Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heat-Flo Hydronic Buffer Tanks 2011

Caricato da

api-221502147Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heat-Flo Hydronic Buffer Tanks 2011

Caricato da

api-221502147Copyright:

Formati disponibili

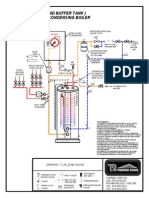

HF-80-BTs piped to Geothermal Heat Pumps

Hydronic Buffer Tank Increase System Efficiency

Eliminate Short Cycling Hydraulically Separate the Source from the Distribution System Available in 40, 60, 80 and 115 gallons Choice of fitting sizes 1 1/4, 1 1/2 or 2

Heat-Flo Inc., 15 Megan Court, Uxbridge, MA 01569 Tel: (508) 278-2400 Fax: (508) 278-2466 www.heat-flo.com

Hydronic Buffer Tanks

Application: Geothermal Heat Pumps / Chillers / Low Mass Boilers

The primary application of a buffer tank is to reduce heat pump, chiller, or boiler short cycling. Hydronic buffer tanks are used in systems operating below the design load condition, which is most of the time, or in systems having several low BTU cooling or heating loads calling at different times. This can cause the heat pump or boiler to short cycle, resulting in reduced operating efficiency and shorter equipment life. The hydronic buffer tanks are built with 4 connections. Two connections can be piped to the heat pump or boiler, and two connections can be piped to the distribution system. If piped correctly, the tank can serve as both a thermal buffer and a hydraulic separator. The heat pump or boiler can be hydraulically decoupled from the distribution system. The tanks are all 316L stainless steel construction with R-12 insulation, and an ABS jacket. A 3/8 ID thermal well is located mid-tank. Thermistors can be inserted 3 into the well, or the well will accept the Honeywell L4006A controls. Buffer tanks are available in 40, 60, 80 and 115 gallon capacities.

Buffer Tank Sizing - Calculating Capacity

The Heat-Flo buffer tanks are a simple, cost effective way to improve overall system operating efficiency by reducing unnecessary equipment short cycling. The recommended capacity or volume of a buffer tank is based on four variables. 1. The duration of the heating or cooling source on time. (minutes) The desired length of on time for each run cycle depends on the type of equipment used. Heat pump and chiller manufacturers typically recommend a minimum of 5 to 10 minutes on time, and boiler manufacturers may recommend a minimum of 10 minutes on time. Check with your equipment manufacturer. Generally, the longer the on time, the higher the overall operating efficiency. 2. The minimum rate of heat input. (BTU/HR) This is based on the heat pump or chiller output, or the boiler output at the minimum firing rate if the boiler has a variable input system that ramps input down as the demand decreases. The minimum system load (BTU/HR) This is the demand placed on the system with the smallest zone calling for heat. The allowable tank temperature rise. (deg. F) This varies depending on the type of heating or cooling system used, and on the design of the distribution system. Chillers may require a tight, (6 deg. F), differential to assure good dehumidification and prevent freezing, heat pumps may require a 10 deg. F differential to maintain a high COP, and boilers with hydronic heating distribution systems may require a differential anywhere between 10 to 40 deg. F depending on the application.

3. 4.

Specify 1 , 1 , or 2 connections.

D

The following formula determines the tank volume: V=T X (Q heat input - Q min. heat load) Tank temp. rise X 500 V = Buffer tank volume (gallons) T = desired heat source on cycle (min.) Q heat source = heat source output (BTU/HR) Q min. heat load = heat output to minimum load Tank temp rise (deg.F) Water to Water Heat Pump Example: Town and Country Mechanical wants a minimum heat pump on time of 10 minutes. The heat pump output is 46,500 BTU/HR. The smallest zone is a 7,000 BTU/HR bathroom. The allowable temperature differential is 90 to 100 deg. F for the radiant heating zones. V=10 X (46,500 - 7,000) = 79.0 Gallons minimum volume. Choose the HF-80BT buffer tank. (100-90) x 500

A B 4 1 2 1 C CONNECTIONS ON RIGHT SIDE ON LEFT SIDE ON TOP

Model

Volume (gal.) 40 60 80 115

A Height 42.0 42.0 52.0 72.0

D Diameter 22.5 26.5 26.5 26.5

Connections (NPT) Specify 1 , 1 or 2 NPT

Max. Working Pressure (psi) 60 60 60 60

HF40-BT-XX HF60-BT-XX HF80-BT-XX HF115-BT-XX

29.0 29.5 39.5 59.5

9.0 9.5 9.5 9.5

Approx. Ship Wt. (lbs.) 87 115 125 160

All dimensions in inches -XX denotes connection size. Specify 1 , 1 , or 2 NPT.

Heat-Flo Inc., 15 Megan Court, Uxbridge, MA 01569 Tel: (508) 278-2400 Fax: (508) 278-2466 www.heat-flo.com

Heat-Flo Inc., 15 Megan Court, Uxbridge, MA 01569 Tel: (508) 278-2400 Fax: (508) 278-2466 www.heat-flo.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- PC4000 GZEBM08199-1 (Completo) MMDocumento1.986 paginePC4000 GZEBM08199-1 (Completo) MMFoto Tortas100% (10)

- Department of Energy Regulatory & Energy Star ChangesDocumento18 pagineDepartment of Energy Regulatory & Energy Star Changesapi-221502147Nessuna valutazione finora

- mc7025 01 13 WxtsizingcardDocumento2 paginemc7025 01 13 Wxtsizingcardapi-221502147Nessuna valutazione finora

- Duo-Tec Brochure-WebDocumento3 pagineDuo-Tec Brochure-Webapi-221502147Nessuna valutazione finora

- Delavan CatalogDocumento28 pagineDelavan Catalogapi-221502147100% (1)

- Oil Nozzles Leaflet Hago Steel Nozzles Vbcea322 2012Documento2 pagineOil Nozzles Leaflet Hago Steel Nozzles Vbcea322 2012api-221502147Nessuna valutazione finora

- ZypdfDocumento12 pagineZypdfapi-221502147Nessuna valutazione finora

- mc10224 09 13 HydromaxDocumento8 paginemc10224 09 13 Hydromaxapi-221502147Nessuna valutazione finora

- 1t 1b Zone ValvesDocumento1 pagina1t 1b Zone Valvesapi-221502147Nessuna valutazione finora

- Plaw 111publ380Documento2 paginePlaw 111publ380api-221502147Nessuna valutazione finora

- Summary of The Reduction of Lead in Drinking Water Act and Frequently Asked QuestionsDocumento14 pagineSummary of The Reduction of Lead in Drinking Water Act and Frequently Asked Questionsapi-221502147Nessuna valutazione finora

- SBT 01Documento2 pagineSBT 01api-221502147Nessuna valutazione finora

- Devis ReserveDocumento1 paginaDevis Reserveapi-221502147Nessuna valutazione finora

- Ahri November 19Documento2 pagineAhri November 19api-221502147Nessuna valutazione finora

- Tekmar 406 House Control p9336 02Documento2 pagineTekmar 406 House Control p9336 02api-221502147Nessuna valutazione finora

- Tekmar 284 Multi Boiler Control p9450 02Documento2 pagineTekmar 284 Multi Boiler Control p9450 02api-221502147Nessuna valutazione finora

- SSDocumento10 pagineSSPrakash KaleNessuna valutazione finora

- ZF Fluegelpumpen CP FP E 08Documento9 pagineZF Fluegelpumpen CP FP E 08Matei AlexandruNessuna valutazione finora

- Lubrication SystemDocumento3 pagineLubrication Systemmellon3duwenNessuna valutazione finora

- Column Chromatography: Prepared by Arbin Singh ThokchomDocumento16 pagineColumn Chromatography: Prepared by Arbin Singh ThokchomBest Movie ClipNessuna valutazione finora

- Layered ShellDocumento2 pagineLayered ShellhernyvargasNessuna valutazione finora

- Theog Lift TD 080615Documento52 pagineTheog Lift TD 080615HemantSharmaNessuna valutazione finora

- State-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateDocumento18 pagineState-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateShaker QaidiNessuna valutazione finora

- JISDocumento30 pagineJISImam SalehNessuna valutazione finora

- GR 7 Term 2 2020 Ns Resource PackDocumento26 pagineGR 7 Term 2 2020 Ns Resource PackLorraine NoloNessuna valutazione finora

- Manual I5006.zf - enDocumento1.048 pagineManual I5006.zf - enBaşarŞenNessuna valutazione finora

- Ethylene Glycol Regeneration Plan - A Systematic Approach To Troubleshoot Common ProblemsDocumento7 pagineEthylene Glycol Regeneration Plan - A Systematic Approach To Troubleshoot Common ProblemsThejaswiniNessuna valutazione finora

- Mechanic Machine Tool Maintenance-Nsqf PDFDocumento63 pagineMechanic Machine Tool Maintenance-Nsqf PDFUjjwal Chauhan100% (3)

- Ceramic Tiles Ceramic TilesDocumento3 pagineCeramic Tiles Ceramic Tilesnaughty_angel18071989Nessuna valutazione finora

- Medium Voltage Switching Devices: Assembly Operation MaintenanceDocumento52 pagineMedium Voltage Switching Devices: Assembly Operation MaintenanceGrid LockNessuna valutazione finora

- HSS Stamping Design ManualDocumento67 pagineHSS Stamping Design ManualjschuryNessuna valutazione finora

- ACI - 2019 Arabic - p490-521Documento32 pagineACI - 2019 Arabic - p490-521Mustafa Al-QawasmehNessuna valutazione finora

- Lateral Support of Wood Beams in Residential Structures PDFDocumento4 pagineLateral Support of Wood Beams in Residential Structures PDFBrian-Marti BoatrightNessuna valutazione finora

- 2007 Belleville Washer TestingDocumento22 pagine2007 Belleville Washer Testingibis_pilotNessuna valutazione finora

- Honeywell 221508a Modutrol IV Resistor BoardDocumento2 pagineHoneywell 221508a Modutrol IV Resistor BoardFeli AlcoserNessuna valutazione finora

- Types and Causes of Cracks in Concrete StructuresDocumento11 pagineTypes and Causes of Cracks in Concrete Structuresraahul_nNessuna valutazione finora

- MaterialData 7754Documento2 pagineMaterialData 7754Joko TriwardonoNessuna valutazione finora

- DAFZ RegulationsDocumento41 pagineDAFZ RegulationsRoger SchulpNessuna valutazione finora

- TECH - Wyntk - Truss Facts For Eng and ArcDocumento24 pagineTECH - Wyntk - Truss Facts For Eng and Arcshaikh85Nessuna valutazione finora

- Super HDB Turbo 15W-40Documento1 paginaSuper HDB Turbo 15W-40izzybjNessuna valutazione finora

- Poisson's RatioDocumento20 paginePoisson's RatioFaiz HaikalNessuna valutazione finora

- Design of Machine Members-II QB PDFDocumento24 pagineDesign of Machine Members-II QB PDFAnonymous hUN4K5fZkeNessuna valutazione finora

- Public Area CleaningDocumento16 paginePublic Area Cleaningnitty loveNessuna valutazione finora

- Thermal StressDocumento104 pagineThermal Stressmanishtopsecrets100% (1)

- CV Hadj Yahia Seba 2023Documento5 pagineCV Hadj Yahia Seba 2023Yahia SebaNessuna valutazione finora