Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VGBJF

Caricato da

Nadeem AhmadDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

VGBJF

Caricato da

Nadeem AhmadCopyright:

Formati disponibili

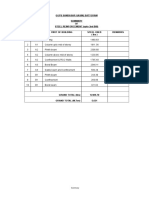

Table 6.

1 "Crashing" the Network

Time Per Activity (wks) Crash Estimates (Accelerated add'l cost/week)

Activity Number

Critical Path

Cost ($) Per Activity/wk

Min time reqd per Activity

Crash Priority

A B C D E F G H

2 3 4 8 2 3 9 4 35

Yes No No Yes No No Yes Yes

$4,000 $2,000 $3,000 $5,000 $1,500 $2,500 $20,000 $8,500

$6,000 $600 $400 $3,000 $700 $650 $5,000 $6,000

2 3 2 6 2 3 7 3 2d (-2 days x $5,000 per day) = $10,000 1st (-2 days x $3,000 per day) =$6,000

Note:

Example same as Figure 6-7

crash cost; in this case it is Activity D, which can be crashed from 8 to 6 weeks for an additional $6,000. Next, crash Activity G by 2 weeks at a cost of $10,000. Reducing both of these activities does not change the critical path. 6.3.3 PDM EXAMPLE

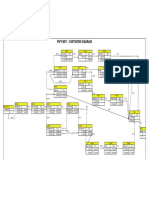

The PDM technique focuses on program activities and the meaning of the constraints among activities. This technique is used in many scheduling software applications, and Path A C F I = 5 + 4 + 5 + 3 = 17 weeks it relies on the same conceptscritical path, slack time, etc., as the other network sched- Path BDGI = 4+(2+3)+2+3 = 14 weeks uling techniques. Path BEHI = 4+5+2+3 = 14 weeks Figure 6-8 shows a PDM network for a project with Activities AI. (Assume that the unit of Thus, Path A-C-F-I is the critical path. working time (duration) is one week.) Note that Activity B cannot start until Activity A The slack times for the activities are deterstarts, and Activity D cannot end until Ac- mined in the same way as in the CPM techtivity C ends. The critical path is determined nique, using earliest and latest start and in essentially the same way as in other net- finish times, ES, EF, LS, LF. Earliest times are works. In PDM, however, one must account computed by making a forward pass through for the different types of constraints. In this the networks paths, and latest times are example, Activities B (duration=4) and D determined making a backward pass. Fig46

(duration=2) will require 6 weeks to complete. However, Activity D can not be completed until Activity C is finished, which is 9 weeks (5 weeks for Activity A and 4 weeks for C). The difference between the 9 and 6 weeks (i.e. 3 weeks) must be added to the time to complete Activity D when determining the critical path. This is shown below in the parenthetical term for Path B-D-G-I. The critical path for this example is determined as follows:

ure 6-9 shows the PDM network with these values, using the activity format shown in Figure 6-4. The values of ES, EF, LS, and LF in Figure 6-9 represent the beginning of the unit of work time, in this case a week; e.g., ES for Activity A is the beginning of week 1, while EF is the beginning of week 6. (The beginning of week 6 corresponds to the end of week 5.) The earliest and latest finish dates for this project , Activity I, is the beginning of week 18, or the end of week 17. Using the formula for slack,

on their path. If Activity B uses 3 weeks of slack, none will be left for either path.

The above example assumes that progressing from one activity to the next requires zero time, which in most projects is unrealistic. The concept of lag time can be used to incorporate the time required to transition from one activity to another, such as machine set-up time or movement of material, parts, or components from one site to another. Lag time can be shown on the network and must be accounted for in deterSlack = LS ES = LF EF, mining critical path and values of ES, EF, LS and LF. Figure 6-10 shows that in moving we see that on path B D G I, activities B, from Activity D to Activity G, there will be a D, and G each have a slack of 3 weeks. This lag of 1 week. The figure also shows the slack is not additive; if Activity D starts at effect of this lag time on the earliest and week 9 vice week 8, then Activity G has only latest start times and on finish times. The 2 weeks of slack remaining. We also see that resulting slack for Activities D and G is now Activities B, E, and H have 3 weeks of slack 2 weeks. This example shows that the PDM

G

3

I

5 2

Figure 6-8. PDM Example 47

6 5

10 4

10

15 5

A

6 1 5 4

C

10 8 10 2

10

15 10 12 2

G

15 18 3

4

Legend

ES EF Duration

11 5

13 10 5

13 10

15

I

12 2 15 18

H

13

LS

8

LF

13

15

Figure 6-9. PDM ExampleEarly and Late Start and Finish Times

1 6 5 6 10 4 10 15 5

A

6 1 5 4

C

10 8 10 2 LAG+1

10

15 11 13 2

G

15 18 3

4

Legend

ES EF Duration

10 5

12 10 5

13 10

15

I

12 2 15 18

H

13

LS

LF

13

15

Figure 6-10. PDM Example with Lag Time FOOTNOTES

Note: The numbering convention used in this PDM network is similar to the CPM network in Figure 6-7; it is described on page 46. Each computer scheduling program uses one (or gives a choice) of methods to relate duration to the time unit.

48

technique provides considerably greater flexibility in handling different types of constraints than does ADM (PERT and CPM). Consequently, it is better suited for use in complex projects, particularly those with many parallel activities and constraints other than finish-to-start. 6.4 NETWORK SCHEDULING WHEN RESOURCES ARE LIMITED In the previous discussion, the assumption was that a new activity could start as soon as any constraints were satisfied because sufficient resources were available to perform the work. In practice, however, resources to proceed are not always available. In those situations, Program Managers can take one or more different actions to reduce the adverse impact on the program. Those actions include: Adding additional resources Reducing the scope of the program

and earliest and latest start and finish times, represented as the beginning of the unit of work time (week). To determine the adequacy of resources (people in this example), assume that each activity will start as early as possible and determine the resource requirements over time. Figure 6-12 shows the personnel loading requirements by time for the duration of the program. During week one, 11 people are required to work on activities A, B, and C. Now, lets suppose only nine people are available to work during this 11 week period. The chart shows there will not be sufficient workers during the first, fourth, and fifth weeks. There will be sufficient workers to perform the work scheduledduring the second and sixth week. During the third and seventh throughout eleventh weeks, there will be a surplus of workers for the work scheduled. The task becomes one of rearranging the schedule so that, insofar as possible, the peaks and valleys are evened out without scheduling more work than nine people can do. In this example, this rearrangement can be accomplished quickly by hand. However, with many activities, it becomes very difficult to find the optimum answer. Fortunately, scheduling software applications are available to assist in solving the problem. Regardless of the approach used (manual or automated), the resource-leveling process is an iterative step-by-step process using a set of rules to establish the priority of the activities requiring the constrained resource, and the actions to be taken.

Adjusting the schedule to accommodate the resource shortfall In this section, we show how network schedules and the concepts of critical path and slack (float) can be applied to make better use of limited resources. Figure 6-11 shows a PDM network with activities A through J. Each node of the network shows the number of people required to complete the activity along with the activity duration (in weeks)

49

Potrebbero piacerti anche

- Assignment On Project Scope ManagementDocumento7 pagineAssignment On Project Scope ManagementMajidMINessuna valutazione finora

- Project SchedulingDocumento51 pagineProject SchedulingkjsNessuna valutazione finora

- Calculating Slack Time and Identifying The Critical PathDocumento3 pagineCalculating Slack Time and Identifying The Critical PathkharismaNessuna valutazione finora

- OR Chapter 5Documento21 pagineOR Chapter 5anon_92845981Nessuna valutazione finora

- A Note On Project Scheduling: Immediate Predecessors, The Smallest Possible List of Tasks Which Must Be CompletedDocumento10 pagineA Note On Project Scheduling: Immediate Predecessors, The Smallest Possible List of Tasks Which Must Be CompletedEmad Bayoumi NewNessuna valutazione finora

- Critical Path Analysis: 2008 Spec. Issue 2 Sept. 2009Documento5 pagineCritical Path Analysis: 2008 Spec. Issue 2 Sept. 2009tuandinNessuna valutazione finora

- Project ManagementDocumento43 pagineProject Managementalp_ganNessuna valutazione finora

- Project SchedulingDocumento41 pagineProject Schedulingtalhawasim100% (1)

- 3 Project Management Resource SchedulingDocumento4 pagine3 Project Management Resource SchedulingfireflyzzzNessuna valutazione finora

- C PertDocumento59 pagineC Pertlimulsa78Nessuna valutazione finora

- Pert CPMDocumento51 paginePert CPMJun Michael Artates VelascoNessuna valutazione finora

- Network Diagram and Critical Path AnalysisDocumento56 pagineNetwork Diagram and Critical Path Analysislimulsa78Nessuna valutazione finora

- Ch08 Project SchedulingDocumento51 pagineCh08 Project SchedulingTimothy Jones100% (1)

- Activity: À: An Activity Which Must Be Completed Is Known AsDocumento60 pagineActivity: À: An Activity Which Must Be Completed Is Known Aslimulsa78Nessuna valutazione finora

- Illustration - 1Documento51 pagineIllustration - 1limulsa78Nessuna valutazione finora

- CPM Explained: Critical Path Method StepsDocumento9 pagineCPM Explained: Critical Path Method StepsLokesh Kumar PariharNessuna valutazione finora

- Chapter12cpm Pert 120130120246 Phpapp01Documento38 pagineChapter12cpm Pert 120130120246 Phpapp01Kendi Kejar IralNessuna valutazione finora

- MPS Recovered) CompleteDocumento17 pagineMPS Recovered) CompleteHue Yang YangNessuna valutazione finora

- Project Scheduling: Prof. DR Amir Azam KhanDocumento53 pagineProject Scheduling: Prof. DR Amir Azam KhanKhairul Azhar Abdul LizaNessuna valutazione finora

- Errors in Network Diagram: Ÿ If An Activity Were Represented As Going Back in TimeDocumento57 pagineErrors in Network Diagram: Ÿ If An Activity Were Represented As Going Back in Timelimulsa78Nessuna valutazione finora

- TQMDocumento6 pagineTQMHaidie DiazNessuna valutazione finora

- Mod 3Documento24 pagineMod 3Luis Enrique Vargas AyalaNessuna valutazione finora

- CHAP 10 ResourcesDocumento25 pagineCHAP 10 Resourceshema16Nessuna valutazione finora

- Management of ProjectsDocumento27 pagineManagement of Projectsccuong_820292841Nessuna valutazione finora

- Project Crashing Algorithm: Initialization StepsDocumento12 pagineProject Crashing Algorithm: Initialization StepsofentseNessuna valutazione finora

- Manage plant turnaround projectsDocumento9 pagineManage plant turnaround projectsRaka Satria PradanaNessuna valutazione finora

- CPM PertDocumento18 pagineCPM PertJunaid YNessuna valutazione finora

- Unit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andDocumento40 pagineUnit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andSuneelKumarNessuna valutazione finora

- PertDocumento28 paginePertHarshit BhatiaNessuna valutazione finora

- Project Scheduling by PERTDocumento24 pagineProject Scheduling by PERTDennis Ray G DumaguinNessuna valutazione finora

- Network Techniques: PERT and CPM SchedulingDocumento31 pagineNetwork Techniques: PERT and CPM SchedulingDejene HailuNessuna valutazione finora

- Critical Path MethodDocumento34 pagineCritical Path Methodfrancis dimakiling100% (1)

- Network Diagrams: Critical Path AnalysisDocumento4 pagineNetwork Diagrams: Critical Path AnalysisHomod S AL-tamimiNessuna valutazione finora

- Recourse AllocationDocumento12 pagineRecourse AllocationBakri BugaNessuna valutazione finora

- Pert/Cpm: Project Scheduling Project SchedulingDocumento51 paginePert/Cpm: Project Scheduling Project SchedulingSandeep NakireddyNessuna valutazione finora

- Activity On Node Diagram: A Is The First Step and Precedes - and C (A - , C)Documento50 pagineActivity On Node Diagram: A Is The First Step and Precedes - and C (A - , C)limulsa78Nessuna valutazione finora

- MGMT 4135 Chapter-6 Project Plan DevelopmentDocumento28 pagineMGMT 4135 Chapter-6 Project Plan DevelopmenttvihofdiNessuna valutazione finora

- Critical Path Analysis CpaDocumento3 pagineCritical Path Analysis CpaNeha KumariNessuna valutazione finora

- ENGINEERING PROJECT MANAGEMENT TOOLSDocumento52 pagineENGINEERING PROJECT MANAGEMENT TOOLSTalha Bin SaeedNessuna valutazione finora

- Both CPM and PertDocumento6 pagineBoth CPM and PertaprsinghNessuna valutazione finora

- Quantitative Analysis - Chapter 6 (Project Management)Documento18 pagineQuantitative Analysis - Chapter 6 (Project Management)Ash0% (1)

- A Ules For Network ConstructionDocumento53 pagineA Ules For Network Constructionlimulsa78Nessuna valutazione finora

- Calculate Critical Path Float ES EF LS LFDocumento9 pagineCalculate Critical Path Float ES EF LS LFnazishtila100% (1)

- Resource AllocationDocumento31 pagineResource AllocationRi ŚhiNessuna valutazione finora

- Scheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisDocumento62 pagineScheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisInderjeet Singh Toor100% (1)

- Activity On Node Diagram: A Is The First Step and Precedes - and C C Precedes D and E. (C D, E)Documento49 pagineActivity On Node Diagram: A Is The First Step and Precedes - and C C Precedes D and E. (C D, E)limulsa78Nessuna valutazione finora

- Critical Path MethodDocumento8 pagineCritical Path MethodAmy AungNessuna valutazione finora

- Use of Network TechniquesDocumento38 pagineUse of Network TechniquesRipudaman BhatnagarNessuna valutazione finora

- Gantt Charts, Took Several Different Forms, Depending On TheirDocumento5 pagineGantt Charts, Took Several Different Forms, Depending On Theirsenior highNessuna valutazione finora

- 21CPMDocumento43 pagine21CPMlimulsa78Nessuna valutazione finora

- Asic ComponentDocumento61 pagineAsic Componentlimulsa78Nessuna valutazione finora

- Line-of-Balance TechniqueDocumento11 pagineLine-of-Balance TechniqueAnturio PiccasoNessuna valutazione finora

- Resource Leveling & Resource SmoothingDocumento6 pagineResource Leveling & Resource SmoothingKabeer QureshiNessuna valutazione finora

- PERT Planning ProcessDocumento8 paginePERT Planning ProcessMaruti ShingadeNessuna valutazione finora

- ACC 104: Management Science: Pamantasan NG CabuyaoDocumento44 pagineACC 104: Management Science: Pamantasan NG CabuyaoHannah MeranoNessuna valutazione finora

- CISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)Da EverandCISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)Valutazione: 1.5 su 5 stelle1.5/5 (3)

- Book 11Documento1 paginaBook 11Nadeem AhmadNessuna valutazione finora

- Lesson+10+Notice+of+a+Claim KMDocumento9 pagineLesson+10+Notice+of+a+Claim KMNadeem AhmadNessuna valutazione finora

- Information Technology... : Strong Revenue Momentum To Continue Despite SeasonalityDocumento5 pagineInformation Technology... : Strong Revenue Momentum To Continue Despite SeasonalityNadeem AhmadNessuna valutazione finora

- PlannDocumento1 paginaPlannNadeem AhmadNessuna valutazione finora

- ControllingDocumento1 paginaControllingNadeem AhmadNessuna valutazione finora

- Content - 2022 12 05 - 2022 12 11Documento6 pagineContent - 2022 12 05 - 2022 12 11Nadeem AhmadNessuna valutazione finora

- Relaxo Footwears LTD: Improving Mobility To Boost RecoveryDocumento6 pagineRelaxo Footwears LTD: Improving Mobility To Boost RecoveryNadeem AhmadNessuna valutazione finora

- 001Documento1 pagina001Nadeem AhmadNessuna valutazione finora

- Finalprojectreportg2 141218075116 Conversion Gate01Documento52 pagineFinalprojectreportg2 141218075116 Conversion Gate01nandiniNessuna valutazione finora

- Complete RCC Design Very ImportantDocumento41 pagineComplete RCC Design Very ImportantAmal PremachandranNessuna valutazione finora

- 001Documento1 pagina001Nadeem AhmadNessuna valutazione finora

- Sched LogDocumento29 pagineSched LogNadeem AhmadNessuna valutazione finora

- 3.03 Initial Data SampleDocumento16 pagine3.03 Initial Data SamplensadnanNessuna valutazione finora

- Cost Baseline TemplateDocumento1 paginaCost Baseline TemplateNadeem Ahmad100% (2)

- Barbending ScheduleDocumento7 pagineBarbending ScheduleSureshKumarNessuna valutazione finora

- How To Get Your CV Into The Recruiter's..Documento6 pagineHow To Get Your CV Into The Recruiter's..Nadeem AhmadNessuna valutazione finora

- Column Design With ExcelDocumento72 pagineColumn Design With ExcelAsifIqbalNessuna valutazione finora

- Autocad ShortcutsDocumento13 pagineAutocad ShortcutsKriscel CaraanNessuna valutazione finora

- MBA in Consultancy ManagementDocumento2 pagineMBA in Consultancy ManagementNadeem AhmadNessuna valutazione finora

- NBC - Fire SafetyDocumento200 pagineNBC - Fire Safetyvenkin84507486% (7)

- Ijiset V3 I3 64 PDFDocumento30 pagineIjiset V3 I3 64 PDFNadeem AhmadNessuna valutazione finora

- MulcahyriskDocumento5 pagineMulcahyriskagarap0% (1)

- Cdol Prospectus 2016Documento29 pagineCdol Prospectus 2016Nadeem AhmadNessuna valutazione finora

- The Haryana Building Code 2016 PDFDocumento83 pagineThe Haryana Building Code 2016 PDFSrishti SinghalNessuna valutazione finora

- Dam Project Network DiagramDocumento20 pagineDam Project Network DiagramNadeem AhmadNessuna valutazione finora

- Design Guide For Interiors PDFDocumento196 pagineDesign Guide For Interiors PDFMohammed Abbas100% (1)

- MTech Construction Engineering & Management Course OutlineDocumento26 pagineMTech Construction Engineering & Management Course OutlineRamzad KumbleNessuna valutazione finora

- Pocket D PDFDocumento1 paginaPocket D PDFNadeem AhmadNessuna valutazione finora

- EVMDocumento18 pagineEVMNadeem AhmadNessuna valutazione finora

- Commercial plots with shops and open spacesDocumento1 paginaCommercial plots with shops and open spacesNadeem AhmadNessuna valutazione finora