Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manual Unigraphics NX - 09 The Master Model

Caricato da

thiagomcasimiroDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manual Unigraphics NX - 09 The Master Model

Caricato da

thiagomcasimiroCopyright:

Formati disponibili

The Master Model

The Master Model

Lesson 9

PURPOSE

To introduce the Master Model concept.

OBJECTIVES Upon completion of this lesson, you will be able to:

D D

Review an existing Master Model. Create a new Master Model.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-1

The Master Model

The Assembly Modeler

The Unigraphics assembly is a file containing stored links to the part files that are pieces of the assembly. The geometry that defines the piece parts of the assembly resides in the original part file only, there is no duplication in the assembly file. A link in the assembly file is referred to as a component object. A component object stores information about the piece part such as its location, attributes, origin, orientation, permissions, degree of display, and its relationship to other parts.

The Master Model Concept

Applying the Master Model Concept in a Drafting situation is simply the creation of an assembly consisting of one component part. It is valuable as a means of promoting concurrent engineering. The person responsible for the design of a part is not the same person responsible for all of the downstream applications performed on the part. These downstream applications may include drafting, manufacturing, analysis, etc. The Master Model Concept is also valuable in protecting the design intent of the part from inadvertent corruption by a downstream user. The downstream user will have write privileges to the assembly file, but only read privileges to the model. The solid model is referenced for the application work, but the downstream user will not have the ability to change it.

Because the application information in the assembly or non-master file is referencing the original master model part, edits to the master model will be updated in the non-master part file. Implementing Master Model theory allows diverse yet dependent design processes to access the same master geometry during development. Therefore, the entire part creation process becomes more efficient allowing many disciplines to work at the same time and allowing master model edits to be automatically updated in non-master parts.

9-2

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model

The power of implementing a Master Model is that the independent design processes are dependent on the same master geometry during development.

Drafting

Assembly

Master Model

Analysis

N/C

Each application uses a separate assembly file. When the Master Model is revised, the other applications will automatically update with minimal or no associativity loss. The design intent of the various design applications can be maintained through protection of the Master Model.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-3

The Master Model

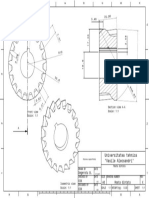

Master Model Example

Manufacturing engineers have the need to design fixture devices, define machining operations, and designate cutter tools and save this data in their models. By creating a manufacturing assembly" and adding a component to it, they can then generate their application specific geometry or data in a separate part file which references the master geometry:

D D

This avoids duplication of model geometry Different users can work in separate files simultaneously

(owned by manufacturing engineer)

abcd1234_mfg.prt

Contains manufacturing data and a component object which references master model part

(owned by designer)

abcd1234.prt

Contains master model geometry

The manufacturing engineer has ownership of the assembly file without necessarily having write access to the master model which is owned by the designer.

9-4

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model

Master Model Drawing Guidelines

D D D D D D D

1. Create the 'drawing' file (Open seedpart_mm or seedpart_in, FILESAVE AS, xxxxxxx_dwg) 2. Start the Assemblies application (APPLICATIONASSEMBLIES) 3. Add the part to be detailed as a component (ASSEMBLIES COMPONENTSADD EXISTING) 4. Change to the Drafting Application (APPLICATIONDRAFTING) 5. Adjust the paper; name, units, size, projection angle (DRAWINGEDIT) 6. Add the drawing formats; title block, border, revision block, standard notes (Site dependent) 7. Set View Display Preferences; hidden line removal, section backgrounds, threads (PREFERENCES VIEW DISPLAY) 8. Add the first 'Imported' view; typically top or front (DRAWINGADD VIEWIMPORT VIEW) 9. Add more views; orthographic, detail, auxiliary, section, isometric, exploded (DRAWINGADD VIEWORTHOGRAPHIC VIEW) 10. Adjust the views; scale, move, align, remove (DRAWINGEDIT VIEW) 11. Adjust the View Display Preferences, per view (PREFERENCES VIEW DISPLAY) 12. Clean up individual views with view dependent edits; erase object, edit entire object, edit object segment (EDITVIEW DEPENDENT EDIT) 13. Add the Utility Symbols; centerlines, target symbols, intersection symbols (INSERTUTILITY SYMBOL) 14. Add the dimensions (INSERTDIMENSION) 15. Add the notes, labels, and GD&T's (INSERTANNOTATION)

D D

D D D

D D

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-5

The Master Model

Activity 1 - Exploring a Master Model Assembly

This activity will demonstrate the advantages of a Master Model Assembly. Step 1 Choose File"Options"Load Options and ensure that the Load Method is From Directory.

Step 2 Open the part file pau_tapedisp_dwg. Make sure that you are selecting pau_tapedisp_dwg.

Step 3 Choose Drafting. Step 4 Inspect the drawing for dimensional values.

-

Zoom in on section view A-A and note the slot width of .88 and the corner radius of .12. Both dimensions have been rounded from the model dimensions to two decimal places.

Slot Width

Corner Radius

9-6

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model -

Restore the view and note the drawing name, SH1, at the lower left corner.

Step 5 Investigate the model.

Choose Modeling. Choose InformationFeature and note that there are no features. Choose ToolsExpression and note that there are no expressions. Choose AssembliesReportsList Components.

An information window appears showing the assembly file structure for the file pau_tapedisp_dwg and indicates that there is one component named pau_tapedisp. This part contains the Master Model definition.

9

Close the information window.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-7

The Master Model

Step 6 Examine the display.

-

Choose InformationObject. Place the cursor over the solid body. When the cursor changes to the cross with the ellipsis (+...) select once. Pass the cursor over the numbers in the QuickPick window until the solid body is highlighted, then select it. Choose OK.

An information window appears with information regarding the solid, its owning part, and confirmation that it is a component.

Dismiss the information window.

Step 7 Retrieve the Master Model file.

Choose Open. Choose pau_tapedisp from the list box.

Step 8 Edit the expression for Roll_width to .75

-

Choose ToolsExpression.

9-8

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model -

Select the Roll_width expression.

Replace the .875 value with .75 and choose OK.

The opening for the tape roll changes in width to accommodate the modified dimension. Step 9 Edit the blend on the inside of the spool cavity.

-

Choose EditFeatureParameters.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-9

The Master Model -

Select the Blend(21) feature at the bottom of the list. Confirm the selection with OK.

In the Radius Dynamic Input Field, key in a new value of .06.

Choose OK. Choose OK.

Step 10 Change Displayed Part to pau_tapedisp_dwg.

-

Choose Windowpau_tapedisp_dwg to change the Displayed Part.

Choose Drafting.

Notice the drawing name now shows (OUT-OF-DATE) to remind you the views are not updated.

9-10

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model

Step 11 Update the drawing.

-

Choose DrawingUpdate Views. Choose All in the Update Views dialog box and choose OK.

Step 12 Zoom in on section A-A again to see the changes to the master model reflected on the drawing

Slot Width

Corner Radius

Step 13 Choose File"Close"All Parts.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-11

The Master Model

Activity 2 - Creating a Master Model Assembly

This activity will demonstrate creation of a Master Model Assembly. Step 1 Open the part file pau_seedpart_in. Step 2 Save the part as ***_dwg_1 where *** represent your initials. Step 3 Add the part pau_dwg_1 to the discipline specific assembly file.

-

Check to see the Assemblies application is toggled on (Choose ApplicationAssemblies, if it is not on). Choose the Add Existing Component icon. Choose the Choose Part File button. Choose pau_dwg_1 from the parts directory, then OK. Change the Positioning option to Absolute. Choose BODY from the Reference Set pull down and choose OK. Press Reset in the Point Constructor dialog box, followed by OK to locate the part at Zero.

Step 4 Choose Save. Step 5 Choose File"Close"All Parts.

9-12

Practical Applications of Unigraphics Student Manual

EDS All Rights Reserved

Unigraphics NX

The Master Model

SUMMARY

This Master Model approach offers many benefits to Unigraphics customers. If these two files were readprotected by different departments, distinct responsibilities would be enforced by the protection and yet all of the appropriate model data is shared by each of the departments concerned. Users can access whatever they want, whenever they want with full confidence that no data or revision work can be lost without active confirmation by the users.

EDS All Rights Reserved

Practical Applications of Unigraphics Student Manual

9-13

Potrebbero piacerti anche

- Gravimetric Determination of Condensable Components: Group StandardDocumento6 pagineGravimetric Determination of Condensable Components: Group Standardthiagomcasimiro100% (1)

- SOLIDWORKS Simulation 2016: A Tutorial ApproachDa EverandSOLIDWORKS Simulation 2016: A Tutorial ApproachValutazione: 5 su 5 stelle5/5 (1)

- NX WAVE Control Structure TutorialDocumento31 pagineNX WAVE Control Structure TutorialTomas Lopez100% (1)

- SolidWorks Surfacing and Complex Shape Modeling BibleDa EverandSolidWorks Surfacing and Complex Shape Modeling BibleNessuna valutazione finora

- ANSYS TurboGrid IntroductionDocumento24 pagineANSYS TurboGrid IntroductionTech MitNessuna valutazione finora

- Designing A StaplerDocumento41 pagineDesigning A StaplerEmmanuel Morales ChilacaNessuna valutazione finora

- Autodesk Inventor - Authoring and Publishing Frame Member Cross-SectionsDocumento8 pagineAutodesk Inventor - Authoring and Publishing Frame Member Cross-SectionsNdianabasi UdonkangNessuna valutazione finora

- Routing - Pipes and TubesDocumento27 pagineRouting - Pipes and TubesricoNessuna valutazione finora

- Learning Autodesk Revit Architecture 2013 PDFDocumento1 paginaLearning Autodesk Revit Architecture 2013 PDFJustSommieNessuna valutazione finora

- Downloaded From WWW - ETTV.tvDocumento1 paginaDownloaded From WWW - ETTV.tvCryNessuna valutazione finora

- Drawing For Architecture JuliaDocumento20 pagineDrawing For Architecture JuliaAntonio Salazar MarrufoNessuna valutazione finora

- ICT CSS 9 Budget of Work 2nd QuarterDocumento3 pagineICT CSS 9 Budget of Work 2nd QuarterJinky Barbie50% (2)

- AutoCAD 2016: A Problem-Solving Approach, Basic and IntermediateDa EverandAutoCAD 2016: A Problem-Solving Approach, Basic and IntermediateValutazione: 3 su 5 stelle3/5 (6)

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsDa EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNessuna valutazione finora

- Pro E Advanced Tutorial W4Documento25 paginePro E Advanced Tutorial W4boubastarNessuna valutazione finora

- Pro/ENGINEER Mechanica Wildfire 4.0: Andy Deighton PTCDocumento50 paginePro/ENGINEER Mechanica Wildfire 4.0: Andy Deighton PTCboubastarNessuna valutazione finora

- Basic: Cad-Based For Greater PowerDocumento2 pagineBasic: Cad-Based For Greater PowerraduvascautiNessuna valutazione finora

- ProE Surfacing - Module 1Documento52 pagineProE Surfacing - Module 1inthemoney8100% (1)

- NX 12 - 5-Surface ModelingDocumento34 pagineNX 12 - 5-Surface Modelingdavidjone90100% (1)

- EDU CAT EN V5E AF V5R16 Lesson7 Toprint7 PDFDocumento189 pagineEDU CAT EN V5E AF V5R16 Lesson7 Toprint7 PDFleydonhdNessuna valutazione finora

- Machining CatiaDocumento327 pagineMachining Catiabodo87_eugenNessuna valutazione finora

- NX Shortcuts ExpressionsDocumento2 pagineNX Shortcuts ExpressionsConrad54Nessuna valutazione finora

- S.Balamurugan: Asst - Prof (SR.G) Departement of Mechanical Engineering SRM UniversityDocumento38 pagineS.Balamurugan: Asst - Prof (SR.G) Departement of Mechanical Engineering SRM UniversityPradeepvenugopalNessuna valutazione finora

- C16 NX11 PDFDocumento82 pagineC16 NX11 PDFVignesh WaranNessuna valutazione finora

- L&T: Project Tow: Designing / Value Engineering A Tow Hitch ReceiverDocumento41 pagineL&T: Project Tow: Designing / Value Engineering A Tow Hitch ReceiverAnubhav Felix DasguptaNessuna valutazione finora

- Create Assembly Model Top DownDocumento8 pagineCreate Assembly Model Top Downsorry can'thelpitNessuna valutazione finora

- Basic Pro-E Ques and AnswerDocumento14 pagineBasic Pro-E Ques and Answerapi-3808872100% (1)

- 001 PDFDocumento14 pagine001 PDFjayakumarNessuna valutazione finora

- NX Progressive Die DesignDocumento3 pagineNX Progressive Die Designbadboys123Nessuna valutazione finora

- NX Environment VariablesDocumento6 pagineNX Environment VariablesrammedaNessuna valutazione finora

- Instruction Design With Studio ShapeDocumento124 pagineInstruction Design With Studio ShapenghiaNessuna valutazione finora

- PowerMill 2019 Feature Comparison MatrixDocumento2 paginePowerMill 2019 Feature Comparison MatrixBojan RadovanovicNessuna valutazione finora

- PARTICIPANT WORKBOOK Pro-EDocumento164 paginePARTICIPANT WORKBOOK Pro-ESouvik SingharoyNessuna valutazione finora

- Introduction To Injection Mold Design: Learning ObjectivesDocumento82 pagineIntroduction To Injection Mold Design: Learning ObjectivesVignesh WaranNessuna valutazione finora

- NX Assign Material PropertiesDocumento54 pagineNX Assign Material PropertiesbiondavNessuna valutazione finora

- Part Design PDFDocumento244 paginePart Design PDFOstromafNessuna valutazione finora

- Notes - Catia Free Style PDFDocumento350 pagineNotes - Catia Free Style PDFsaimanju1890100% (1)

- Flow Sim Studentwb 2011 EngDocumento36 pagineFlow Sim Studentwb 2011 EngCarl VincentNessuna valutazione finora

- Wireframe and Surface Design: CATIA TrainingDocumento208 pagineWireframe and Surface Design: CATIA TrainingHomer Texido FrangioniNessuna valutazione finora

- Manual Unigraphics NX - 13 SketchingDocumento108 pagineManual Unigraphics NX - 13 SketchingWagner AndradeNessuna valutazione finora

- Open Learning Book CadDocumento348 pagineOpen Learning Book CadLoughton BtyNessuna valutazione finora

- Exercises WireframeandSurfaceDocumento107 pagineExercises WireframeandSurfaceTam BotNessuna valutazione finora

- Basic To Advanced CAD Using NX 12 Sample PDFDocumento29 pagineBasic To Advanced CAD Using NX 12 Sample PDFYaseen JamilNessuna valutazione finora

- Autodesk Inventor - Using Splines and SurfacesDocumento20 pagineAutodesk Inventor - Using Splines and SurfacesNdianabasi UdonkangNessuna valutazione finora

- Autodesk Tube An Pipe Aplications 1Documento7 pagineAutodesk Tube An Pipe Aplications 1Billy ZununNessuna valutazione finora

- Creo 80 Enhancement Summary DeckDocumento106 pagineCreo 80 Enhancement Summary DeckMuhammad AtifNessuna valutazione finora

- Core and Cavity ExtractionDocumento129 pagineCore and Cavity ExtractionSaggam Narasimharaju100% (1)

- Mt16020 S Nx8 Sheet MetalDocumento401 pagineMt16020 S Nx8 Sheet MetalIsaque SilvaNessuna valutazione finora

- NX7 For Engineers and DesignersDocumento1 paginaNX7 For Engineers and DesignersDreamtech Press100% (1)

- Catia Syllabus Duration:-60 HoursDocumento7 pagineCatia Syllabus Duration:-60 HoursprabhakarNessuna valutazione finora

- Designing and Manufacturing Ruled Surface Blades: Peter Klein, CAM Software Director, Concepts NRECDocumento6 pagineDesigning and Manufacturing Ruled Surface Blades: Peter Klein, CAM Software Director, Concepts NRECCésarNessuna valutazione finora

- Generally Specific: Data Driven Formwork' Used To Generate An Active Thermal EnvelopeDocumento42 pagineGenerally Specific: Data Driven Formwork' Used To Generate An Active Thermal Envelopekb2543Nessuna valutazione finora

- NX9.0 Manual PDFDocumento240 pagineNX9.0 Manual PDFToni Pérez100% (3)

- CATIA V5 Mechanical DesignerDocumento6 pagineCATIA V5 Mechanical DesignerKALIDAS MANU.MNessuna valutazione finora

- Design For Assembly A Complete Guide - 2020 EditionDa EverandDesign For Assembly A Complete Guide - 2020 EditionNessuna valutazione finora

- Branded Liner - Technical Update - February2016Documento2 pagineBranded Liner - Technical Update - February2016thiagomcasimiroNessuna valutazione finora

- Totalseal 1169Documento2 pagineTotalseal 1169thiagomcasimiroNessuna valutazione finora

- PDF Data Sheet - 3M PT Series TapesDocumento4 paginePDF Data Sheet - 3M PT Series TapesthiagomcasimiroNessuna valutazione finora

- Maximizing The Benefits of 3D Printing With Facet ModelingDocumento10 pagineMaximizing The Benefits of 3D Printing With Facet ModelingthiagomcasimiroNessuna valutazione finora

- Lenovo Z2 Plus Review: How Does It Fare?Documento8 pagineLenovo Z2 Plus Review: How Does It Fare?thiagomcasimiroNessuna valutazione finora

- InstructionsDocumento1 paginaInstructionsthiagomcasimiroNessuna valutazione finora

- Powerful English Speaking - A.J.hogeDocumento14 paginePowerful English Speaking - A.J.hogeSpongeBobLongPants50% (2)

- WWRG Read Me!Documento1 paginaWWRG Read Me!thiagomcasimiroNessuna valutazione finora

- Welcome GuideDocumento4 pagineWelcome GuideكارينكاجوNessuna valutazione finora

- Lesson 22 - Sentences For Anki En-EnDocumento7 pagineLesson 22 - Sentences For Anki En-EnthiagomcasimiroNessuna valutazione finora

- Lesson 22 - Knock Out, Brush Off, and Build UpDocumento5 pagineLesson 22 - Knock Out, Brush Off, and Build UpthiagomcasimiroNessuna valutazione finora

- UG-NX TutorialDocumento235 pagineUG-NX Tutorialesrayansenkeliat50% (2)

- Lesson 22 - Sentences For Anki en-PTDocumento9 pagineLesson 22 - Sentences For Anki en-PTthiagomcasimiroNessuna valutazione finora

- Aula 44 - Curso InglesDocumento2 pagineAula 44 - Curso InglesthiagomcasimiroNessuna valutazione finora

- Catalagol Huhoco PDFDocumento19 pagineCatalagol Huhoco PDFthiagomcasimiroNessuna valutazione finora

- Trigonometry PDFDocumento1 paginaTrigonometry PDFVanderson De Andrade SantosNessuna valutazione finora

- Skype Third Party AttributionsDocumento12 pagineSkype Third Party AttributionsdalordetriusNessuna valutazione finora

- 2008-11-04a Benchmark Copetitors (Thiel)Documento46 pagine2008-11-04a Benchmark Copetitors (Thiel)thiagomcasimiroNessuna valutazione finora

- Manual Unigraphics NX - 05 Face OperationsDocumento12 pagineManual Unigraphics NX - 05 Face OperationsthiagomcasimiroNessuna valutazione finora

- Excercice Catia v5 BookDocumento207 pagineExcercice Catia v5 BookthiagomcasimiroNessuna valutazione finora

- Manual Unigraphics NX - 08 Introduction To AssembliesDocumento34 pagineManual Unigraphics NX - 08 Introduction To AssembliesthiagomcasimiroNessuna valutazione finora

- Manual Tekla Structures Ingles.Documento663 pagineManual Tekla Structures Ingles.Andres Hugo GalloNessuna valutazione finora

- CATIA Fry BasketDocumento135 pagineCATIA Fry BasketPuix Ozil TherPanzerNessuna valutazione finora

- AliasDesign - Sketching A Car in 12 StepsDocumento1 paginaAliasDesign - Sketching A Car in 12 StepsthiagomcasimiroNessuna valutazione finora

- Free Resources For 3D Artists - Blender DailyDocumento2 pagineFree Resources For 3D Artists - Blender DailyShreyash BadoleNessuna valutazione finora

- Joseph Guardino ParenoDocumento4 pagineJoseph Guardino ParenodomieneilsalasNessuna valutazione finora

- Engineering Graphics 1E9: Lecture 5: PerspectiveDocumento40 pagineEngineering Graphics 1E9: Lecture 5: PerspectivevenkiteshksNessuna valutazione finora

- Tle Computer Systems Servicing - 9: Let Us DiscoverDocumento4 pagineTle Computer Systems Servicing - 9: Let Us DiscoverWilma Montis-AbendanNessuna valutazione finora

- Ebook FloorplansDocumento29 pagineEbook FloorplansHorace PaisleyNessuna valutazione finora

- Drawing and EstimatesDocumento359 pagineDrawing and EstimatesceanilNessuna valutazione finora

- TLE-EPAS Module 9Documento29 pagineTLE-EPAS Module 9franz.aguilanNessuna valutazione finora

- DQ - CRAB For Lyo LoadingDocumento30 pagineDQ - CRAB For Lyo Loadingdhanu_lagwankarNessuna valutazione finora

- Kenneths Resume2003docxDocumento2 pagineKenneths Resume2003docxKenneth Lewis Calvin JordanNessuna valutazione finora

- Technical Drawing 8 (Quarter 2 - Week 8)Documento4 pagineTechnical Drawing 8 (Quarter 2 - Week 8)chaNessuna valutazione finora

- Roadway Design Using InRoads XM - CurriculumDocumento6 pagineRoadway Design Using InRoads XM - CurriculumjimmyNessuna valutazione finora

- Detailed Lesson Plan. Drafting - Final DemoDocumento15 pagineDetailed Lesson Plan. Drafting - Final DemoMhiejhayyNessuna valutazione finora

- Universitatea Tehnica "Vasile Alecsandri": XXX A3 X Degeratu B. Roata DintataDocumento1 paginaUniversitatea Tehnica "Vasile Alecsandri": XXX A3 X Degeratu B. Roata DintataCazan StelianNessuna valutazione finora

- Module No.5 Draft Architectural Layout and DetailsDocumento32 pagineModule No.5 Draft Architectural Layout and DetailsJay S. On100% (3)

- TR Scaffold Erection NC IiDocumento64 pagineTR Scaffold Erection NC IiAtoniya Skills Education INC100% (1)

- ArchiCAD 16 - Help Center - ArchiCAD, BIMx, BIM Server Knowledge Base From GRAPHISOFTDocumento19 pagineArchiCAD 16 - Help Center - ArchiCAD, BIMx, BIM Server Knowledge Base From GRAPHISOFTGabriel KarikasNessuna valutazione finora

- Working Drawing: Staking PlanDocumento5 pagineWorking Drawing: Staking PlanKarl Joseph PaladaNessuna valutazione finora

- Building Information Modeling (BIM) The Untapped Potential For Preservation Documentation and ManagementDocumento169 pagineBuilding Information Modeling (BIM) The Untapped Potential For Preservation Documentation and ManagementKhalidAlsadaniNessuna valutazione finora

- TechDraw 7 Q1Documento52 pagineTechDraw 7 Q1Fritz Private8654100% (1)

- Cad DraftsmanDocumento4 pagineCad DraftsmanPramod KumarNessuna valutazione finora

- 20ME12P Unit 04 Orthographic To Isometric ProjectionsDocumento10 pagine20ME12P Unit 04 Orthographic To Isometric ProjectionsThanmay JSNessuna valutazione finora

- Assembly and Detail Drawings ReadingDocumento5 pagineAssembly and Detail Drawings ReadingJeyEnDee 20Nessuna valutazione finora

- Engineering GraphicsDocumento23 pagineEngineering Graphicsk4r7hyNessuna valutazione finora

- DraftingDocumento17 pagineDraftingroiNessuna valutazione finora

- AutoCAD 2018 Essential TrainingDocumento3 pagineAutoCAD 2018 Essential TraininglaikienfuiNessuna valutazione finora

- Engineering - GR 2008 CAD StandardsDocumento63 pagineEngineering - GR 2008 CAD Standardscadcamcae01Nessuna valutazione finora

- Evidence - Writing My Personal StatementDocumento2 pagineEvidence - Writing My Personal StatementJose Leonardo Cabrejo100% (1)

- Dassault Systemes: XXX User A3 XXX X XXXDocumento1 paginaDassault Systemes: XXX User A3 XXX X XXXdouglas issomesmoNessuna valutazione finora