Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Seismic Retrofit RCBridge Columns

Caricato da

youngc71Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Seismic Retrofit RCBridge Columns

Caricato da

youngc71Copyright:

Formati disponibili

Seismic Retrofit Study of RC Bridge Columns

K.C. Chang

1

, L.L. Chung

2

, B.J. Lee

3

, Y.F. Li

4

, K.C. Tsai

1

, J.S. Hwang

5

, S.J. Hwang

5

Abstract

This paper presents the progress of a NCREEs research program on seismic retrofit of

existing RC bridge columns during the last three years. More than sixty large-scale specimens

were designed and constructed to simulate the worst scenario of the construction practice in

Taiwan prior to 1987. Twenty-four of the test columns were used as the benchmark for

comparison with other specimens retrofitted or repaired using the carbon fiber reinforced

plastics (CFRP) jacketing, steel jacketing, and RC jacketing. Experimental results showed that,

in general, the retrofit methods used in the U.S. and Japan are effective also effective for the

existing RC bridge columns in Taiwan. However, due to the poor concrete compressive

strength and the lap splicing at the plastic hinge zone, the retrofit measures developed for

better ductility and shear strength are not always effective. More research effort is necessary

to develop effective methods for RC columns lap-spliced at the plastic hinge zones.

1

Prof., Dept. of Civil Engr, National Taiwan University, Taipei, Taiwan.

2

Research Fellow, National Center for Research on Earthquake Engineering

3

Prof., Dept. of Civil Engr., Feng Chia University, Taichung 100, Taiwan.

4

Associate Prof., Dept. of Civil Engr., National Taipei University of Technology, Taipei, Taiwan.

5

Prof., Dept. of Construction Engr., National Taiwan University of Science and Technology, Taipei, Taiwan.

Introduction

A 4-years coordinated research effort on seismic retrofit of existing RC bridge columns

has been established at the National Center for Research on Earthquake Engineering (NCREE)

since 1998. Major objectives of this program are to develop effective seismic retrofit methods

of existing bridges in Taiwan due to (1) inadequate design strength, (2) inadequate

confinement at potential plastic hinge region, (3) inadequate shear strength due to large lateral

steel spacing, and (4) lap-splicing in the plastic hinge zone, etc., identified as some the most

severe weaknesses of the existing RC bridge columns for seismic hazard.. Observations of the

bridge damage during the 1999 Chi-Chi earthquake indicate that many existing bridges in

Taiwan are indeed vulnerable to major earthquakes and the coordinated research program

conducted at NCREE is necessary and urgent. This coordinated research program includes a

master plan administrated by NCREE and seven coordinated projects handled by the

investigators from six universities and research institutions. Results of this research program

will provide a domestic test database for seismic bridge engineering applications and to

provide seismic retrofit guidelines for highway officials in Taiwan. Many retrofit techniques

that have been extensively studied and widely implemented in the United States, Japan and

New Zealand are studied in this joint research.

Experimental Program

More than 60 large scale specimens were tested during the last three years, including 24

bench-mark specimens that were designed to represent typical pre- and after 1987 bridge

columns in Taiwan. Cross sectional dimensions of the rectangular columns and circular

columns are 600mm by 750 mm and 760 mm diameter, respectively, roughly 2/5 scale of the

prototype columns. The worst details that may be expected in the existing bridges are

International Training Programs for Seismic Design of Building Structures

Hosted by National Center for Research on Earthquake Engineering

Sponsored by Department of International Programs, National Science Council

assumed in the specimens, such as the double U-shaped transverse reinforcements with large

spacing, and the lap-spliced of main reinforcements at the plastic hinge zone. Retrofit

techniques used in the specimens include steel jacketing, FRP wrapping, and RC jacketing. In

addition, seismic performance of column-foundation connections, beam-column connections

as well as the wall type piers are also studied. Details of the test specimens are listed in Tables

1-3.

Summary of results

Seismic Retrofit of Rectangular RC Bridge Columns Using FRP Jacket

Test specimens

Flexural failure mode specimens

These specimens represent the benchmark and the CFRP wrapped, named as BMR2,

BMR3, FR1, and FR2 respectively. Specimen FR1 is retrofitted with 4 layers of FRP (0.55 )

along the whole height.

For specimen FR2, it is retrofitted based on the ductility requirement of 6. This specimen

is retrofitted in the plastic hinged zone with 8 layers of FRP (1.1 ), and the other areas are

retrofitted with 2 layers of FRP (0.275 ).

Lap-spliced failure mode specimens

These specimens represent the benchmark, CFRP wrapped, and combined steel plate and

CFRP, named as BMRL100, FRL100, SFRL100, respectively. For specimen FRL100, one

third of the column height (1100 mm) is retrofitted with 8 layers of CFRP (1.1mm), and the

other areas are with 4 layers. For specimen SFRL100, steel plates are attached to each column

face before wrapping the CFRP. Combining the steel plate, the cross section became a little

close to oval-shaped. The curvature of the shape is advantageous for FRP to produce inward

confinement stress to prevent bond slip failure.

Shear failure mode specimens

These specimens represent the benchmark and the CFRP wrapped, named as BMRS and

FRS, respectively. In order to observe the short column effect, the column height is reduced.

For specimen FRS, it is retrofitted with 4 layers of FRP (0.55 ) along the whole height.

Experimental Results and Discussion

Fig. 1-1 to 1-9 shows the lateral force and displacement relationships of the specimens.

The sequence from top to bottom is BMR2, BMR3, FR1, FR2, BMRL100, FRL100,

SFRL100, BMRS, and FRS. It is shown that both displacement ductility and energy

dissipation in BMRL100 and BMRS are quite poor. Compared to specimen BMRL100, it can

be seen that specimen SFRL100 performs very well. Not only it gets the 7.24 times of the

dissipation energy of the specimen BMRL100, but also enhances 6.03 times of the

displacement ductility, a value close to the flexural failure mode. This figure demonstrates

clearly that this retrofit method has a good potential in seismic retrofit of rectangular RC

columns lap-spliced at the plastic hinge zones.

Conclusions

1 Flexural failure mode

Seismic Retrofit Stud of RC Bridge Columns

1. Test results show that failure of the flexural type specimen under larger axial load will

result in speeding up the degradation of strength and energy dissipation capacity.

2. Standard hoop arrangements can gain better confinement than the double-U shaped

alternation arrangement used in many existing bridges.

3. The retrofit efficiency of force-based design and displacement-based design is nearly

the same. The displacement ductility levels of 7 can be reached.

2 Shear failure mode

1. Brittle shear failure occurs due to insufficient transverse reinforcement spacing.

2. Retrofitted by wrapping FRP shows great performance in improving shear strengths,

and transfers the failure mode to flexural-shear type.

3 Lap spliced failure mode

1. Without enough confinement stress, bond slip occurred between the lap-spliced

longitudinal reinforcements and resulted in brittle failure.

2. Applying CFRP directly cant provide enough confinement stress to increase frictional

force between the lap spliced longitudinal reinforcements.

3. A new method by attaching steel plates before wrapping FRP shows great potential in

increasing the confinement stress and energy dissipate capacity for rectangular RC members.

The strength, ductility, and energy dissipation capacity are also greatly improved. Further

study is necessary to better understand the mechanism and to determine the critical

parameters for retrofit design applications.

Reference

K.C. Chang, and F.S. Chung (2000), Seismic Shear and Lap-Spliced Retrofit of Rectangular

Bridge Columns using FRP, National Center for Research on Earthquake Engineering,

Technical Report.

K.C. Chang, and H.F. Chang (2000), Seismic Flexural Retrofit of Rectangular Bridge

Columns using FRP, National Center for Research on Earthquake Engineering,

Technical Report.

K.C. Chang, K.Y. Liu, F.S. Chung, and S.B. Chang (2000), Seismic Retrofit study of RC

rectangular bridge column lap spliced at plastic hinge zone , Proceeding of the thirteen

KKNN symposium on Civil Engineering, December 7-8,2000, Taipei, Taiwan.

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-400

-200

0

200

400

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

0 1 2 3 4 5 6

BMR2

Py = 240 kN

Dy = 20.58 mm

Pmax = 303.37 kN

Dmax = 65 mm

Pu = 242.70 kN

Du = 130 mm

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-400

-200

0

200

400

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

0 1 2 3 4

BMR3

Py = 251.25 kN

Dy = 32.72 mm

Pmax = 260 kN

Dmax = 48.75 mm

Pu = 208.0 kN

Du = 130.0 mm

Fig 1-1 Hysteresis curve of specimen BMR2 Fig1-2. Hysteretic curve of specimen BMR3

S sm c tro t St d o C Br d Col mns

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-400

-200

0

200

400

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

0 2 4 6 8

FR1

Py = 245.0 kN

Dy = 15.3 mm

Pmax = 357.77 kN

Dmax = 97.5 mm

Pu = 286.22 kN

Du = 130.0 mm

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-400

-200

0

200

400

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

0 1 2 3 4 5 6 7

FR2

Py = 245.0 kN

Dy = 18.04 mm

Pmax = 297.96 kN

Dmax = 65 mm

Pu = 238.37 kN

Du = 130.0 mm

Fig1-3. Hysteretic curve of specimen FR1 Fig1-4. Hysteretic curve of specimen FR2

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-600

-400

-200

0

200

400

600

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-2

-1

0

1

2

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

01

BMRL100

Py = 275.0 kN

Dy = 14.21 mm

Pmax = 328.0 kN

Dmax = 24.3 mm

Pu = 262.4 kN

Du = 21.93 mm

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-600

-400

-200

0

200

400

600

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

0 1 2

FRL100

Py = 384.0 kN

Dy = 32.46 mm

Pmax = 415 kN

Dmax = 48.83 mm

Pu = 332.0 kN

Du = 65.94 mm

Fig1-5. Hysteretic curve of specimen BMRL100 Fig1-6. Hysteretic curve of specimen FRL100

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-600

-400

-200

0

200

400

600

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

SFRL100

Py = 400.0 kN

Dy = 21.5 mm

Pmax = 512.75 kN

Dmax = 97.39 mm

Pu = 410.2 kN

Du = 129.75 mm

0 1 2 3 4 5 6

-150 -100 -50 0 50 100 150

Displacement (mm)

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drift Ratio (%)

01

BMRS

Py = 657.0 kN

Dy = 17.20 mm

Pmax = 681.0 kN

Dmax = 26.78 mm

Pu = 544.8 kN

Du = 26.0 mm

Fig1-7. Hysteretic curve of specimen SFRL100 Fig1-8. Hysteretic curve of specimen BMRS

-150 -100 -50 0 50 100 150

Displacement (mm)

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

L

a

te

r

a

l F

o

r

c

e

(

k

N

)

-1

0

1

P

/P

y

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drift Ratio (%)

0 1 2 3 4 5

FRS

Py = 745.0 kN

Dy = 12.85 mm

Pmax = 941.0 kN

Dmax = 53.0 mm

Pu = 752.0 kN

Du = 74 mm

Fig1-9. Hysteretic curve of specimen FRS

Steel Jacketing Retrofit Design

Lateral confinement deficient specimens

The steel jacketing details for the retrofitted specimens were shown in Fig. 2-1. The SR1

and SR3 were retrofitted using the octagonal steel jacket, while the SR2 and SR4 were

retrofitted with the elliptical steel jacket. For the SR2, the dimensions of the ellipse were

computed in order to minimize the overall cross-sectional area. The 3-mm thick A36 grade

steel elliptical jacket for the SR2, SR4 was designed considering the equivalent radius (Sun et

al. 1993) and a target ductility capacity of 6 following the procedures recommended in the

reference (Priestley et al. 1996). For the purposes of comparison, the same 3-mm thick steel

plate was adopted in the fabrication of the octagonal jacket for the SR1. Specimen SR3 has a

S ismic R tr fit Stud f RC Brid C lum s

smaller octagonal cross sectional area, but a thicker steel jacket (6mm) than SR1. The

thickness of the steel jacket for the SR3 is computed from the static equilibrium assuming the

same confinement pressure to be developed in Specimens SR1. Noted that the dimensions of

the elliptical jacket for SR4 is slightly different from those of the SR2 in order to ensure the

rods for applying the vertical load not to impinge on the retrofitted column.

Lap-splice deficient specimens

For the retrofitted specimens, SRL1 was retrofitted with a 6mm thick octagonal steel jacket

while SR2 was retrofitted with a 3mm thick elliptical steel jacket. Fig. 2-1 Details of the steel

jacketing.

Shear-deficient specimens

The SRS1 was retrofitted with an octagonal steel jacket, and the SRS2 was retrofitted with

a rectangular steel jacket. The 3mm thick steel plate was adopted in both Specimens SRS1

and SRS2. Fig. 2-1 Details of the steel jacketing.

Response of the retrofitted specimens

Test results given in Fig.2-2 and Fig.2-3 confirm that the seismic performance of

rectangular RC bridge columns can be significantly and equally enhanced by properly

designed elliptical or octagonal steel jacket following the procedures noted above. Bridge

columns retrofitted with the octagonal or the elliptical steel jacket exhibit stable lateral

force-displacement hysteretic response, possess excellent displacement ductility and energy

dissipation capacities.

For the SRS2 specimen retrofitted with a rectangular steel jacket, outward bulging of the

steel jacket was observed at a drift angle of 0.03 radian. In the mean time, significant strength

degradation occurred due to the loss of the lateral confinement. Test results confirmed that the

rectangular steel jacketing is ineffective in providing lateral confinement.

Conclusions

1. Test results confirmed that the seismic performance of the rectangular RC bridge

columns can be significantly and equally enhanced by properly constructed elliptical or

octagonal steel jacket.

2. It is found that the cost of the octagonal jacketing is 15% lower than that for the

elliptical jacketing in the case studied of SR1 and SR2 specimens.

3. Using a thicker jacket can reduce the cross-sectional area of an octagonal steel jacketing

rectangular RC bridge column. The thickness of the steel jacket can be determined from the

static equilibrium assuming the same confinement pressure is to be developed for different

thickness of the steel jacket.

4. Rectangular steel jacketing can effectively prevent a shear-deficient column from shear

failure; however, it is not effective in improving the flexural ductility.

5. Octagonal steel jacketing scheme is cost-effectively and can provide lateral confinement

and the shear strength to mitigate seismic failures of rectangular RC bridge columns due to a

lack of lateral confinement, improper lap-splice or inadequate shear capacity.

6. A smaller cross-sectional area and better seismic performance than the elliptical steel

jacketing scheme have been achieved from the octagonal steel jacketing.

Reference

S ismic R tr fit Stud f RC Brid C lum s

Sun, Z.L., Seible, F. and Priestley, M.J.N. (1993), Flexural Retrofit of Rectangular Reinforced

Concrete Bridge Columns by Steel Jacketing, Structural System Research Project, Report

No. SSRP-93/01, Department of Applied Mechanics and Engineering Science, U.C. San

Diego.

Tsai, K.C. and Lin, M.L. (2000), Steel Jacketing for Seismic Retrofit of RC Rectangular

Columns, National Center for Research on Earthquake Engineering, Technical Report

43.5cm

54cm

SR2

Steel Plate t=3 mm , A36

43.5cm

54cm

Steel Plate t=3 mm , A36

SR1

Steel Plate t=6 mm , A36

60cm

42cm

SR3

50cm

37cm

Steel Plate t=3 mm , A36

60cm

SR4

42cm

(a) lateral confinement deficient specimen

SRL1

39cm

48cm

Steel Plate t= 6 mm ,A36

46cm

56cm

Steel Plate t= 3 mm ,A36

SRL2

(b) lap-splice specimen

Steel Plate t= 3 mm ,A36

48cm

39cm

SRS1

SRS2

Steel Plate t= 3 mm ,A36

33 cm

40cm

(c) shear-deficient specimen

Fig. 2-1 Details of the steel jacketing

-500

-250

0

250

500

-8 -6 -4 -2 0 2 4 6 8

Drift Rati o(%radian)

F

o

r

c

e

(

k

N

)

SR-1

Vmax=456kN

-500

-250

0

250

500

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%radian)

F

o

r

c

e

(

k

N

)

BMR-3

Vmax=290kN

-500

-250

0

250

500

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%radian)

F

o

r

c

e

(

k

N

)

SR-2

Vmax=400kN

-500

-250

0

250

500

-8 -6 -4 -2 0 2 4 6 8

Drift Rati o(%radian)

F

o

r

c

e

(

k

N

)

SR-3

Vmax=418kN

-500

-250

0

250

500

8 6 4 2 0 2 4 6 8

F

o

r

c

e

(

k

N

)

SR-4

Vmax=423kN

-500

-250

0

250

500

8 6 4 2 0 2 4 6 8

F

o

r

c

e

(

k

N

)

BMR-3

SR-1

SR-2

SR-3

SR-4

P=0.15f'cAg

=1400kN

(a) lateral confinement deficient specimen

-800

-400

0

400

800

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%)

F

o

r

c

e

(

k

N

)

BMRL100

P=0.15f'cAg

=1400kN

Vmax=- 368kN

-800

-400

0

400

800

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%)

F

o

r

c

e

(

k

N

)

SRL1

P=0.15f'cAg

=1400kN

Vmax= - 622kN

-800

-400

0

400

800

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%)

F

o

r

c

e

(

k

N

)

SRL2

P=0.15f'cAg

=1400kN

Vmax=602kN

-800

-400

0

400

800

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%)

F

o

r

c

e

(

k

N

)

BMRL100

SRL1

SRL2

(b) lap-splice specimen

-1200

-600

0

600

1200

-8 -6 -4 -2 0 2 4 6 8

Drift Ratio(%)

F

o

r

c

e

(

k

N

)

BMRS

SRS1

SRS2

FRS

-1200

-600

0

600

1200

-8 -6 -4 -2 0 2 4 6 8

Dri ft Ratio(%)

F

o

r

c

e

(

k

N

)

SRS2

P=0.15f'cAg

=1400kN

Vmax= 982kN

-1200

-600

0

600

1200

-8 -6 -4 -2 0 2 4 6 8

Dri ft Ratio(%)

F

o

r

c

e

(

k

N

)

SRS1

P=0.15f'cAg

=1400kN

Vmax= 1086kN

-1200

-600

0

600

1200

-8 -6 -4 -2 0 2 4 6 8

Dri ft Ratio(%)

F

o

r

c

e

(

k

N

)

BMRS

P=0.15f'cAg

=1400kN

Vmax=- 722kN

(c) shear-deficient specimen

Fig. 2-2 Cyclic load-deflection relationships

Se sm c etro t St d o C Br dge Co m s

(a)

0

50

100

150

200

250

0 1 2 3 4 5 6

Cyclic Drift Ratio(% radian)

E

n

e

r

g

y

D

i

s

s

i

p

a

t

i

o

n

(

k

N

-

m

)

BMR3

SR1

SR3

SR2

SR4

Each Two Cycles

0

50

100

150

200

250

300

0 1 2 3 4 5 6

Cyclic Drift Ratio(% radian)

E

n

e

r

g

y

D

i

s

s

i

p

a

t

i

o

n

(

k

N

-

m

)

BMR100

SRL1

SRL2

Each Two Cycles

0

50

100

150

200

250

0 1 2 3 4 5 6

Cyclic Drift Ratio(% radian)

E

n

e

r

g

y

D

i

s

s

i

p

a

t

i

o

n

(

k

N

-

m

)

BMRS

SRS1

SRS2

Each Two Cycles

Fig. 2-3 Energy dissipation curves

Seismic Retrofit of Circular RC Bridge Columns Using Steel Jacket

Experimental Program and Results

In the test program (Hwang and Hseih 1999, Hwang and Kuo 2000 ), four 0.4-scaled

down test specimens are designed according to the details of existing circular RC bridge

columns. The retrofitted specimens corresponding to the weaknesses of the four existing

column details are also designed (Hwang et al 1998) and tested for validation purpose. The

targeted weaknesses of the existing bridge details include (1) the lack of volumetric ratio of

lateral hoop; (2) the early termination of 50% main reinforcement at the mid-height of the

column, together with a much larger pitch of the lateral hoop at the upper region of the

column; (3) the lap-splice failure at the plastic hinge zone; and (4) the shear failure of short

columns. The tests results are summarized in Fig. 3-1 to Fig. 3-4. From the figure it is

concluded that the retrofit using steel jacketing is effective in enhancing the seismic resistance

of the existing circular RC bridge columns in Taiwan.

References

Kuo, S.S. (1998) Seismic evaluation and retrofit of existing highway bridges with circular

single column bents. M.S. Thesis, Dept. of Construction Engineering, National Taiwan

University of Science and Technology.

Hwang, J.S. and Hseih, Y.M. (1999) Seismic retrofit of RC bridge columns suing steel

jacket. Report No. 99016, National Center for Research on Earthquake Engineering of

Taiwan.

Hwang, J.S. and Kuo, M.Y. (2000) Seismic setrofit of existing RC bridge columns shear

strength and lap splice retrofit Report No. National Center for Research on Earthquake

Engineering of Taiwan.

Hwang, J.S, et. al. (1998) Seismic retrofit manual for highway bridges, Research Report,

Department of Transportation and Communication, Taiwan

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6 7 8

Main bar yield point

Spalling point

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6 7 8 9 10 11 12 13

Main bar yield point

Fig.3-1 Columns with the lack of confinement (a)existing (b)retrofitted

S ismic R trofit St dy of RC ridg Col m s

(a)

(b)

(b)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6 7

Main bar yield point

Spalling point

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6 7 8 9 10

Main bar yield point

Fig.3-2 Columns with termination of main reinforcement (a)existing (b)retrofitted

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-700

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

700

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6

Main bar yield point

Spalling point

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-700

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

700

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Ratio (%)

1 2 3 4 5 6 7 8 9

Main bar yield point

Fig.3-3 Columns with lap-splice (a)existing (b)retrofitted

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Displacement (mm)

-1400

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

1400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drift Ratio (%)

1 2 3 4 5

Main bar yield point

Spalling point

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Displacement (mm)

-1400

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

1400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drift Ratio (%)

1 2 3 4 5 6 7 8 9

Main bar yield point

Fig.3-4 Columns with shear failure (a)existing (b)retrofitted

Seismic Retrofit of Circular Section Bridge Column by Using CFRP

Experimental results and observation

The rules of naming the bridge columns are as following. For names beginning with

BM, BM means benchmark, C means circular section, and the remaining letter stands

for failure mode. For example, F means flexural failure, L means lap splice failure, and

S means shear failure. Beside the BM series, other names begin with letters

representing the retrofit method, for example, F means CFRP jacketing. The second letter

C means circular section and the third letter is the failure mode, as mentioned above.

Table 4 is the material properties of CFRP.

Flexural Failure Retrofit

From Fig.4-1, the ductility of CF2 is 8.7, and the maximum lateral force of CF2 is 360

kN. FCF2 and FCF3 are retrofitted by using 4-layer CFRP (FAW=200g/m2). The ductility

of FCF2 and FCF3 are 12.3 and 12.4, and the maximum lateral forces of FCF2 and FCF3 are

all about 310 kN, as seen in Fig 4-2 and Fig. 4-3. The difference between FCF2 and FCF3 is

that column FCF2 was applied with lateral force till 0.5mm crack widths initiate, then it was

retrofitted with 4-layer CFRP; FCF3 was retrofitted with 4-layer CFRP before applied with

Se sm c Retrof t St d of R r d e o mns

lateral force. As seen in Fig.4-2 and Fig. 4-3, even though there are circumference cracks in

column FCF2, the ductility of FCF2, after retrofitted by using 4-layer CFRP, is similar to the

ductility of FCF3. For columns FCF2 and FCF3 with CFRP jacketing, the failure mode

changes from flexural failure to the breaking of the longitudinal bar in the bottom of the

columns. CF4 is the flexural-shear failure. From Fig. 4-4, the ductility of CF4 is 7.0, and

the maximum lateral force is 250 kN.

Lap Splice Failure Retrofit

From Fig. 4-5, the ductility of BMCL100 is 2.5, and the maximum lateral force is 350

kN. Columns FCL100, FCL100-1 and FCL100-2 are retrofitted by using CFRP jacketing

(FAW=250g/m2) with, respectively, 6-layer (in the transverse direction), 4-layer (in the

transverse direction), and 2 (transverse)-2 (longitudinal)-2 (transverse)-layer. The ductility of

FCL100, FCL100-1 and FCL100-2 are 8.9, 5.7, and 4.6, and the maximum lateral forces are

440 kN, 340 kN and 450 kN, as seen in Figures 4-6, 4 -7 and 4-8, respectively. After

retrofitting with steel and CFRP jacketing, the failure mode changes from lap splice failure to

flexural failure (Hsieh, 1999).

Shear Failure Retrofit

From Fig. 4-9, the ductility of BMCS is 2.3, and the maximum lateral force is 660 kN.

Columns FCS, FCS-1 and FCS-2 are retrofitted by using 4-layer, 3-layer, and 2-layer CFRP

(FAW=250g/m2). In Fig. 4-10 to Fig 4-12, the ductility of FCS, FCS-1 and FCS-2 are 9.3,

15.8 and 12.8, and the maximum lateral forces are about 860, 800 and 820 kN, respectively.

The failure mode of SCS and FCS changes from shear failure to flexural failure with the

breaking of the longitudinal bars. And the failure mode of FCS-1 and FCS-2 changes from

shear failure to flexural failure but with CFRP broken. The ductility of FCS-1 and FCS-2 is

higher than the ductility of FCS because the final failure modes are different. It is worth

noting that more layers of CFRP may not have higher ductility.

Conclusion

In the experimental results and observations of this paper, we can arrive at the following

conclusions:

Using tie bar, 2 semicircular stirrups with hoop, and reducing the distance of the stirrups

can increase the confinement strength and ductility of bridge column, which is an effective

design detail to increase the seismic capacity of bridge columns.

Using CFRP to retrofit bridge columns, the performance of bridge columns with

circumference cracks is almost the same as the bridge columns without cracks.

With steel jacketing and CFRP jacketing, the failure mode changes from flexural failure to

the breaking of longitudinal bar in the bottom of the columns, and the ductility and maximum

lateral force have increased.

For lap splice failure mode, using steel and CFRP jacketing can tremendously increase the

confinement strength and ductility of bridge columns. The more layers of CFRP can obtain

higher ductility.

For shear failure mode, using steel and CFRP jacketing can also tremendously increase the

confinement strength and ductility of bridge columns. But, more layers of CFRP may not

have higher ductility; yet more layers result in different failure modes, which cannot be

compared with each other

Se sm c Retrof t St d of R r d e o mns

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

1 2 3 4 5 6 7 8 9 10 11

g

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

g

Fig.4-1 The Hysteresis curve of column CF2 Fig.4-1 The Hysteresis curve of column FCF2

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

g

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

1 2 3 4 5 6 7 8

g

Fig.4-3 The Hysteresis curve of column FCF3 Fig.4-4 The Hysteresis curve of column CF4

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-700

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

700

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Rati o (%)

1 2 3 4

g

Main bar yield point

Spalling point

g=2.6

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement (mm)

-700

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

700

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7

Drift Rati o (%)

1 2 3 4 5 6 7 8 9

g

Main bar yield point

g=7.3

Fig.4-5 The Hysteresis curve of column BMCL100 Fig.4-6 The Hysteresis curve of column FCL100

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

-500

-400

-300

-200

-100

0

100

200

300

400

500

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70

Drift Ratio(%)

-250 -200 -150 -100 -50 0 50 100 150 200 250

Displacement(mm)

Fig.4-7 The Hysteresis curve of column FCL100-1 Fig.4-8 The Hysteresis curve of column FCL100-2

Seismi Retrofit Stu of R ri ge olumns

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Di splacement (mm)

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drif t Ratio (%)

1 2 3 4 5

g

Main bar yield point

Spalling point

g=2.3

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Di splacement (mm)

-1400

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

1400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Drif t Ratio (%)

1 2 3 4 5 6 7 8

g

Main bar yield point

g=7.5

Fig.4-9 Hysteresis curve of column BMCS Fig. 4-10 The Hysteresis curve of column FCS

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Displacement (mm)

-1400

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

1400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8

Dri ft Ratio (%)

1 2 3 4 5 6 7 8 9 10 1112 13 1415 16

15.78

-150 -125 -100 -75 -50 -25 0 25 50 75 100 125 150

Displacement (mm)

-1400

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

1400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

1 2 3 4 5 6 7 8 9 101112 13

12.80

Drift Ratio (%)

Fig.4-11 The Hysteresis curve of column FCS-1 Fig.4-12 The Hysteresis curve of column FCS-2

Seismic Retrofit and Repair of Bridge Columns by Reinforced Concrete Jacketing

Seismic Retrofit and Repair Design

Specimen RCCL1 is retrofitted for the weakness of 100 % longitudinal reinforcement

lap-spliced at the bottom of bridge column so that its design before retrofitting is the same as

specimen BMCL100. The bridge column is jacketed with 9-cm-thick reinforced concrete to

the full height. In the reinforced concrete jacketing, there are 12 #5 longitudinal

reinforcement with nominal yielding strength 2800 kg/cm2. The longitudinal reinforcement

is imbedded 18 cm into the foundation. The space of the transverse reinforcement is 7 cm

with nominal yielding strength 2800 kg/cm2.

Specimen RCCL2 is almost the same as specimen RCCL1 except the longitudinal

reinforcement of the reinforced concrete jacketing is not imbedded into the foundation.

There is a 3-cm gap between the reinforced concrete jacketing and the foundation.

Specimen RCC2 is retrofitted for the weakness of 50 % longitudinal reinforcement

terminated at the mid-height of bridge column so that its design before retrofitting is the same

as specimen BMC4. The design of reinforced concrete jacketing for specimen RCC2 is the

same as that for specimen RCCL2.

Specimen BMC4-RC is repaired for the weakness of 50 % longitudinal reinforcement

terminated at the mid-height of bridge column. It is a repaired specimen after the specimen

BMC4 is tested to fail. The design of reinforced concrete jacketing for specimen BMC4-RC

is the same as that for specimen RCC2.

Specimen BMCL50-RC is repaired for the weakness of 50 % longitudinal reinforcement

lap-spliced at the bottom of bridge column. It is a repaired specimen after the specimen

BMCL50 is tested to fail. The design of reinforced concrete jacketing for specimen

BMCL50-RC is the same as that for specimen BMC4-RC.

S ismic o i S d o id o mns

Experimental Results

The cyclic test for specimen RCCL1 is terminated when the amplitude of displacement is

130 mm (drift ratio 4 %). The cover concrete at the bottom is crushed so that confinement

loses its effect. The performance in ductility and energy dissipation is not satisfied and no

longitudinal reinforcement is fractured (Photo 5-1). The elastic stiffness of the bridge

column is 31.57 kN/mm, the ultimate strength is 543.9 kN and the ductility ratio is 5.49.

Energy 2746 kN-m is dissipated during the cyclic test (Fig. 5-1).

The cyclic test for specimen RCCL2 is terminated when the amplitude of displacement is

195 mm (drift ratio 6 %). Some of the longitudinal reinforcement is fractured and the

concrete at the bottom is cracked but not to a serious extent. The performance in ductility and

energy dissipation is excellent (Photo 5-2). The elastic stiffness of the bridge column is

25.56 kN/mm, the ultimate strength is 492.6 kN and the ductility ratio is 7.19. Energy 7872

kN-m is dissipated during the cyclic test (Fig. 5-2).

The cyclic test for specimen RCC2 is terminated when the amplitude of displacement is

195 mm (drift ratio 6 %). Some of the longitudinal reinforcement is fractured and the

concrete at the bottom is cracked but not to a serious extent. The performance in ductility and

energy dissipation is excellent (Photo 5-3). The elastic stiffness of the bridge column is

24.76 kN/mm, the ultimate strength is 390.3 kN and the ductility ratio is 6.21. Energy 6300

kN-m is dissipated during the cyclic test (Fig. 5-3).

The cyclic test for specimen BMC4-RC is terminated when the amplitude of

displacement is 162.5 mm (drift ratio 5 %). Some of the longitudinal reinforcement is

fractured and the concrete at the bottom is spalled (Photo 5-4). The elastic stiffness of the

bridge column is 13.07 kN/mm, the ultimate strength is 352.0 kN and the ductility ratio is

4.65. Energy 3120 kN-m is dissipated during the cyclic test (Fig. 5-4).

The cyclic test for specimen BMCL50-RC is terminated when the amplitude of

displacement is 195 mm (drift ratio 6 %). Some of the longitudinal reinforcement is

fractured and the concrete at the bottom is spalled (Photo 5-5). The elastic stiffness of the

bridge column is 22.15 kN/mm, the ultimate strength is 353.5 kN and the ductility ratio is

6.36. Energy 3580 kN-m is dissipated during the cyclic test (Fig. 5-5).

-150 -100 -50 0 50 100 150

Displacement (mm)

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

RCCL1

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Drift Ratio (%)

Photo 5-1. Failure of RCCL1 Fig. 5-1. Force and displacement of RCCL1

S ismic o i S d o id o mns

-200 -100 0 100 200

Displacement (mm)

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

RCCL2

-600

-500

-400

-300

-200

-100

0

100

200

300

400

500

600

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Drift Ratio (%)

Photo 5-2. Failure of RCCL2 Fig. 5-2. Force and displacement of RCCL2

-200 -100 0 100 200

Displacement (mm)

-400

-300

-200

-100

0

100

200

300

400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

RCC2

-400

-300

-200

-100

0

100

200

300

400

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Drift Ratio (%)

Photo 5-3. Failure of RCC2 Fig. 5-3. Force and displacement of RCC2

-200 -100 0 100 200

Displacement (mm)

-400

-300

-200

-100

0

100

200

300

400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

BMC4-RC

-400

-300

-200

-100

0

100

200

300

400

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Drift Ratio (%)

Photo 5-4. Failure of BMC4-RC Fig. 5-4. Force and displacement of BMC4-RC

-200 -100 0 100 200

Displacement (mm)

-400

-300

-200

-100

0

100

200

300

400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

BMCL50-RC

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Drift Ratio (%)

-400

-300

-200

-100

0

100

200

300

400

Photo 5-5. Failure of BMCL50-RC Fig. 5-5. Force and displacement of BMCL50-RC

S ismic o i S d o id o mns

Seismic Assessment and Retrofit of Bridge Column Footings on Piles

Test Specimens

As-built column footing RF1, shown in Fig. 6-1(a), had no joint hoops in the footing,

providing no reliable shear-resisting mechanism in the joint region. Column longitudinal

reinforcement was anchored by

90

deg hooks bent outwards with insufficient development

length. Retrofit column footing RF3, as shown in Fig. 6-1(b), had the same existing column

dimensions as RF1. Existing

cm 45 180 245

footing of RF3 was enlarged to

cm 55 200 255

by adding reinforced concrete overlay (Xiao et al. 1996 and McLean and

Marsh 1999).

Observed Behavior

The cracks observed in both the as-built column footing RF1 and the retrofit column

footing RF3 are indicative of a joint shear failure at the column-footing connection.

Horizontal force-displacement hysteretic response histories for the as-built column footing

RF1 and the retrofit column footing RF3 are shown in Fig. 6-2 (a) and 6-2 (b), respectively.

As shown in Fig. 2, the retrofit column footing RF3 developed higher strength and more

ductile hysteretic behavior than the as-built column footing RF1.

Assessment of Joint Shear Strength

The softened strut-and-tie model for determining the shear strength of beam-column

joints for seismic resistance has been developed (Hwang and Lee 2000). For column-footing

connection, the upper and lower ends of the diagonal strut have different values. The

crushing of the concrete strut should be examined at both ends, and the weaker portion

controls the shear strength of the column-footing joint.

The softened strut-and-tie model was used to calculate the joint shear strength of RF1

and RF3, as presented in Table 5. The strength ratios that are listed as the ratios of the

measured to the calculated strength indicate the precision of the softened strut-and-tie model.

The strength ratios for the column footing RF1 and RF3 are 1.37 and 1.03 (Table 5),

respectively. This indicates the applicability of the softened strut-and-tie model in the

seismic assessment for column-footing joints. More details can be found in the Reference of

Jian and Hwang 2000.

Conclusions

The test results of the retrofitted model column footing indicated that the reinforced

concrete overlay atop the existing footing on piles is an effective retrofitting measure.

Experimental observations and theoretical analyses indicated that the shear strength of joint

can be predicted by the softened strut-and-tie model. As an improvement to current footing

retrofit design methodology, it is recommended that the softened strut-and-tie model be used

to assess the shear strength of column-footing connection, and to design the appropriate

overlay depth.

References

Hwang, S. J., and Lee, H. J. (2000). Analytical Model for Predicting Shear Strengths of

Interior Reinforced Concrete Beam-Column Joints for Seismic Resistance, ACI

Structural Journal, 97(1), 35-44.

S ismic o i S d o id o mns

McLean, D. I., and Marsh, M. L. (1999). Seismic Retrofitting of Bridge Foundations, ACI

Structural Journal, 96(2), 174-182.

Xiao, Y., Priestley, M. J. N., and Seible, F. (1996). Seismic Assessment and Retrofit of

Bridge Column Footings, ACI Structural Journal, 93(1), 79-94.

Jian, J. Y., and Hwang, S. J. (2000). Seismic Assessment and Retrofit of Bridge Column

Footings on Piles, Report of National Center for Research on Earthquake Engineering,

NCREE-00-027, Taipei, Taiwan, 188 pp (in Chinese)

.

(a) "As built" column footing RF1

cm 8 @ 4 #

cm Footing 45 180 245 :

side each

cm 15 @ 8 #

cm Column 50 75 :

8 # 20

245cm

cm 75

direction Loading

side each cm 15 @ 8 #

cm 45

(b) Retrofitted column footing RF3

cm 8 @ 4 #

cm Footing 55 200 255 :

cm 15 @ 6 #

cm 10

8 # 20

cm Column 50 75 :

245cm

255cm

cm 75

bond and drill

cm of spacing

at Dowels

15

4 # 150

cm 5 . 16

direction Loading

side each cm 15 @ 8 #

Fig. 6-1. Footing details

H

O

R

I

Z

O

N

T

A

L

F

O

R

C

E

(

k

N

)

(a) Footing RF1

-8 -6 -4 -2 0 2 4 6 8

-500

-400

-300

-200

-100

0

100

200

300

400

500

-1.0

-0.5

0.0

0.5

1.0

DRIFT RATIO (%)

kN load Axial

kN H

kN H

y

500

385

347

max

=

=

=

1 4 2 5 3

HORIZONTAL DISPLACEMENT (mm)

y

H

H

/

-200 -100 0 100 200

first yield

max. load

(b) Footing RF3

DRIFT RATIO (%)

H

O

R

I

Z

O

N

T

A

L

F

O

R

C

E

(

k

N

)

-8 -6 -4 -2 0 2 4 6 8

-500

-400

-300

-200

-100

0

100

200

300

400

500

-1.0

-0.5

0.0

0.5

1.0

kN load Axial

kN H

kN H

y

550

473 max

370

=

=

=

1 8 5

HORIZONTAL DISPLACEMENT (mm)

y

H

H

/

-200 -100 0 100 200

first yield

max. load

Fig. 6-2. Hysteretic response of column footings

Retrofit of Circular Reinforced Concrete Bridge Columns by CFRP

The aim of this study is to evaluate the seismic resistance enhancement of circular RC

bridges columns retrofitted by CFRP. In out tests, the as-built columns are scaled down from

Seismi Retrofit Stu of R ri ge olumns

typical RC bridges built in Taiwan. The structural deficiencies considered in this study are

(1) inadequate flexural ductility, (2) the splice of the transverse hoop, (3) high longitudinal

steel volumetric ratio, (4) low aspect ratio and (5) the reduction of longitudinal and transverse

steel. Due to the competition of moment strength with shear strength in earthquake, as-built

columns will develop different failure modes. Series tests have been performed on as-built

and retrofitted columns. Test results show CFRP is a good retrofit material for bridge columns,

which can effectively enhance the ductility and shear capacity of bridge columns.

Experimental Results

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

1820-A

Pull

Push

y = 7.0 mm

= 8 . 5 6

-100 0 100

-100

0

100

-160-140 -120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm )

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

1820-C

Pull

Push

y = 11.4 mm

= 12.3

-100 0 100

-100

0

100

Fig.7-1 The Hysteresis curve of column 1820-A Fig.7-2 The Hysteresis curve of column 1820-C

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

1820L-A

Pull

Push

y = 8 . 9 mm

= 5 . 3 8

-100 0 100

-100

0

100

-160 -140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

1820L-C

Pull

Push

y = 12.1 mm

= 11.6

-100 0 100

-100

0

100

Fig.7-3 The Hysteresis curve of column 1820L-A Fig.7-4 The Hysteresis curve of column 1820L-C

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-280

-260

-240

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

5420-A

Pull

Push

y = 1 5 . 0 mm

= 3 . 4 7

-100 0 100

-200

0

200

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-280

-260

-240

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

5420-B

Pull

Push

y = 21.1 mm

= 6.64

-100 0 100

-200

0

200

Fig.7-5 The Hysteresis curve of column 5420-A Fig.7-6 The Hysteresis curve of column 5420-B

Se c Re rof S d of RC Br dge Col

-160 -140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-400

-360

-320

-280

-240

-200

-160

-120

-80

-40

0

40

80

120

160

200

240

280

320

360

400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

5420S-A

Pull

Push

y = 17.2 mm

= 2

-100 0 100

-400

-200

0

200

400

-160-140 -120 -100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-400

-360

-320

-280

-240

-200

-160

-120

-80

-40

0

40

80

120

160

200

240

280

320

360

400

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

5420S-B

Pull

Push

y = 15.0 mm

= 8.67

-100 0 100

-400

-200

0

200

400

Fig.7-7 The Hysteresis curve of column 5420S-A Fig.7-8 The Hysteresis curve of column 5420S-B

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-280

-260

-240

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

2533-A

Pull

Push

y = 23.4 mm

= 3.46

-100 0 100

-200

0

200

-160-140-120-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160

Deflection ( mm)

-280

-260

-240

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

-9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

Drift Ratio / L ( % )

2533-B

Pull

Push

y = 19.8 mm

= 7.07

-100 0 100

-200

0

200

Fig.7-9 The Hysteresis curve of column 2533-A Fig.7-10 The Hysteresis curve of column 2533-B

Seismic Retrofit of Circular RC Bridge Columns Using Steel Jacket

The purpose of this study is to evaluate the seismic resistance of old wall piers and to

retrofit the piers using CFRP. The characteristics of old wall piers are low longitudinal and

transverse steel volumetric ratio. There are four wall pier models designed in this study. Two

of them are as-built models exerting repeated force in the long and short direction. Others

exerting repeated force in the long and short direction are strengthened by carbon FRP and

compare with above as-built models. Due to the competition of moment strength with shear

strength in earthquake, as-built columns will develop different failure modes. Based on the

results of cyclic loading tests, it is concluded that old wall piers may not perform well. Wall

pier exerting repeated force in the long direction has major improvement after it is

strengthened by CFRP. But wall pier exerting repeated force in the short direction does not

have obvious improvement after it is strengthened by CFRP.

Max Load 166.40KN

-200

-150

-100

-50

0

50

100

150

200

-200 -150 -100 -50 0 50 100 150 200

Deflection (mm)

L

a

te

r

a

l F

o

r

c

e

(

K

N

)

Max Load

171.13KN

-200

-150

-100

-50

0

50

100

150

200

-200 -150 -100 -50 0 50 100 150 200

Deflection (mm)

L

a

te

r

a

l F

o

r

c

e

(

K

N

)

Fig. 8-1 The Hysteresis curve of specimens SW Fig. 8-2 The Hysteresis curve of specimens FSW

S c R ro S d o RC Br d Col

Max Load 457.88KN

-600

-400

-200

0

200

400

600

-125 -75 -25 25 75 125

Deflection (mm)

L

a

t

e

r

a

l

F

o

r

c

e

(

K

N

)

Max Load 546.43KN

-600

-400

-200

0

200

400

600

-125 -75 -25 25 75 125

Deflection (mm)

L

a

t

e

r

a

l

F

o

r

c

e

)

L

O

*

Fig. 8-3 Hysteresis curve of specimens LW Fig. 8-4 Hysteresis curve of specimens FLW

Table 1 Detail of Benchmark Specimens

Material

Longitudinal

reinforcement

Transverse

reinforcement

Arrangement

Cross

section

Height

Axial

Load

Conc.

fc

Long.

Rein. fy

Trans.

Rein. fyh

Arrange-

ment

Cut off

height

PHZ. Non-PHZ.

Note

Failure

Type

Specimen

(mm) (mm)

(fcAg

)

(Mpa) (Mpa) (Mpa) (mm) (mm) (mm) (mm) Code

BMR1 750*600 3250 0.1 25.97 490 490 32-19 --- 9@100 9@100 New

BMR2 750*600 3250 0.1 25.97 343 490 32-16 1800 9@130 9@240 Old

BMR3 750*600 3250 0.15 25.48 343 490 32-16 1800 9@130 9@240 Old

BMR4 750*600 3250 0.15 20.48 386.81 450.8 32-16 1800 9@230 9@230 Old

BMR1-R 750*60 3250 0.15 22.05 436.79 450.8 34-19 1800 9@100 9@100 New

BMC1 D=760 3250 0.15 25.97 490 490 34-19 --- 9@70 9@100 New

BMC2 D=760 3250 0.15 25.51 343.35 490.5 30-16 1800 9@130 9@220 Old

BMC3 D=760 3250 0.15 21.29 387.2 451.26 30-16 1800 9@230 9@230 Old

BMC4 D=760 3250 0.15 20.6 274.68 274.68 30-17 1800 9@130 9@220 Old

SC1 D=760 3250 0.15 26 343.35 490.5 26-16 1250 9@140 9@240 Old

SC1-R D=760 3250 0.15 26 343.35 490.5 26-16 1250 9@140 9@240 Old

FC1 D=750 3250 0.15 26 343.35 490.5 32-16 --- 9@100 9@100 New

Flexural

FC4 D=750 3250 0.15 25.51 343.35 490.5 18-16 --- 9@300 9@300 Old

BMRS 750*600 1750 0.15 16.67 421.83 412.02 30-19 --- 9@300 9@300 Old

Shear

BMCS D=760 1750 0.15 16.67 425.22 426.2 30-19 --- 9@300 9@300 Old

BMRL100 750*600 3250 0.15 16.67 421.83 412.02 30-19 760 9@130 9@220 Old

BMRL50 750*600 3250 0.15 17.89 411.6 421.4 30-19 760 9@130 9@220 Old

BMCL100 D=760 3250 0.15 19.99 425.22 426.2 30-19 760 9@130 9@220 Old

Lap -

splices

BMCL50 750*600 3250 0.15 20.6 274.68 274.68 30-19 760 9@130 9@220 Old

SW

1250*500

R=250

3250 0.15 16.67 421.83 412.02 8-25 1530 9@230 9@350 Old

Wall

type

LW

1250*500

R=250

3250 0.15 16.67 421.83 412.02 8-25 1530 9@230 9@350 Old

RF0 245*180 450 0.05 25.2 423.1 423.1 25@150 --- 25@150 25@150 New

RF1 245*180 450 0.05 41.7 423.1 423.1 25@150 --- 25@150 25@150 Old

Foun-

dation

RF2 245*180 450 0.05 36.8 423.1 423.1 25@150 --- 25@150 25@150 Old

Total24 benchmark specimens

S m c t t Stud C d C lumn

Table 2 Retrofit & Repair methods of rectangular specimens

Failure Type Retrofit / Repair Specimen Benchmark Note

FR1 BMR2 FRP (8 layers)

FR2 FRP (4 layers)

SR1 Large octagon

SR2 Ellipse

SR3 Small octagon

Flexural

SR4

BMR3

Ellipse

FRS FRP (4 layers)

SRS1 Small octagon

SRS2 Ellipse

Shear

BMRS-RC

BMRS

RC (9cm)

FRL100 FRP (8 layers)

SFRL100 FRP (layers)

SRL1 Small octagon

SRL2 Ellipse

BMRL100-RC

BMRL100

RC (9cm)

Lap splices

BMRL50-RC BMRL50 RC (9cm)

FSW SW FRP (2 layers)

Wall type

FLW LW FRP (2 layers)

Foundation RF3 RF1 RC (10cm)

Total19 rectangular retrofit/repair specimens

S m c t t Stud C d C lumn

Table 3 Retrofit & Repair methods of Circular specimens

Failure Type Retrofit / Repair Specimen Benchmark Note

SC2 SC1 Steel (3mm)

SC3 BMC2 Steel (3mm)

FC2 FRP (4 layers)

FC3

FC2

FRP (4 layers)

RCC2 BMC2 RC (9 cm)

Flexural

BMC4-RC BMC4 RC (9 cm)

SCS Steel (3mm)

FCS FRP (4 layers)

FCS-1 FRP (3 layers)

FCS-2 FRP (2 layers)

Shear

FCS-3

BMCS

High Pressure

Epoxy injected

SCL100 Steel (3mm)

FCL100 FRP (6-2 layers)

FCL100-1 FRP (4-2 layers)

FCL100-2 FRP (6-2 layers)

FCL100-3 FRP (6-2 layers)

RCCL1 RC (9 cm)

RCCL2

BMCL100

RC (9 cm)

Lap splices

BMCL50-RC BMCL50 RC (9 cm)

Total19 circular retrofit/repair specimens

Table 4 Material property of CFRP

Material specification FAW 200 (g/m) FAW 205 (g/m)

Yang's modulus Ecf (kgf/cm) 2.36 x 106 2.36 x 106

Thickness (mm/layer) 0.11 0.1375

Ultimate strain 0.015 0.015

Table. 5 Test results and comparison with theoretical predictions

Concrete crushed at upper end Concrete crushed at lower end

Test

unit

Measured

strength

test jv

V

,

kN

mm

a

t s,

mm

b

t s,

calc jv

test jv

V

V

,

,

mm

a

b s,

mm

b

b s,

calc jv

test jv

V

V

,

,

RF1 1311 288 613 0.66 113 690 1.37

RF3 1539 299 638 0.59 138 740 1.03

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- UDOT Seismic Design ExampeDocumento82 pagineUDOT Seismic Design Exampeyoungc71Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- LRFD - Design - Example - Leap ConspanDocumento110 pagineLRFD - Design - Example - Leap Conspanaraml001100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Example - Bearing ReplacementDocumento44 pagineExample - Bearing Replacementyoungc71Nessuna valutazione finora

- Anchorage Zone Reinforcement For Post-Tensioned Concrete GirderDocumento214 pagineAnchorage Zone Reinforcement For Post-Tensioned Concrete Girderyoungc71100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Ce 240204Documento15 pagineCe 240204youngc71Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Basic Data Viper40 15066 enDocumento10 pagineBasic Data Viper40 15066 enArmando RiveraNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Divine Measure of Time and SpaceDocumento94 pagineThe Divine Measure of Time and SpaceSaroya Fanniel100% (16)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocumento8 pagineTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Stats&Prob - WEEK 1Documento3 pagineStats&Prob - WEEK 1Ji PaoNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Dissipation Test - ENGDocumento3 pagineDissipation Test - ENGADS ADSNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- WP Correct Weight-Handling enDocumento4 pagineWP Correct Weight-Handling enbertan dağıstanlıNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hydrotest Pressure CalculationDocumento26 pagineHydrotest Pressure Calculationrudrakr0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Contoh Dan Jawaban Soal Metode Elemen HinggaDocumento16 pagineContoh Dan Jawaban Soal Metode Elemen HinggadhiafahheraNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- (Darryl D. Hol,) Geometric Mechanics Rotating, TR (B-Ok - CC) PDFDocumento304 pagine(Darryl D. Hol,) Geometric Mechanics Rotating, TR (B-Ok - CC) PDFOceanNessuna valutazione finora

- UBD Physics Unit 2 - Energy and The EnviornmentDocumento5 pagineUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- QTMS Brochure Rev2Documento8 pagineQTMS Brochure Rev2ManibalanNessuna valutazione finora

- Adnan Aljarallah 1988 Kinetic of MTBE Over AmberlystDocumento6 pagineAdnan Aljarallah 1988 Kinetic of MTBE Over AmberlystJason NunezNessuna valutazione finora

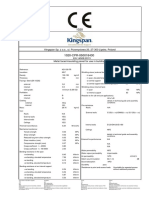

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Documento1 paginaA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- C 14Documento26 pagineC 14pfylNessuna valutazione finora

- Vega Antennas 131-133Documento3 pagineVega Antennas 131-133siroguzNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Chapter 1 - Introduction To GeologyDocumento76 pagineChapter 1 - Introduction To GeologyZulaikha KamalNessuna valutazione finora

- Gravitator: "How I Control Gravitation" British Patent # 300,311Documento17 pagineGravitator: "How I Control Gravitation" British Patent # 300,311Brian BennNessuna valutazione finora

- Incubator ReportDocumento26 pagineIncubator ReportxiastellaNessuna valutazione finora

- Ation Words That Best Completes The SentenceDocumento8 pagineAtion Words That Best Completes The SentenceMG's Fhya Part II0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Lesson Plan Solar SystemDocumento4 pagineLesson Plan Solar SystemAnneValdezAcostaNessuna valutazione finora

- Cse169 01Documento49 pagineCse169 01hhedfiNessuna valutazione finora

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocumento15 pagineA Presentation On Lithium Bromide Absorption Refrigeration SystemAyub GNNessuna valutazione finora

- Crystallization: A. BackgroundDocumento8 pagineCrystallization: A. Backgroundchamp delacruzNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Slides OctaveDocumento24 pagineSlides Octaveamru_rzlNessuna valutazione finora

- Purga Fondo BBV 980 A PDFDocumento2 paginePurga Fondo BBV 980 A PDFaugusto7777Nessuna valutazione finora

- AcousticsDocumento7 pagineAcousticscancan25Nessuna valutazione finora

- CALC SHEET ZOLA - CompressedDocumento33 pagineCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNessuna valutazione finora