Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Timing Simulation

Caricato da

Karthik SharmaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Timing Simulation

Caricato da

Karthik SharmaCopyright:

Formati disponibili

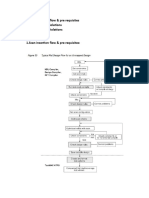

Timing simulation: Timing simulation takes NETLIST, library models of the cells and constraints (clock period, skew,

setup and hold time) as INPUTS and gives OUT as delay through the combinational logic. Timing simulation allows you to check that implemented design meets all timing requirements and behaves as you expected in the device. Timing simulation helps you to find Post synthesis implementation functionality changes. Dual-port RAM collisions. Missing component generics for VHDL. Missing module defparams for verilog. Missing or improperly applied timing constraints. Operation of asynchronous paths.

Timing constraints: Timing constraints used to control clock freq, setup and hold times for synchronous inputs and clock-to-output time for synchronous outputs. Setup time For an edge triggered sequential element, the setup time is the time interval before the active clock edge during which the data should remain unchanged Hold time Time interval after the active clock edge during which the data should remain unchanged

Both the above 2 timing violations can occur in a design when clock path delay > data path delay Pulse width

It is the time between the active and inactive states of the same signal Signal (Clock/Data) slew Amount of time it takes for a signal transition to occur. Clock Latency Difference between the reference (source) clock slew to the clock tree endpoint signal slew values Rise latency and fall latency are specified Slack It is the difference between the required (constraint) time and the arrival time (inputs and delays). Negative slack indicates that constraints have not been met, while positive slack indicates that constraints have been met. Slack analysis is used to identify timing critical paths in a design by the static timing analysis tool Critical path Any logical path in the design that violates the timing constraints Path with a negative slack Clock skew Its a measure of difference between any two leaf pins in a clock tree It is also defined as the difference in time that a single clock signal takes to reach two different registers.

TESTING: Boundary scan: In boundary scan, all flip flops enter a test mode where they are controllable and observable. After functional verification, normal flip flops are replaced by scan flip flops. Only D flip flops must be used. Clocks must not be generated internally

Controllable: Difficulty in setting a signal to 0 or 1. Observable: Difficulty of reading a specific signal. STATIC SIMULATION ANALYSIS:

Effective methodology for verifying the timing characteristics of a design without the use of test vectors Conventional verification techniques are inadequate for complex designs Simulation time using conventional simulators Thousands of test vectors are required to test all timing paths using logic simulation Increasing design complexity & smaller process technologies Increases the number of iterations for STA

Potrebbero piacerti anche

- Simulation Mismatches Can Foul Up Test-Pattern VerificationDocumento6 pagineSimulation Mismatches Can Foul Up Test-Pattern VerificationAdhi SuruliNessuna valutazione finora

- DFT DocumentationDocumento20 pagineDFT Documentationyamini100% (1)

- What Is DFT in VLSIDocumento22 pagineWhat Is DFT in VLSINaga Nithesh100% (4)

- A Practical Clock Control Circuit Design & Example Tessent ATPG Test CaseDocumento22 pagineA Practical Clock Control Circuit Design & Example Tessent ATPG Test CaseSiva Sreeramdas100% (1)

- Few Important QuestionsDocumento7 pagineFew Important QuestionsShankhadeep DasNessuna valutazione finora

- DFT Interview QuestionsDocumento2 pagineDFT Interview Questionsrupesh kumarNessuna valutazione finora

- DFT Imp Questions 250+Documento5 pagineDFT Imp Questions 250+Mayur Mestry100% (1)

- Frequencies.: Transition Fault Model: This Is Considered To Stuck at Fault Model Within A TimeDocumento15 pagineFrequencies.: Transition Fault Model: This Is Considered To Stuck at Fault Model Within A TimedeepaNessuna valutazione finora

- Scan Insertion Lab ObservationsDocumento2 pagineScan Insertion Lab ObservationssenthilkumarNessuna valutazione finora

- Assignment - 6Documento4 pagineAssignment - 6kishorNessuna valutazione finora

- Scan Insertion - Week2&3Documento48 pagineScan Insertion - Week2&3VENKATRAMAN100% (1)

- Wrapper p1500Documento8 pagineWrapper p1500srikanth100% (1)

- Streaming Scan NetworkDocumento51 pagineStreaming Scan NetworkVENKATRAMAN100% (1)

- (Design For Testability) Atpg: - Jaganath SinghDocumento23 pagine(Design For Testability) Atpg: - Jaganath SinghSAI KIRAN100% (3)

- Post-Silicon SOC: Keywords: DFT (Design For Testability), ATPG (Automatic Test Pattern Generation)Documento10 paginePost-Silicon SOC: Keywords: DFT (Design For Testability), ATPG (Automatic Test Pattern Generation)Amena FarhatNessuna valutazione finora

- DFT Interview QuestionsDocumento3 pagineDFT Interview QuestionsJayesh PopatNessuna valutazione finora

- Embedded Deterministic Test: by M. BalakrishnaDocumento28 pagineEmbedded Deterministic Test: by M. Balakrishnasuryatejamula0% (1)

- Assignment Section-1 1. What Is DFT?Documento18 pagineAssignment Section-1 1. What Is DFT?PAVAN KUMAR TAVADABOINA100% (1)

- DFT QnsDocumento6 pagineDFT QnsRajishaNessuna valutazione finora

- ATPG Methodology FlowDocumento37 pagineATPG Methodology FlowaanbalanNessuna valutazione finora

- Training On EDT (1) - Copy (1) (3) 1Documento52 pagineTraining On EDT (1) - Copy (1) (3) 1veena100% (1)

- Assignment 1 Poovika.tDocumento12 pagineAssignment 1 Poovika.tsenthilkumarNessuna valutazione finora

- QUALCOMM Interview Questions 1. Basic View of Compression?Documento9 pagineQUALCOMM Interview Questions 1. Basic View of Compression?deepa100% (2)

- Tips For Simulation Debug PDFDocumento21 pagineTips For Simulation Debug PDFSaurin Shah100% (1)

- Atpg Lab Notes PDFDocumento11 pagineAtpg Lab Notes PDFrajkumar gunja100% (1)

- Why Masking Is Needed: Scan Chain Masking in The AcompactorDocumento6 pagineWhy Masking Is Needed: Scan Chain Masking in The AcompactorIlaiyaveni IyanduraiNessuna valutazione finora

- Scan Insertion Lab Observation (K.S.K.S.sarma)Documento33 pagineScan Insertion Lab Observation (K.S.K.S.sarma)Kittu Krishna100% (2)

- Scan Insertion Lab Observations: Vlsiguru DFT TrainingDocumento3 pagineScan Insertion Lab Observations: Vlsiguru DFT Trainingsenthilkumar100% (1)

- Compression AssignmentDocumento7 pagineCompression Assignmentpoojithas acharya100% (1)

- Basic Interview Questions On DFTDocumento5 pagineBasic Interview Questions On DFTHardik TrivediNessuna valutazione finora

- DFT Interview Questions - Welcome To World of VLSIDocumento5 pagineDFT Interview Questions - Welcome To World of VLSINaganithesh GhattamaneniNessuna valutazione finora

- Synthesis Netlist - Library Model - Dofile CommandsDocumento30 pagineSynthesis Netlist - Library Model - Dofile CommandsPrafulani GajbhiyeNessuna valutazione finora

- Mahitha Scan Insertion Observation PDFDocumento30 pagineMahitha Scan Insertion Observation PDFPrafulani Gajbhiye100% (1)

- SCAN DRC Violation Solutions: Add - Cell - Models Report - DFT - CheckDocumento3 pagineSCAN DRC Violation Solutions: Add - Cell - Models Report - DFT - CheckJayesh Popat100% (2)

- DFT Interview Questions & AnswersDocumento22 pagineDFT Interview Questions & Answersdeepa100% (4)

- DFT FaqDocumento15 pagineDFT FaqBrijesh S D100% (1)

- Atpg Question Answer: Name: Meet ZankatDocumento7 pagineAtpg Question Answer: Name: Meet ZankatMeet Zankat100% (2)

- Basic ScanDocumento20 pagineBasic Scansaikumar bhavana100% (1)

- COMPRESSION PPT by HK - OdpDocumento23 pagineCOMPRESSION PPT by HK - Odpsuneetha100% (5)

- Name DFT Trainee Atpg Insertion Cases ObservationsDocumento17 pagineName DFT Trainee Atpg Insertion Cases ObservationssenthilkumarNessuna valutazione finora

- ATPG Srivatsa PPTDocumento37 pagineATPG Srivatsa PPTMayur Mestry100% (1)

- DFT (Design For Testability)Documento21 pagineDFT (Design For Testability)lavanyaNessuna valutazione finora

- Scan Insertion FlowDocumento9 pagineScan Insertion Flowsharath ANessuna valutazione finora

- Interview Questions Related To Scan, ATPG, EDT and SimulationDocumento1 paginaInterview Questions Related To Scan, ATPG, EDT and SimulationSiva SreeramdasNessuna valutazione finora

- DFT QuestionsDocumento8 pagineDFT QuestionsNaga NitheshNessuna valutazione finora

- On DFTDocumento16 pagineOn DFTAman TyagiNessuna valutazione finora

- Scan InsertionDocumento16 pagineScan InsertionRUPIREDDY PRAVEENNessuna valutazione finora

- Debugging Simulation Mismatches in Fastscan: by Geir Eide Last Modified: July 03, 2001Documento21 pagineDebugging Simulation Mismatches in Fastscan: by Geir Eide Last Modified: July 03, 2001prakashthamankar100% (3)

- Jtag PresentationDocumento21 pagineJtag PresentationNivaz ChockkalingamNessuna valutazione finora

- Segregated QuestionsDocumento1 paginaSegregated QuestionsdeepaNessuna valutazione finora

- Lab2 Block Level SSN Insertion On Processor CoreDocumento33 pagineLab2 Block Level SSN Insertion On Processor Corezys WdNessuna valutazione finora

- ATPGDocumento54 pagineATPGsrikanth100% (1)

- EDTDocumento47 pagineEDTRaghavendra MatturNessuna valutazione finora

- DFT Interview QuestionsDocumento2 pagineDFT Interview Questionsrupesh kumar100% (1)

- Scan PDFDocumento49 pagineScan PDFferoz100% (1)

- NXP Interview QuestionsDocumento29 pagineNXP Interview Questionsdeepa100% (1)

- 1 LOS and LOC in Vlsi Conference-ProceedingDocumento9 pagine1 LOS and LOC in Vlsi Conference-Proceedingbharghav saiNessuna valutazione finora

- Named Capture ProcedureDocumento2 pagineNamed Capture Proceduresenthilkumar67% (3)

- STA BasicsDocumento13 pagineSTA BasicsMaulin Sheth100% (1)

- Assignment 2Documento10 pagineAssignment 2Vishakh BharadwajNessuna valutazione finora

- INTERNATIONAL ASSOCIATION OF ENGINEERS April 24th ClassDocumento4 pagineINTERNATIONAL ASSOCIATION OF ENGINEERS April 24th ClassSol MoniecNessuna valutazione finora

- Top 10 Reasons Why Systems Projects FailDocumento9 pagineTop 10 Reasons Why Systems Projects FailKurt_Wheeler_5068Nessuna valutazione finora

- Canada National Plumbing CodeDocumento14 pagineCanada National Plumbing CodeEngineering ESIINessuna valutazione finora

- CoDocumento154 pagineCoFazal JadoonNessuna valutazione finora

- J.C.Bose University of Science and Technology, YMCA, FaridabadDocumento66 pagineJ.C.Bose University of Science and Technology, YMCA, FaridabadMaster fskmNessuna valutazione finora

- Sl. No. Sap Id Name of The StudentDocumento10 pagineSl. No. Sap Id Name of The StudentMaster WayneNessuna valutazione finora

- Spanstress Floor SystemDocumento23 pagineSpanstress Floor SystemFrancis Pattung100% (3)

- Vem Brochure - PDF - Digital Signal Processor - Embedded SystemDocumento1 paginaVem Brochure - PDF - Digital Signal Processor - Embedded SystemLeggings LivingNessuna valutazione finora

- Introduction To Mechatronic DesignDocumento19 pagineIntroduction To Mechatronic DesignDouglas LuanNessuna valutazione finora

- Product Design and Value EngineeringDocumento5 pagineProduct Design and Value EngineeringParth PatelNessuna valutazione finora

- Choosing A Stream After X: Dr. Ramesh KatariaDocumento12 pagineChoosing A Stream After X: Dr. Ramesh KatariarameshNessuna valutazione finora

- LMS Test - Lab Vibration ControlDocumento12 pagineLMS Test - Lab Vibration ControlTấtAnPhanNessuna valutazione finora

- Analysis of Precast Multistoreyed Building - A Case Study: I J I R S E TDocumento9 pagineAnalysis of Precast Multistoreyed Building - A Case Study: I J I R S E TalexanderNessuna valutazione finora

- Precast Concrete Buildings in Seismic AreasDocumento10 paginePrecast Concrete Buildings in Seismic AreasAlan100% (1)

- Guide To Site - Box CulvertDocumento4 pagineGuide To Site - Box Culvertjs kalyana ramaNessuna valutazione finora

- AISI S200-07 Standard and Commentary (1st Printing) PDFDocumento46 pagineAISI S200-07 Standard and Commentary (1st Printing) PDFthjozsefNessuna valutazione finora

- Sophomore Electrical - Group (1) : Specialized Programs - Spring 2022Documento14 pagineSophomore Electrical - Group (1) : Specialized Programs - Spring 2022Tasneem YounesNessuna valutazione finora

- Akash Ranjan ResumeDocumento2 pagineAkash Ranjan ResumeKumarSwapnilNessuna valutazione finora

- Newterra Quality Plan - Uganda WWTP - PWTPDocumento1 paginaNewterra Quality Plan - Uganda WWTP - PWTPJulius MuhimboNessuna valutazione finora

- Green Engineering, Process Safety and Inherent Safety: A New ParadigmDocumento55 pagineGreen Engineering, Process Safety and Inherent Safety: A New ParadigmAbroo KhattakNessuna valutazione finora

- A REPORT ON Auto Power Supply Control DifferentDocumento8 pagineA REPORT ON Auto Power Supply Control DifferentWolf AshNessuna valutazione finora

- Cat Fluids - Oils: Recommended UseDocumento4 pagineCat Fluids - Oils: Recommended UseAndrei Bleoju100% (2)

- Siempelkamp Metalforming Presses-EngDocumento9 pagineSiempelkamp Metalforming Presses-EngAbdulsalamNessuna valutazione finora

- Open ElectiveDocumento45 pagineOpen ElectiveBanupriya-Nessuna valutazione finora

- Assignment: Mehran University of Engineering & Technology, Szab Campus, Khairpur Mir'SDocumento4 pagineAssignment: Mehran University of Engineering & Technology, Szab Campus, Khairpur Mir'SSibghatullahNessuna valutazione finora

- 4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As AggregateDocumento9 pagine4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As Aggregateget100% (2)

- Safety Instrumented Systems SummersDocumento19 pagineSafety Instrumented Systems SummersOussama AbderrahimNessuna valutazione finora

- Commentary To Assessment and Improvement of Unreinforced Masonry Buildings For Earthquake ResistanceDocumento315 pagineCommentary To Assessment and Improvement of Unreinforced Masonry Buildings For Earthquake ResistanceJuan Carlos Jiménez PachecoNessuna valutazione finora

- TNY Cat6aDocumento8 pagineTNY Cat6aDávid DobóNessuna valutazione finora