Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design of Transmission Systems 1key 1

Caricato da

srajapratyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design of Transmission Systems 1key 1

Caricato da

srajapratyCopyright:

Formati disponibili

REGULATION : 2003 B.E.

DEGREE EXAMINATION, APRIL 2006 Mechanical Engineering 03M603 Design of Transmission Systems Use of Approved Data book is permitted Time : Three hours Answer ALL questions UNIT I 1.a. 1.b. Write short notes on timing belts - 2 marks Design a V belt drive for the following dimensions. Driving pulley diameter : 500 mm Driven pulley diameter : 150 mm Speed of driving pulley : 300 rpm Center distance : 925 mm Power to be transmitted : 7.5 kW. - 18 marks OR 2.a. 2.b. Write short notes on rope lay - 4 marks Design a chain drive to run a compressor from a 11 kW electric motor running at 970 rpm. The speed of compressor is 330 rpm. The compressor operates 16 hours / day. The center distance is about 500 mm. The tension in the chain may be adjusted by shifting the motor on rails - 16 marks UNIT II What is the use of Load correction factor in the design of spur gears? - 2 marks Design a straight spur gear drive for transmitting a power of 8 kW with a pinion speed of 764 rpm. Speed ratio is 2. The gears are to be made of C45 steel. Life is to be 10,000 hours. - 18 marks OR Why the minimum number of teeth should be maintained as 17 for spur gears? - 2 marks A pair of straight teeth spur gears is to transmit 20 kW when the pinion rotates at 300 rpm. The velocity ratio is 1:3. The allowable static stresses for the pinion and gear materials are 120 MPa and 100MPa respectively. The pinion has 15 teeth and its face width is 14 times the module. Determine 1. module, 2. face width and 3. pitch circle diameters of both pinion and gear from the standpoint of view of strength only, with out taking into consideration of the effect of the dynamic loading. The tooth form factor y = 0.154 expressed in m/sec. 5.a.

0.912 3 ; and the velocity factor C v = , v is the velocity Z 3+v

Max: 5 x 20 = 100 marks

3.a. 3.b.

4.a. 4.b.

18 marks

UNIT III List out the advantages and disadvantages of helical gear - 2 marks

5.b.

6.a. 6.b. 6.c.

7.

8.

Design a bevel gear drive to transmit 3.5 kW. Speed ratio = 4. Driving shaft speed is 200 rpm. The drive is non reversible. The pinion is made of Steel whereas wheel is of CI. Assume a life of 25,000 hrs. - 18 marks OR What do you mean by Zero bevel gear? - 2 marks In which condition of shafting, worm gears are used, and What is major failure for worm gear drive? - 2 marks Design a worm gear drive to transmit 22.5 kW at a worm speed of 1440 rpm. Velocity ratio is 24:1. An efficiency of atleast 85% is desired. The temperature rise should be restricted to 400C. - 16 marks UNIT IV The spindle of a pillar drill is to run at 12 different speeds in the range of 100 rpm and 355 rpm. Design a three stage gear box with a standard step ratio. Sketch the layout of the gear box, indicating the number of teeth on each gear. The gear box receives 5 kW from an electric motor running at 360 rpm. Sketch also the speed diagram. OR Draw the kinematic diagram and speed diagram of the gear box in a head stock of a lathe having 9 spindle speeds ranging from 31.5 rpm to 1050 rpm. Calculate the number of teeth on all gears if the minimum number of teeth is 25. Also calculate the % of deviation in speeds. UNIT V List out the factors to be considered while designing a friction clutch.

9.a. 9.b.

- 6 marks A leather faced conical clutch has cone angle of 300. The pressure between the contact surface is limited to 0.35 N/mm2 and the breadth of the conical surface is not to exceed 1/3 of the mean radius. Determine the dimensions of the contact surface to transmit 22 kW at 2000 rpm. Also calculate the force required to engage the clutch. Take the coefficient of friction as 0.15. - 14 marks OR 10.a. List the desirable characteristics of brake lining material - 6 marks 10.b. A differential band brake is to be used for a winch lifting a load of 45 kN through a rope wound around a barrel of 500 mm in diameter. The brake drum to be keyed to the same shaft is to be 600 mm in diameter and the angle of lap of the brake band over the drum is 2500 approximately. Determine the width and thickness of the band. Operating arms of the brake are 40 mm and 200 mm and the operating lever is 1.5 m long. - 14 marks

Potrebbero piacerti anche

- Design of Transmission Systems 3Documento2 pagineDesign of Transmission Systems 3srajapratyNessuna valutazione finora

- Me 1352Documento6 pagineMe 1352arunramakrishnanNessuna valutazione finora

- Designn of Tranmission SystemDocumento4 pagineDesignn of Tranmission Systemsathiskumar411Nessuna valutazione finora

- Design of Transmission Systems Question BankDocumento10 pagineDesign of Transmission Systems Question BankDesejo SozinandoNessuna valutazione finora

- Me 2352 - DTS Q BankDocumento5 pagineMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- Me-1352 Design of Transmission SystemDocumento7 pagineMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Design of Transmission Systems 10Documento2 pagineDesign of Transmission Systems 10srajapratyNessuna valutazione finora

- Design of Transmission Systems - Important QuestonsDocumento5 pagineDesign of Transmission Systems - Important QuestonsPost BoxNessuna valutazione finora

- Dts Important Ques 2 16 MarksDocumento5 pagineDts Important Ques 2 16 MarksBas RamuNessuna valutazione finora

- ME2352 Design of Transmission Question BankDocumento4 pagineME2352 Design of Transmission Question BankKarthik SubramaniNessuna valutazione finora

- Design of Transmission ElementDocumento42 pagineDesign of Transmission ElementVenkatesh MohanNessuna valutazione finora

- MD II Machine Design AssignmentsDocumento5 pagineMD II Machine Design Assignmentsrishabhk28995Nessuna valutazione finora

- ME6601.16 MarksDocumento6 pagineME6601.16 Markssathiskumar411Nessuna valutazione finora

- Te 2008Documento273 pagineTe 2008Smith KashidNessuna valutazione finora

- Dts Model Que Type B 2018-19Documento2 pagineDts Model Que Type B 2018-19rammit2007Nessuna valutazione finora

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Documento3 pagineJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixNessuna valutazione finora

- Design of Transmission SystemsDocumento6 pagineDesign of Transmission SystemsSelva KumarNessuna valutazione finora

- MD2 Model QuestionsDocumento2 pagineMD2 Model Questionsmanish sharmaNessuna valutazione finora

- Design of Transmission System-QbDocumento5 pagineDesign of Transmission System-QbGanapathi SekaranNessuna valutazione finora

- 12 Me 5dcdm2Documento3 pagine12 Me 5dcdm2Abhyudaya SinghNessuna valutazione finora

- Question Paper Code:: (10×2 20 Marks)Documento3 pagineQuestion Paper Code:: (10×2 20 Marks)PradeepNessuna valutazione finora

- Design of Transmission SystemsDocumento3 pagineDesign of Transmission SystemsSaravanan KumarNessuna valutazione finora

- Question Paper Code:: (10×2 20 Marks)Documento3 pagineQuestion Paper Code:: (10×2 20 Marks)PradeepNessuna valutazione finora

- Design of Transmission Systems Model ExamDocumento3 pagineDesign of Transmission Systems Model ExamrajkumardotcomNessuna valutazione finora

- Projects For Lab BDocumento91 pagineProjects For Lab BPeter AshrafNessuna valutazione finora

- Design of Transmission System Question BankDocumento18 pagineDesign of Transmission System Question BankAravind50% (2)

- Machine Design-II Question BankDocumento32 pagineMachine Design-II Question BankAbhishek SakatNessuna valutazione finora

- ME6601 QbsdfwsdfsDocumento8 pagineME6601 QbsdfwsdfsvivekzzNessuna valutazione finora

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocumento2 pagine2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNessuna valutazione finora

- Me0405 7 SemDocumento2 pagineMe0405 7 SemSurya BalamuruganNessuna valutazione finora

- WWW Manaresults Co inDocumento4 pagineWWW Manaresults Co inGod deva123Nessuna valutazione finora

- Design of Transmission Systems examDocumento3 pagineDesign of Transmission Systems examCyril JasonNessuna valutazione finora

- Sathyabama University: Register NumberDocumento3 pagineSathyabama University: Register NumberSecret SecretNessuna valutazione finora

- DTS QBDocumento19 pagineDTS QBHem KumarNessuna valutazione finora

- Belt Types and Wire Rope ApplicationsDocumento14 pagineBelt Types and Wire Rope ApplicationsmechfameNessuna valutazione finora

- Iat-I QPDocumento2 pagineIat-I QPBalaChandarNessuna valutazione finora

- Moun T Zio N Col L Ege of Enginee Rin G & Technol Ogy: Department of Mechanical EngineeringDocumento1 paginaMoun T Zio N Col L Ege of Enginee Rin G & Technol Ogy: Department of Mechanical EngineeringAzaath AzuNessuna valutazione finora

- Design of Machine Elements-II Exam QuestionsDocumento9 pagineDesign of Machine Elements-II Exam QuestionsPrasinNessuna valutazione finora

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocumento12 pagineTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96Nessuna valutazione finora

- ASSIGNMENTS OF MD II New FormatDocumento15 pagineASSIGNMENTS OF MD II New Formatsushant vermaNessuna valutazione finora

- DMM Ii (2015)Documento35 pagineDMM Ii (2015)gorijalaNessuna valutazione finora

- ME2352-DTS Question BankDocumento8 pagineME2352-DTS Question BankNaresh015Nessuna valutazione finora

- ME6601 Transmission Design QuestionsDocumento11 pagineME6601 Transmission Design QuestionsMURUGANNessuna valutazione finora

- Supp Nov 2009Documento10 pagineSupp Nov 2009prk74Nessuna valutazione finora

- Design of Machinery Jntua Previous PapersDocumento20 pagineDesign of Machinery Jntua Previous PapersHimadhar SaduNessuna valutazione finora

- Design of Machine Elements - IIDocumento8 pagineDesign of Machine Elements - IIprasaad26Nessuna valutazione finora

- DTS ND06-QPDocumento3 pagineDTS ND06-QPsrajapratyNessuna valutazione finora

- Unit3 Premodel1Documento2 pagineUnit3 Premodel1T.V.B.BabuNessuna valutazione finora

- Me 8651Documento10 pagineMe 8651selvam cNessuna valutazione finora

- Chp1 3Documento47 pagineChp1 3Azhar BaigNessuna valutazione finora

- Diploma Board Examination - December 2020Documento2 pagineDiploma Board Examination - December 2020Pradeep AppuNessuna valutazione finora

- 181505-181902-MD - IiDocumento2 pagine181505-181902-MD - IiSiddharth PanchalNessuna valutazione finora

- Me 7 Sem Design of Mechanical Drives 3560 Summer 2019Documento2 pagineMe 7 Sem Design of Mechanical Drives 3560 Summer 2019djniksthehearteditorNessuna valutazione finora

- Me 7 Sem Design of Mechanical Drives Winter 2017Documento2 pagineMe 7 Sem Design of Mechanical Drives Winter 2017djniksthehearteditorNessuna valutazione finora

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDa EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNessuna valutazione finora

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- Energy-saving Principles and Technologies for Induction MotorsDa EverandEnergy-saving Principles and Technologies for Induction MotorsNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- DtsDocumento2 pagineDtssrajapratyNessuna valutazione finora

- Java Notes by PrinceDocumento92 pagineJava Notes by PrinceSandeep ParabNessuna valutazione finora

- GRE Practice Questions All 2Documento16 pagineGRE Practice Questions All 2mojeebmashalNessuna valutazione finora

- Fluid Mechanics and MachineryDocumento10 pagineFluid Mechanics and Machinerysrajapraty50% (2)

- Design of Transmission Systems 1 KeyDocumento9 pagineDesign of Transmission Systems 1 KeysrajapratyNessuna valutazione finora

- Design of Transmission Systems 2 MarksDocumento22 pagineDesign of Transmission Systems 2 MarkssrajapratyNessuna valutazione finora

- Design of Transmission Systems Key 2Documento12 pagineDesign of Transmission Systems Key 2srajapratyNessuna valutazione finora

- I RoboticsDocumento1 paginaI RoboticssrajapratyNessuna valutazione finora

- Me 2301 - Thermal EngineeringDocumento10 pagineMe 2301 - Thermal EngineeringsrajapratyNessuna valutazione finora

- Question Bank - FMDocumento14 pagineQuestion Bank - FMsrajapratyNessuna valutazione finora

- Me1202 - Fluid Mechanics MachineriesDocumento122 pagineMe1202 - Fluid Mechanics MachineriessrajapratyNessuna valutazione finora

- Mechanics of MachinesDocumento11 pagineMechanics of MachinessrajapratyNessuna valutazione finora

- Me 1352 - DTSDocumento8 pagineMe 1352 - DTSsrajapratyNessuna valutazione finora

- I RoboticsDocumento1 paginaI RoboticssrajapratyNessuna valutazione finora

- Thermodynamic Cycles QBDocumento8 pagineThermodynamic Cycles QBsrajapratyNessuna valutazione finora

- Me-2204 FMM Internal 1Documento2 pagineMe-2204 FMM Internal 1srajapratyNessuna valutazione finora

- Design of Transmission Systems 2 MarksDocumento22 pagineDesign of Transmission Systems 2 MarkssrajapratyNessuna valutazione finora

- Design of Transmission Systems 1 KeyDocumento9 pagineDesign of Transmission Systems 1 KeysrajapratyNessuna valutazione finora

- DtsDocumento2 pagineDtssrajapratyNessuna valutazione finora

- Design of Transmission Systems Key 2Documento12 pagineDesign of Transmission Systems Key 2srajapratyNessuna valutazione finora

- Design of Transmission Systems 1 KeyDocumento9 pagineDesign of Transmission Systems 1 KeysrajapratyNessuna valutazione finora

- Design of Transmission Systems 10Documento2 pagineDesign of Transmission Systems 10srajapratyNessuna valutazione finora

- Design of Transmission Systems 6Documento7 pagineDesign of Transmission Systems 6srajapratyNessuna valutazione finora

- Me-2204 FMM Internal 1Documento2 pagineMe-2204 FMM Internal 1srajapratyNessuna valutazione finora

- Design of Transmission Systems SyllabusDocumento1 paginaDesign of Transmission Systems SyllabussrajapratyNessuna valutazione finora

- Design of Transmission Systems 5Documento2 pagineDesign of Transmission Systems 5srajapratyNessuna valutazione finora

- Design of Transmission Systems 1 KeyDocumento9 pagineDesign of Transmission Systems 1 KeysrajapratyNessuna valutazione finora

- Design of Transmission Systems 1key 1Documento2 pagineDesign of Transmission Systems 1key 1srajapratyNessuna valutazione finora

- Machine Design 2 Quiz SolutionsDocumento2 pagineMachine Design 2 Quiz SolutionsMarc Graham NacuaNessuna valutazione finora

- GBC Parts CatalogDocumento28 pagineGBC Parts CatalogKeith RobertsNessuna valutazione finora

- 5 Troubleshooting: MSHE-112-001Documento22 pagine5 Troubleshooting: MSHE-112-001Automan IntertradeNessuna valutazione finora

- MM - 9E Planetary Axle Wheel Ends PDFDocumento41 pagineMM - 9E Planetary Axle Wheel Ends PDFPABLO ANDRES RODRIGUEZ FARIASNessuna valutazione finora

- AIWA AZG-W SvcMnlsDocumento36 pagineAIWA AZG-W SvcMnlsavrelecNessuna valutazione finora

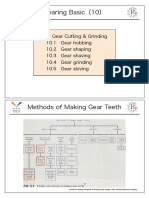

- GearingBasic 03Documento14 pagineGearingBasic 03Jojee MarieNessuna valutazione finora

- DorisDocumento78 pagineDorisjaviercj5477100% (1)

- Vespa 150 t4 ReviewDocumento56 pagineVespa 150 t4 ReviewOni Budi WicaksonoNessuna valutazione finora

- Screw Thread N GearsDocumento71 pagineScrew Thread N Gearshyundai310100% (3)

- Clutch DesignDocumento22 pagineClutch DesignLalitkumar JugulkarNessuna valutazione finora

- 85362A0Documento127 pagine85362A0Urip S. SetyadjiNessuna valutazione finora

- Fanuc Robotics System 1Documento35 pagineFanuc Robotics System 1Kevin KellyNessuna valutazione finora

- 1pf2gf - Pgf-Int-Gp-Re10213Documento20 pagine1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingNessuna valutazione finora

- Manual 9 10 13 PDFDocumento236 pagineManual 9 10 13 PDFFelipe Chimborazo100% (1)

- Review On Structural Analysis of Bevel GearDocumento3 pagineReview On Structural Analysis of Bevel GearEditor IJTSRDNessuna valutazione finora

- Is 1710 - 1989 - Vertical Turbine PumpDocumento34 pagineIs 1710 - 1989 - Vertical Turbine PumpRavi Shankar Mishra100% (1)

- Design and Fabrication of Mechanically Operated Side Stand RemoverDocumento24 pagineDesign and Fabrication of Mechanically Operated Side Stand RemovernaraNessuna valutazione finora

- Screw Thread ReportDocumento17 pagineScrew Thread Reportkittikhun_simlee100% (1)

- Warco20cat PDFDocumento59 pagineWarco20cat PDFAhmed SlimNessuna valutazione finora

- Bridgeport - j1 - Head - 2 - 0 - 01 Rebuild-10 PDFDocumento69 pagineBridgeport - j1 - Head - 2 - 0 - 01 Rebuild-10 PDFcbr6000100% (4)

- Volvo Trucks Parts ListDocumento6 pagineVolvo Trucks Parts ListImran MehboobNessuna valutazione finora

- Conveyor Belt Technique: Design and CalculationDocumento161 pagineConveyor Belt Technique: Design and CalculationMarianne Hernández100% (1)

- Dynawinch Industries LTD Catalog1Documento105 pagineDynawinch Industries LTD Catalog1casda73100% (1)

- Cvs - Repairing MB Transmission G 60 / G 85 and ZF Transmission S 5-42Documento70 pagineCvs - Repairing MB Transmission G 60 / G 85 and ZF Transmission S 5-42Linio Calixto De JesusNessuna valutazione finora

- Pulsar 220 Workshop Manual ENGLISHDocumento45 paginePulsar 220 Workshop Manual ENGLISHTim ChesbroNessuna valutazione finora

- Eickhoff Gearbox Operating ManualDocumento83 pagineEickhoff Gearbox Operating Manualjjohnsco100% (5)

- Fuller Heavy Duty Transmissions TRSM0440: Service ManualDocumento180 pagineFuller Heavy Duty Transmissions TRSM0440: Service ManualmattkidoNessuna valutazione finora

- GH - ManualDocumento98 pagineGH - ManualLucile Fernandes100% (1)

- RPP04 Edisi 5 Semakan 3 - BDA37401 Sem2 2022-2023 SignedDocumento6 pagineRPP04 Edisi 5 Semakan 3 - BDA37401 Sem2 2022-2023 SignedkfodskfoNessuna valutazione finora

- Shark Screw Air Compressor: Installation, Maintenance and User ManualDocumento43 pagineShark Screw Air Compressor: Installation, Maintenance and User ManualSatria Baru Perkasa RetesterNessuna valutazione finora