Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shital Envelope

Caricato da

Utpal MondalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Shital Envelope

Caricato da

Utpal MondalCopyright:

Formati disponibili

Concrete Batching Plant, Barka

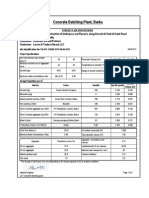

COMBINED GRADATION OF AGGREGATES Project Client Consultant Upgrading of Mawellah 132/33 KV Grid Station (Tender No. 262/2011) OMAN ELECTRICITY TRANSMISSION CO. S.A.O.C. ENERGOPROJEKT ENTEL L.L.C.

Contractor Larsen & Toubro (Oman) LLC Mix Identification No. C 35/20 -OPC-ID-020 Sample Deasription Sampling Method Test Method Location Mix Type

10 mm

: : : : :

10 mm 20.0% 20 20 4.86 0.06 0

Aggregates for Concretes BS EN 932 Part 1 BS 813 Part 103 Concrete Batching Plant, Barka 20 mm + 10 mm + Washed Sand + Fine Sand

Date : Washed Sand % Passing 100 100 99 27 7 37.0% 37 37 36.63 9.99 2.59 Fine Sand % Passing 100 100 100 100 31 6.0% 6 6 6 6 1.86 Limits as per (BS - 882 Table 5) 100 95-100 35-55 10-35 0-8

Sieve Size (mm) 37.5 20.0 5.0 0.600 0.150

% Passing 37.0% % Passing 100.0 95.0 1.0 0 0 37.0 35.2 0.4 0.0 0.0 100 100 24.3 0.3 0

Combined Grading 100.0 98.2 47.9 16.1 4.5

COMBINED GRADATION CURVE

100 90 80

70 % of Passinng 60 50 40 30 20 10 0

15000 3000 5550 900

0.1

1.0

Sieve Size (mm)

10.0

Material Engineer L & T Concrete Batching Plant

Concrete Batching Plant, Barka

CONCRETE MIX PROPORTIONS TM 020 CONCRETE MIX PROPORTIONS

Project Client Consultant Contractor

Upgrading of Mawellah 132/33 KV Grid Station OMAN ELECTRICITY TRANSMISSION CO. S.A.O.C. ENERGOPROJEKT ENTEL L.L.C. Larsen & Toubro (Oman) LLC

Date :

Mix Identification No. C 35/20 -OPC-ID-020 Project Specifications :

28-d Charecteristics Cube Strength 2 (N/mm ) Max. Nominal size of aggregate (mm) Cement Type Maximum W/C ratio

35 20 OPC Max. 0.42

48.12 20 OPC 0.41

Placement Slump Temaprature of Concrete Range of Cement Content (Kg/m3)

Max 30 Min 400

<30 420

Design Proportions per m3

Material Source Quantity Sp. Gravity Absolute 3 Volume (m )

Cement (Kg) Microsilica (Kg) Natural Washed Sand Kg. (SSD) Fine Sand Kg. (SSD) 10 mm Crushed Kg. (SSD) 20 mm Crushed Kg. (SSD) Water (Liters) *Admixture, Rheobuild 857

Oman Cement Company -Oman Rock Crusher, Barka Bousher AFI Enterprises crusher, Barka AFI Enterprises crusher, Barka Sanayya pumping Station, Barka BASF

420 0 669.0 130.0 372.0 688.0 167.3 8.20

3.15 2.2 2.710 2.700 2.800 2.830 1 1.23

0.133 0.000 0.247 0.048 0.133 0.243 0.167 0.008

Total Free Water (L) Effective W/C ratio Aggregate 20 mm Aggregate 10 mm Aggregate Natural Washed Sand Fine Sand

172.2 0.41 Proportion by mass (%) 37.00% 20.00% 37.00% 6.00%

Air Content (assumed) (%) Total Absolute Volume (m3) Aggregate- Cementitious Ratio (Volume) Hydrated Paste (% by volume) Minimum Wet Mixing Time (Sec.) Fineness Modulus

2% 1.00 5.03

40

* The dosage of admixture may vary depending on the slump required at site & ambient conditions.

Material Engineer L & T Concrete Batching Plant

Concrete Batching Plant, Barka

Mix Design Calculations

Project Upgrading of Mawellah 132/33 KV Grid Station Client OMAN ELECTRICITY TRANSMISSION CO. S.A.O.C. Consultant ENERGOPROJEKT ENTEL L.L.C. Contractor Larsen & Toubro (Oman) LLC Mix Identification No. -C 35/20 -OPC-ID-020

Characteristic Compressieve Strength Max. Size of Aggregate Max. w/c ratio Range of Cement Content Type of Cement Characteristic Compressieve Strength Target Mean Strength W/c ratio adopted Cement content Water content Admixture ( % of cement)

: : : : : : : : : : : : : : : : : : : : : : : :

35 20 0.42 Min 400 OPC 35 48.12 0.41 420 167.28 2.4% 10.08 8.20 2.830 2.800 2.710 2.700 3.15 1.23 2% 0.133 0.167 0.008 0.309 0.671

By Weight

N/mm2 mm Kg/m3

N/mm

Kg/m3 Lit/m3

Sp. Gravity of 20 mm Sp. Gravity of 10 mm Sp. Gravity of washed sand Sp. Gravity of fine sand Sp. Gravity of cement Sp. Gravity of admixture Air content ( Assumed ) Absolute Volume of cement Absolute Volume of water Absolute Volume of Admixture Total Absolute Volume of Aggregates

By Volume

Percentage of 10 mm in total aggregate Percentage of w. sand in total aggregate Percentage of fine sand in total aggregate

: : :

37 20 36 7

36.22 19.79 36.8 7.18

a b c

Material Engineer L&T Concrete Batching Plant

Page 2 of 3

Absolute Volume of 20 mm in combined aggregates Calculated quantity of 20 mm aggregate Quantity of 20 mm aggregate ( Say) Absolute Volume of 10 mm in combined aggregates Calculated quantity of 10 mm aggregate Quantity of 10 mm aggregate ( Say) Absolute Volume of w.sand in combined aggregates Calculated quantity of w.sand aggregate Quantity of w.sand aggregate ( Say) Absolute Volume of fine sand in combined aggregates Calculated quantity of fine sand aggregate Quantity of fine sand aggregate ( Say)

: : : : : : : : : : : :

0.243 688.0 688.0 0.133 371.9 372.0 0.247 669.4 669.0 0.048 130.1 130.0

Mix Proportion per cubic meter Cement Water 20 mm 10 mm Washed Sand Fine Sand Admixture Check for Volume Cement Water 20 mm 10 mm Washed Sand Fine Sand Admixture assumerd air content Total : : : : : : : : 0.133 0.167 0.243 0.133 0.247 0.048 0.008 0.020 Cum Cum Cum Cum Cum Cum Cum Cum 1.000 Cum : : : : : : 420.0 167.3 688.0 372.0 669.0 130.0 8.20 kg kg kg kg kg kg lit

Material Engineer L&T Concrete Batching Plant

Page 3 of 3

Concrete Batching Plant, Barka

LAB TRAIL MIX OBSERVATION DATA

Project Client Consultant Contractor Upgrading of Mawellah 132/33 KV Grid Station OMAN ELECTRICITY TRANSMISSION CO. S.A.O.C. ENERGOPROJEKT ENTEL L.L.C. Larsen & Toubro (Oman) LLC Mix Proportion : Batch Wight Mix Data TM20D-C 35/20 _OPC_ C - 35/20 OPC Design W/C 0.42 Target W/C 0.41

Material

Corrected Batch Quantity Batch Moisture Corrected Batch Water SSD Condition Quantity Dry Content Batch Quantity Absorption Condition (Kg) (Kg) (%) Quantity (Kg) (Kg) (%) For 0.025 For 1 Cum. for 1 Cum. for 1 cum Cum. 420 669.0 130.0 372.0 688.0 167.28 8.20 0 1.800 1.900 0.600 0.400 420 657.0 127.5 369.8 685.2 186.8 8.20 0 3.9 0.6 0.1 0.1 420 682.6 128.3 370.1 685.9 160.0 8.20 10.50 17.06 3.21 9.25 17.15 4.00 0.205 0

Remarks

Cement Washed Sand Fine Sand 10 mm Crushed Agg. 20 mm Crushed Agg. Water BASF (lit) Microsilica

37.00% 6.00% 20.00%

2.40%

Slump (mm) Time Concrete Temp (C) Slump Ambient Temp (C)

Initial

30 min

60 min

90 min

120 min

150 min

180 min

Remarks

Humidity =

Remarks :

no. cubes cast for Compressive Strength

No Bleeding Observed

Wet Concrete Density =

2457.0 Kg/cum

Material Engineer &T Concrete Batching Plant

http://www.handymath.com/cgi-bin/dnstywtvol.cgi?submit=Entry

Potrebbero piacerti anche

- Information Brochure M.sc. B.tech.Documento3 pagineInformation Brochure M.sc. B.tech.Utpal MondalNessuna valutazione finora

- Asphalt Special SpecDocumento16 pagineAsphalt Special SpecUtpal MondalNessuna valutazione finora

- Scheme Details: Outright SaleDocumento1 paginaScheme Details: Outright SaleUtpal MondalNessuna valutazione finora

- MDD OmcDocumento2 pagineMDD OmcUtpal Mondal100% (1)

- Quality Week - Agenda PDFDocumento1 paginaQuality Week - Agenda PDFUtpal MondalNessuna valutazione finora

- Asphalt General SpecDocumento39 pagineAsphalt General SpecUtpal MondalNessuna valutazione finora

- Ncat 1087 ManualDocumento69 pagineNcat 1087 ManualSreekanthNessuna valutazione finora

- Class Cement Content (Kg/Cum) Admixture Qty (Ltr/Cum) % Weight of Cement ContentDocumento1 paginaClass Cement Content (Kg/Cum) Admixture Qty (Ltr/Cum) % Weight of Cement ContentUtpal MondalNessuna valutazione finora

- Summary of Excavated Soil Sample Results Dated 27.10.13Documento4 pagineSummary of Excavated Soil Sample Results Dated 27.10.13Utpal MondalNessuna valutazione finora

- C 09 - R0 Los Angeles Abrasion - Barka Batching PlantDocumento5 pagineC 09 - R0 Los Angeles Abrasion - Barka Batching PlantUtpal MondalNessuna valutazione finora

- 4th WEEK SEPTDocumento8 pagine4th WEEK SEPTUtpal MondalNessuna valutazione finora

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDocumento1 paginaC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- Preparation of Concrete Cubes: Concrete Batching Plant, BarkaDocumento1 paginaPreparation of Concrete Cubes: Concrete Batching Plant, BarkaUtpal MondalNessuna valutazione finora

- Alccofine 1203Documento1 paginaAlccofine 1203Utpal MondalNessuna valutazione finora

- Material Test July 2013: Concrete Batching Plant - BarkaDocumento2 pagineMaterial Test July 2013: Concrete Batching Plant - BarkaUtpal MondalNessuna valutazione finora

- 01 TM 013 C30 20 08 06 2013 Mix ProportionDocumento1 pagina01 TM 013 C30 20 08 06 2013 Mix ProportionUtpal MondalNessuna valutazione finora

- Boolean Algebra & Karnaugh Maps: Points To RememberDocumento8 pagineBoolean Algebra & Karnaugh Maps: Points To RememberUtpal MondalNessuna valutazione finora

- 01 TM 014 C40 20 MS Concrete Mix ProportionsDocumento1 pagina01 TM 014 C40 20 MS Concrete Mix ProportionsUtpal Mondal100% (1)

- MgSo4 TestDocumento2 pagineMgSo4 TestUtpal MondalNessuna valutazione finora

- Testing: Coarse Aggregate Specific GravityDocumento16 pagineTesting: Coarse Aggregate Specific GravityUtpal MondalNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- PAES 224 - Rice Combine - SpecsDocumento11 paginePAES 224 - Rice Combine - Specslennahfe19Nessuna valutazione finora

- European CV Format-1Documento2 pagineEuropean CV Format-1BayisaGebre100% (1)

- BTP List 25881f798de425Documento3 pagineBTP List 25881f798de425PrijinprakashNessuna valutazione finora

- T19101 118Documento18 pagineT19101 118Chintan Raval100% (1)

- Engineering DictionaryDocumento115 pagineEngineering DictionaryNandNNessuna valutazione finora

- Steel Sheet PileDocumento8 pagineSteel Sheet PileTee Bun PinNessuna valutazione finora

- Asme Material Specs PDFDocumento4 pagineAsme Material Specs PDFJulio Cesar Morales CruzNessuna valutazione finora

- SOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical GuidelinesDocumento2 pagineSOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical Guidelinest836549Nessuna valutazione finora

- 20d-Stepped Masonry Retaining Wall-Stability CheckDocumento6 pagine20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- Anna University Chennai:: Chennai - 600025. Office of The Controller of Examinations Rank List April / May 2022 ExaminationsDocumento74 pagineAnna University Chennai:: Chennai - 600025. Office of The Controller of Examinations Rank List April / May 2022 ExaminationsJoseph DurairajNessuna valutazione finora

- Engineering and Ethics SyllabusDocumento6 pagineEngineering and Ethics SyllabusSarah BurgenNessuna valutazione finora

- Case Study 2 R.E ConstructionDocumento4 pagineCase Study 2 R.E ConstructionGiaFebieDeAsis0% (1)

- ViewPublicDocument 3Documento637 pagineViewPublicDocument 3Prathamesh PatikNessuna valutazione finora

- Arcnet IeteDocumento3 pagineArcnet Ietenaivedya_mishraNessuna valutazione finora

- DO 117 s2017Documento24 pagineDO 117 s2017EFLORENDO25Nessuna valutazione finora

- Page0036 PDFDocumento1 paginaPage0036 PDFkapereshemNessuna valutazione finora

- What Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Documento3 pagineWhat Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Abdulyunus AmirNessuna valutazione finora

- Lundberg Lilienkamp Marsden 2004 Low Cost Magnetic Levitation Project KitsDocumento6 pagineLundberg Lilienkamp Marsden 2004 Low Cost Magnetic Levitation Project KitsWalter NuasNessuna valutazione finora

- Software Testing Session 10 WIMSDocumento30 pagineSoftware Testing Session 10 WIMSkanthu1984Nessuna valutazione finora

- Tunnel Ventilation: Project Component Unidirectional Jet FanDocumento4 pagineTunnel Ventilation: Project Component Unidirectional Jet Fanadi jayaNessuna valutazione finora

- INSDAGDocumento37 pagineINSDAGapi-3774289100% (2)

- Lucrarea 6Documento16 pagineLucrarea 6Dorin BarcanNessuna valutazione finora

- Agile Model in Software EngineeringDocumento40 pagineAgile Model in Software EngineeringThanh PhamNessuna valutazione finora

- Experion CEE-based Controllers and I/O: Doc EP03-290-400Documento43 pagineExperion CEE-based Controllers and I/O: Doc EP03-290-400MesratNessuna valutazione finora

- Connection Types: Simple (Shear) ConnectionsDocumento5 pagineConnection Types: Simple (Shear) Connectionsmahhor82_635643838Nessuna valutazione finora

- Advance Water Distrubution System Final1Documento60 pagineAdvance Water Distrubution System Final1Suraj RaghuwanshiNessuna valutazione finora

- Mir Titiles About PDFDocumento20 pagineMir Titiles About PDFgauriNessuna valutazione finora

- Plo Transcript ReportDocumento3 paginePlo Transcript ReportDayyan Zahid KhanNessuna valutazione finora

- RSBDocumento2 pagineRSBJohn Aries Almelor SarzaNessuna valutazione finora

- NTUST Electrical EngineeringDocumento2 pagineNTUST Electrical EngineeringTri CardoNessuna valutazione finora