Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technomagnete Clamp2

Caricato da

NazriDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technomagnete Clamp2

Caricato da

NazriCopyright:

Formati disponibili

MONOLITHIC TECHNOLOGY

Attracted by the Quality!

The innovative magnetic system for quick mold clamping

Monolithic construction Solid steel surface Reduced thickness Higher rigidity Longer life

Safety through power

NEW INTERNATIONAL PATENT

The future of the innovation

The original technology

MAG

Pioneer of permanent-electro technology developed in the early 70s, Tecnomagnete has revolutionized the world of heavy duty magnetic applications with the Quadsystem technology, patented in the 80s, becoming the world leader in the production of clamping systems for machine tools, for plastic injection machines, for metal stamping and for handling ferrous loads. Strength, safety, reliability and constant performances, no residual magnetism and no strays flux are the strong points of this technology.

MONOLITHIC TECHNOLOGY

The Neutral Yoke

The chess board morphology of Quadsystem allows the circuit to ensure a flat and horizontal travelling of the magnetic flux, totally concentrated in the polar area, i.e. on the workpiece to be clamped. The N/S poles perfectly equal in size grant a perfect balancing of the circuit, avoiding any possible leakage of magnetic flux with the total absence of any interference and any power loss.

An incomparable experience

Total Safety

A permanent-electro magnetic circuit is intrinsically safe. In fact an electrical pulse of few seconds activates the system and afterward the mold remain firmly clamped for indefinite period of time without any electricity supply, just attracted by the strength of high-energy permanent magnets. Through a subsequent electrical pulse the system can be deactivated.

DEMAG

The bi-directional magnetic circuit with all poles N/S activated by a double magnet (Alnico+ Neodymium) is able to generate the highest level of magnetic induction in the steel (20.000 Gauss, equivalent to 16 daN/cm2) as well as ensuring a high coefficient of Magneto-Motive Force (MMF) to operate safely even in the presence of operative air gaps.

The bi-directional circuit

The know-how gained by Tecnomagnete in several sectors has been used as an indispensable element for the further development of Quadsystem technology in the new patent called Quadsystem MONOLITE. This new technology allows the introduction of a new generation of magnetic equipments, characterized by the monolithic construction with no mechanical parts assembled, capable of providing exceptional robustness and compactness. The circular polar areas come integral with the structure and the working surface becomes full metallic. The original polar geometry allows to leave free solid areas evenly distributed to carry out the necessary machining for the fixing holes, for the ejectors holes or for dedicated mechanical elements.

International patent WO 2009/130721

An impenetrable shield

The integral steel surface totally uniform, with no resin, no brass insert, no sealing, becomes an impenetrable mechanical shield full proof making impossible any kind of infiltration and ensuring a final protection of the electrical circuit and the permanent magnets built inside. The contact surface with the mold will always remain planar over time.

The ultimate system for quick mould clamping

The QUADSYSTEM MONOLITE technology applied to the new generation of magnetic systems PressTec for clamping molds on plastic injection machines, can provide total safety, great flexibility and practical use, with enhanced competitive advantage over the traditional systems. PressTec systems are the ideal solution for any type of machine, from the smallest to the largest, both horizontal and vertical, for a dramatic increase in productivity in several sectors, as automotive, electronics, packaging, medical, house appliances and many others.

The reliability

A substantial added value

A machine equipped with PressTec becomes immediately more productive and maintains this value over time. PressTec protects the machine avoiding wear and damage of the platens and prevents the mold being under operative stress, deflection or deformation thus reducing the need for periodic maintenance.

The monolithic honeycomb structure of PressTec provides great rigidity and sturdiness even under hard working conditions, keeping constant coefficients of thermal and mechanical resistance. The absence of any insert and moving parts eliminates possible wear and ensures longer life with more reliable, predictable and predetermined performances, without any specific maintenance program.

No interference

PressTec avoids any form of magnetic flux strays, avoiding unwanted attractions and interference with the machines apparatus. The ejectors and the injection nozzle always travel in a neutral areas free of magnetic field.

A recognized standard

The extreme compactness

The Practicality

The uniform and smooth surface in contact with the mold is easy to keep clean and efficient. Besides the circular footprint of the polar area prevents vacuum effect.

PressTec is available with a full range of standardized solutions according to the guidelines of international standards EUROMAP / SPI / JIS, relevant to the mechanical and electrical interface with the machine. PressTec modules are easy to install on machines of any types and sizes using the existing slots and holes on the fixed and moving platens. They are standard equipped with the fixing holes, the passageways for the ejectors rods and the removable centering ring.

The 46 mm thickness only exploit the best characteristics of the machine daylight and the reduced weight keep down all the dynamic stress.

The respect for the environment

The absence of energy consumption, heat generation, electrical interference and any kind of pollution together with the 95% recycling make PressTec the best expression of the concept of respecting the environment.

1.81 in. 46 mm

All under control

An advanced electronic control unit, designed according to the international standard Euromap / SPI / JIS and the EMC (Electro Magnetic Compatibility) norms, is available in different configurations, allowing the interface with any type of machine. The standard version includes a robust remote keypad to manage the operational functions of MAG / DEMAG (activation and deactivation) - SAFE (to prevent accidental activation) and light signals to communicate the status of the system to the operator. The unit also manages the specific functions related to PROXIMITY (mold presence sensors) - UCS (unit control system) - FCS (flux control system). A safety key allows the enabling of the MCS procedure (mold change mode) permitting the relevant Mag and Demag cycles.

Electrical interface

STANDARD: Version for existing machines without EUROMAP interface with independent push button, with machine, proximity and MCS enable. EUROMAP 70.0: Version for OEMs with independent push button to be interfaced with the machine enable and MCS procedure. Harting plug with 15 m cable included. EUROMAP 70.1: Version for OEMs to be fully integrated with the machine PLC including MAG / DEMAG functions, proximity and MCS included and with all signals managed by the machine. Auxiliary buttons with Harting plug and 15m cable included.

IPC To interact with the force

Thanks to the unique characteristics of the bi-directional QUADSYSTEM circuit, the interactive IPC system is capable of automatically detect the actual clamping force depending on the size of the mold, the quality of the contact, the thickness and material of the mold base plate. No need for the operator to enter any data in relation to the mold.

A Safe driving

Through a color touch-screen the IPC provides all the information to the operator, leading step by step the correct procedure for the mold installation and the machine start up. Any errors are reported and the machine cannot be started in case the magnetic force is not reaching the threshold value assigned. Mold data can be logged and the value of force can be recorded for the specific mold to be used as a reference for subsequent operations.

Temperature chart

A real and true Tutor

Clamping force on the mold Mold data log selection, mould details

Updatable by USB

Different access profiles: technician / supervisor / operator History of all transactions carried out by operator, with the possibility to export data. Controlling the temperature of the magnetic surface Graphic display of operating time / mold use / operator activity Step-by-step help pages with graphic illustration and explanation. Multi language interface Mold data log

MONOLITHIC TECHNOLOGY

Great advantages for higher productivity

Flexibility: molds of any shapes and sizes clamped with simplicity Rapidity: quick mould change with super fast clamping Quality: perfect and constant molding without flaws Repeatability: always reliable, controllable and predetermined operations Convenience: reduction of all costs and better use of the space

All around accessibility

The absence of any obstacle, allows an optimal use of machine platens, making possible clamping molds of various sizes, even bigger than the normal size in use on the press machine. By giving up the mechanical clamps provides a total freedom for a quick and easy positioning of the mold. It also means an easier access to all electrical, hydraulic and pneumatic peripherals.

High quality through total uniformity

PressTec clamping

Fast and Flexible

With conventional systems, the mold get clamped on its perimeter, thus generating tensions and deformation resulting in deflections during production, due to the opening effort and to the weight of the mold. A magnetic system provides an uniform clamping all over the contact surface. No movement of the mold translates immediately in better quality and repeatability of the molded parts and it prevents also the over-packing phenomena.

Traditional clamping

All JIT (Just in Time) and SMED (Single Minute Exchange Die) procedures can be optimized with a mold changing time reduced up to 90% compared to a conventional clamping system. Molds can be conveniently loaded from top or with a side loading device, perfectly matched and placed on the magnetic surface, without any further adjustment. PressTec is suitable for all the molds with steel back plate, even with a small size, with no modification.

Advanced Molding

The precise coupling of the entire mold and its stability make PressTec the ideal solution for high accuracy operations like with multi-cavity molding or with bi-color rotary table and with placement of films (in-mold labeling) or inserts (in-mold insert).

Reducing costs

Easiness and ergonomics

A single operator, with no particular specialization, can perform the task of the mould change without working inside the machine and remaining always at a safe distance from the mold.

The complete management process of inventory can be optimized. The space available will be better utilized. Not anymore need to manage clamps, bolts, consumables hardware, dedicated tooling No more oil disposal and maintenance responsibility for the hydraulic circuits. No hidden costs.

Quick pay back

The limited investment and the great operative convenience can grant a quick pay back, that in some cases it may be just a few months. The PressTec value will remain high even the end of the machine life.

MONOLITHIC TECHNOLOGY

A design concept at the state of the art

A - Proximity sensors

An inductive sensor checks the presence of the mold for the activation of the magnetization cycle (MAG). The range of reading to 0.2 mm allows to stop immediately the machine operation in case of mold detachment.

B - Air grid

Circular recesses prevent the mold from sticking and stabilize the temperature.

C - Centering ring

B C

It allows a fast and correct positioning of the mold.

D - Ejectors holes

The magnetic module on the moving side is provided with through holes for the ejectors.

E - Fixing holes

According to the required standard EUROMAP / SPI / JIS

F - Connection box

Integral with the steel frame of modules

G - Spacers

Rectangular steel spacers to widen the support area of the mold (AS OPTION)

The FCS flux sensor system

detects the value of magnetic saturation before enabling machine cycle.

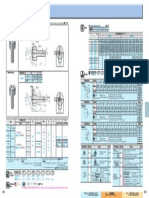

Installation layout and Control unit dimensions

Dimensions

Machine tonnage Up to 1600 t mm 600 600 200 in 23.62 23.62 7.87 over to 1600 t mm 1200 600 300 in 47.24 23.62 11.81 Standard push-buttons mm 140 140 80 in 5.51 5,51 3.15

Touch screen IPC

Electrical cabinet ST400

mm 211 159 65 in 8.30 6.25 2.55 Box touch screen IPC mm 270 248 95 in 10.62 9.76 3.74

Air Gap Curve

The curve F / T shows the behavior of the magnetic field when varying the quality of contact between the mold and magnetic surface. PressTec guarantees performance in total safety, even with operative air gap related to the surface of the mold base plate, not perfectly flat or little rusted.

FORCE

PressTec

Mold

AIR-GAP - T (mm)

Standard supply

Up to 16 kg / cm2 Up to 90 Ton /m2 46mm (1.81 in.) 120 C (248 F) 20mm (0.78 in.) 0,2mm (0.0078 in.) 200 - 480VAC, 50/60 Hz Standard Standard Standard On request Standard Standard Standard on each side Standard Standard

Avarage air-gap - T (mm)

Technical characteristics

Magnetic force on the polar area Magnetic force on the mould contact area Module thickness Max working Temp in contact Magnetic flux depth Activation range proximity sensors Standard voltages Holes for fixing Holes for ejectors Centering ring fixed side Centering Ring mobile side Control unit ST 400 Standard push buttons Proximity sensors UCS system FCS System

EUROMAP / SPI / JIS standard to be specified

Permanent electro magnetic modules in solid steel, for the fixed and moving side, with centering ring. Set of mounting holes and ejectors holes according to EUROMAP / SPI / JIS standards Electronic power control with bi-phase feeding in IP54 cabinet, complete with PLC machine interface, UCS , FCS control systems. Push button remote control, complete with indicator lights and key interlock. Set of cables to connect the control unit and magnetic modules, for the interface and power supply. Proximity sensors to detect mould presence installed on-board of the modules (1 each side) Fixing bolts and nuts. Instructions book in language and TUV/CE certificate.

ON REQUEST:

IPC

Interactive power control system with touch screen monitor

PressTec is available on request in two standard configurations: HD high polar density ST Simplified polar density

Standard configurations

FCP

Electronic control system for real time monitoring of any change in the magnetic flux

Special configurations

CT

Set of connectors on the electrical cabinet for machine interface / keyboard (Harting) and PressTec modules (Feme)

Configurable versions for vertical molding machines, multi-injection rotary table, with pre-arrangement for side loading, and with dedicated special execution are available on request.

THB

Temperature sensor embedded in the module fixed side.

UTC

System for detecting the temperature over the whole area area with signal of the magnetic state and warning alarm.

Material handling

From QuadPress to PressTec The evolution of a success

Tecnomagnete has not only revolutionized the world of magnetism for industrial applications with the invention of permanent-electro technology and later on with the QuadSystem patent, but it has been also the first company to start applying magnetic systems for quick clamping and change of molds in the plastics injection molding machines, in the late 80s. Many thousands of installations of the Quad Press line have been put in operation all over the world by the most prestigious molding companies active in different fields. Now the technological evolution of the new PressTec line, is to create another attraction in terms of convenience, safety and reliability, key aspects that always have distinguished the entire range of Tecnomagnete products including clamping systems for injection moulding, for metal stamping, machine tools and for ferrous loads handling. With a wide spread presence all over the world, consisting of a network of subsidiaries, regional offices, technical sales and service centers and the active collaboration with the leading global OEMs, Tecnomagnete is proposed as a reliable partner committed to always offer the best services to all customers thus giving a strong edge over the competition.

leading the way in magnetism

TECNOMAGNETE spa

20020 Lainate (MI), Via Nerviano 31 Tel. +39 02.937.591 Fax +39 02.935.708.57 e-mail: info@tecnomagnete.it www.tecnomagnete.com

Workholding

Moulding and stamping

Subsidiaries:

China

TECNOMAGNETE SHANGHAI R.O. TECNOMAGNETE S.A.R.L.

Germany Japan USA

TECNOMAGNETE GmbH TECNOMAGNETE Ltd. TECNOMAGNETE Inc.

South Korea Singapore Distributor

We reserve the right to make changes connected with engineering progress.

France

PT-ENG 092011

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocumento14 pagineRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriNessuna valutazione finora

- Assembly Drawing ExercisesDocumento57 pagineAssembly Drawing ExercisesAli HassanNessuna valutazione finora

- Pengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaDocumento18 paginePengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaNazriNessuna valutazione finora

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocumento14 pagineRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriNessuna valutazione finora

- How To Use Mirror: in This Tutorial, You Will Create This PartDocumento5 pagineHow To Use Mirror: in This Tutorial, You Will Create This PartNazriNessuna valutazione finora

- How To Use Hole WizardDocumento4 pagineHow To Use Hole WizardNazriNessuna valutazione finora

- How To Use Loft: in This Tutorial You Will Create This Part Using Loft FeatureDocumento5 pagineHow To Use Loft: in This Tutorial You Will Create This Part Using Loft FeatureNazriNessuna valutazione finora

- Task 1 Tomography Industrial Medical App 19feb15Documento12 pagineTask 1 Tomography Industrial Medical App 19feb15NazriNessuna valutazione finora

- AFTERNOON, POINCIANA SessionDocumento1 paginaAFTERNOON, POINCIANA SessionNazriNessuna valutazione finora

- How To Model Aeroplane WingsDocumento5 pagineHow To Model Aeroplane WingsNazriNessuna valutazione finora

- How To Creating A Basic SweepDocumento2 pagineHow To Creating A Basic SweepNazriNessuna valutazione finora

- How To Creating A Basic SweepDocumento2 pagineHow To Creating A Basic SweepNazriNessuna valutazione finora

- How To Use Hole WizardDocumento4 pagineHow To Use Hole WizardNazriNessuna valutazione finora

- How Solidworks WorksDocumento7 pagineHow Solidworks WorksNazriNessuna valutazione finora

- How To Change To Metric UnitsDocumento1 paginaHow To Change To Metric UnitsNazriNessuna valutazione finora

- Correction Coment PRSDocumento20 pagineCorrection Coment PRSNazriNessuna valutazione finora

- Task 1 Tomography Industrial Medical App 19feb15Documento12 pagineTask 1 Tomography Industrial Medical App 19feb15NazriNessuna valutazione finora

- Practical Applications of Synthetic Aperture Imaging - 2010 - Arendt Et Al. - UnknownDocumento10 paginePractical Applications of Synthetic Aperture Imaging - 2010 - Arendt Et Al. - UnknownNazriNessuna valutazione finora

- Correction Coment PRSDocumento20 pagineCorrection Coment PRSNazriNessuna valutazione finora

- Technical Specifications For Aerial BunchedDocumento5 pagineTechnical Specifications For Aerial BunchedNazriNessuna valutazione finora

- Jurnal Teknologi Full Paper A Review On Electrical Capacitance Tomograp PDFDocumento7 pagineJurnal Teknologi Full Paper A Review On Electrical Capacitance Tomograp PDFNazriNessuna valutazione finora

- R Fo Pe Er Re VI Ew Fo R P Ee R R - Unknown - Electronics - UnknownDocumento8 pagineR Fo Pe Er Re VI Ew Fo R P Ee R R - Unknown - Electronics - UnknownNazriNessuna valutazione finora

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocumento5 pagineLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriNessuna valutazione finora

- Sprue Bushing JIS B Type 635-636Documento1 paginaSprue Bushing JIS B Type 635-636NazriNessuna valutazione finora

- Real 2 Corrison PipeDocumento2 pagineReal 2 Corrison PipeNazriNessuna valutazione finora

- Real 3 Corrision PipeDocumento8 pagineReal 3 Corrision PipeNazriNessuna valutazione finora

- Sumber 31 OgosDocumento3 pagineSumber 31 OgosNazriNessuna valutazione finora

- Patch Antenna Via Fused DepositionDocumento4 paginePatch Antenna Via Fused DepositionNazriNessuna valutazione finora

- Olga RadiologyDocumento38 pagineOlga RadiologyNazriNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- R2RDocumento2 pagineR2RGabriel PerazaNessuna valutazione finora

- Secondary Injection Testing Vs PrimaryDocumento2 pagineSecondary Injection Testing Vs Primaryeddie2166Nessuna valutazione finora

- AT89LP6440Documento200 pagineAT89LP6440cmbataginiNessuna valutazione finora

- Ws 9608 ManualDocumento12 pagineWs 9608 ManualAntonio CarlosNessuna valutazione finora

- Cert WorkCentre 5845-5855-5865-5875-5890 Information Assurance Disclosure Paper v1.01Documento59 pagineCert WorkCentre 5845-5855-5865-5875-5890 Information Assurance Disclosure Paper v1.01abid qayyumNessuna valutazione finora

- Anchor Grout DesignDocumento129 pagineAnchor Grout DesignNil DG100% (1)

- Udoo ManualDocumento46 pagineUdoo ManualAlexandru100% (1)

- BSNL JTO 2009 Question Paper SolutionsDocumento25 pagineBSNL JTO 2009 Question Paper SolutionsGurwinder DhindsaNessuna valutazione finora

- ResumeDocumento2 pagineResumeVidhuran VidhuNessuna valutazione finora

- Ict Gadgets Gadget Basic Functions Image Brand Model Date of ReleaseDocumento4 pagineIct Gadgets Gadget Basic Functions Image Brand Model Date of ReleaseMark Erwin SalduaNessuna valutazione finora

- Synopsis - Complaint Management SystemDocumento6 pagineSynopsis - Complaint Management SystemRinkle Kapur50% (2)

- Ansi - c37.20 & Nema SG - 5Documento20 pagineAnsi - c37.20 & Nema SG - 5Subrat Das100% (1)

- Computer Port (Hardware) : This Article Has Multiple Issues. Please HelpDocumento11 pagineComputer Port (Hardware) : This Article Has Multiple Issues. Please HelpeddieNessuna valutazione finora

- IRB 660 Product Specifications 3HAC023932-001 - ReDocumento48 pagineIRB 660 Product Specifications 3HAC023932-001 - ReAsim PedicNessuna valutazione finora

- Personas 86 Currency Dispenser - Stage 1: Appendix 17.6ADocumento14 paginePersonas 86 Currency Dispenser - Stage 1: Appendix 17.6AMichael BuanNessuna valutazione finora

- Introduction To R (LECT 1)Documento15 pagineIntroduction To R (LECT 1)Fahad NasirNessuna valutazione finora

- Optical Transport NetworkDocumento4 pagineOptical Transport NetworknarayanbscribidNessuna valutazione finora

- Engineers Mini NotebookDocumento80 pagineEngineers Mini NotebookvibhutepmNessuna valutazione finora

- MIG WeldigDocumento92 pagineMIG WeldigTonluck KaimakNessuna valutazione finora

- Hydraulic Universal Testing MachineDocumento9 pagineHydraulic Universal Testing Machineleodegarioporral100% (1)

- ARM Cortex-R4 Technical Reference ManualDocumento570 pagineARM Cortex-R4 Technical Reference ManualGanesh Kumar CNessuna valutazione finora

- SWT300Documento8 pagineSWT300yasirNessuna valutazione finora

- FreeBSD Installing PortsnapDocumento3 pagineFreeBSD Installing PortsnapmaxblurgNessuna valutazione finora

- Broadcast StormDocumento12 pagineBroadcast StormkaushikramkumarNessuna valutazione finora

- AS380S Series Elevator Integrated Controller Operation Manual V2.0Documento126 pagineAS380S Series Elevator Integrated Controller Operation Manual V2.0Francisco Javier Burgos0% (1)

- VSDC Manual PDFDocumento31 pagineVSDC Manual PDFMuhamadMaruf67% (3)

- HEP-1 Laboratory Manual: Coreel TechnologiesDocumento17 pagineHEP-1 Laboratory Manual: Coreel TechnologiesGaurav PatelNessuna valutazione finora

- 1TNC920204D0201-AO11 User's Guide-En V1Documento18 pagine1TNC920204D0201-AO11 User's Guide-En V1HujiLokoNessuna valutazione finora

- Manual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFDocumento16 pagineManual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFJorge A VilalNessuna valutazione finora

- Transfer Box and Final DriveDocumento67 pagineTransfer Box and Final DriveTaller Energy EnergyNessuna valutazione finora