Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Max Shortterm Strain Concept

Caricato da

vkms0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni0 pagineMax Shortterm Strain concept

Titolo originale

Max Shortterm Strain concept

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMax Shortterm Strain concept

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni0 pagineMax Shortterm Strain Concept

Caricato da

vkmsMax Shortterm Strain concept

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 0

DSM Engineering Plastics Technical Guide

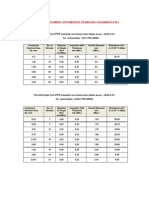

Maximum allowable short-term strain

The maximum allowable short-term strain in plastics must be known to calculate the maximum

permissible deformation, for instance of

- snap fits during assembly and disassembly,

- threads during stripping from the mould,

- parts with undercuts during ejection from the mold etc.

The maximum allowable short-term strain is:

70% of the yield strain for materials with a clear yield point*. 50% of the strain at break for materials that break

without yielding, as is the case for most glass filled materials.

The table below gives some typical values at a temperature of 23C. Because values are temperature dependent

and different temperatures can be encountered during the various manufacturing steps, real values at those

temperatures should be used.

The yield strain and the strain at break can be found in the DSM material database.

All information supplied by or on behalf of DSM in relation to its products, whether in the nature of data, recommendations or otherwise, is supported by research and, in good faith, believed reliable, but DSM assumes no liability

and makes no warranties of any kind, express or implied, including, but not limited to, those of title, merchantability, fitness for a particular purpose or non-infringement or any warranty arising froma course of dealing, usage, or

trade practice whatsoever in respect of application, processing or use made of the aforementioned information or product. The user assumes all responsibility for the use of all information provided and shall verify quality and

other properties or any consequence fromthe use of all such information.

DSM Engineering Plastics Technical Guide

Typical values for the maximum allowable short-term strain at 23C

DSM Products Polymer description (%)

Dry / condioned

PA6 and PA66 2.5 / 10

(

*

)

PA6 and PA66 +15-35% GF 1.8 / 2.8

PA6 and PA66 +40-50% GF 1.5 / 2.0

Akulon

PA6 and PA6.6 +GF +IM 2.3 / 4.0

PA46 7.0 / 10

(

*

)

PA46 +FR 3.5 / 10

(

*

)

PA46 +IM 10 / 10

(

*

)

PA46 +15% GF 2.0 / 4.0

PA46 +15% GF +FR 1.5 / 3.0

PA46 +30% GF 2.0 / 3.5

PA46 +30% GF +FR 1.3 / 1.8

PA46 +40% GF 1.5 / 3.0

PA46 +40-45% GF +FR 1.0 / 1.5

PA46 +50% GF 1.4 / 2.5

Stanyl

PA46 +60% GF 1.0 / 1.5

PBT 2.5

(

*

)

PBT +FR 3.2

(

*

)

PBT +IM 2.8

(

*

)

PBT +15-30% GF 1.5

PBT +15-30% GF +FR 1.3

PBT +20% GF +IM 2.0

PBT +35% GF 1.3

PET 2.8

(

*

)

PET +20-35% GF 1.3

PET +30-33% GF 1.0

Semi-

crystalline

materials

Arnite

PET +50% GF 1.0

PC 4.2

PC +10% GF 3.5

PC +20% GF 2.0

PC +30% GF 1.0

Xantar

PC +40% GF 0.8

Xantar C PC +ABS 3.0

Amorphous

materials

Stapron E PC +PET 4.2

FR =flame retardant

GF =glass fibre

IM =impact modifier

For applications where repeated loading and unloading is experienced, 60% of the mentioned values is

recommended.

(*) Note, even higher strains, close to the yield strain, could be accepted for unfilled semi-crystalline thermoplastics

with a clear yield point. Although no breakage will occur, this can result into unacceptable plastic deformation.

All information supplied by or on behalf of DSM in relation to its products, whether in the nature of data, recommendations or otherwise, is supported by research and, in good faith, believed reliable, but DSM assumes no liability

and makes no warranties of any kind, express or implied, including, but not limited to, those of title, merchantability, fitness for a particular purpose or non-infringement or any warranty arising froma course of dealing, usage, or

trade practice whatsoever in respect of application, processing or use made of the aforementioned information or product. The user assumes all responsibility for the use of all information provided and shall verify quality and

other properties or any consequence fromthe use of all such information.

Potrebbero piacerti anche

- Bottles, Preforms and Closures: A Design Guide for PET PackagingDa EverandBottles, Preforms and Closures: A Design Guide for PET PackagingValutazione: 4.5 su 5 stelle4.5/5 (3)

- B.3.4 Design Calculations For Snap-Fit Joints, FarbigDocumento18 pagineB.3.4 Design Calculations For Snap-Fit Joints, FarbigpchannagoudarNessuna valutazione finora

- P840J Feb, 09Documento2 pagineP840J Feb, 09Tan Chen TatNessuna valutazione finora

- P640JDocumento2 pagineP640JTan Chen TatNessuna valutazione finora

- UltramidB3EG7 IsoDocumento3 pagineUltramidB3EG7 IsoGerardo XZNessuna valutazione finora

- P740JDocumento2 pagineP740JTan Chen TatNessuna valutazione finora

- FORTRON® 1120L4 - PPS - Specialty: DescriptionDocumento2 pagineFORTRON® 1120L4 - PPS - Specialty: DescriptionAdam GordonNessuna valutazione finora

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDocumento2 pagineEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatNessuna valutazione finora

- 2628Documento3 pagine2628renebbNessuna valutazione finora

- Ultramid B3WG6Documento3 pagineUltramid B3WG6renebbNessuna valutazione finora

- 7564 Sigmatherm 540Documento2 pagine7564 Sigmatherm 540Ibrahim MahranNessuna valutazione finora

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Documento2 paginePA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNessuna valutazione finora

- 7285 - Sigma Ecofleet 238Documento0 pagine7285 - Sigma Ecofleet 238eraswastaNessuna valutazione finora

- Sigmacover 630 March 13Documento6 pagineSigmacover 630 March 13leonciomavarezNessuna valutazione finora

- S 54 D 59 U 000Documento2 pagineS 54 D 59 U 000Joshua RomanNessuna valutazione finora

- Lotrène FE8000 2014 04 16 PDFDocumento2 pagineLotrène FE8000 2014 04 16 PDFHameer SattarNessuna valutazione finora

- Sigma PrimeDocumento7 pagineSigma Primegstketut0% (1)

- AlphaSeal PU25VLS NGDocumento3 pagineAlphaSeal PU25VLS NGMuthukumar JayaveerapandianNessuna valutazione finora

- B.3.3 Plastic Parts With Integrally Molded Threads, FarbigDocumento26 pagineB.3.3 Plastic Parts With Integrally Molded Threads, FarbigVasil GospodinovNessuna valutazione finora

- Polycarbonate Film Makrofol LM228 160005 CurbellDocumento4 paginePolycarbonate Film Makrofol LM228 160005 CurbellVinaya Almane DattathreyaNessuna valutazione finora

- Flame Retardant Polystyrene (Fr-Hips) : Processing: Applications: CharacteristicsDocumento2 pagineFlame Retardant Polystyrene (Fr-Hips) : Processing: Applications: CharacteristicsSuchita SamalNessuna valutazione finora

- Sigmarine 28Documento3 pagineSigmarine 28aangNessuna valutazione finora

- 1401005riodin He00Documento2 pagine1401005riodin He00Ivonne DuymovichNessuna valutazione finora

- SP 566Documento2 pagineSP 566Suchita SamalNessuna valutazione finora

- SC3004Documento4 pagineSC3004A MahmoodNessuna valutazione finora

- Hdpe 5200B1Documento1 paginaHdpe 5200B1Sergio Rubens Oliveira SantosNessuna valutazione finora

- Sigmatherm 175: Description Principal CharacteristicsDocumento3 pagineSigmatherm 175: Description Principal CharacteristicsJose Antonio GomezNessuna valutazione finora

- Semi Finished Products EngDocumento7 pagineSemi Finished Products Engbassu86Nessuna valutazione finora

- MTM44 1 Datasheet Issue6Documento6 pagineMTM44 1 Datasheet Issue6Leolix PavlixNessuna valutazione finora

- 7102 - Sigma Vikote 63Documento0 pagine7102 - Sigma Vikote 63eraswastaNessuna valutazione finora

- ISO Datasheet UE-71D10 Preliminary BMSTDocumento1 paginaISO Datasheet UE-71D10 Preliminary BMSTNamtien UsNessuna valutazione finora

- Properties Data Sheet: HDPE - 5220BNDocumento1 paginaProperties Data Sheet: HDPE - 5220BNSergio Rubens Oliveira SantosNessuna valutazione finora

- Ketronpeek Gf30 e Pds 0907Documento1 paginaKetronpeek Gf30 e Pds 0907ellisforheroesNessuna valutazione finora

- Basf Processing Styrinic Polymers and CopolymersDocumento14 pagineBasf Processing Styrinic Polymers and CopolymersTejender SinghNessuna valutazione finora

- 7117 - Sigmarine 28Documento0 pagine7117 - Sigmarine 28eraswastaNessuna valutazione finora

- F 477 - 02 RJQ3NWDocumento4 pagineF 477 - 02 RJQ3NWHumberto GutierrezNessuna valutazione finora

- SM256Documento1 paginaSM256Tan Chen TatNessuna valutazione finora

- Formulation: StartingDocumento4 pagineFormulation: StartingA MahmoodNessuna valutazione finora

- Avalon 90ABDocumento2 pagineAvalon 90ABborlixNessuna valutazione finora

- Dow 3504Documento2 pagineDow 3504khantoNessuna valutazione finora

- 3M Series NB Filter Bags: Product EHS & Regulatory InformationDocumento4 pagine3M Series NB Filter Bags: Product EHS & Regulatory Informationalgarcia13Nessuna valutazione finora

- 8052 Cerabest Rev (1409)Documento2 pagine8052 Cerabest Rev (1409)Trịnh Minh KhoaNessuna valutazione finora

- MNZBKDJFFKJDDocumento1 paginaMNZBKDJFFKJDMd MinhajNessuna valutazione finora

- Wear Rings / Bearings: Catalog EPS 5276/USADocumento52 pagineWear Rings / Bearings: Catalog EPS 5276/USAÉmilie RiverinNessuna valutazione finora

- Astm F477-08Documento4 pagineAstm F477-08ALARCONISTANessuna valutazione finora

- Sigmadur 550Documento4 pagineSigmadur 550gstketutNessuna valutazione finora

- Catalogo Hydaulic Seals Parker PDFDocumento162 pagineCatalogo Hydaulic Seals Parker PDFMarcelo Godinho BatistaNessuna valutazione finora

- H5818J Feb, 09Documento2 pagineH5818J Feb, 09Tan Chen TatNessuna valutazione finora

- All DatasheetsDocumento485 pagineAll Datasheetssflynn79Nessuna valutazione finora

- Low Density Polyethylene: DescriptionDocumento2 pagineLow Density Polyethylene: DescriptionlyesNessuna valutazione finora

- Tds Orevac T 9304Documento2 pagineTds Orevac T 9304Claudio RottmanNessuna valutazione finora

- Pergut S 20Documento2 paginePergut S 20Cesar MartinezNessuna valutazione finora

- PR143 TDSDocumento2 paginePR143 TDSAero GuyNessuna valutazione finora

- Estane 58887Documento2 pagineEstane 58887Amit KumarNessuna valutazione finora

- Amercoat 8 8 0: Product Data/ Application InstructionsDocumento2 pagineAmercoat 8 8 0: Product Data/ Application InstructionsMehman NasibovNessuna valutazione finora

- 3M Preservation Sealing Tape 481Documento6 pagine3M Preservation Sealing Tape 481Mait YNessuna valutazione finora

- Mpif 35 PM Structural 2007Documento81 pagineMpif 35 PM Structural 2007stone00yang100% (3)

- Polyethylene: For Blow Moulding & Blown Film GradeDocumento1 paginaPolyethylene: For Blow Moulding & Blown Film GradeRikinNessuna valutazione finora

- Astm F477Documento4 pagineAstm F477Hernando Andrés Ramírez Gil100% (1)

- PVF Pps-Mesh en 2017Documento2 paginePVF Pps-Mesh en 2017vkmsNessuna valutazione finora

- Standard Wire & Cable Co.: Air PlenumDocumento1 paginaStandard Wire & Cable Co.: Air PlenumvkmsNessuna valutazione finora

- 739 Plastic AdhesiveDocumento4 pagine739 Plastic AdhesivevkmsNessuna valutazione finora

- Application: Business Group Automotive CablesDocumento1 paginaApplication: Business Group Automotive CablesvkmsNessuna valutazione finora

- MIL DTL 17 Cable DescriptionsDocumento1 paginaMIL DTL 17 Cable DescriptionsvkmsNessuna valutazione finora

- Econoseal J Series (Mark II+)Documento1 paginaEconoseal J Series (Mark II+)vkmsNessuna valutazione finora

- Standard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)Documento1 paginaStandard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)vkmsNessuna valutazione finora

- Bare Solid Soft Drawn Copper WireDocumento1 paginaBare Solid Soft Drawn Copper WirevkmsNessuna valutazione finora

- Mil DTL 22759,16Documento1 paginaMil DTL 22759,16vkmsNessuna valutazione finora

- HDPE Vs LDPE ArticleDocumento2 pagineHDPE Vs LDPE ArticleJanene DenilaNessuna valutazione finora

- Nylon Tie-Raps A17: Marine Fuel Line ApplicationDocumento1 paginaNylon Tie-Raps A17: Marine Fuel Line ApplicationvkmsNessuna valutazione finora

- 4 - JASO D 611 Auto CablesDocumento1 pagina4 - JASO D 611 Auto CablesvkmsNessuna valutazione finora

- Process Engineers - CONCEPT DETAILS (Plating)Documento1 paginaProcess Engineers - CONCEPT DETAILS (Plating)vkmsNessuna valutazione finora

- HDPE - Specification and DetailsDocumento1 paginaHDPE - Specification and DetailsvkmsNessuna valutazione finora

- Iso Octane Toluene 50 50 Astm d471Documento4 pagineIso Octane Toluene 50 50 Astm d471vkmsNessuna valutazione finora

- Schools Physical Ancillary FacilitiesDocumento548 pagineSchools Physical Ancillary FacilitiesThejesh GNNessuna valutazione finora

- GM Connectors A13: 56 SeriesDocumento1 paginaGM Connectors A13: 56 SeriesvkmsNessuna valutazione finora

- Scotchlok Connectors A15: Pictures Are Not Actual SizeDocumento1 paginaScotchlok Connectors A15: Pictures Are Not Actual SizevkmsNessuna valutazione finora

- What Is It?: Symbols To Indicate Critical Features On A Part DrawingDocumento1 paginaWhat Is It?: Symbols To Indicate Critical Features On A Part DrawingvkmsNessuna valutazione finora

- Precision and Bias: Measurement - Method and ProcessDocumento2 paginePrecision and Bias: Measurement - Method and ProcessvkmsNessuna valutazione finora

- White Paper On Solving Quality Issues GDandDocumento2 pagineWhite Paper On Solving Quality Issues GDandvkmsNessuna valutazione finora