge Tie waterstops will provide resistance against hydrostatic pressure from both faces. Waterproofing/Tanking Systems Where a moisture / vapour proof basement, roof or similar structure is required the PVC Edge Tie/ Bitumat flexible tanking system can be adopted to provide total building security. Site Jointing The process of heat fusion or welding is used to provide butt joints between lengths of Bitumat PVC Edge-Tie Waterstop or between lengths of waterstop and preformed junction pieces. A special portable jig (2) is provided for this purpose and is used in conjunction with a heated blade (1). The ends of the waterstop having been cut square, the jig is used to line up the two ends of the waterstop in precise opposition. The heated blade is then inserted between the two ends and the material is melted on contact. The blade is then removed and the two ends of the waterstop pushed together in the jig where they achieve fusion These bending radii are based on an ambient temperature of 20oC and will increase slightly at lower temperatures. Typical Junction Pieces Available for Flat Dumbell and Centre Bulb Waterstops. Additional patterns other than those illustrated are available. Non regular design requirements of all types can be met by the supply of irregular L and Y Junction pieces manufactured in the full range of sizes. When ordering specify all the included angle. Supply for construction/contraction joints Flat Dumbell 170mm wide 15m rolls wt 21.9 kg 210mm wide 15m rolls wt 27.8 kg 250mm wide 15m rolls wt 36.7 kg Supply for expansion/movement joints Centre Bulb 210mm wide 15m rolls wt 26.9 kg 260mm wide 15m rolls wt 38.4 kg . Recommended movement range for PVC Edge Tie to be limited to 12mm. For movements in excess of this, please consult our Engineering Department for guidance.

USES

BITUSTOP PVC WATERSTOPS are used for providing water impermeability in expansioncontraction (structure) joint seen in concrete stuctures exposed to high & low water pressure and for preventing vibrations and deformations that would appear in concrete blocks.

OUTSTANDING FEATURES

Proven Profile - Solid circular end bulbs promote better concrete compaction and simplifies site jointing. Flexible - Will accomodate movement during construction and service life. Valve Action - Created by concrete shrinkage around end bulbs. Grou-tite-fins - Promotes dense concrete and prevents loss of fines at stop-end shutter. Edge Flange - Provide positive acnhorage for tying wires fastened through reinforced wiring holes. Moulded Transitions - Available to link with Bitumat external waterstops. WRc approved for potable water. Flat Dumbell - For construction / contraction joints with partial restraint. Centre Bulb - For expansion / movement joints subject to a limited degree of deflection. PVC Edge Tie is an internally cast PVC waterstop system manufactured in a range of sizes for use in reinforced concrete structures. It is essential to form a continuous waterstop network at all joints to prevent the ingress of moisture and it is vital to use factory produced fabrications for changes of direction or profile, with site jointing limited to simple butt welds. PVC Edge Tie, internal flexible waterstop systems, have been developed with solid circular end bulbs for positive embedment in insitu concrete by creating a valve action to seal the water path, suitable for horizontal and vertical applications. They are extruded from high grade polyvinyl-chloride compounded with first quality plasticisers to form a pliable waterstop which remains flexible at low temperatures ideally suited

SVD02

20-J

R-00

00

Ancillary Materials

External Waterstops for Range of sizes available non-suspended slabs for use in water retaining and water excluding structures Heavy duty internal Range of sizes available waterstops for critical for deep water retaining structures structures LM, low modolus Range of sizes available internal waterstops for for water retaining large movements joints structures & joints subject to mining subsidence of settlement

site joints limited to simple butt welds between similar sections.

Product Range at a glance

SN 1 2 3 4 5 6 7 FD 170 210 250 CB HD EX

210 260 240 240

Equipment PVC Edge Tie Welding Jigs Unit various sizes Electric (110v or 220v) Unit Welding Knife Mild Steel Welding Knife Unit Equipment by others Fine tooth saw, wire brush, Stanley knife, 110v or 220v power source, blow lamp if non-electrical mild steel knife is used. Application Slab joints The Bitumat PVC Edge Tie waterstop is supported in specially prepared split stop-end formwork which holds the waterstop in the horizontal plane to prevent dis-placement and folding so that half its width will be cast into the concrete approximately half way through the thickness of the slab. Care must be taken to ensure that the waterstop is retained 'in the horizontal plane and that adequate compaction of concrete takes place below the web of the waterstop in order to avoid "honeycombing". Lifting the waterstop during compaction to release entrapped air will assist in forming dense compacted concrete. After stripping the formwork supporting the waterstop, the second half can be cast into the adjoining slab with similar precautions taken with regard to "honeycombing". Wall joints The waterstop must be supported in split-end form work as described for slab joints, with great care taken to ensure that the waterstop does not fold over ufider the weight of the poured concrete. To eliminate fold-over, the waterstop should be wired to the reinforcing stee! using the wiring holes provided. A fully continuous waterstop network shall be formed using factory made junctions with

Health and Safety Fused site welded jointing of PVC waterstops can result in the liberation of hydrochloric acid fumes. In confined spaces forced ventilation must be provided or a suitable respirator used. On open sites special precautions are not normally required but operators should avoid inhaling any fumes. Before using electric welding knife ensure that it is correctly earthed. Specification Bitumat PVC Edge Tie waterstops of the size and dimension specified shall be used to form a continuous network as shown on the detailed drawings and fixed in position with site jointing limited to butt joints, strictly in accordance with the manufacturer's instructions. Properties of PVC Compound Tensile strength 13.78 N/mm2 (2000 psi) Elongation at break 300% B.S. Softness 45 Specific Gravity 1.3 Compound Tested in accordance with BS 2571 and US Corps of Engineers CRD-C572-74.

The information given is based on data and knowledge considered to be true and accurate and is offered for the user's consideration, investigation and verification but since the conditions of use are beyond our control we do not warrant the results to be obtained. Please read all statements, recommendations or suggestions in conjunction with our conditions of sale including those limiting warranties and remedies which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use which would violate or intringe statutory obligations or any rights belonging to a third party.

Potrebbero piacerti anche

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- GR E Trabajo Grupal 8 PDFDocumento5 pagineGR E Trabajo Grupal 8 PDFDavid SuquilloNessuna valutazione finora

- Method Statement For Water Stopper-BSMMUDocumento5 pagineMethod Statement For Water Stopper-BSMMUEngr. Masud RahmanNessuna valutazione finora

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Astm b214 16 PDFDocumento4 pagineAstm b214 16 PDFWarsonoNessuna valutazione finora

- R5888C Quadramho A4RBDocumento336 pagineR5888C Quadramho A4RBdbeard811100% (1)

- Supercast PVC WaterstopDocumento4 pagineSupercast PVC WaterstopArun KumarNessuna valutazione finora

- Supercast PVCDocumento8 pagineSupercast PVCVenkata RaoNessuna valutazione finora

- PVC WaterstopsDocumento6 paginePVC WaterstopsHiren DesaiNessuna valutazione finora

- PVC Waterstop DatasheetsDocumento2 paginePVC Waterstop DatasheetssfgfhgfjNessuna valutazione finora

- Supercast PVCDocumento4 pagineSupercast PVCVenkata Raju KalidindiNessuna valutazione finora

- General Waterstop BrochureDocumento8 pagineGeneral Waterstop Brochureomar112233Nessuna valutazione finora

- RFA-TECH Waterproofing BrochureDocumento48 pagineRFA-TECH Waterproofing Brochuresilvereyes18Nessuna valutazione finora

- PVC Installation GuideDocumento3 paginePVC Installation GuideChâu TúNessuna valutazione finora

- Sika - Waterbars: Flexible PVC WaterstopsDocumento5 pagineSika - Waterbars: Flexible PVC WaterstopsRonald MassoraNessuna valutazione finora

- PVC Waterstop Design ConsiderationsDocumento2 paginePVC Waterstop Design ConsiderationsbelajiNessuna valutazione finora

- Sika PDS E PVC WaterstopDocumento2 pagineSika PDS E PVC Waterstoplwin_oo2435Nessuna valutazione finora

- CONCRETE SUPPLIESDocumento8 pagineCONCRETE SUPPLIESSherazNessuna valutazione finora

- PVC Water StopDocumento2 paginePVC Water StopBassemM100% (1)

- Sika WaterbarsDocumento5 pagineSika WaterbarschaubeyskcNessuna valutazione finora

- Construction Materials PVC Waterstop Product Data SheetDocumento2 pagineConstruction Materials PVC Waterstop Product Data SheetvertigoNessuna valutazione finora

- Design Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeDocumento14 pagineDesign Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeUnibellNessuna valutazione finora

- PVC Waterstop - Design Guide: Suggested Master SpecificationDocumento4 paginePVC Waterstop - Design Guide: Suggested Master Specificationarvin jay santarinNessuna valutazione finora

- Riw Waterstop: Ci/Sfb Tr9 L1415 November 2013Documento3 pagineRiw Waterstop: Ci/Sfb Tr9 L1415 November 2013Eni XhambaziNessuna valutazione finora

- Hydrostop AWDocumento2 pagineHydrostop AWosama mohNessuna valutazione finora

- Hydrostop SKDocumento2 pagineHydrostop SKosama mohNessuna valutazione finora

- Westec Design GuideDocumento2 pagineWestec Design GuideSrinivasan ReddyNessuna valutazione finora

- Water BarsDocumento13 pagineWater BarsVijay YadavNessuna valutazione finora

- PVC and Hydrotite Retrofit Waterstop Installation GuideDocumento2 paginePVC and Hydrotite Retrofit Waterstop Installation GuideSrinivasKalasapatiNessuna valutazione finora

- Euclid Chemical Euco Waterstop PVC FC AsiaDocumento4 pagineEuclid Chemical Euco Waterstop PVC FC AsiarosarioNessuna valutazione finora

- Sure Stop PVC Waterstops TDSDocumento3 pagineSure Stop PVC Waterstops TDSrosarioNessuna valutazione finora

- Comprehensive Study On WaterstopsDocumento18 pagineComprehensive Study On WaterstopsFrederick TanNessuna valutazione finora

- Mea Polybit Tds Polybit Polystop CJ en MeaDocumento2 pagineMea Polybit Tds Polybit Polystop CJ en MeaVaittianathan MahavapillaiNessuna valutazione finora

- Sure-Stop PVC Waterstops: Technical Data SheetDocumento4 pagineSure-Stop PVC Waterstops: Technical Data SheetmystrophanNessuna valutazione finora

- Brosur WATERSTOP CONSOLDocumento4 pagineBrosur WATERSTOP CONSOLAnjar Satria NugrahaNessuna valutazione finora

- Masterflex PVC WaterstopDocumento0 pagineMasterflex PVC WaterstopVenkata Raju KalidindiNessuna valutazione finora

- Bridge Expansion JointDocumento46 pagineBridge Expansion JointSiva Prasad MamillapalliNessuna valutazione finora

- Galvanized Tank BrochureDocumento5 pagineGalvanized Tank Brochurem4004Nessuna valutazione finora

- Viking Johnson ProductsDocumento31 pagineViking Johnson ProductsAlvin MiraNessuna valutazione finora

- Waterstops PDFDocumento26 pagineWaterstops PDFjmusopoleNessuna valutazione finora

- Waterstop Range MS 0Documento12 pagineWaterstop Range MS 0Sun ShadeNessuna valutazione finora

- RFA-TECH Waterproofing Brochure PDFDocumento48 pagineRFA-TECH Waterproofing Brochure PDFsilvereyes18Nessuna valutazione finora

- Hoja de Datos Kits AislamientoDocumento7 pagineHoja de Datos Kits AislamientoJorge Navas VargasNessuna valutazione finora

- (LR) Rainwater System Gyrojoint 04062015Documento32 pagine(LR) Rainwater System Gyrojoint 04062015sungshinnNessuna valutazione finora

- Catalog Tevi Fitinguri Pvcu PlassonDocumento41 pagineCatalog Tevi Fitinguri Pvcu PlassonzenogredinaNessuna valutazione finora

- Water StopperDocumento6 pagineWater StopperMF YousufNessuna valutazione finora

- Viega Profipress ManualDocumento16 pagineViega Profipress Manualhasmit1Nessuna valutazione finora

- u-PVC Casing & Screen PipesDocumento6 pagineu-PVC Casing & Screen Pipessaadpervaiz14Nessuna valutazione finora

- Sika® Waterbar®: Product Data SheetDocumento3 pagineSika® Waterbar®: Product Data SheetSarwan ArifinNessuna valutazione finora

- Water StopsDocumento3 pagineWater StopsHussein BeqaiNessuna valutazione finora

- Sika Waterbar V VNDocumento3 pagineSika Waterbar V VNSlamet Tri UsadhaNessuna valutazione finora

- Sure-Stop PVC Waterstop BrochureDocumento4 pagineSure-Stop PVC Waterstop Brochuremyke_0101Nessuna valutazione finora

- Masterpren PVC WaterstopDocumento7 pagineMasterpren PVC WaterstopjmusopoleNessuna valutazione finora

- Ductile Iron Fittings & Specials - by NeoDocumento59 pagineDuctile Iron Fittings & Specials - by NeoSomu DahiyaNessuna valutazione finora

- Water Bars BY VIJAY KUMARDocumento13 pagineWater Bars BY VIJAY KUMARVijay YadavNessuna valutazione finora

- Single Seal Expansion JointsDocumento8 pagineSingle Seal Expansion JointsbosskojNessuna valutazione finora

- Bending PVC ASTM D3034Documento4 pagineBending PVC ASTM D3034Oscar PachecoNessuna valutazione finora

- Pipe SleeveDocumento12 paginePipe Sleeveparthasarathy2812Nessuna valutazione finora

- Water Closet Supports Technical DataDocumento5 pagineWater Closet Supports Technical DataMac ShaikNessuna valutazione finora

- Supercast TP Waterstop - Mega Tec Consolidation Sdn. BHDDocumento4 pagineSupercast TP Waterstop - Mega Tec Consolidation Sdn. BHDCarlos GilNessuna valutazione finora

- TDS Supercast PVC Saudi ArabiaDocumento8 pagineTDS Supercast PVC Saudi Arabiaashraf komiNessuna valutazione finora

- Culvert SlipliningDocumento8 pagineCulvert SlipliningbetopagoadaNessuna valutazione finora

- Simple Plumbing Repairs for the Home and FarmsteadDa EverandSimple Plumbing Repairs for the Home and FarmsteadNessuna valutazione finora

- MRT Safety Controls for Adjacent DevelopmentDocumento7 pagineMRT Safety Controls for Adjacent DevelopmentTuntun TatNessuna valutazione finora

- Sika Plug® PDFDocumento2 pagineSika Plug® PDFTuntun TatNessuna valutazione finora

- Book 1Documento1 paginaBook 1Tuntun TatNessuna valutazione finora

- Dtss Phase 2 D Wall Layout 10.4mDocumento1 paginaDtss Phase 2 D Wall Layout 10.4mTuntun TatNessuna valutazione finora

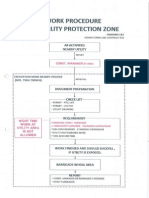

- Work Procedure With Utility Protection Zone PDFDocumento1 paginaWork Procedure With Utility Protection Zone PDFTuntun TatNessuna valutazione finora

- Schedule (Bentonie Line) Rev.1 PDFDocumento1 paginaSchedule (Bentonie Line) Rev.1 PDFTuntun TatNessuna valutazione finora

- CA - Annex 1Documento75 pagineCA - Annex 1Tuntun TatNessuna valutazione finora

- HYDRO2Documento1 paginaHYDRO2Tuntun TatNessuna valutazione finora

- RF Cabl Protection PDFDocumento1 paginaRF Cabl Protection PDFTuntun TatNessuna valutazione finora

- Silo (Temp.) ModelDocumento1 paginaSilo (Temp.) ModelTuntun TatNessuna valutazione finora

- Hydro1 PDFDocumento1 paginaHydro1 PDFTuntun TatNessuna valutazione finora

- Tuksu EngineeringDocumento3 pagineTuksu EngineeringTuntun TatNessuna valutazione finora

- Silo Settlement Marker Photos PDFDocumento12 pagineSilo Settlement Marker Photos PDFTuntun TatNessuna valutazione finora

- Cowboy Songs - (Red River Valley Tab) PDFDocumento3 pagineCowboy Songs - (Red River Valley Tab) PDFTuntun TatNessuna valutazione finora

- Load Capacity of PilesDocumento16 pagineLoad Capacity of PilesTuntun TatNessuna valutazione finora

- Anchorage Bond StressDocumento2 pagineAnchorage Bond StressTuntun TatNessuna valutazione finora

- ES01 D-Wall CASE - With GMP Pile ConditionDocumento1 paginaES01 D-Wall CASE - With GMP Pile ConditionTuntun TatNessuna valutazione finora

- Working Platform 1Documento126 pagineWorking Platform 1Tuntun TatNessuna valutazione finora

- Sketch On Bundle Rebar of W9Documento93 pagineSketch On Bundle Rebar of W9Tuntun TatNessuna valutazione finora

- 2013 잔여공정 (6 21)Documento1 pagina2013 잔여공정 (6 21)Tuntun TatNessuna valutazione finora

- C922 Rectification WorksDocumento185 pagineC922 Rectification WorksTuntun TatNessuna valutazione finora

- Date: 1 Aug 2011 Our Ref: JLE/TEC/Q-024/11/jlDocumento2 pagineDate: 1 Aug 2011 Our Ref: JLE/TEC/Q-024/11/jlTuntun TatNessuna valutazione finora

- Aps Asia Pda EntDocumento2 pagineAps Asia Pda EntTuntun TatNessuna valutazione finora

- BP Cage LiftingDocumento1 paginaBP Cage LiftingTuntun TatNessuna valutazione finora

- 6 Zer296rr-Tmp1202aDocumento1 pagina6 Zer296rr-Tmp1202aTuntun TatNessuna valutazione finora

- w9 CouplerDocumento1 paginaw9 CouplerTuntun TatNessuna valutazione finora

- Tension Test Load For U-ClipDocumento122 pagineTension Test Load For U-ClipTuntun TatNessuna valutazione finora

- ER296 Daily Report (New-Dec 2013) (12.31)Documento1 paginaER296 Daily Report (New-Dec 2013) (12.31)Tuntun TatNessuna valutazione finora

- Proposed Utility Gap For RF Cable-Affected Dwall at P2P LinkDocumento1 paginaProposed Utility Gap For RF Cable-Affected Dwall at P2P LinkTuntun TatNessuna valutazione finora

- AP Discovery of WLCDocumento2 pagineAP Discovery of WLCLucija Fioretti100% (1)

- Cable Tray Installation ProcedureDocumento3 pagineCable Tray Installation ProcedureNorman Polilin100% (1)

- Plasma Samsung PS50B530 BN68-02355H-03L10 - 1026 PDFDocumento382 paginePlasma Samsung PS50B530 BN68-02355H-03L10 - 1026 PDFje_accuseNessuna valutazione finora

- IP8850 User Guide - enDocumento19 pagineIP8850 User Guide - enhoang kim haoNessuna valutazione finora

- Dinesh Op. Mgmt.Documento26 pagineDinesh Op. Mgmt.Nino Dinesh TaringNessuna valutazione finora

- MB Manual Ga-78lmt-S2 v.1.1 eDocumento44 pagineMB Manual Ga-78lmt-S2 v.1.1 eNicolas BarbosaNessuna valutazione finora

- Liberator Parts - m50206 - R - 2010Documento34 pagineLiberator Parts - m50206 - R - 2010Nestor Marquez-DiazNessuna valutazione finora

- C.V - Muhammad Ifrahim - Scaffolding PDFDocumento5 pagineC.V - Muhammad Ifrahim - Scaffolding PDFIfrahimNessuna valutazione finora

- Manual Implem Note 1982417 CONTRATOS SEPEDocumento24 pagineManual Implem Note 1982417 CONTRATOS SEPEfrubenvegaNessuna valutazione finora

- Log Alarm 6140 LE0124Documento4 pagineLog Alarm 6140 LE0124Wilson DiazNessuna valutazione finora

- Saudi Aramco UPS Inspection PlanDocumento30 pagineSaudi Aramco UPS Inspection PlanVISAKHNessuna valutazione finora

- Service BulletinDocumento5 pagineService Bulletinohromeo100% (1)

- Architect's ResumeDocumento3 pagineArchitect's ResumeovaishashmiNessuna valutazione finora

- Sauer S90 3Documento20 pagineSauer S90 3Leandro Sal100% (1)

- UA08 1 RNC Paging Engineering Guidelines V02Documento84 pagineUA08 1 RNC Paging Engineering Guidelines V02SORO YALAMOUSSANessuna valutazione finora

- Synopsis On ChatAppDocumento43 pagineSynopsis On ChatAppRaj GuptaNessuna valutazione finora

- ZIEHL ABEGG Flyer ZAdynpro EnglishDocumento8 pagineZIEHL ABEGG Flyer ZAdynpro EnglishbzivkovicNessuna valutazione finora

- Astm e 1226Documento12 pagineAstm e 1226João Pedro Bravo100% (1)

- Failure Cause Code ReferenceDocumento54 pagineFailure Cause Code ReferenceHuỳnh Thanh Tuấn0% (1)

- C Programming Language - StringsDocumento58 pagineC Programming Language - Stringsdandyanke1100% (1)

- 611 PjuDocumento380 pagine611 Pjucoolsam6969Nessuna valutazione finora

- Ppap 1Documento2 paginePpap 1atulrathor828Nessuna valutazione finora

- Practical Lab 1.2Documento5 paginePractical Lab 1.2Ustaz DurianNessuna valutazione finora

- LTMC For Master Data Step by Step Process - SAP BlogsDocumento24 pagineLTMC For Master Data Step by Step Process - SAP BlogsshamsNessuna valutazione finora

- Construction Audit Guide for Liberia's Public Works MinistryDocumento2 pagineConstruction Audit Guide for Liberia's Public Works MinistryJohn N. ConstanceNessuna valutazione finora

- BGP Scalling PDFDocumento89 pagineBGP Scalling PDFjnahamedNessuna valutazione finora

- Latex ResumeDocumento3 pagineLatex ResumeetherealsnstuffNessuna valutazione finora