Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4 Silicon LDMOS

Caricato da

thap_dinhCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4 Silicon LDMOS

Caricato da

thap_dinhCopyright:

Formati disponibili

Silicon RF transistors II: LDMOS

Silicon RF transistors II: LDMOS

Lars Vestling Uppsala University, Sweden

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary References

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

What is a DMOS?

LDMOS Lateral double-diffused MOS VDMOS Vertical double-diffused MOS

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

History

1969 the first LDMOS was presented 1972 the LDMOS as a microwave device was presented Switching devices

Power supplies Motor controls etc.....

From mid-90s Base station applications

NMT, GSM, 3G, (900 MHz-3 GHz) Philips, Freescale (Motorola), Infineon (Ericsson)

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

Base stations RF power transistors

Power amplifiers (PA) Base stations

Source: Ericsson

RF power devices has other demands than CMOS

Output power Efficiency Linearity

2006-02-23 Lars Vestling - Uppsala University

RF-devices

Silicon RF transistors II: LDMOS

Why LDMOS in base station applications?

Compared to Bipolar Junction Transistors (BJT) Better linearity Grounded substrate

source connected to substrate => no bondwire required => substrate inductance decreased packaging, BeO can be avioded

Reliability

negtive temperature coefficient

Higher gain The VDMOS has some of the BJT drawbacks as well

2006-02-23 Lars Vestling - Uppsala University 6

Silicon RF transistors II: LDMOS

Typical transistor data

Power

5-10 W up to 150 W per transistor

Frequencies

900 MHz to 2.7 GHz today

Supply voltage

VDD=26-28 V which implies a BV>60 V

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

Market

Base station applications, market share of 90% for LDMOS

Devces working at 28 V, up to 2.7 GHz, gain of 15dB and efficiency of 25%.

RF-LDMOS market

dominated by Freescale (former Motorola) with ~80% of market others are: Philips, Infineon, STMicroectronics

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

Cross-section of a modern LDMOS device

source: Freescale

2006-02-23

Lars Vestling - Uppsala University

Silicon RF transistors II: LDMOS

Important transistor parameters

ID,sat saturated current BV breakdown voltage RON vs BV onresistance vs breakdown voltage fT, fMAX cut-off frequencies

2006-02-23

Lars Vestling - Uppsala University

10

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary

2006-02-23

Lars Vestling - Uppsala University

11

Silicon RF transistors II: LDMOS

Manufacturing

Specific issues compared to CMOS Substrate

Resistivity and epi-thickness sets BV 10 cm, 10 m => BV=60-100V

P+sinker

Area comsuming Temperature budget

Gate

Polycide, gate resistance Oxide thickness, VT, BVOX Gate length, Cgd, gate length not equal to channel length

Double diffused Channel engineering Drain engineering Drift region, RESURF technology

2006-02-23 Lars Vestling - Uppsala University 12

Silicon RF transistors II: LDMOS

Double-diffused

p-well and n+source are double-diffused to create the channel

LDMOS for Power ICs

Suitable for circuit integration Device design for avalanche ruggedness

2006-02-23

LDMOS for RF

Deep p+sinker to provide substrate contact Device design for superior RF performance

Lars Vestling - Uppsala University

13

Silicon RF transistors II: LDMOS

Channel engineering

By modifying the doping in and near the channel, different behaviour can be obtained VT Lch

channel length determines speed channel doping level sets threshold voltage and controls punch-through p-well curvature controls junction breakdown

NA

BV

2006-02-23

Lars Vestling - Uppsala University

14

Silicon RF transistors II: LDMOS

Drain engineering

Used to reduce peak electric field

Tailoring doping profiles through implantation and annealing

Minimizes IDQ drift Do not affect BV and RON Drain engineering applied in this region

2006-02-23

Lars Vestling - Uppsala University

15

Silicon RF transistors II: LDMOS

Drift region, RESURF

RESURF

REduced SURface Field

Lateral and vertical diodes interact to provide 2D-depletion Not LDMOS specific

Works for all lateral HV devices

Charge balance Lower RON

2006-02-23

Lars Vestling - Uppsala University

16

Silicon RF transistors II: LDMOS

Layout

Device divided in gate fingers to reduce gate resistance

Gate

Example

each finger is 100 m total width is 20 mm

Drain

2006-02-23 Lars Vestling - Uppsala University 17

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary

2006-02-23

Lars Vestling - Uppsala University

18

Silicon RF transistors II: LDMOS

Models

Ordinary MOS-models (SPICE) are not sufficient. SPICE sub-circuits may solve the problem.

Enhancement MOS for channel region JFET for drainunder-gate region JFET or R(V,I) for extended drain

Difficult to extract model parameters!

2006-02-23

Lars Vestling - Uppsala University

19

Silicon RF transistors II: LDMOS

Models - problems

The channel/drain-end potential, VX

Decides the channel transistor

How model the drift region

JFET Resistor, R(I,Vgs,Vds) Analytical expressions

VX

All LDMOS devices are different => difficult to have a generic LDMOS model

2006-02-23

Lars Vestling - Uppsala University

20

Silicon RF transistors II: LDMOS

MOS model 20 (Philips)

SPICE model Combination of MOS model 9 and MOS model 31

MOS model 9 enhancement type MOSFET model for the channel region. MOS model 31 - junction-isolated accumulation/depletion-type MOSFET model. Used for the drain extension of high-voltage MOS devices.

Model includes:

charge dynamics of the drain extension region. not the quasi-saturation (current compression) effect.

2006-02-23

Lars Vestling - Uppsala University

21

Silicon RF transistors II: LDMOS

The Chalmers model

Generic large-signal model Analytical expression for the drain current, Ids Parasitics appended

C=const. or C=C(V)

I ds = I pk (1 + tanh( )) tanh(Vds ) (1 + Vds )

2 3 =P 1 (Vgs V pk ) + P 2 (Vgs V pk ) + P 3 (Vgs V pk ) L

drain current

Pout PAE drain voltage input power

Lars Vestling - Uppsala University 22

2006-02-23

Silicon RF transistors II: LDMOS

Thermal modeling

Power devices generate heat The heat is distributed unevenly depending on the layout Problem characterizing the thermal properties

Pulsed measurement removes heating Pulsed S-parameter measurements with thermal chuck

Big challenge!!!

2006-02-23

Lars Vestling - Uppsala University

23

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary

2006-02-23

Lars Vestling - Uppsala University

24

Silicon RF transistors II: LDMOS

What is done to improve the performance?

Miller capacitance Shielding Metal sinker

Better temperature budget Less area consuming

Metalization

Gold, AlCu

Plastic encapsulation

Lower cost but worse thermal properties than ceramics

Scaling

tOX, LG, thinner substrates (<100 microns)

2006-02-23 Lars Vestling - Uppsala University 25

Silicon RF transistors II: LDMOS

Miller effect - gate-drain capacitance

Feedback capacitance affects gain

Vgs must be maximized for max gain Vgs determined by Miller capacitance

GA ( g mVgs ) 2 Ropt VS2 /(4 RS )

Must minimize Cgd to minimize gain reduction due to Miller effect

2006-02-23

Lars Vestling - Uppsala University

26

Silicon RF transistors II: LDMOS

1GS

2GS

Shielding

Example (Motorola)

Re-designing the metal shield lower CGD lower IM3 IM3 vs PAE CGD vs VDS 1GS 2GS

2006-02-23

Lars Vestling - Uppsala University

27

Silicon RF transistors II: LDMOS

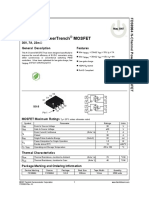

Freescale (Motorola) MRF5S19060

Typical characteristics

Power gain, GA = 14 dB Drain efficiency, D = 23 % IM3 = 37 dBc @ VDD=28V, IDQ=750 mA, 1960 MHz, Pout=12W BV=65 V

2006-02-23

Lars Vestling - Uppsala University

28

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary

2006-02-23

Lars Vestling - Uppsala University

29

Silicon RF transistors II: LDMOS

Future concepts

The supply voltage will increase to 50 V. [ITRS] BV must increase from 60 to more than 100 V New device concepts for higher supply voltages are needed. Avaliable devices (28 V) can not be directly scaled to 50 V. Solution?: Novel LDMOS device concept with a dual-layer extended drain region, which shields the active gate region from high voltage.

2006-02-23

Lars Vestling - Uppsala University

30

Silicon RF transistors II: LDMOS

UU LDMOS project

Objective

Implement a new type of LDMOS in a standard CMOS process Breakdown voltages above 100 V and at the same time fT and fMAX at around 10 GHz Demonstrate RF-performance for frequencies relevant to telecommunication, 1-3 GHz.

Challenge

How to combine high voltage with a short channel?

2006-02-23

Lars Vestling - Uppsala University

31

Silicon RF transistors II: LDMOS

Standard LDMOS concept, CMOS compatible

Source Gate n+ poly p+ p-base

channel kanal

Drain

n+

n+

n- drift region p-substrate

Lateral diffusion of p-base -> short channel 0.3 m Long poly-gate -> low gate resistance Long drift region -> high breakdown voltage

2006-02-23

Lars Vestling - Uppsala University

32

Silicon RF transistors II: LDMOS

Double depletion LDMOS

Source Gate n+ poly p+ p-base

channel kanal

Drain

n+

p-top

n+

n- drift region p-substrate

Lateral diffusion of pbase => short channel Long poly-gate => low RG Long drift region => high BV

2006-02-23

Buried p-top => more effective drift region depletion => higher drift region doping => lower resistance for preserved BV => higher current

Lars Vestling - Uppsala University 33

Silicon RF transistors II: LDMOS

Dual conduction layer LDMOS

Source Gate n+ poly p+ p-base

channel kanal

Drain

n+

n-top p-top

n+

n- drift region p-substrate

Lateral diffusion of pbase => short channel Long poly-gate => low RG Long drift region => high BV

2006-02-23

Buried p-top => more effective drift region depletion => higher drift region doping => lower resistance for preserved BV => higher current N-top at surface => higher current for preserved BV

Lars Vestling - Uppsala University 34

Silicon RF transistors II: LDMOS

Enhanced dual conduction layer LDMOS

Source Gate n+ poly p+ p-base

channel kanal

Drain

n+

n-top p-top

n+

n- drift region p-substrate

Lateral diffusion of pbase => short channel Long poly-gate => low RG Long drift region => high BV

2006-02-23

Buried p-top => more effective drift region depletion => higher drift region doping => lower resistance for preserved BV => higher current Blanket N-top at surface => even higher current for preserved BV

Lars Vestling - Uppsala University 35

Silicon RF transistors II: LDMOS

Dual depletion effect

LDMOS without p-top layer

Badly distributed field over the drift region

LDMOS with p-top layer

Uniformly distributed field over the drift region

2006-02-23

Lars Vestling - Uppsala University

36

Silicon RF transistors II: LDMOS

UU LDMOS performance

World record results were achieved.

2 W/mm @ 70 V and 1 GHz 1 W/mm @ 28 V and 1 GHz High linear gain 23dB 1 W/mm @ 50 V, 3.2 GHz 0.6 W/mm @ 28 V, 3.2 GHz Comparable with SiC MESFET f=1.9 GHz Vds=48 V Vgs=1.1 V

POUT PAE

Input power (dBm)

2006-02-23 Lars Vestling - Uppsala University 37

Silicon RF transistors II: LDMOS

UU LDMOS

This device concept offers

RF performance in a wide voltage range Very high breakdown voltages (fMAX=4 GHz @ BV=400 V)

LDMOS

33 32 31 30 29 28 27 26 10 20 30 40 D ra in v o lta g e (V ) 50 60 1 0 .9 0 .8 0 .7 0 .6 0 .5 0 .4 p a tte rn e d n -to p f= 3 .2 G H z Pout -3dB compression (W /mm)

fT and fMAX vs BV ft fmax

Pout -3dB compression (dBm)

10 Cut-off frequency [GHz] 1 10 100 BV [V] 1000

2006-02-23

Lars Vestling - Uppsala University

38

Silicon RF transistors II: LDMOS

Linearity

The linearity performance of LDMOS is very critical for the overall PA performance Output power normally backed-off in order to meet linearity requirements power efficiency also drops drastically The linearity may be improved with some methods, e.g. combining transistors with different VT more ideal transfer characteristic Major improvement can probably be achieved if the device structure itself is changed (doping profiles, dimensions etc.) The key is to understand the silicon

2006-02-23 Lars Vestling - Uppsala University 39

Modified device

Silicon RF transistors II: LDMOS

Better linearity with modified channel

Simulation has shown that by changing the doping profile in the channel the transfer characteristic is improved

A uniform channel doping provides more ideal transfer curve and has a higher VIP3 than the usual graded doping profile. This modification can be achieved with modified process steps VIP3 is a linearity measure

2006-02-23

8 7 6 5 4 3

VIP3

1

8 7 6 5

vip3 uniform channel vip3 graded channel

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

Gate Voltage (V)

Lars Vestling - Uppsala University

40

Silicon RF transistors II: LDMOS

Further improvements

Other transistor parasitics may also make the device less ideal less linear Parasitics also influence other parameters, such as output power and efficiency One important parasitic is the coupling to the silicon substrate This will affect the transistor output resistance in off-state

2006-02-23

Lars Vestling - Uppsala University

41

Silicon RF transistors II: LDMOS

Why off-state ROUT important?

ID

Load line

PA operates along a load line. In on-state ROUT (Rds) is mainly determined by the channel output conductance The ROUT in off-state determines the losses. Affects the power efficieny of PA

VD

2006-02-23

Lars Vestling - Uppsala University

42

Silicon RF transistors II: LDMOS

HR silicon substrate improves ROUT - Efficiency

Simulation have shown that both substrate resistivity and thickness strongly affects the off-state ROUT

Cds Source Cjs Cjsub Vx Gsub Gd

109

Optimized 1 kcm substrate p- epi/p+ substrate

ROUT (mm)

Drain

107

Increasing drain voltage

105

Csub

103

Substrate

10X improvement in off-state output resistance when using high resistivty bulk-Si (1 kcm)

2006-02-23

101 107

108

109 Frequency (Hz)

1010

1011

Lars Vestling - Uppsala University

43

Silicon RF transistors II: LDMOS

LDMOS on SOI?

The use of SOI may further reduce the coupling to the substrate HR SOI may therefore be interesting Traditionally (CMOS) SOI also reduces other parasitics, which may lead to better overall device performance

Bulk LDMOS

2006-02-23 Lars Vestling - Uppsala University

SOI LDMOS

44

Silicon RF transistors II: LDMOS

LDMOS on SOI?

It has been shown that very effective RESURF can be achieved on SOI substrates good RON vs. BV Self-heating may be a problem LDMOS on high resistivity SOI has shown impressive RFperformance (40% PAE @ 7.2 GHz) However, inversion and accumulation charge underneath the BOX severely degrades the RF-performance, and must therefore be dealt with.

inversion accumulation

2006-02-23 Lars Vestling - Uppsala University

depletion

45

Silicon RF transistors II: LDMOS

Low-voltage LDMOS

The LDMOS transistor may also be scaled down in voltage. A CMOS compatible LDMOS concept enables integrated PA solutions, e.g. mobile handsets

10 9 80 12 7.5

R

On-Resistance [mm] 8 7 6 5 4 3 2 0 1

70 10 60 50 40 30 Breakdown Voltage [V] Frequency [GHz]

MAX

ON

Transconductance [mS]

g

8

6.5

BV

f

4

20 10

5.5

2 3 Gate Length [m]

Gate Length [m]

RON, BV vs LG

2006-02-23

fT, fMAX, gm vs LG

Lars Vestling - Uppsala University 46

Silicon RF transistors II: LDMOS

Low-voltage LDMOS - RF performance

Impressive performance with 400 V design rules!

30 25 Output Power [dBm] 20 15 10 5 0 -10 60

VG=3 V VD=6 V f=1 GHz

P

out

50 40 30 20 10 0 20

Power Added Efficiency |%]

PAE

2 mm LDMOS for on-wafer characterisation

2006-02-23

-5

0 5 10 Input Power [dBm]

15

Lars Vestling - Uppsala University

47

Silicon RF transistors II: LDMOS

Outline

Introduction Manufacturing LDMOS Models State-of-the-art LDMOS techniques Future LDMOS concepts Summary

2006-02-23

Lars Vestling - Uppsala University

48

Silicon RF transistors II: LDMOS

Summary LDMOS

Main advantages

Majority carrier device -> carrier speed is larger than for BJT Backside source contact - reduced source inductance, no toxic BeO in the package, improved cooling High gain Better thermal uniformity compared to BJT Excellent back-off linearity

LDMOS (28V) benchmarking results showed > 5 dBc better IM3 and 2% worse efficiency @ fixed WCDMA back off power (Pavg) compared to GaAs (12V).

2006-02-23

Adjustable BV -> Adjustable application voltage Mature technology Ease of CMOS integration Reasonable ease of scaling up device size

Lars Vestling - Uppsala University 49

Silicon RF transistors II: LDMOS

Summary LDMOS

Main disadvantages

Frequency response limited by gate charging and transit time required through N- drift region -> < 3 GHz operation Excess efficiency degradation with increasing frequency operation -> Cds Hot electron injection or IDQ drift issue

Future

LDMOS device concept for higher voltages (required by ITRS) has successfully been demonstrated. LDMOS definitely has a bright future for RF power applications.

If you can do it in Silicon. Do it!

2006-02-23 Lars Vestling - Uppsala University 50

Silicon RF transistors II: LDMOS

Acknowledgements

Klas-Hkan Eklund, COMHEAT Microwave AB Jrgen Olsson, Uppsala University

The work reported here was performed in the context of the network TARGET Top Amplifier Research Groups in a European Team and supported by the Information Society Technologies Programme of the EU under contract IST-1-507893NOE, www.target-org.net

2006-02-23

Lars Vestling - Uppsala University

51

Silicon RF transistors II: LDMOS

References

J. Ankarcrona, High Frequency Analysis of Silicon RF MOS Transistors, Ph.D. Theses, Uppsala University, Uppsala, Sweden, 2005. J. A. Appels and H. M J. Vaes, High Voltage Thin Layer Devices (RESURF Devices), IEDM Tech. Dig., pp. 238-241, 1979. H. Brech et al., Record Efficiency and Gain at 2.1GHz of High Power RF Transistors for Cellular and 3G Base Stations, IEDM Tech. Dig., pp. 359-362, 2003. W. Burger et al., RF-LDMOS: A Device Technology for High Power RF Infrastructure Applications, IEEE CSIC Dig., pp. 189-192, 2004. The International Technology Roadmap for Semiconductors, 2005, http://public.itrs.net/. A. W. Ludikhuize et al., Extended (180V) Voltagein 0.6um Thin-Layer-SOI A-BCD3 Technology on 1um BOX for Display, Automotive & Consumer Applications, Proc. ISPSD, pp. 77-80, 2002. Bob Metzger, LDMOS turns up the power, Compound Semiconductor Magazine, June 2002. J. Olsson et al., 1 W/mm RF Power Density at 3.2 GHz for a Dual-Layer RESURF LDMOS Transistor, IEEE Electron Dev. Let., vol. 23, no. 4, pp. 206-208, 2002. J. Scholvin, J. G. Fiorenza, and J. A. del Alamo, The impact of substrate surface potential on the performance of RF power LDMOSFETs on high-resistivity SOI, IEDM Tech. Dig., pp. 363-366, 2003. A. Sderbrg et al., Integration of a Novel High-Voltage Giga-Hertz DMOS Transistor into a Standard CMOS Process, IEDM Tech. Dig., pp. 975-978, 1995. L. Vestling, J. Olsson, and K.-H. Eklund, Drift Region Optimization of Lateral RESURF Devices, Solid-State Electronics, vol. 46, no. 8, pp. 1177-1184, 2002.

2006-02-23

Lars Vestling - Uppsala University

52

Potrebbero piacerti anche

- Silicon Integrated CircuitsDa EverandSilicon Integrated CircuitsDawon KahngValutazione: 4 su 5 stelle4/5 (1)

- HFE0106 TraskPart2Documento5 pagineHFE0106 TraskPart2arunkr1Nessuna valutazione finora

- Characterization of Integrated Circuit Packaging MaterialsDa EverandCharacterization of Integrated Circuit Packaging MaterialsNessuna valutazione finora

- Radio Test Procedure ManualDocumento161 pagineRadio Test Procedure ManualQll Communications100% (1)

- British Special Quality Valves and Electron Tube Devices Data Annual 1964–65Da EverandBritish Special Quality Valves and Electron Tube Devices Data Annual 1964–65Nessuna valutazione finora

- LearnEMC - Magnetic-Field Coupling (Inductive Coupling)Documento3 pagineLearnEMC - Magnetic-Field Coupling (Inductive Coupling)danitranoster8512Nessuna valutazione finora

- Antenna Matching Within An EnclosureDocumento5 pagineAntenna Matching Within An EnclosureNitin PatelNessuna valutazione finora

- III-V Semiconductor Materials and DevicesDa EverandIII-V Semiconductor Materials and DevicesNessuna valutazione finora

- EdmDocumento16 pagineEdmaj87_goswamiNessuna valutazione finora

- Awr-Axiem - Understanding Grounding Concepts in em SimulatorsDocumento11 pagineAwr-Axiem - Understanding Grounding Concepts in em Simulatorsagmnm1962Nessuna valutazione finora

- The Transmission-Line Modeling (TLM) Method in ElectromagneticsDocumento132 pagineThe Transmission-Line Modeling (TLM) Method in ElectromagneticsRafael CoelhoNessuna valutazione finora

- InGaAs LDMOS Power TransistorsDocumento13 pagineInGaAs LDMOS Power TransistorsMamidala Jagadesh KumarNessuna valutazione finora

- Optimization of LDMOS TransistorDocumento84 pagineOptimization of LDMOS TransistorLuís PaisNessuna valutazione finora

- 5 Channel Radio Remote ControlDocumento3 pagine5 Channel Radio Remote ControlAshish ArunNessuna valutazione finora

- 2x813 Linear Amplifier Cathode Input GW0FZYDocumento16 pagine2x813 Linear Amplifier Cathode Input GW0FZYGus RudyNessuna valutazione finora

- High-Speed Backplane Interconnect: Vladimir Stojanovic (With Slides From J. Zerbe, P. Desai, R. Kollipara)Documento49 pagineHigh-Speed Backplane Interconnect: Vladimir Stojanovic (With Slides From J. Zerbe, P. Desai, R. Kollipara)A. VillaNessuna valutazione finora

- Grid Connected Inverter Design GuideDocumento52 pagineGrid Connected Inverter Design GuideRakesh SandarativjuNessuna valutazione finora

- Electronic Load PDFDocumento73 pagineElectronic Load PDFserviciobsasNessuna valutazione finora

- Thermister TrainingDocumento6 pagineThermister TrainingkazishahNessuna valutazione finora

- Introduction To LTSpiceDocumento39 pagineIntroduction To LTSpiceXimena AGNessuna valutazione finora

- Kenwood TS-940S Fixes ReviewsDocumento151 pagineKenwood TS-940S Fixes Reviewsk1dnrNessuna valutazione finora

- Vector Magnetic Potential of a Small Loop AntennaDocumento12 pagineVector Magnetic Potential of a Small Loop Antennaalkesh.eng100% (1)

- Constant Current Led DriverDocumento27 pagineConstant Current Led DriverSreekanth RaveendranNessuna valutazione finora

- LDMOS For RF Power AmplifiersDocumento12 pagineLDMOS For RF Power Amplifierscse_boby_01Nessuna valutazione finora

- Tia Eia 613Documento19 pagineTia Eia 613NeatMarineNessuna valutazione finora

- Class Ab Output BufferDocumento4 pagineClass Ab Output BufferrivercamNessuna valutazione finora

- RF OscillatorsDocumento11 pagineRF OscillatorsMohammad Irani0% (1)

- RF Communication Circuits Lecture 3: Transmission Lines theoryDocumento57 pagineRF Communication Circuits Lecture 3: Transmission Lines theoryHussein DahirNessuna valutazione finora

- 2014 Handbook Supplemental FilesDocumento13 pagine2014 Handbook Supplemental FilesIñaki PerezNessuna valutazione finora

- Transformer Distributed Capacitance PaperDocumento9 pagineTransformer Distributed Capacitance PaperdaolmedoNessuna valutazione finora

- Hombrew Air Core Balun Goran SM2YERDocumento6 pagineHombrew Air Core Balun Goran SM2YERblackbeast8Nessuna valutazione finora

- Ec6304 Electronic Circuits-I OldDocumento204 pagineEc6304 Electronic Circuits-I OldVijayakumar SNessuna valutazione finora

- Siplace S: Best-In-Class For Flexible High SpeedDocumento4 pagineSiplace S: Best-In-Class For Flexible High Speedamrina23Nessuna valutazione finora

- EL156 AUDIO POWER AMPLIFIERDocumento8 pagineEL156 AUDIO POWER AMPLIFIERnicolae12100% (1)

- Measuring Coaxial Cable Impedance Using Oscilloscope To Analyze WaveformDocumento24 pagineMeasuring Coaxial Cable Impedance Using Oscilloscope To Analyze WaveformlufrasaNessuna valutazione finora

- Siemens Absolute EncoderDocumento4 pagineSiemens Absolute EncoderAditya Pavan VinjamuriNessuna valutazione finora

- BASIC OPERATING PRINCIPLES AND PILOT PROTOTYPE DEVELOPMENTDocumento8 pagineBASIC OPERATING PRINCIPLES AND PILOT PROTOTYPE DEVELOPMENTtheodorakis017781Nessuna valutazione finora

- Ground Wave Propagation 2. Sky Wave PropagationDocumento18 pagineGround Wave Propagation 2. Sky Wave PropagationajiistanNessuna valutazione finora

- MW TUBES FUNDAMENTALSDocumento58 pagineMW TUBES FUNDAMENTALSDilpreet SinghNessuna valutazione finora

- Antena Bomer 4 ElemenDocumento2 pagineAntena Bomer 4 ElemenAudi MirantiNessuna valutazione finora

- Biquad Antenna ConstructionDocumento7 pagineBiquad Antenna ConstructionLlodiam OrtizNessuna valutazione finora

- Op Amp ExpDocumento23 pagineOp Amp Expram12_leoNessuna valutazione finora

- Device ModelingDocumento199 pagineDevice Modelingchiyu10100% (1)

- Diode Clamper Circuit. by - Engr - Irshad Rahim Memon - PPT Video Online DownloadDocumento9 pagineDiode Clamper Circuit. by - Engr - Irshad Rahim Memon - PPT Video Online DownloadAlejandro100% (1)

- Crystal Oscillator Circuits Krieger Matthys PDFDocumento252 pagineCrystal Oscillator Circuits Krieger Matthys PDFAnonymous O1vCfgkeaT100% (1)

- The Beauty of The 6C33Documento9 pagineThe Beauty of The 6C33RastekHINessuna valutazione finora

- Effects Masterclass With Pete CornishDocumento10 pagineEffects Masterclass With Pete Cornishshu2uNessuna valutazione finora

- PH8253-Physics For Electronics Engineering PDFDocumento10 paginePH8253-Physics For Electronics Engineering PDFKhrishNessuna valutazione finora

- Stepper MotorDocumento6 pagineStepper Motortilakkanti100% (9)

- Dual Trace Oscilloscope Block Diagram & SpecsDocumento8 pagineDual Trace Oscilloscope Block Diagram & SpecsSudip MondalNessuna valutazione finora

- Trask TLT TutorialDocumento7 pagineTrask TLT TutorialAnonymous Lf5zuYsNessuna valutazione finora

- Applications of Metamaterial in Antenna EngineeringDocumento4 pagineApplications of Metamaterial in Antenna EngineeringInternational Jpurnal Of Technical Research And ApplicationsNessuna valutazione finora

- AirCraft Band Receiver 2012Documento4 pagineAirCraft Band Receiver 2012Smail HondoNessuna valutazione finora

- 1 Electrical - and - Electronics - Measurment. McGraw Hill, 2013-413-651Documento239 pagine1 Electrical - and - Electronics - Measurment. McGraw Hill, 2013-413-651Andrea Acuña100% (1)

- How To Build SMPS Transformer Home Make 12V 10A SWDocumento11 pagineHow To Build SMPS Transformer Home Make 12V 10A SWwaseem ul haqueNessuna valutazione finora

- Laser and Fiber OpticDocumento33 pagineLaser and Fiber Optictiara mahendraNessuna valutazione finora

- Power ElectronicsDocumento37 paginePower ElectronicsMohammad Tabrez AlamNessuna valutazione finora

- Modelling of SOI-LDMOS TransistorDocumento13 pagineModelling of SOI-LDMOS TransistorchaitudscNessuna valutazione finora

- Digital GyroscopesDocumento26 pagineDigital Gyroscopesthap_dinh100% (1)

- Extended Gradient Predictor and Filter For Smoothing RSSI: Fazli Subhan, Salman Ahmed and Khalid AshrafDocumento5 pagineExtended Gradient Predictor and Filter For Smoothing RSSI: Fazli Subhan, Salman Ahmed and Khalid Ashrafthap_dinhNessuna valutazione finora

- HTML5 Cheat SheetDocumento1 paginaHTML5 Cheat SheetRegina AlegridNessuna valutazione finora

- Pkdd07 SongDocumento17 paginePkdd07 Songthap_dinhNessuna valutazione finora

- Indoor Wireless Localization Using Kalman Filtering in Fingerprinting-Based Location Estimation SystemDocumento12 pagineIndoor Wireless Localization Using Kalman Filtering in Fingerprinting-Based Location Estimation Systemthap_dinhNessuna valutazione finora

- 2nd Order Comp Filter SimulationDocumento3 pagine2nd Order Comp Filter Simulationthap_dinhNessuna valutazione finora

- 4a 4Documento10 pagine4a 4thap_dinhNessuna valutazione finora

- Disser Ta CaoDocumento85 pagineDisser Ta Caothap_dinhNessuna valutazione finora

- Project 1 - Wifi PositioningDocumento8 pagineProject 1 - Wifi Positioningthap_dinhNessuna valutazione finora

- Algo 3 DFusions MemsDocumento5 pagineAlgo 3 DFusions Memsthap_dinhNessuna valutazione finora

- JFormDesigner LicenseDocumento2 pagineJFormDesigner Licensethap_dinhNessuna valutazione finora

- Consume Webservice in An..Documento7 pagineConsume Webservice in An..thap_dinhNessuna valutazione finora

- Class4 KNNDocumento20 pagineClass4 KNNthap_dinhNessuna valutazione finora

- 11 Java Layout ManagersDocumento22 pagine11 Java Layout Managersthap_dinhNessuna valutazione finora

- 05 Layout ManagersDocumento8 pagine05 Layout Managersthap_dinhNessuna valutazione finora

- Yun 2006Documento12 pagineYun 2006thap_dinhNessuna valutazione finora

- Chuong4 TebaoDocumento29 pagineChuong4 Tebaothap_dinhNessuna valutazione finora

- Kalman and Extended Kalman Concept, Derivation and PropertiesDocumento44 pagineKalman and Extended Kalman Concept, Derivation and Propertiesliuocean613Nessuna valutazione finora

- Lect 7Documento78 pagineLect 7thap_dinhNessuna valutazione finora

- EE 122: Intro to Communication Networks LectureDocumento58 pagineEE 122: Intro to Communication Networks Lecturethap_dinhNessuna valutazione finora

- Java Media Framework: RTP: Summary: SourcesDocumento14 pagineJava Media Framework: RTP: Summary: SourcesjhuarayaNessuna valutazione finora

- Names & Addresses: EE 122: IP Forwarding and Transport ProtocolsDocumento8 pagineNames & Addresses: EE 122: IP Forwarding and Transport Protocolsthap_dinhNessuna valutazione finora

- Csharp4 MVCDocumento16 pagineCsharp4 MVCthap_dinhNessuna valutazione finora

- AlohaDocumento47 pagineAlohathap_dinhNessuna valutazione finora

- Untitled DocumentDocumento1 paginaUntitled Documentthap_dinhNessuna valutazione finora

- Coding the Arduino: Getting Started with Embedded SystemsDocumento21 pagineCoding the Arduino: Getting Started with Embedded Systemsthap_dinhNessuna valutazione finora

- Design of Low Noise Amplifier at 4 GHZDocumento4 pagineDesign of Low Noise Amplifier at 4 GHZthap_dinhNessuna valutazione finora

- Select Right RF AmplifierDocumento12 pagineSelect Right RF Amplifierthap_dinhNessuna valutazione finora

- 665 PA - NotesDocumento31 pagine665 PA - Notesthap_dinhNessuna valutazione finora

- Transmission Line TheoryDocumento25 pagineTransmission Line Theorythap_dinhNessuna valutazione finora

- Demonstrate The Use of Diodes in Clipper Circuits (Series Diode Clipping Circuit)Documento6 pagineDemonstrate The Use of Diodes in Clipper Circuits (Series Diode Clipping Circuit)shahid rasheedNessuna valutazione finora

- Infineon Bipolar AN20012 01 Technical Information An v1.0 enDocumento84 pagineInfineon Bipolar AN20012 01 Technical Information An v1.0 enflash_90697638Nessuna valutazione finora

- Ee8451 Lic NotesDocumento224 pagineEe8451 Lic NotesUma100% (1)

- Silicon N-Channel Junction: For Low-Frequency Amplification For Switching FeaturesDocumento2 pagineSilicon N-Channel Junction: For Low-Frequency Amplification For Switching Featureskedwin vasquezNessuna valutazione finora

- 2016 Ch2-MOS TransistorsDocumento47 pagine2016 Ch2-MOS Transistorsជើងកាង ភូមិNessuna valutazione finora

- Thesis PHD Cagdas SSDDocumento196 pagineThesis PHD Cagdas SSDUsha ChevulaNessuna valutazione finora

- Matoshri College of Engineering and Research Center Nasik Department of Computer EngineeringDocumento18 pagineMatoshri College of Engineering and Research Center Nasik Department of Computer EngineeringAditya DarekarNessuna valutazione finora

- SM4377NSKP: Pin Description FeaturesDocumento13 pagineSM4377NSKP: Pin Description FeaturesSilvio VasconcelosNessuna valutazione finora

- National Institute of Technology Warangal: B.Tech. in Electronics and Communication EngineeringDocumento142 pagineNational Institute of Technology Warangal: B.Tech. in Electronics and Communication EngineeringSrikar DNessuna valutazione finora

- IXYS ICD ProductCatalog 2019Documento48 pagineIXYS ICD ProductCatalog 2019PhilippNessuna valutazione finora

- BQ 24735Documento46 pagineBQ 24735Carlos GomesNessuna valutazione finora

- Lab-05 Layout: "Layout of Basic Gates Using 0.25 Micron Technology in Microwind" 1. ObjectiveDocumento3 pagineLab-05 Layout: "Layout of Basic Gates Using 0.25 Micron Technology in Microwind" 1. ObjectiveSheikh Abdullah Al SalmanNessuna valutazione finora

- Nmos Design Rules LayoutDocumento53 pagineNmos Design Rules Layouttarun aggarwalNessuna valutazione finora

- MOSFET CapacitancesDocumento19 pagineMOSFET CapacitancesAnushkaNessuna valutazione finora

- 11 - Small-Signal Transistor Amplifiers PDFDocumento14 pagine11 - Small-Signal Transistor Amplifiers PDFsgw67100% (1)

- GATE EE 2015 Solved PaperDocumento629 pagineGATE EE 2015 Solved PaperDeepakKumar100% (1)

- g5250 r2.1 GMTDocumento14 pagineg5250 r2.1 GMTPoon Electronic Training CentreNessuna valutazione finora

- Kdl40d3100 LCD TVDocumento73 pagineKdl40d3100 LCD TVRM200Nessuna valutazione finora

- Transimpedance Amplifier / Current To Voltage ConverterDocumento2 pagineTransimpedance Amplifier / Current To Voltage ConverterAmrendra Kumar MishraNessuna valutazione finora

- Irf9540, Irf9541, Irf9542, Irf9543, RF1S9540, RF1S9540SMDocumento7 pagineIrf9540, Irf9541, Irf9542, Irf9543, RF1S9540, RF1S9540SMcombra24grNessuna valutazione finora

- Layout Design RuleDocumento71 pagineLayout Design RuleSuja Ganesan100% (7)

- MIT Subthreshold OperationDocumento29 pagineMIT Subthreshold Operationsanjeevsoni64Nessuna valutazione finora

- Cree CGH 25120FDocumento12 pagineCree CGH 25120FQazi KamalNessuna valutazione finora

- MDD7N25Documento6 pagineMDD7N25José Manuel Izea NavarroNessuna valutazione finora

- FINFETDocumento15 pagineFINFETPrajwal GowdaNessuna valutazione finora

- RF Operation 1-15Mhz: Arf444 300W 300V 13.56Mhz Arf445 300W 300V 13.56MhzDocumento4 pagineRF Operation 1-15Mhz: Arf444 300W 300V 13.56Mhz Arf445 300W 300V 13.56MhzSuresh KurumaNessuna valutazione finora

- Environmental Science: PaperDocumento8 pagineEnvironmental Science: Paperbelqis ratuNessuna valutazione finora

- Double-Gate Tunnel FET With High-Gate Dielectric: Kathy Boucart and Adrian Mihai Ionescu, Member, IEEEDocumento9 pagineDouble-Gate Tunnel FET With High-Gate Dielectric: Kathy Boucart and Adrian Mihai Ionescu, Member, IEEEavril lavingneNessuna valutazione finora

- BITS Pilani IC Fabrication LectureDocumento44 pagineBITS Pilani IC Fabrication LectureKrishnaNessuna valutazione finora

- N-Channel Powertrench Mosfet: 30V, 7A, 23M General Description FeaturesDocumento6 pagineN-Channel Powertrench Mosfet: 30V, 7A, 23M General Description FeaturesLuis CarlosNessuna valutazione finora

- The Importance of Being Earnest: Classic Tales EditionDa EverandThe Importance of Being Earnest: Classic Tales EditionValutazione: 4.5 su 5 stelle4.5/5 (42)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherDa EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNessuna valutazione finora

- Other People's Dirt: A Housecleaner's Curious AdventuresDa EverandOther People's Dirt: A Housecleaner's Curious AdventuresValutazione: 3.5 su 5 stelle3.5/5 (104)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtDa EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtValutazione: 4 su 5 stelle4/5 (60)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticDa EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticValutazione: 3.5 su 5 stelle3.5/5 (10)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedDa EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedValutazione: 4.5 su 5 stelle4.5/5 (5)

- The Inimitable Jeeves [Classic Tales Edition]Da EverandThe Inimitable Jeeves [Classic Tales Edition]Valutazione: 5 su 5 stelle5/5 (3)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesDa EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesValutazione: 3.5 su 5 stelle3.5/5 (7)

- Spoiler Alert: You're Gonna Die: Unveiling Death One Question at a TimeDa EverandSpoiler Alert: You're Gonna Die: Unveiling Death One Question at a TimeValutazione: 4 su 5 stelle4/5 (57)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogDa EverandLessons from Tara: Life Advice from the World's Most Brilliant DogValutazione: 4.5 su 5 stelle4.5/5 (42)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolDa EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolValutazione: 4 su 5 stelle4/5 (14)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreDa EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreNessuna valutazione finora

- The Comedians in Cars Getting Coffee BookDa EverandThe Comedians in Cars Getting Coffee BookValutazione: 4.5 su 5 stelle4.5/5 (8)

- My Man, Jeeves, The Inimitable Jeeves and Right Ho, Jeeves - THREE P.G. Wodehouse Classics! - UnabridgedDa EverandMy Man, Jeeves, The Inimitable Jeeves and Right Ho, Jeeves - THREE P.G. Wodehouse Classics! - UnabridgedNessuna valutazione finora

- Si-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleDa EverandSi-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleValutazione: 4.5 su 5 stelle4.5/5 (16)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)