Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mech

Caricato da

ரமேஷ் பாலக்காடுTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mech

Caricato da

ரமேஷ் பாலக்காடுCopyright:

Formati disponibili

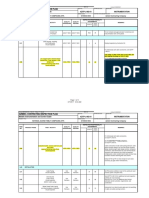

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Final Insp of Tank Installation (Tanks)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

Instructions on use of this checklist: 1. Any Item marked as "Fail" requires to be identified with the specific description and location of the descripancy/violation and shall be listed in the Contractor's Re-Instatement Punchlist Form, SATR-A-2011. 2. Column "Y/N" is used to pre-determine each respective item as required for start-up ( Y), or not required for start-up (N). Final designation of "Y/N" items will be at the Mechanical Completion Punchlisting by Saudi Aramco Inspection. 3. This Checklist along with the Re-Instatement Punchlist, with or with out cleared items, shall be submitted to Saudi Aramco on or before the requested time for Mechanical Completion Punchlisting. ITEM No. A

ACCEPTANCE CRITERIA Equipment Documentation The Design Engineer have completed the data storage tank data sheet for the tank being purchased in accordance with this standard The SIS is prepared, approved and issued by Project Manager for the new construction projects Test and Inspection Plan (SATIPs) and Inspection Checklists for field installation as detailed in SATIP-D-109-01 were verified to be complete and accepted. All non-conformance reports and worksheets have been resolved to the satisfaction of Inspection Department. All log book entries have been resolved to the satisfaction of Inspection Department. All equipment fabrication documents, inspection record books and Equipment Instrument Schedules (EIS) are available for review. P&ID Check / Walkthrough All vessel components are installed in their respective locations as shown in the P&ID. (i.e: piping, removable pipe spools, valves, vents, drains, spectacle plates, blinds, flange spacers, etc) All in-line equipment & Instruments are installed in their respective locations as shown in the P&ID. (i.e: Strainer, meter tube, straightening vanes, flow meter, orifice fitting, Pressure Indicators, Temperature, temperature indicators, sample probes, etc) Installed Relief Valves were verified and the corresponding Form 3099A signed. Safety Devices installed are identified. (Form 2693-ENG item 37,38,39, 40,41,42) Dial thermometers are installed, when required by the Operating Unit at the specific facility. The size and location of thermometers is as shown on Form SA 2696ENG.

REFERENCE

PASS

FAIL

N/A

Y/N

RE-INSP DATE

A1

SAES-D-109 Para 8.1.1 SAES-A-005 Para 6 GI-2.710 Para. 4.1.1.2 GI-2.710 Para. 4.1.1.4 GI-2.710 Para. 4.1.1.4 GI-2.710 Para. 4.1.1.6

A2

A3

A4

A5

A6

B1

P&ID # ____________

B2

P&ID # ____________ SAES-J-600, Sec. 10 SAES-A-005 Attachment D-2 SAES-D-109 Para 9.4.1 SAES-D-109 Para 9.4.1

B3 B4

Y Y

B5

B6

Page 1 of 4

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Final Insp of Tank Installation (Tanks)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. B7

ACCEPTANCE CRITERIA Minimum of one level gauging instrument per tank, readable either from grade or from an access platform, is installed. Provisions for manual gauging is provided, even if the tank is provided with an automatic gauging device. Sample connection is provided, when required by the Operating Unit at the specific facility. Internal cleanliness and vessel closure has been performed. Form SATR-D-2003 has been completed. A detailed inspection performed on the vessel internals to include holiday detection of internal coating and installation of mechanical internals. Properly close up all vessel internal manways and openings per the proper torquing procedures, after final inspection or after charging of chemicals, catalysts, etc., is completed. Install all relief valves after Aramco or approved Agency, sets and test them. Paint and/or tag all relief valves, car sealed valves and safety equipment per Aramco Standards. Structural Items: All access areas including platforms, walkways, stairs, ladders are free of debris, tools and extraneous materials which would impede operation or cause an unsafe condition. All lifting equipment are tested and witnessed by the Inspection Department's Crane Inspection Representative and are provided with a current inspection sticker of the successful tests. Access platforms, ladders, stairs, walkways and handrails are complete. ( Inspect using SAIC-M-2011). Access gratings are firmly anchored with a minimum of 2 fasteners at each support with a minimum of 4 fasteners per panel. (Note: Non-compliance shall be identified as "YES" item in the Facility Exception Item List for the MCC.) Access to the roof of aboveground, vertical, cylindrical, tanks is provided.

REFERENCE SAES-D-109 Para 9.5.2 SAES-D-109 Para 9.5.3 SAES-D-109 Para 9.6.1 GI-2.710-06, Item 5.10e GI-2.710-06, Item 5.10f GI-2.710-06, Item 5.10h GI-2.710-06, Item 6 e GI-2.710-06, Item 6 g

PASS

FAIL

N/A

Y/N

RE-INSP DATE

B8

B9 B10

Y Y

B11

B12

B13 B14 C

Y Y

C1

GI-2.710-06, Item 1e GI-2.710-06, Item 1i GI-2.710-06, Item 2c 12-SAMSS-007, Para. 6.1.16

C2

C3

C4

C5

SAES-D-109 Para 9.7.2 SAES-D-109 Para 9.7.2 SAES-B-054, Para. 6.21 SAES-D-109 Para 10.2 SAES-Q-005, Par. 4.3.2 (a) SAES-D-109, Sec. 6

C6

A vertical ladder is installed for tanks that do not require spiral stairways. Toeboards is installed on all open sides (except at the entrance of stairways or ladders) to provide an installed height of 4 inches above the treadway. (API Spec 12F Para D.6) Painting is performed on tank as specified painting requirements on the tank data sheet in accordance with SAES-H-101. The top of concrete is of 150 mm above finished grade. Supports provided with thru holes for tie down are slotted or open ended to allow for thermal expansion and contraction. (UL 142 Para 30.1.3)

C7

C8

C9

C10

Page 2 of 4

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Final Insp of Tank Installation (Tanks)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. D

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

Y/N

RE-INSP DATE

Associated Piping/trim Pipe bolted to nozzles are resting fully on pipe supports. Shims are installed and seal welded to pipe supports to maintain contact where required. Pipe clamps are tightened and in full contact with the pipe. Jack screw bolts installed in flanges with spectacle plates. (NOTE: With concurrence from the proponent, jack screw bolts may be deleted if flange spreader is available. ) Standpipe and individual level instruments are connected directly to vessels and not to inlet or outlet piping. Connections to the bottom of vessels are avoided whenever possible, and are not be used when settlement of solids may be expected. SAES-L-350, Para. 14.2.2 SAES-L-350, Para. 14.2.2 SAES-L-350, Para. 10.5 SAES-J-300, Par. 4.1 SAES-J-300, Par. 4.1

D1

D2

D3

Y/N

D4

D5

D6

A 2" dia. block valve is installed at the top and bottom connection of the standpipe to the vessel. (Saudi Aramco Library Drawing DC-950045.) Type of block valve installed is in conformance with the project drawing or P&ID. Vent valve with plug installed on the top blind flange and drain valve on the bottom blind flange of the standpipe. (Saudi Aramco Library Drawing DC-950045.) Standpipe is rigidly supported on the vessel. Diagonal bracing in horizontal and/or vertical plane may be required to avoid vibration. (Saudi Aramco Library Drawing DC-950045.) All pressure instrument installations are equipped with vent/drain valves.

SAES-J-300, Par. 4.5.1

D7

SAES-J-300, Par. 4.5.1

D8

SAES-J-300, Par. 4.5.1 SAES-J-200, Par. 6.4 GI-2.710-6, Item 4a GI-2.710-6, Item 1.j. GI-2.710-6, Item 1.j.

D9

D10

Pressure test of field installed piping and components are complete.

D11

All nuts and bolts of flange connections are fully engaged. Flange joints for piping Class ANSI 600# and above were verified to be tightened using the applicable Torque procedure. Painting Works Identification of all equipment are provided. Identification numbers shall be legible from 50 feet away for process equipment. Painting are complete enough so that an excessive amount of scaffolding is not left still standing in the areas where the operators must work to start up the plant. Coating on structural items is complete and conforms with the project coating requirements.

D12 E

E1

GI-2.710-06, Item 1a GI-2.710-06, Item 1d Scope of Work

Y/N

E2

Y/N

E3

Page 3 of 4

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Final Insp of Tank Installation (Tanks)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Safety yellow-and-black stripes are painted on obstructions that present bump hazards. (concrete supports at the base of stairways or ladders, passageway pinch points, unguarded edges, tripping hazards). Stripes shall be 100 mm wide. Lifting equipment and devices shall be painted safety yellow and clearly marked with the rated capacity of the equipment in Arabic and English in metric tons. Insulation works/Fire Proofing All fire proofing are complete. Insulation is complete per applicable SATIP-N-001-01 or SATIP-N-00102

REFERENCE

PASS

FAIL

N/A

Y/N

RE-INSP DATE

E4

SAES-B-067, Para. 4.2.3 a

E5 F F1 E6

SAES-B-067, Para. 4.4

GI-2.710-06, Item 1c Scope of Work

Y Y

REMARKS:

REFERENCE DOCUMENTS: 1. G.I.-2.710 (13 July, 2004) Mechanical Completion and Performance Acceptance of Facilities 2. SAES-D-109 -- Design of Small Tanks, 30 November 2003 3. SAES-A-005 -- Safety Instruction Sheet, 31 December 2001 4. SAES-J-300 -- Level, 30 April 2003 5. SAES-D-001 (30 March 2005) Design Criteria for Pressure Vessels 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. SAEP-20, Equipment Inspection Schedule, (29 January, 2003) SAES-M-001(30 June, 2004) Structural Design Criteria for Non-Building Structures SAES-L-350 (30 September, 2003), Construction of Plant Piping SAES-J-200 (31 May, 2003), Pressure SAES-J-600 (31 March, 2003) Pressure Relief Devices SAES-B-054 (31 March, 2001) Access, Egress, and Materials Handling for Plant Facilities SAES-B-067, Safety Identification and Safety Colors, (30 November, 2003) SAES-J-400, Temperature, (31 May, 2004) SAIC-M-2011, Saudi Aramco Inspection Checklist for System Punchlisting of Structural Installation, Rev. 0 SAES-Q-005 -- Concrete Foundations, 30 June 2004 32-SAMSS-030 -- Manufacture of Small Tanks, 30 November 2003 UL 142 -- Standard for Safety Steel Aboveground Tanks for Flammable and Combustible Liquids, July 2002 API SPEC 12F -- Specification for Shop Welded Tanks for Storage of Production Liquids, November 1994

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 4 of 4

Potrebbero piacerti anche

- SAIC-D-2012 Rev 2Documento4 pagineSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocumento10 pagineSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalTariqMalikNessuna valutazione finora

- Procedure for hydro & pneumatic tank testingDocumento3 pagineProcedure for hydro & pneumatic tank testingNupesh katreNessuna valutazione finora

- 7560-Hydro Test - Sequence 1Documento9 pagine7560-Hydro Test - Sequence 1Bala MuruganNessuna valutazione finora

- ARCC Hydrotest Packages Summary ReportDocumento4 pagineARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqNessuna valutazione finora

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocumento5 pagineSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNessuna valutazione finora

- Ip Gauge Calibration ChecklistDocumento1 paginaIp Gauge Calibration ChecklistKumarNessuna valutazione finora

- Asa-146 NSH Apco Ir 040Documento10 pagineAsa-146 NSH Apco Ir 040Fahad AhmadNessuna valutazione finora

- Pressure Form Test RecordDocumento1 paginaPressure Form Test Recordphyo7799Nessuna valutazione finora

- Scope: Painting ProcedureDocumento2 pagineScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสNessuna valutazione finora

- Client Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved byDocumento7 pagineClient Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved bySARSAN NDTNessuna valutazione finora

- Piping Test Pack Clearance ReportDocumento2 paginePiping Test Pack Clearance ReportKarthikNessuna valutazione finora

- Inspection and Testing Plan (Itp) Item: Instruments Air PipingDocumento9 pagineInspection and Testing Plan (Itp) Item: Instruments Air PipingNguyen DienNessuna valutazione finora

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Documento6 pagineEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNessuna valutazione finora

- Bs Tech: Electrodes Issue and Return RegisterDocumento1 paginaBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNessuna valutazione finora

- Inspection Checklist For: Control ValvesDocumento2 pagineInspection Checklist For: Control Valvesabdelkader benabdallahNessuna valutazione finora

- SATR-W-2019 Rev 7 (05-NOVT-16 To 10-NOV-16) - 019Documento2 pagineSATR-W-2019 Rev 7 (05-NOVT-16 To 10-NOV-16) - 019asiqNessuna valutazione finora

- NDE Requirements for Header Box WeldsDocumento9 pagineNDE Requirements for Header Box Weldsrony16novNessuna valutazione finora

- MARAFIQ Piping Specification DetailsDocumento14 pagineMARAFIQ Piping Specification DetailsjaseelNessuna valutazione finora

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Documento1 paginaSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNessuna valutazione finora

- A-4 Calibration Check ReportDocumento2 pagineA-4 Calibration Check ReportheikelNessuna valutazione finora

- Manufacturing Quality PlanDocumento4 pagineManufacturing Quality PlanDIENSHNessuna valutazione finora

- Qap 8000ce Reactor - Repat - 1Documento2 pagineQap 8000ce Reactor - Repat - 1AliasgarNessuna valutazione finora

- Water Tank Fabrication QAPDocumento2 pagineWater Tank Fabrication QAPYOGESHNessuna valutazione finora

- Painting Procedure Rev.ADocumento12 paginePainting Procedure Rev.Aคุณพ่อน้อง บิ๊กบอสNessuna valutazione finora

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Documento4 pagineInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNessuna valutazione finora

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocumento12 pagineAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNessuna valutazione finora

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocumento1 paginaFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- Offshore Design Section Functional Specification For Level TransmitterDocumento10 pagineOffshore Design Section Functional Specification For Level TransmitterGerman ToledoNessuna valutazione finora

- 30 Mainline Hydrotesting 111Documento25 pagine30 Mainline Hydrotesting 111rexNessuna valutazione finora

- Pressure Transmitter Elec: Instrument Calibration ResultDocumento2 paginePressure Transmitter Elec: Instrument Calibration ResultIsaalexNessuna valutazione finora

- 2.FIT-UP & 3. Welding ReportDocumento2 pagine2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocumento2 pagineElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNessuna valutazione finora

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDocumento5 pagineAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavNessuna valutazione finora

- KP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksDocumento3 pagineKP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksUtku Can KılıçNessuna valutazione finora

- Vendor document review cover sheetDocumento9 pagineVendor document review cover sheetvelmurug_balaNessuna valutazione finora

- Hydro Vs PneumaticDocumento4 pagineHydro Vs PneumaticAnonymous rYZyQQot55Nessuna valutazione finora

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDocumento3 pagineSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNessuna valutazione finora

- Method Statement for Pipe Handling and StorageDocumento14 pagineMethod Statement for Pipe Handling and StorageShambu S VtkNessuna valutazione finora

- Pttep Painitng of Offshore FacilitiesDocumento66 paginePttep Painitng of Offshore FacilitiesSufianNessuna valutazione finora

- ITP Buckling Pin Relief Valves Inspection Test PlanDocumento4 pagineITP Buckling Pin Relief Valves Inspection Test PlanjfdlksaNessuna valutazione finora

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocumento1 paginaNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Wps Mig PDF FreeDocumento3 pagineWps Mig PDF Freehanz bermejoNessuna valutazione finora

- Hydrotest QI304-sampleDocumento3 pagineHydrotest QI304-sampleHanuman Rao100% (1)

- Procedure For DYE PENETRANT TestingDocumento10 pagineProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- 24.tank Oil Chalk TestDocumento3 pagine24.tank Oil Chalk TestShubham ShuklaNessuna valutazione finora

- Valve Hydro Test Status For AramcoDocumento3 pagineValve Hydro Test Status For AramcousmanNessuna valutazione finora

- Inspectation Test PlanDocumento1 paginaInspectation Test Planazimr157Nessuna valutazione finora

- LOWER FARS HEAVY OIL DEVELOPMENT PHASE-1 PIPING TEST PLANDocumento4 pagineLOWER FARS HEAVY OIL DEVELOPMENT PHASE-1 PIPING TEST PLANmuralidmurthyNessuna valutazione finora

- How To Write A Welding Procedure Specification (WPS)Documento5 pagineHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Itp For SSDP Project Rev CDocumento9 pagineItp For SSDP Project Rev CRachel FloresNessuna valutazione finora

- Inspection RoleDocumento18 pagineInspection Rolesribd9128Nessuna valutazione finora

- Mfjo694 MRB 0001 IndexDocumento2 pagineMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Liquid Penetrant Testing Report SummaryDocumento1 paginaLiquid Penetrant Testing Report SummaryAbdul NaveedNessuna valutazione finora

- Qap HPCLDocumento13 pagineQap HPCLdarshan100% (1)

- Package 2s E0001 - Jupiter DCR 30-10-2021Documento96 paginePackage 2s E0001 - Jupiter DCR 30-10-2021senthilNessuna valutazione finora

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Documento15 pagineSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- Code Ref.Documento155 pagineCode Ref.Selvakpm06Nessuna valutazione finora

- API Repair ProcedureDocumento1 paginaAPI Repair ProcedurejacquesmayolNessuna valutazione finora

- SAIC-D-2022 Rev 2Documento5 pagineSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Computer Exam For QC WeldingDocumento4 pagineSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDocumento2 pagineOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNessuna valutazione finora

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Documento62 pagineSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுNessuna valutazione finora

- Duties of A Welding Inspector 1Documento12 pagineDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2023 Rev 2Documento2 pagineSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Pew205 Slide ShowDocumento23 paginePew205 Slide Showரமேஷ் பாலக்காடுNessuna valutazione finora

- Responabilities of A Welding InspectorDocumento13 pagineResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுNessuna valutazione finora

- Online Reg Certfct PDF PDFDocumento2 pagineOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNessuna valutazione finora

- Codes Standards and SpecificationsDocumento15 pagineCodes Standards and Specificationsரமேஷ் பாலக்காடுNessuna valutazione finora

- Gouging 01Documento2 pagineGouging 01ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2023 Rev 2Documento2 pagineSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2022 Rev 2Documento5 pagineSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Air Carbon Arc Gouging: ElectrodeDocumento1 paginaAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-E-2001 Rev 2Documento7 pagineSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Welding Processes ModuleDocumento27 pagineWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Computer Kerala - 4 Folder LockDocumento2 pagineComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNessuna valutazione finora

- 0 Wis10 Contents ListDocumento1 pagina0 Wis10 Contents ListSangram RoutarayNessuna valutazione finora

- Computer Kerala - 4 Folder LockDocumento2 pagineComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNessuna valutazione finora

- API 510 Examination Sample ItemsDocumento3 pagineAPI 510 Examination Sample ItemsMagira PasaribuNessuna valutazione finora

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocumento362 paginePractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNessuna valutazione finora

- Vedic Maths TutorialDocumento12 pagineVedic Maths TutorialNitin Jain100% (15)

- Computer Kerala - 4 Folder LockDocumento2 pagineComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-F-2007 Rev 2Documento1 paginaSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-E-2002 Rev 2Documento7 pagineSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocumento1 paginaSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2006 Rev 2Documento2 pagineSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2023 Rev 2Documento2 pagineSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2006 Rev 2Documento2 pagineSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- February 17, 2012 Strathmore TimesDocumento28 pagineFebruary 17, 2012 Strathmore TimesStrathmore TimesNessuna valutazione finora

- Materi Kesatu Apt Ari - Webinar Hisfarsi Jatim 9Documento86 pagineMateri Kesatu Apt Ari - Webinar Hisfarsi Jatim 9Fara Ester100% (1)

- Marcus Simpson VS Cal Poly Pomona, Et Al.Documento25 pagineMarcus Simpson VS Cal Poly Pomona, Et Al.hko100% (3)

- EXPERIMENT 2: Absorption of Carbon Dioxide in WaterDocumento4 pagineEXPERIMENT 2: Absorption of Carbon Dioxide in WaterAzrol Azmir Long67% (6)

- Brushless and Brushed DC MotorsDocumento27 pagineBrushless and Brushed DC MotorsMarc Jairro GajudoNessuna valutazione finora

- Ap4498 Flight 2nd Stage Maint ManxDocumento20 pagineAp4498 Flight 2nd Stage Maint ManxdaviddealbaNessuna valutazione finora

- Ranjit CVR Calaveras Vineyard CaseDocumento7 pagineRanjit CVR Calaveras Vineyard CaseAdityaSinghNessuna valutazione finora

- The Elliott Wave PrincipleDocumento4 pagineThe Elliott Wave PrincipledewanibipinNessuna valutazione finora

- SBM Documentation for School ImprovementDocumento13 pagineSBM Documentation for School ImprovementKristine Grace Venturillo AsuqueNessuna valutazione finora

- A Note On Cryptocurrency Stabilisation Seigniorage SharesDocumento8 pagineA Note On Cryptocurrency Stabilisation Seigniorage SharesTomy1969Nessuna valutazione finora

- Fitness, Sports and Recreation Leadership: Quarter 3 - Module 1Documento29 pagineFitness, Sports and Recreation Leadership: Quarter 3 - Module 1Elvin Sajulla BulalongNessuna valutazione finora

- FOTOSÍNTESISyRELACIONES TRÓFICAS0680 w09 QP 1-2Documento2 pagineFOTOSÍNTESISyRELACIONES TRÓFICAS0680 w09 QP 1-2Ada JustinianoNessuna valutazione finora

- Internship Opportunity at Movidu Technology-HyderabadDocumento1 paginaInternship Opportunity at Movidu Technology-HyderabadPurushotham MPNessuna valutazione finora

- 5 PracticeDocumento12 pagine5 PracticeAyush DhamijaNessuna valutazione finora

- Gathering Information and Scanning The Environment: Marketing Management, 13 EdDocumento23 pagineGathering Information and Scanning The Environment: Marketing Management, 13 EdSaket JangleNessuna valutazione finora

- Nebosh IGC2 Part 4Documento54 pagineNebosh IGC2 Part 4MuhammadAkram50% (2)

- MFM Assignment 2Documento14 pagineMFM Assignment 2Satadeep DattaNessuna valutazione finora

- Siemens Simotion Engineering ManualDocumento112 pagineSiemens Simotion Engineering ManualCaptive MahbubNessuna valutazione finora

- ESG FinalDocumento9 pagineESG FinalLidia GutiérrezNessuna valutazione finora

- PDF Online Art Gallery DocumentationDocumento21 paginePDF Online Art Gallery Documentationzarar ghaniNessuna valutazione finora

- 115 Part CDocumento6 pagine115 Part Capi-660176745Nessuna valutazione finora

- FlywheelDocumento2 pagineFlywheelSaravanan MathiNessuna valutazione finora

- STM32 Training 12W06 1V0Documento73 pagineSTM32 Training 12W06 1V0Oussama Riahi ChNessuna valutazione finora

- Voice Action Sprint Deck - 3-Day TemplateDocumento59 pagineVoice Action Sprint Deck - 3-Day TemplateTravis MendozaNessuna valutazione finora

- ICT Rollout - Assessment & Data Gathering Room 1Documento27 pagineICT Rollout - Assessment & Data Gathering Room 1eko rudiistiantoNessuna valutazione finora

- GEOTEXTILES AND GEOMEMBRANESDocumento16 pagineGEOTEXTILES AND GEOMEMBRANESsai srinivasNessuna valutazione finora

- Philippine Education Department's GSP Action PlanDocumento2 paginePhilippine Education Department's GSP Action PlanCharie P. Gracia100% (1)

- SEO StrategyDocumento10 pagineSEO StrategyLuanaNessuna valutazione finora

- PW615F A PDFDocumento7 paginePW615F A PDFValBMSNessuna valutazione finora

- Salam and Istisna: From Current Issues To An Ideal Model For Islamic Banks in PakistanDocumento14 pagineSalam and Istisna: From Current Issues To An Ideal Model For Islamic Banks in PakistanMr BalochNessuna valutazione finora