Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wheat Vodka Recipe

Caricato da

pana0048Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wheat Vodka Recipe

Caricato da

pana0048Copyright:

Formati disponibili

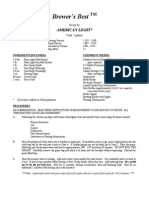

ALL- GRAIN WHEAT- MASH VODKA

Most home distillers make vodka from sugar and water fermented with turbo yeast. However, the majority of commercial vodka distilleries make their finest vodkas from Winter wheat. By its broadest definition, vodka is simply pure alcohol diluted with pure water. However, in practice the alcohol is never completely pure, so there are always trace congeners present that impart subtle flavours to the vodka. The character of these flavours is determined by the feedstock used to make the vodka mash. Wheat as a vodka mash is world famous for making the finer vodkas because the trace congeners resulting from it are preferable to those of other feedstocks. This text describes how home distillers can make 30L of wheat mash (approximately 20L to be distilled after straining) in a large pot on a kitchen stove. The yield will be between 3 and 4L of 40% abv vodka.

Mashing

Equipment 34-40L pot with lid a large plastic or wooden stirring spoon a floating dairy thermometer graduated from 0oC to 110oC (32oF to 230oF) pH meter; or, pH papers: ranges 2-12 & 5.0-6.5; or, 5.2 pH Adjuster tincture of iodine measuring spoons eye dropper Ingredients 23L of fairly soft municipal tap water. E.g. hardness level of 4; almost no iron; 100 ppm calcium; pH 8.5. 10-ml (2-tsp) Gypsum (CaSO4) 95% sulphuric acid (H2SO4); or, citric or tartaric acid; or, 18 ml (1.2 tablespoons) 5.2 pH Adjuster 8L (4K or 8.8 lbs) flaked wheat 1 L (K or 1.65 lbs) of finely crushed wheat malt Method This method is one of the easiest and least time consuming methods of mashing, and it scales up to large mashing quantities very well.

The principle behind this method, which is a single infusion-mash method, is to use flaked wheat rather than undispersed hard wheat. This eliminates the need to perform a full boil to disperse the grain starches. With flaked wheat, which is pre-gelatinized wheat that is hot-rolled the way rolled oats are made, the grain starches easily disperse in the 65.5oC (150oF) mash water without the need of boiling. Prepare the mash water by placing 23L of tap water in the large pot on the stove. Thoroughly mix the 10-ml (2-tsp) of gypsum into the water, and measure the pH using the pH meter or the range 2-12 pH papers. Use this pH measurement to determine what pH adjustment the water requires. Let s assume the pH, as with most municipal tap waters, is approximately 8 or 9. Begin adding 95% H2SO4 one drop at a time, mixing thoroughly, and measuring the pH with the pH meter or the range 5.0-6.5 pH papers between each drop until the pH is about 5.8 or 6.0. If citric or tartaric acid is used, which are both powders, the additions should be 1 ml ( tsp), and will take about 10 ml (2 tsp) or so in total to achieve pH 5.8 to 6.0 from a source water of pH 8.5. If you accidentally overshoot pH 5.8 with the acid, you can correct by simply making additions of 500 ml of source water (i.e. pH 8 or 9) and measuring the pH, until the target pH of 5.8 is achieved. Once this correction is complete, it will be necessary to remove a total equivalent volume of mash water as was added to do the correction and discard it, leaving 23L of mash water at pH 5.8 or 6.0. Of course, if the pH of the source water were below 5.8, the water would require treating with calcium carbonate (CaCO3) instead of acid. Similarly, an accidental overshoot can be corrected the same way with additions of the source water. Now, if you will be using 5.2 pH Adj ust er , an additive available at homebrew shops and web sites, the pH adjustment is very easy. Simply add 18 ml (1.2 tablespoons) of 5.2 pH Adj ust er to 23L of mash water after the addition of the gypsum, and the pH of the water will be automatically buffered to pH 5.2 regardless of the starting pH of the source water. This happens because the product is a pH buffer that

compensates for the other factors that would influence the pH of the water. The reason the product is formulated for a pH of 5.2, the optimum pH for mashing, is because it will hold the pH of the mash water to 5.2 even after the grain is added and the effects of enzyme activity have taken place. When adjusting the pH with acid it s adjusted to 5.8 instead of 5.2 because, unlike with the presence of a pH buffer, the pH will be further lowered by the addition of the grain and by the enzyme activity, which ultimately brings it down to about 5.2. After the mash water is prepared, turn the stove on high, cover the pot, and let the water heat up to the conversion strike temperature, 74oC (165oF). You will have to periodically stir the water thoroughly and measure the temperature as the water heats up until the strike temperature is reached. When the water is at the strike temperature, turn off the heat, and stir in the 8L of flaked wheat. The temperature should come to rest at about 68oC (155oF) or higher. Stir the mash for about five minutes while the starches disperse (i.e. gel into a thick porridge). It should take about 15 to 25 minutes for the temperature to cool to 66.5oC (152oF). The mash should be stirred every five minutes or so until it cools to that temperature. When the mash is at 66.5oC (152oF), stir in the 1L of crushed wheat malt. The mash temperature should rest at 65oC (149oF). Cover the mash pot and leave it for 90 minutes for the starches to convert to sugars. It s helpful to stir the mash every 15 minutes or so during the 90-minute conversion rest. The mash can even be left for eight or ten hours (e.g. overnight) to cool to fermentation temperature (i.e. under 29.5oC (85oF)). Or, an immersion chiller can be used to force cool the mash to fermentation temperature after the 90-minute conversion rest is complete. After the conversion rest, the starches should be completely converted to sugars. This can be tested for by an iodine starch test.

Fermentation

Ingredients 30L wheat mash 1 package of low-volatile Vodka Yeast with AG

Equipment 2 30+L primary fermenters with at least one lid Or + 1 30 L primary fermenter with lid, and an aquarium pump with an aeration stone 1 standard winemaking hydrometer and cylinder 1 floating dairy thermometer graduated from 0oC-110oC (32oF230oF) Method Initially, the mash will be in the pot on the stove with the lid on. The mash should have been left to settle for at least 90 minutes, possibly as long as overnight, and cooled to below 29.5oC (85oF). The mash solids will have settled out, and there should be 7 or 8 cm (3 ) of clear liquid on top of the mash. Carefully take a sample of the clear liquid and measure its Originating Gravity (OG) using the hydrometer. Be sure to make the necessary temperature correction for the hydrometer reading. The OG should be in the range 1.060-1.070, but a deviation of .010 from that is not a problem. The mash produced by the above recipe is most likely to fall into that range. Next, the mash needs to be transferred to a clean 30+L fermenter. The temperature should have cooled to below 29.5oC (85oF) before it is transferred. For the 30L batch, the mash can be left to cool until the temperature is below 29.5oC (85oF). For larger batch sizes, it will be necessary to employ an immersion chiller to force cool the mash. Once the mash has cooled to below 29.5oC (85oF) it can be transferred. This can be done by pouring the entire mash, grain and liquid together, from the mash pot to a clean 30+L fermenter. If the full mash pot is too heavy or too awkward to pick up and pour, the mash can be ladled with a one or two litre measuring cup into the fermenter until the volume is down to a manageable level. For larger batch sizes, a grain pump can be used to make all transfers. The mash is now ready for aerating (i.e. providing dissolved oxygen). For the 30L batch, you can vigorously pour the mash from one

fermenter to another four to six times. This works extremely well. You can also use an aquarium pump to pump air through an aeration stone placed in the mash. The aeration stone should be left to bubble in the mash for about 30 minutes. The yeast and AG can be added while the aeration stone is still bubbling in the mash. On the larger scale, bubbling with an aeration stone can be done, perhaps using a larger pump and larger stone. Also, mechanically rousing the mash in a manner that causes splashing for 20 or 30 minutes will work well. After the mash has been aerated, the yeast can be pitched (i.e. added to the mash) and stirred in if it hasn t already been added during the aeration stage. Just make sure the mash temperature is below 29.5oC (85oF) before adding the yeast. Place the fermenter where it s going to sit undisturbed for the next three days, and ensure the ambient temperature is between 21 and 29.5oC (70 and 85oF). After 30 minutes the yeast will have hydrated in the liquid and can be thoroughly stirred in. Within 60 minutes of pitching the yeast, vigorous fermentation will be evident (i.e. vigorous bubbling). The bubbling will continually rouse the mash throughout the fermentation, keeping the mash mixed. Leave the mash for 72 hours from when the yeast was pitched. It s helpful to stir the mash thoroughly every 24 hours, but not necessary. After 72 hours the fermentation will either be complete and the activity will have diminished to a slow spurious bubbling, or the fermentation will still be active and only have slowed down slightly. If the latter is the case, monitor it every six hours or so until the fermentation is very slow and therefore, finished. Fermentation shouldn t take more than 84 hours. When the fermentation is complete, it s important that the mash be strained, placed in the still, and heated to above 52oC (125oF) within 24 hours or off-flavours may develop. After the fermentation is complete the mash is ready to be strained. For the 30L of wheat mash, it can be strained by hand using a large straining bag, available at most homebrew shops. Larger volumes will require mechanical solids-separating equipment.

After straining, the volume of liquid retrieved will be about 70% of the entire-mash volume. If the mash were mechanically pressed, the volume of liquid retrieved would be closer to 80% of the entire-mash volume. In the case of the 30L of wheat mash strained by hand, between 20 and 22L of liquid will be retrieved. After the mash is strained and has settled for 30 to 60 minutes, a fairly clear sample of the mash liquid can be collected from the surface, and the Terminating Gravity (TG) can be measured. With the OG and the TG, the alcohol percentage can be calculated using the following formula: (OG TG) x 1000 / 7.4 = % abv.

Before transferring to the still, the mash should be allowed to settle for up to twelve hours so the fine particles can settle out and the clear liquid siphoned off. This avoids transferring too much suspended solids to the still, which could burn or crust up in the still boiler. After the completion of this fermentation step, you will have about 20L of fermented and strained wheat mash at about 8.5% abv, and you will be ready to proceed to the distillation steps. From this point, the distillation process is exactly the same as for any other vodka mash formulation. Ian Smiley

Potrebbero piacerti anche

- Iso-Thermal Infusion Mash: Mashing Systems (Techniques)Documento4 pagineIso-Thermal Infusion Mash: Mashing Systems (Techniques)Eduardo Herrera GnecchiNessuna valutazione finora

- All-Grain Brewing GuideDocumento3 pagineAll-Grain Brewing GuideEidetikosNessuna valutazione finora

- 2020-All Grain BrewingDocumento3 pagine2020-All Grain Brewingmichael.c.torresNessuna valutazione finora

- Making Rindless Blue Cheese - An Excerpt From Mastering Artisan CheesemakingDocumento4 pagineMaking Rindless Blue Cheese - An Excerpt From Mastering Artisan CheesemakingChelsea Green Publishing100% (1)

- Robo Brew 35 L InstructionsDocumento5 pagineRobo Brew 35 L Instructionssteve_milenNessuna valutazione finora

- Bulldog Brews InstructionsDocumento4 pagineBulldog Brews InstructionsrciobanasuNessuna valutazione finora

- Making Your Own Barm 2008Documento2 pagineMaking Your Own Barm 2008kkd108Nessuna valutazione finora

- Fantome Saison-Style Ale (16C) - All GrainDocumento2 pagineFantome Saison-Style Ale (16C) - All GrainMonitoreo SPERNessuna valutazione finora

- Brew in A BagDocumento2 pagineBrew in A BagJohnRykerNessuna valutazione finora

- US Patent for Fish Protein IsolateDocumento3 pagineUS Patent for Fish Protein IsolateIron HeartNessuna valutazione finora

- WH Beer Recipe 1 PDFDocumento1 paginaWH Beer Recipe 1 PDFfunbobNessuna valutazione finora

- 10 Steps To Better Extract BrewingDocumento3 pagine10 Steps To Better Extract BrewingmykkramerNessuna valutazione finora

- Stone Pail Ale RecipeDocumento3 pagineStone Pail Ale Recipekillahertz18Nessuna valutazione finora

- 12 Rules For Life by Jordan PetersonDocumento5 pagine12 Rules For Life by Jordan PetersonVictor Filip18% (11)

- Sweet Gouda RecipeDocumento5 pagineSweet Gouda Recipeسیفی فقیرNessuna valutazione finora

- American Pale Ale: High Sierra Pale Ale (5 Gallons/19 L, Extract With Grains)Documento3 pagineAmerican Pale Ale: High Sierra Pale Ale (5 Gallons/19 L, Extract With Grains)Ognjen PopovicNessuna valutazione finora

- SAKE Home BrewDocumento22 pagineSAKE Home Brewcris kingNessuna valutazione finora

- NEGRA MODELO CLONE ALL-GRAIN RECIPEDocumento2 pagineNEGRA MODELO CLONE ALL-GRAIN RECIPEKevin van HollandNessuna valutazione finora

- American Pale AleDocumento2 pagineAmerican Pale AleJustin GarciaNessuna valutazione finora

- JB's Best India AleDocumento2 pagineJB's Best India AleJesso GeorgeNessuna valutazione finora

- Homebrew Oatmeal Stout Kit GuideDocumento3 pagineHomebrew Oatmeal Stout Kit Guideriffs_ahoyNessuna valutazione finora

- Red Stripe Clone All GrainDocumento1 paginaRed Stripe Clone All GraincanilvanderbiltNessuna valutazione finora

- AgarDocumento5 pagineAgardelta3tjNessuna valutazione finora

- How To Specialty Grains Home BrewingDocumento3 pagineHow To Specialty Grains Home BrewingcodyNessuna valutazione finora

- Appalachian Corn Moonshine Life Recipes1607717442Documento2 pagineAppalachian Corn Moonshine Life Recipes1607717442Clinton EbanksNessuna valutazione finora

- Beginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.NzDocumento6 pagineBeginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.Nzerickscribduy321Nessuna valutazione finora

- K-Bglu 1107 DataDocumento16 pagineK-Bglu 1107 Datapi_yoanaNessuna valutazione finora

- 10 and 20 Gallon Mash Tun Configurations, Operation, and Best PracticesDocumento5 pagine10 and 20 Gallon Mash Tun Configurations, Operation, and Best PracticesOscar Zamora GuardiaNessuna valutazione finora

- Brewers Friend Checklist ExtractDocumento2 pagineBrewers Friend Checklist ExtractGanges LimNessuna valutazione finora

- Recipes for Brewing Different Types of Beers and AlesDa EverandRecipes for Brewing Different Types of Beers and AlesNessuna valutazione finora

- 1018 American LightDocumento2 pagine1018 American LightAhmet MetinNessuna valutazione finora

- Avant-Garde Kitchen Appliances.Documento9 pagineAvant-Garde Kitchen Appliances.p3p1t0c4j1t4Nessuna valutazione finora

- 3 EditionDocumento47 pagine3 EditionVictor Sá100% (1)

- SFBI - PretzelDocumento2 pagineSFBI - PretzelSergio VelosoNessuna valutazione finora

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsDa EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNessuna valutazione finora

- How to make vodka at home in 5 easy stepsDocumento11 pagineHow to make vodka at home in 5 easy stepsRaad AshkarNessuna valutazione finora

- 25L Pot Still: ManualDocumento8 pagine25L Pot Still: ManualrectechNessuna valutazione finora

- Brooklyn Brew Shop - Everyday IPA InstructionsDocumento3 pagineBrooklyn Brew Shop - Everyday IPA Instructionstecleador10% (1)

- Crisp Malt Scotch Distilling Mash ProtocolDocumento7 pagineCrisp Malt Scotch Distilling Mash ProtocolRajeev Kumar YadavNessuna valutazione finora

- Coffee (Automatic Coffee Maker) : BEVERAGES No.C 003 00Documento1 paginaCoffee (Automatic Coffee Maker) : BEVERAGES No.C 003 00David BradleyNessuna valutazione finora

- Acetyl Chloride, Acetic Anhydride and Propionic AnhydrideDocumento1 paginaAcetyl Chloride, Acetic Anhydride and Propionic Anhydridede palo100% (1)

- Gooder Than GuinnessDocumento1 paginaGooder Than GuinnesslegionsixNessuna valutazione finora

- Project Statement S2 2015 (V2)Documento10 pagineProject Statement S2 2015 (V2)Devandra Eko RadityoNessuna valutazione finora

- Production and Usage of Natural Lactic AcidDocumento1 paginaProduction and Usage of Natural Lactic AcidpmusNessuna valutazione finora

- Rice BeerDocumento8 pagineRice BeerPied7PiperNessuna valutazione finora

- Making GoudaDocumento1 paginaMaking GoudaRohit jhaNessuna valutazione finora

- Preparation of Plasmid DNA by Alkaline Lysis With SDSDocumento5 paginePreparation of Plasmid DNA by Alkaline Lysis With SDStanjent50% (2)

- Morebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemDocumento2 pagineMorebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemTeddy Riaño AlarconNessuna valutazione finora

- MoA - Lactobacillus SPPDocumento3 pagineMoA - Lactobacillus SPPdjalovicNessuna valutazione finora

- Dairy ConfectioneryDocumento9 pagineDairy Confectionerysa ltyNessuna valutazione finora

- Basic Homebrewed Lambic: in The Loft at Cantillon. You Can (Barely) See Bales of Hops Aging in The Back LeftDocumento5 pagineBasic Homebrewed Lambic: in The Loft at Cantillon. You Can (Barely) See Bales of Hops Aging in The Back LeftBruno MelloNessuna valutazione finora

- SFBT58Documento1 paginaSFBT58leotottiNessuna valutazione finora

- Extract Brewing Instructions: Necessary Equipment and SuppliesDocumento2 pagineExtract Brewing Instructions: Necessary Equipment and SuppliesHenry Clark TravagliniNessuna valutazione finora

- Killians RED Beer Reciepe 03638Documento2 pagineKillians RED Beer Reciepe 03638Joe MoldovanNessuna valutazione finora

- Making A Mash BeerDocumento2 pagineMaking A Mash BeerJohnRykerNessuna valutazione finora

- Sfa Us05Documento1 paginaSfa Us05ernestojacintopintoNessuna valutazione finora

- 31.2.03 AOAC of Fi Cial Method 952.04 Pec Tic Acid in Ca Cao Prod UctsDocumento2 pagine31.2.03 AOAC of Fi Cial Method 952.04 Pec Tic Acid in Ca Cao Prod UctsDayana AriasNessuna valutazione finora

- Fred Eckhardt SRC 43 NewDocumento20 pagineFred Eckhardt SRC 43 Newcorbu_georgeNessuna valutazione finora

- GUIDE TO MAKING MOONSHINE: A detailed step by step guide to create several kinds of moonshine recipes like a pro from homeDa EverandGUIDE TO MAKING MOONSHINE: A detailed step by step guide to create several kinds of moonshine recipes like a pro from homeNessuna valutazione finora

- Instant Pot Family Meals: 60+ Fast, Flavorful Means for the Dinner TableDa EverandInstant Pot Family Meals: 60+ Fast, Flavorful Means for the Dinner TableValutazione: 4 su 5 stelle4/5 (2)

- C1A Practice Test 2 C5-8Documento9 pagineC1A Practice Test 2 C5-8pana0048Nessuna valutazione finora

- Psittacine Birds 2eDocumento13 paginePsittacine Birds 2epana0048Nessuna valutazione finora

- Animal Migration Research, Jeff Kelly LabDocumento3 pagineAnimal Migration Research, Jeff Kelly Labpana0048Nessuna valutazione finora

- Equilibrium Vapor PressureDocumento1 paginaEquilibrium Vapor Pressurepana0048Nessuna valutazione finora

- Le Chatelier's PrincipleDocumento2 pagineLe Chatelier's Principlepana0048Nessuna valutazione finora

- Galvanic CellDocumento2 pagineGalvanic Cellpana0048Nessuna valutazione finora

- Galvanic CellDocumento2 pagineGalvanic Cellpana0048Nessuna valutazione finora

- Making A SolutionDocumento2 pagineMaking A Solutionpana0048Nessuna valutazione finora

- 49 Lecture Nervous SystemDocumento94 pagine49 Lecture Nervous Systempana0048Nessuna valutazione finora

- WILD9 ScienceandStewardship SMDocumento236 pagineWILD9 ScienceandStewardship SMpana0048Nessuna valutazione finora

- Acid Base TitrationDocumento2 pagineAcid Base Titrationpana0048Nessuna valutazione finora

- How a Small Jar of Yeast Extract Gets People So Worked UpDocumento13 pagineHow a Small Jar of Yeast Extract Gets People So Worked Uppana0048Nessuna valutazione finora

- AP Chemistry Practice Test, Ch. 6: ThermochemistryDocumento10 pagineAP Chemistry Practice Test, Ch. 6: Thermochemistrypana0048Nessuna valutazione finora

- Limiting ReactantsDocumento1 paginaLimiting Reactantspana0048Nessuna valutazione finora

- 55 Lecture EcosystemsDocumento100 pagine55 Lecture Ecosystemspana0048Nessuna valutazione finora

- 56 Lecture ConservationDocumento135 pagine56 Lecture Conservationpana0048Nessuna valutazione finora

- NPR 8 (4) 334-344Documento11 pagineNPR 8 (4) 334-344pana0048Nessuna valutazione finora

- Armenia Agricultural PolicyDocumento79 pagineArmenia Agricultural Policypana0048Nessuna valutazione finora

- 07 Lecture MembranesDocumento85 pagine07 Lecture Membranespana0048Nessuna valutazione finora

- 07 Lecture MembranesDocumento85 pagine07 Lecture Membranespana0048Nessuna valutazione finora

- Labour in South AfricaDocumento6 pagineLabour in South Africapana0048Nessuna valutazione finora

- Water and LifeDocumento61 pagineWater and LifeVanessa DacerNessuna valutazione finora

- 02 Lecture PresentationDocumento94 pagine02 Lecture Presentationpana0048Nessuna valutazione finora

- 11 Lecture Cell CommunicationDocumento90 pagine11 Lecture Cell Communicationpana0048Nessuna valutazione finora

- 04 Lecture PresentationDocumento57 pagine04 Lecture Presentationpl205041Nessuna valutazione finora

- AGRS097 GDocumento66 pagineAGRS097 Gpana0048Nessuna valutazione finora

- AGRS097 GDocumento66 pagineAGRS097 Gpana0048Nessuna valutazione finora

- Hints for First Class EmigrantsDocumento103 pagineHints for First Class Emigrantspana0048Nessuna valutazione finora

- Pheromone Spray Coverage for Strawberry PestsDocumento2 paginePheromone Spray Coverage for Strawberry Pestspana0048Nessuna valutazione finora

- PDF FileDocumento9 paginePDF Filepana0048Nessuna valutazione finora

- Live Animal As Diet, Served To Reptiles of Kamla Nehru Zoological Garden at AhmadabadDocumento63 pagineLive Animal As Diet, Served To Reptiles of Kamla Nehru Zoological Garden at AhmadabadNaresh KadyanNessuna valutazione finora

- Potts 1993 (E. Arabia)Documento50 paginePotts 1993 (E. Arabia)menducatorNessuna valutazione finora

- Annual Report on Animal Husbandry, Dairying and FisheriesDocumento114 pagineAnnual Report on Animal Husbandry, Dairying and FisheriesKarthik TamilNessuna valutazione finora

- FCE Test 3Documento14 pagineFCE Test 3Mabel Corpa0% (1)

- Natural Rubber in IndiaDocumento6 pagineNatural Rubber in Indiaor02ag5846Nessuna valutazione finora

- Contoh Contoh Soal Smerter 2 SDDocumento110 pagineContoh Contoh Soal Smerter 2 SDYunansi pangiNessuna valutazione finora

- Eneseo Vs TulopDocumento3 pagineEneseo Vs TulopJo Vic Cata BonaNessuna valutazione finora

- URBAN FARMING Case Study - 23.11.19Documento5 pagineURBAN FARMING Case Study - 23.11.19gaurav dhoreNessuna valutazione finora

- Pre-Operative Check Up of Farm Tools and EquipmentDocumento2 paginePre-Operative Check Up of Farm Tools and EquipmentRamz Latsiv Yohgat67% (9)

- PicklingDocumento12 paginePicklingIlham ZainuddinNessuna valutazione finora

- (Very Short Introductions) Lawrence, Mark Atwood-The Vietnam War - A Concise International History-Oxford University Press (2008)Documento225 pagine(Very Short Introductions) Lawrence, Mark Atwood-The Vietnam War - A Concise International History-Oxford University Press (2008)Милан Стевановић100% (2)

- Indian Standard: Specification FOR Structural Timber in BuildingDocumento33 pagineIndian Standard: Specification FOR Structural Timber in BuildinggiriNessuna valutazione finora

- How Sustainable Is Organic Agriculture in The Phils Rodel G. Maghirang Et AlDocumento33 pagineHow Sustainable Is Organic Agriculture in The Phils Rodel G. Maghirang Et AlianmaranonNessuna valutazione finora

- Thesis Tejaswi 18th Aug 2008 Final 1Documento91 pagineThesis Tejaswi 18th Aug 2008 Final 1salman khalilNessuna valutazione finora

- Modified Non-Linear Index (MNLI)Documento11 pagineModified Non-Linear Index (MNLI)sergonzalezNessuna valutazione finora

- Caesalpinia Sappan LDocumento4 pagineCaesalpinia Sappan LSriArthiNessuna valutazione finora

- Combating Rural Youth Unemployment Through Agricultural InnovativepracticesinZambia - Kellyson-Siamunjo - EditedDocumento15 pagineCombating Rural Youth Unemployment Through Agricultural InnovativepracticesinZambia - Kellyson-Siamunjo - EditedKellyson SiamunjoNessuna valutazione finora

- Limus® - Urea InhibitorDocumento6 pagineLimus® - Urea InhibitorsharemwNessuna valutazione finora

- Wildlife Fact File - Mammals - Pgs. 211-220Documento20 pagineWildlife Fact File - Mammals - Pgs. 211-220ClearMind84100% (3)

- Pola Tanam: Cropping PatternDocumento31 paginePola Tanam: Cropping PatternTeja KusumaNessuna valutazione finora

- A PROJECT REPORT On Consumer Perception and Preference Towards Nandini Curd in Dharwad CityDocumento77 pagineA PROJECT REPORT On Consumer Perception and Preference Towards Nandini Curd in Dharwad CityBabasab Patil (Karrisatte)Nessuna valutazione finora

- Rwanda Agribusiness MarketScan ReportDocumento48 pagineRwanda Agribusiness MarketScan Reportnabcdh100% (1)

- Analysis PresentationDocumento7 pagineAnalysis Presentationapi-542560527Nessuna valutazione finora

- CLA Cattle Market Report July 12, 2023Documento1 paginaCLA Cattle Market Report July 12, 2023Clovis Livestock AuctionNessuna valutazione finora

- Chapter 1Documento20 pagineChapter 1Vera Carpentero LamisNessuna valutazione finora

- Divine Child High School Science Class 8th Std NotesDocumento12 pagineDivine Child High School Science Class 8th Std Notesshivam thakurNessuna valutazione finora

- Host Preference and Performance of Fruit Flies Bactrocera Zonata (Saunders) and Bactrocera Cucurbitae (Coquillett) (Diptera: Tephritidae) For Various Fruits and VegetablesDocumento7 pagineHost Preference and Performance of Fruit Flies Bactrocera Zonata (Saunders) and Bactrocera Cucurbitae (Coquillett) (Diptera: Tephritidae) For Various Fruits and VegetablesAmin MojiriNessuna valutazione finora

- Bio CompleteDocumento9 pagineBio Completesoya beanNessuna valutazione finora

- Ali Case Petition Teodoro Jr. (Valencia)Documento10 pagineAli Case Petition Teodoro Jr. (Valencia)MJNessuna valutazione finora

- Grade 8 History Term 2 ExamDocumento14 pagineGrade 8 History Term 2 ExamNeo NetandaNessuna valutazione finora