Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TS16949 Records Requirement

Caricato da

Seda De DrasniaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TS16949 Records Requirement

Caricato da

Seda De DrasniaCopyright:

Formati disponibili

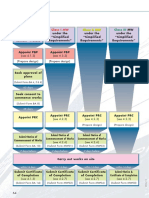

RECORD REQUIREMENTS:

SECTION

4.2.1 General 4.2.3.1 Engineering specifications 4.2.4 Control of records 4.2.4.1 Records retention 5.6.1 Management Review General 5.6.1 .1 Quality Management system Performance 6.2.2 Competence, Awareness, and Training 7.1 Planning a product realization 7.2.2 Review of requirements related to the product 7.3.2 Design and development inputs 7.3.4 Design and development review 7.3.5 Design and development verification 7.3.6 Design and development of validation 7.3.7 Control of design and development changes 7.4.1 Purchasing process 7.5.2 Validation of processes for production and service provision 7.5.3 Identification and traceability 7.5.4 Customer property 7.6 Control of monitoring and measuring devices

DESCRIPTION

Reference to records required by the standard Records of date on which engineering specifications are implemented in production (includes updation dates of documents) Records are established and maintained to provide evidence of conformity The control of records shall satisfy regulatory and customer requirements Management Review records Monitoring of quality objectives and reporting and evaluation of cost of poor quality. Records to show at a minimum , evidence of achievement of quality objectives and customer satisfaction Education, training, skills, and experience Evidence is recorded that the realization processes and resulting product meet requirements Results of the review and actions are rising from the review Inputs relating to product requirements Results of the reviews and any necessary actions Results of the verification and any necessary actions Records of the results of validation and any necessary actions Results of the review of changes in any necessary actions Results of supplier evaluations and any necessary actions are rising from the valuation Requirements for records as applicable Where traceability is a requirement, the unique identification of the product Records of customer property that has lost, damaged, or unsuitable for use Where no standards exist, bases used for calibration is recorded Records of the results of calibration and verification are maintained Records of validity of previous measuring results when equipment is found not to conform to requirements Records of audit results

8.2.2 Internal audit (QMS, Manufacturing process audit , product audit)

8.2.3.1 Monitoring and measurement of manufacturing processes 8.2.4 Monitoring and measurement of product 8.3 Control of non-conforming product 8.5.2 Corrective action 8.5.2.4 Rejected product test / analysis 8.5.3 Preventive action

Implied records for reporting verification follow up activities and results Records of effective dates of process changes Records indicates the person(s) authorizing the release of the product The nature of nonconformities and any subsequent actions taken, including concessions obtained Records for corrective action results taken Records of rejected product analysis Records for preventive action results taken

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- D451333 eDocumento15 pagineD451333 eSeda De DrasniaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- LSS GB SIPOC Diagram Johnson Anderson2Documento2 pagineLSS GB SIPOC Diagram Johnson Anderson2Seda De DrasniaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Appendix 25 VDA 6 3 Process AuditDocumento12 pagineAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Total Productive Maintenance WorksheetDocumento2 pagineTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- VSM InstructionsDocumento34 pagineVSM InstructionsSeda De DrasniaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Aceptance Agreement 031921 ADocumento6 pagineAceptance Agreement 031921 ASeda De DrasniaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Reglamento ReachDocumento849 pagineReglamento ReachSeda De DrasniaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- VDA 6.3 Based Supplier AssessmentDocumento11 pagineVDA 6.3 Based Supplier AssessmentSeda De Drasnia100% (4)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Perform JaguarDocumento8 paginePerform JaguarSeda De DrasniaNessuna valutazione finora

- Reach B2O3Documento19 pagineReach B2O3Seda De DrasniaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- APQP Second EditionDocumento113 pagineAPQP Second EditionSeda De DrasniaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Reglamento ReachDocumento849 pagineReglamento ReachSeda De DrasniaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Value Stream MappingDocumento35 pagineValue Stream MappingNevets NonnacNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Supply Chain Management Project ReportDocumento33 pagineSupply Chain Management Project Reportgauravu_5100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- M - 34106 Cohen KappaDocumento8 pagineM - 34106 Cohen KappaSeda De DrasniaNessuna valutazione finora

- STJLR-99-9999 - Iss 2Documento17 pagineSTJLR-99-9999 - Iss 2Seda De DrasniaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Perform JaguarDocumento8 paginePerform JaguarSeda De DrasniaNessuna valutazione finora

- STJLR-99-9999 - Iss 2Documento17 pagineSTJLR-99-9999 - Iss 2Seda De DrasniaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- NLQM-Ereformerand Tibur Full IntroDocumento25 pagineNLQM-Ereformerand Tibur Full IntroShailesh JoshiNessuna valutazione finora

- Exemplo Design e ManufaturaDocumento10 pagineExemplo Design e ManufaturaRenata OliveiraNessuna valutazione finora

- 3 Testing NotesDocumento14 pagine3 Testing NotessanjivkrkrisNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 1qualification & ValidationDocumento19 pagine1qualification & Validationmanojdhamne5802Nessuna valutazione finora

- 32-04-033-F Vehicle Cockpit General RequirementsDocumento32 pagine32-04-033-F Vehicle Cockpit General RequirementsFreddy Tituaña Cadena50% (2)

- CSV Risks Requirements Tests and TraceabilityDocumento44 pagineCSV Risks Requirements Tests and TraceabilitymonsepackNessuna valutazione finora

- Regulation of Certifying AuthoritiesDocumento10 pagineRegulation of Certifying AuthoritiesAanika AeryNessuna valutazione finora

- Validimi I Metodave AnalitikeDocumento3 pagineValidimi I Metodave AnalitikeFlorendMuslijiNessuna valutazione finora

- PMC IpdDocumento19 paginePMC IpdAbhik BhattacharjeeNessuna valutazione finora

- Petroleum Safety Measures Act (PSMA) 1984Documento38 paginePetroleum Safety Measures Act (PSMA) 1984HnisjjNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Requirements Management PlanDocumento28 pagineRequirements Management PlanSafdar Ali100% (1)

- PR-1159 - Commissioning and Start-UpDocumento116 paginePR-1159 - Commissioning and Start-Uparsalan100% (2)

- ISO 16143-2 2014 (E) - Character PDF DocumentDocumento44 pagineISO 16143-2 2014 (E) - Character PDF Documentshamrajj100% (1)

- Index: Designverifikation Designverifikation Design Verification Design-Verifikation Vérification de La ConceptionDocumento23 pagineIndex: Designverifikation Designverifikation Design Verification Design-Verifikation Vérification de La ConceptiondwdawadNessuna valutazione finora

- Materi ETOPS-2018Documento57 pagineMateri ETOPS-2018saiful hidayatNessuna valutazione finora

- CQI-09.Ver 4Documento128 pagineCQI-09.Ver 4Nethaji MettNessuna valutazione finora

- Technical Standard Order: TSO-C110aDocumento4 pagineTechnical Standard Order: TSO-C110aP_leeNessuna valutazione finora

- UntitledDocumento25 pagineUntitledDr.Marufa FaruqiNessuna valutazione finora

- Guidelines Pressure Equipment Directive 2014 68 Eu Essential Safety Requirements On MaterialsDocumento32 pagineGuidelines Pressure Equipment Directive 2014 68 Eu Essential Safety Requirements On MaterialsJean-Noël Leroux0% (1)

- Allergen Information ManualDocumento39 pagineAllergen Information ManualAhmedAmer1100% (1)

- ISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0Documento37 pagineISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0umtNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Qualification of GMP by Lucy GakuhaDocumento22 pagineQualification of GMP by Lucy Gakuhaemma100% (1)

- AIS Module 7Documento98 pagineAIS Module 7Maricar PinedaNessuna valutazione finora

- Reviewing PQP Guide To InspectorsDocumento21 pagineReviewing PQP Guide To InspectorsMohamed S. ElrapatNessuna valutazione finora

- NUREG-1824 (Vol. 1)Documento73 pagineNUREG-1824 (Vol. 1)William IvansNessuna valutazione finora

- Unit-Iii: Developing A Software Testing StrategyDocumento20 pagineUnit-Iii: Developing A Software Testing Strategykarthik gunjaNessuna valutazione finora

- 2006 CSTE CBOK Skill Category 2Documento54 pagine2006 CSTE CBOK Skill Category 2api-3733726Nessuna valutazione finora

- Quality Management System Introduction To AuditingDocumento127 pagineQuality Management System Introduction To Auditingravindra_jivani100% (1)

- Class 1 Minor Work Standard ProcedureDocumento2 pagineClass 1 Minor Work Standard ProcedureWong WesleykitNessuna valutazione finora

- Guidelines For Certification of Forced Hot-Air Treatment Facilities For Wood Packaging Material Government of India Ministry of AgricultDocumento31 pagineGuidelines For Certification of Forced Hot-Air Treatment Facilities For Wood Packaging Material Government of India Ministry of AgriculttayefehNessuna valutazione finora