Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-A-2026 Rev 2

Caricato da

ரமேஷ் பாலக்காடுDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-A-2026 Rev 2

Caricato da

ரமேஷ் பாலக்காடுCopyright:

Formati disponibili

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

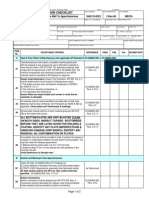

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of API Tanks

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2026

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA QC Documentation, Test Package & Tank Weld Map Verification: Test Diagram is submitted showing the following: A) Limits of equipment to be tested incl. test manifold & equipment included in the test. B) Test pressure of the system C) Relief valve setting D) Safety Instruction Sheet Procedure has been approved & meets the detailed requirements of SAIC-A-2001 (Review Procedure - Pressure Testing)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-A-004, Para. 5.6.1

A2

SAES-A-004, Para. 7.1.1

A3

Verify drawing conformance of tank construction. Check all nozzles, supports, attachments (orientation & dimemsion) Systematically complete, verify & accept all drawings incl. details

Contract drawings

A4

Verify complete code construction incl. support attachments. Repairs, Weld Pick-up (ID/OD), (welding) is 100% accepted.

SAES-W-017, Section 16, 17

A5

Weld Summary Record (SAEP-1160 Welding Database) was verified to indicate completion/acceptance of all weld joints, repairs, modifications & any applicable weld inspection reqmts (visual, NDE). All required inspection & testing (RT, MT, PT, PWHT, PMI) has been completed & inspection control sheet has been signed by SA. As applicable, an SAEP-1160 Welding Database is reviewed SEE SAIC-W-2087, SAIC-W-2088 are completed & accepted Post Weld Heat Treatment (PWHT) & Production Weld Hardness Testing is complete & accepted. SAIC-W-2089 & SAIC-W-2014.

SAEP-1160 & SAES-W-017, Para 16.1.2

A6

Applicable code Welding & NDT Appendix & checklist

A7

SAEP-1160, Section 6

A8

32-SAMSS-005 is checklist for API Atmospheric Tanks. 32-SAMSS-006 is checklist for API Low Pressure Tanks. Testing has been completed in accordance with SA Inspection Requirements Form 175-324900 & following additional requirements of 32-SAMSS-005, Section 5 (Utilize SAMSS as a checklist here). Testing has been completed in accordance with SA Inspection Requirements Form 175-324901 & following additional requirements of 32-SAMSS-006, Section 7 (Utilize SAMSS as a checklist here). The tank shall be completely drained and thoroughly dried immediately after completion of the hydrostatic test. The Tank Manufacturer has a plan for disposal of hydrotest water that has been evaluated against SAEP-327 by the engineering contractor.

As Referenced

A9

32-SAMSS-005, Para. 5.3.1.9

A10

32-SAMSS-006, Para. 7.18.1.1

A11

Planning 32-SAMSS-005, 32-SAMSS-006, Para. 7.18.1.5

Page 1 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

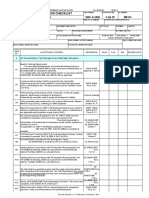

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of API Tanks

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2026

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. A12

ACCEPTANCE CRITERIA Ensure all 32-SAMSS-006 Test Preliminaries of Section 7.18.2 have been completed. USE SAMSS AS A CHECKLIST. Safety Instruction Sheet (SIS) for vessesl/equipment is complete & approved. Verify correct test pressure for system/equipment.

REFERENCE 32-SAMSS-006, Para. 7.18.2 SAES-A-005, Para. 4.2

PASS

FAIL

N/A

RE-INSP DATE

A13 B

Field Verification/Pre-Test Inspection of API Tanks (32-SAMSS-005 & 32-SAMSS-006) Vents are provided at all high points in the position in which it is to be tested to purge all possible air during water filling.

B1

SAES-A-004

B2

Prior to final inspection & pressure testing, the inside & outside of tank shall be thoroughly cleaned of all slag, scale, dirt, grit, weld spatter, paint, oil, etc. (If internally coated special weld prep req'd)

32-SAMSS-005, Para. 5.3.1.7

B3

Strength of existing foundation/supports shall be confirmed to be adequate for additional weight of hydrotest fluid. STEP 1.

SAES-A-004, Para. 6.3.1

B4

Tank Settlement Measurements or Elev. Survey (STEP 2) Base elevation shall be established & recorded at several equidistant locations around the tank circumference in multiples of four, but not to exceed 10 m (32.8 foot) between each reference point and no less than eight (8) locations. Measurement points shall be at well marked locations on the bottom projection outside tanks or on clips welded to shell. Elevation readings are taken: 1) Before hydrostatic testing has started. 2) At filled point. PLAN RESPONSIBILITY & NOTIFICATION 3) At filled point. PLAN RESPONSIBILITY & NOTIFICATION 4) After 24* hours from filling tank at maximum fill height. *HOLD TIME. PLAN RESPONSIBILITY & NOTIFICATION 5) After tank has been emptied of test water. FINAL SURVEY PREPARE DOCUMENTATION & PLAN FOR THESE EVENTS . SURVEY RESULTS ARE FORWARDED TO SA FOR REVIEW. RESULTS ARE A PERMANENT PART OF TANK RECORDS. HOLD POINT FOR SA! USE ESTABLISHED BENCHMARKS!

32-SAMSS-005, Para. 5.6.1 & 32-SAMSS-006, Para. 7.18.11.1 Applies to Both SAMSS

B5

SURVEY STEPS & DIRECTION FOR FILLING (CRITICAL): Any differential settlement greater than 1.5 mm (60 mils) per meter of circumference, or a uniform settlement in excess of 50 mm (2"), shall be reviewed by the Saudi Aramco Engineer. Filling shall be stopped until clearance to continue has been received from the Saudi Aramco Engineer. INSPECTOR VERIFIES AND ENFORCES. SURVEY STEPS BEFORE & AFTER TESTING (CRITICAL): For tanks 15.24 m (50 foot) diameter and larger, internal bottom elevation measurements shall be made before & after hydrostatic test. These measurements shall be made at 3 meter intervals along diametric lines across the bottom. Diametric lines shall be spaced approximately 10 meters (32.8 foot) apart at the tank shell. Tanks tested by filling with Quality water per SAES-A-007 to: A) The maximum design liquid level, H specified in API STD 650. B) For a fixed roof tank, to 50 mm (2 in.) above the weld connecting the roof plate or compression bar to the top angle or shell; or C) To a level lower than that specified in items (a) or (b) when

32-SAMSS-005, Para. 5.6.2 & 32-SAMSS-006, Para. 7.18.11.2 Applies to Both SAMSS 32-SAMSS-005, Para. 5.6.3 & 32-SAMSS-006, Para. 7.18.11.3 Applies to Both SAMSS 32-SAMSS-005, Para. 5.3.5.1 API 650 Tanks ONLY

B6

B7

Page 2 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of API Tanks

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2026

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Rate of Water Filling and Water Temperature (Per API 620): (Exception) Water filling rate for non-refrigerated cylindrical tanks shall not exceed those shown in the following Table.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B8

32-SAMSS-006, Para. 7.18.7 API 620 Tanks ONLY

REMARKS: REFERENCE DOCUMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30 March, 2005) 2. SAES-A-005, Safety Instruction Sheet, (28 February 2005) 3. SAES-D-100, Design Criteria of Atmospheric & Low Pressure Tanks, (31 December, 2003) 5 SAES-W-017, Welding Requirements for API Tanks, (7 December 2005) 6. 32-SAMSS-005, Manufacture of Atmospheric Tanks, (31 December 2003) 7. 32-SAMSS-006, Manufacture of Low Pressure Tanks, (31 December 2003)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 3 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of API Tanks

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2026

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Tank Settlement Measurements or Elev. Survey (STEP 2) Base elevation shall be established & recorded at several equidistant locations around the tank circumference in multiples of four, but not to exceed 10 m (32.8 foot) between each reference point and no less than eight (8) locations. Measurement points shall be at well marked locations on the bottom projection outside tanks or on clips welded to shell. Elevation readings are taken: 1) Before hydrostatic testing has started. 2) At filled point. PLAN RESPONSIBILITY & NOTIFICATION 3) At filled point. PLAN RESPONSIBILITY & NOTIFICATION 4) After 24* hours from filling tank at maximum fill height. *HOLD TIME. PLAN RESPONSIBILITY & NOTIFICATION 5) After tank has been emptied of test water. FINAL SURVEY PREPARE DOCUMENTATION & PLAN FOR THESE EVENTS . SURVEY RESULTS ARE FORWARDED TO SA FOR REVIEW. RESULTS ARE A PERMANENT PART OF TANK RECORDS. HOLD POINT FOR SA! USE ESTABLISHED BENCHMARKS! SURVEY STEPS & DIRECTION FOR FILLING (CRITICAL): Any differential settlement greater than 1.5 mm (60 mils) per meter of circumference, or a uniform settlement in excess of 50 mm (2"), shall be reviewed by the Saudi Aramco Engineer. Filling shall be stopped until clearance to continue has been received from the Saudi Aramco Engineer. INSPECTOR VERIFIES AND ENFORCES. SURVEY STEPS BEFORE & AFTER TESTING (CRITICAL): For tanks 15.24 m (50 foot) diameter and larger, internal bottom elevation measurements shall be made before & after hydrostatic test. These measurements shall be made at 3 meter intervals along diametric lines across the bottom. Diametric lines shall be spaced approximately 10 meters (32.8 foot) apart at the tank shell. Tanks tested by filling with Quality water per SAES-A-007 to: A) The maximum design liquid level, H specified in API STD 650. B) For a fixed roof tank, to 50 mm (2 in.) above the weld connecting the roof plate or compression bar to the top angle or shell; or C) To a level lower than that specified in items (a) or (b) when restricted by overflow, an internal floating roof, or other freeboard. EXACT FILL HEIGHT SHALL BE DETERMINED & MEASURED BY INSPECTOR PRIOR TO FILLING & CHECKED AGAINST DOCS. Rate of Water Filling and Water Temperature (Per API 620): (Exception) Water filling rate for non-refrigerated cylindrical tanks shall not exceed those shown in the following Table.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B4

32-SAMSS-005, Para. 5.6.1 & 32-SAMSS-006, Para. 7.18.11.1 Applies to Both SAMSS

B5

B6

32-SAMSS-005, Para. 5.6.2 & 32-SAMSS-006, Para. 7.18.11.2 Applies to Both SAMSS 32-SAMSS-005, Para. 5.6.3 & 32-SAMSS-006, Para. 7.18.11.3 Applies to Both SAMSS

B7

32-SAMSS-005, Para. 5.3.5.1 API 650 Tanks ONLY

B8

32-SAMSS-006, Para. 7.18.7 API 620 Tanks ONLY

REMARKS: REFERENCE DOCUMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30 March, 2005) 2. SAES-A-005, Safety Instruction Sheet, (28 February 2005) 3. SAES-D-100, Design Criteria of Atmospheric & Low Pressure Tanks, (31 December, 2003) 5 SAES-W-017, Welding Requirements for API Tanks, (7 December 2005) 6. 32-SAMSS-005, Manufacture of Atmospheric Tanks, (31 December 2003) 7. 32-SAMSS-006, Manufacture of Low Pressure Tanks, (31 December 2003)

Page 4 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Test Inspection of API Tanks

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2026

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 5 of 5

Potrebbero piacerti anche

- Api 510 QuizletDocumento6 pagineApi 510 QuizletMahmoud Alwasif100% (1)

- Api 653 (CB-109)Documento37 pagineApi 653 (CB-109)Naveen RajNessuna valutazione finora

- CBT TanveerDocumento5 pagineCBT TanveerBapiNessuna valutazione finora

- Car ParkingDocumento18 pagineCar ParkingYash SinghNessuna valutazione finora

- Method Statement & Risk Assessment For Hot Works WeldingDocumento4 pagineMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- SAIC-D-2023 Rev 2Documento2 pagineSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- API 653 - 577 Flash Cards - 62 QuestionsDocumento8 pagineAPI 653 - 577 Flash Cards - 62 QuestionsSERFORTEC CIA. LTDA.Nessuna valutazione finora

- Radiographic Requirements On Api 650tanksDocumento1 paginaRadiographic Requirements On Api 650tankssbmmlaNessuna valutazione finora

- API 653 NotesDocumento3 pagineAPI 653 NotesPavan_yoyoNessuna valutazione finora

- CBT QuestionsDocumento17 pagineCBT QuestionsNaseer Ahmed SokhalNessuna valutazione finora

- 1 API 653 Memories Sept 2012Documento20 pagine1 API 653 Memories Sept 2012majid100% (1)

- Saudi Aramco Standards: WeldingDocumento12 pagineSaudi Aramco Standards: WeldingGEORGE IVANNessuna valutazione finora

- 2014) - (11 Api 653 653 ApiDocumento4 pagine2014) - (11 Api 653 653 Apitayyab ali100% (1)

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocumento2 pagineSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNessuna valutazione finora

- I Object: Repair Procedure For Tank BottomDocumento6 pagineI Object: Repair Procedure For Tank BottomZouhair BenmabroukNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocumento1 paginaSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387Nessuna valutazione finora

- 2-Questions API 650 Question N°02 2022Documento3 pagine2-Questions API 650 Question N°02 2022korichiNessuna valutazione finora

- SAIC-W-2078 Review PWHT Proc For TankDocumento5 pagineSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNessuna valutazione finora

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocumento8 pagineQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNessuna valutazione finora

- API 570 Daily ExamDocumento3 pagineAPI 570 Daily Examalouis100% (1)

- ASME Pressure Vessel JointDocumento5 pagineASME Pressure Vessel JointRodrigo CarneiroNessuna valutazione finora

- API 653 PC 15may04 Exam 2 ClosedDocumento8 pagineAPI 653 PC 15may04 Exam 2 ClosedShaalan AliNessuna valutazione finora

- API 653 PC 07jan08 PTR 4Documento3 pagineAPI 653 PC 07jan08 PTR 4Mohammed ShakilNessuna valutazione finora

- Api653 Question N°06 ResponsesDocumento3 pagineApi653 Question N°06 ResponseskorichiNessuna valutazione finora

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocumento6 pagineAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiNessuna valutazione finora

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocumento50 pagineASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNessuna valutazione finora

- API 653 PC 15may04 Exam 3 OpenDocumento5 pagineAPI 653 PC 15may04 Exam 3 Openraobabar21Nessuna valutazione finora

- Weld Repair of Grade 91 Piping and Components in PDocumento27 pagineWeld Repair of Grade 91 Piping and Components in PKyi HanNessuna valutazione finora

- Api 650Documento4 pagineApi 650arif99pak100% (1)

- Api 570 - 02 Asme B 31.3Documento12 pagineApi 570 - 02 Asme B 31.3Mohammad RawoofNessuna valutazione finora

- Saic D 2025Documento10 pagineSaic D 2025jerinNessuna valutazione finora

- Pressure Vessel RT TestDocumento3 paginePressure Vessel RT TestAriq FauzanNessuna valutazione finora

- Varun CBT QuestionDocumento7 pagineVarun CBT Questionmedication abbasNessuna valutazione finora

- SATIP-N-001-02 Rev. 4Documento2 pagineSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Api 510Documento7 pagineApi 510Ranaweera AriyamanjulaNessuna valutazione finora

- Aramco General Mechanical QuestionsDocumento2 pagineAramco General Mechanical QuestionsJlkKumarNessuna valutazione finora

- ch4 - API 574 PDFDocumento6 paginech4 - API 574 PDFRAMADOSSNessuna valutazione finora

- Aws SpecificationDocumento4 pagineAws Specificationnike_y2kNessuna valutazione finora

- Tube-To-Tube Sheet Joint RequirementsDocumento2 pagineTube-To-Tube Sheet Joint RequirementsWaqas WaqasNessuna valutazione finora

- TDC 1150Documento3 pagineTDC 1150shazanNessuna valutazione finora

- RFI Entered Successfully Quality Record No L-8137: User1: - Role: Change Password - LogoutDocumento1 paginaRFI Entered Successfully Quality Record No L-8137: User1: - Role: Change Password - Logoutarulselvam100% (1)

- Tank Erection Itp Org ChartDocumento34 pagineTank Erection Itp Org Chartvasantha kumar100% (1)

- Gas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesDocumento5 pagineGas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesnasrNessuna valutazione finora

- API571 - NEW APP - Effective 2011 - CompletedDocumento12 pagineAPI571 - NEW APP - Effective 2011 - Completedtong2jeNessuna valutazione finora

- API 510 Data Sheets - QuizletDocumento1 paginaAPI 510 Data Sheets - Quizletads_1203Nessuna valutazione finora

- CORROSION QUIZ - InG - Painting and CoatingDocumento3 pagineCORROSION QUIZ - InG - Painting and CoatingErik Alfiandy100% (1)

- CBT Questions-1Documento2 pagineCBT Questions-1kumarNessuna valutazione finora

- 1st April 2021 653 PaperDocumento7 pagine1st April 2021 653 Papermohamed haMEEM100% (1)

- Alert 01 002Documento2 pagineAlert 01 002SUKhanNessuna valutazione finora

- Code Sec.: PD C Se P Y C D Set Xcrxyrs C DDocumento1 paginaCode Sec.: PD C Se P Y C D Set Xcrxyrs C DsubhaNessuna valutazione finora

- LADWER API 510 - API RP 577 April 2017Documento7 pagineLADWER API 510 - API RP 577 April 2017Luthfi ArdiansyahNessuna valutazione finora

- Plant Inspections PDFDocumento5 paginePlant Inspections PDFMohamedNessuna valutazione finora

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocumento3 pagineDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistAbdul HannanNessuna valutazione finora

- Open Book For API 653Documento10 pagineOpen Book For API 653gopiNessuna valutazione finora

- Tender Document - GAIL - MIJ PDFDocumento17 pagineTender Document - GAIL - MIJ PDFVeer GangjiNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289Nessuna valutazione finora

- SAIC-A-2026 Rev 6 Pre Test API TankDocumento6 pagineSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNessuna valutazione finora

- SAIC-A-2010 Rev 0Documento3 pagineSAIC-A-2010 Rev 0philipyapNessuna valutazione finora

- SAIC-D-2022 Rev 2Documento5 pagineSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Air Carbon Arc Gouging: ElectrodeDocumento1 paginaAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNessuna valutazione finora

- Welding Processes ModuleDocumento27 pagineWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- SAIC-D-2022 Rev 2Documento5 pagineSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Computer Kerala - 4 Folder LockDocumento2 pagineComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNessuna valutazione finora

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocumento362 paginePractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNessuna valutazione finora

- SAIC-D-2006 Rev 2Documento2 pagineSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocumento4 pagineSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2006 Rev 2Documento2 pagineSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocumento1 paginaSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2009 Rev 2Documento6 pagineSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2012 Rev 2Documento4 pagineSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2007 Rev 2Documento4 pagineSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2009 Rev 2Documento6 pagineSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-D-2005 Rev 2Documento4 pagineSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Ksp-Instrument Impulse Piping & TubingDocumento18 pagineKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNessuna valutazione finora

- Biw Welding Fixture DesignDocumento5 pagineBiw Welding Fixture DesignDeshraj SindhuNessuna valutazione finora

- Ultra-Narrow Gap Fiber Laser Conduction Welding Technology For 304 Stainless Steel Thick Plates and The Mechanical Properties of Welding JointsDocumento12 pagineUltra-Narrow Gap Fiber Laser Conduction Welding Technology For 304 Stainless Steel Thick Plates and The Mechanical Properties of Welding JointsMaxNessuna valutazione finora

- Jacking Procedurefor Construction of Tanks OLDDocumento10 pagineJacking Procedurefor Construction of Tanks OLDVikram RangasamyNessuna valutazione finora

- WPS2Documento2 pagineWPS2aleventNessuna valutazione finora

- Ferrx 5000 Magnetic SeparatorDocumento6 pagineFerrx 5000 Magnetic SeparatorleontoledoNessuna valutazione finora

- Hand RailDocumento5 pagineHand RailpandiangvNessuna valutazione finora

- The Development of An Australian Standard For Stainless Steel StructuresDocumento15 pagineThe Development of An Australian Standard For Stainless Steel Structureswaynectw100% (1)

- PWHTDocumento4 paginePWHTDelvin Davis MNessuna valutazione finora

- Robotics: Classification of Robots Based On Their ConfigurationDocumento7 pagineRobotics: Classification of Robots Based On Their ConfigurationBharath Narasimha100% (1)

- 09 Samss 091Documento27 pagine09 Samss 091AbhilashNessuna valutazione finora

- Ae2027 QBDocumento5 pagineAe2027 QBAero GopalNessuna valutazione finora

- ANChor DesignDocumento16 pagineANChor DesignAditya KNessuna valutazione finora

- 2a1 Physics Spot WeldDocumento25 pagine2a1 Physics Spot WeldNitish RanjanNessuna valutazione finora

- C1.welded Connection1 PDFDocumento25 pagineC1.welded Connection1 PDFWindy GeeNessuna valutazione finora

- As 3857-1999 Heat Exchangers - Tubeplates - Methods of DesignDocumento7 pagineAs 3857-1999 Heat Exchangers - Tubeplates - Methods of DesignSAI Global - APACNessuna valutazione finora

- Pickling Paste 101Documento2 paginePickling Paste 101George BogdanNessuna valutazione finora

- Welding Chrome-Moly Steel: What You Should Know About T-1 WiresDocumento22 pagineWelding Chrome-Moly Steel: What You Should Know About T-1 WiresKentDemeterioNessuna valutazione finora

- Gas Metal Arc Welding: Product and Procedure SelectionDocumento96 pagineGas Metal Arc Welding: Product and Procedure SelectionSubhash SharmaNessuna valutazione finora

- Maske Za Zavarivanje SpeedglasDocumento52 pagineMaske Za Zavarivanje SpeedglasPraesidium Potens d.o.o.Nessuna valutazione finora

- Batch History SHSDocumento4 pagineBatch History SHSJunior PayatotNessuna valutazione finora

- DPT Report - U1Documento88 pagineDPT Report - U1kannagi198Nessuna valutazione finora

- NDT Audit Check ListDocumento7 pagineNDT Audit Check ListShrikant Utekar50% (6)

- Image Processing For Radiographic Films of Weld InspectionDocumento7 pagineImage Processing For Radiographic Films of Weld InspectionMahmoud AbdullahNessuna valutazione finora

- Series 5Documento40 pagineSeries 5svaasandNessuna valutazione finora

- Katalog 2012 EN Cloos PDFDocumento324 pagineKatalog 2012 EN Cloos PDFTeo PericNessuna valutazione finora

- Flash BainiteDocumento25 pagineFlash BainiteJOSE MIGUELNessuna valutazione finora

- Engineering Design Basis (Structural)Documento21 pagineEngineering Design Basis (Structural)Kamaraj Bangarusamy100% (1)

- Method Statment For Above Ground PipingDocumento7 pagineMethod Statment For Above Ground PipingMuhammad Anjum JabranNessuna valutazione finora