Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fig I.: Oct. 6, 1942. S, H. Gordon Etal 2,298,051

Caricato da

Rakesh SrivastavaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fig I.: Oct. 6, 1942. S, H. Gordon Etal 2,298,051

Caricato da

Rakesh SrivastavaCopyright:

Formati disponibili

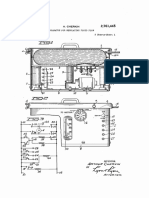

Oct. 6, 1942.

s, H. GORDON ETAL

ELECTRIC FLASH WELDING MACHINE

2,298,051

5 Sheets-Sheet 1

Filed Jan. 18, 1941

Fig I.

Oct. 6, 1942.

$_ H~ GORDON ETAL

ELECTRIOFLASH WELDING momma

'

2,298,051

_ 5 Sheets-Sheet?

Filed Jan. 18, 1941

S

62

2. Fig.

Oct. 6, 1942.

s. H. GORDON ETAL

ELECTRIC FLASH WELDING MACHINE

vFiled Jan. 18, 1941

2,298,051

5 Sheets-Sheet 3

WVVE/VRMS

H

@ \

5.H.GOR DON

NF. YOUNG

"Hay

'

ATTORNEYS

Oqt. 5, 1942. _

' s. H. GORDON ETAL

ELECTRIC FLASH WELDING'MAGHINE

2,293,051

5 Sheets-Sheet 4

FilOd Jan. 18, 1941

Fig.4.

zdimm emfwzn r

Och 5, 1942-

s. H. GORDON ETALELECTRIC FLASH WELDING MACHINE

2,298,051

5 Sheets-Shet 5

,Filed Jan. 18, 1941

Fig. 4A.

76

62

60 52

54

50 m1 Vf/VTOR

$.H,GORDON

uLFrYouN &

?air) diltuiw

A TTORNEKS

Patented Oct. 6, 1942

2,298,051

UNITED STATES PATENT OFFICE

2,298,051

ELECTRIC FLASH WELDING momm: .

Samuel Hunter Gordon and William Forbes

> Young, Inverness, Scotland

Application January 18, 1941, Serial No. 375,074

In Great Britain January 11, 1940

(Cl. Gil-54.5) not dependent upon the temperature of the liquid. ?ash-wielding machines of the kind described in 7 Patent No. 2,187,452. In the speci?cation of that Referring to the accompanying drawings:

I _ . 6 Claims.

'Ihisv invention relates to automatic electric

,! Figure l is a diagrammatic side elevation 5 partly in section of mechanism according to this piecesto'bewelded-to the other, for the purpose ' invention. , ' of preheating the workpieces, is maintained by Figure 2 is a side elevation partly in section of v ?uctuations of ?uid pressure in a ?uid-operated the pump mechanism, _ ?uctuations being Figure 3 is a plan of Figure 2, and ' feed mechanism, . these

patent means are described whereby a recipro cating motion of approach of one of the work

brought about by the meeting together of the

cation the regulation of the speed of the feeding

10

_Figure 4 is a circuit diagram,

cold unsoftened workpieces. In the embodiment

I . of that invention described in the priorspeci?

Referring to Figure 1, the feed mechanism con sists of two hydraulic cylinders Ill, l2 placed back to back and secured to a ?xed part ll of the

welding machine. The cylinder I0 is larger in creep valve, whereby the rate at which liquid 15 diameter than the cylinder 12 and a ram I6 in ' ?owed into or out of a hydraulic cylinder could the cylinder i0 is connected directly to the mov be adjusted. In some circumstancesthis mode ' ing head l6, so that outward movement of the

' of regulating the feed movement has the disad ' vantage that with a given adjustment the speed -

movement was e?fected by means of an adjustable

" advantages would be free from liability to un

ram i6 causes the forward feed movement. A ram 20 in the cylinder I2 is attached to a cross will vary with the temperature of the liquid. It 20 head 22 connected by tie-rods 24 to the moving is the object of the present invention to provide head [8, the outward movement of the ram 26 an improved feed mechanism which among other thereby causing the return motion of the moving

head.

cylinder and bored to receive a ?xed ram 30.

desired variation due to changes of temperature. The pump consists of a double ram compris According to this invention the moving head 425 ing a fixed cylinder 26, a ram 28 moving in this

of the welding vmachine is moved in both direc-, 'tions'by hydraulic means supplied with liquid, by-a mechanically driven reversible pump, the reversing means being under the control of a

The cylinder 26 is connected by a pipe 32 to, the feed cylinder l0 and the bore in the moving ram 28 is connected by a pipe 34 to the return cylin device sensitive to the pressure of the liquid 30 der =2 through a passage 36 extending from end to end of the ?xed ram 36. The ratio of the di which causes the forward movement of the mov ing head. ' ameters of the pump cylinder 26 and of the ,bore in the moving ram 28 is equal to the ratio of It will be appreciated that when the cold work

the diameters of the cylinders ill, l2. Thus, if feed movement, thereby causing a rise of pressure 35 the moving ram 28 is moved to the left liquid will be forced into the cylinder i0 thereby driving in the hydraulic driving means and when this the moving head i8 forward, while liquid will be pressure exceeds a predetermined aniount the driven out of the cylinder l2 into the'bore in v l movement of the pump is reversed automatically the moving ram 28. If this ram 28 is moved to' thereby separating the workpieces. The pres sure thereupon falls, the pressure-sensitive de 40 the right, liquid will be forced into the cylinder i2, while the liquid displaced from the cylinder viee is no longer operative and the pump reverts ill will passlinto the pump cylinder 26. The di to. its original direction of operation to cause ameter of the pump cylinder is only a fraction. v the forward feed movement to be resumed. of that of the forward feed cylinder i0 and there These successive reversals of movement will con tinue until the workpieces attain such a tempera 45 fore the travel of the moving head I6 will be much smaller than the travel of the pump ram ; ture that ?ashing occurs, whereupon no further 28. As shown in Figures, 2 and 3, the: ram 28 mechanical resistance to the feed movement oc carries a crossh'ead 38 in which are ?xed two ~ curs, the pressure of the liquid does not rise be nuts 40, 42 threaded onto similarly threaded ' yond the predetermined limit and therefore the

piecesmeet they will oppose resistance to the

forward feed movement continues uninterrupted

50 - ed screw inv spindles hearings 46, in All, brackets Thesespindles 46, 66 which are support mount- _ _ 1 ".

Owing to the fact that the pump is'mechan

ically driven and that restricted ori?ces are not

the cylinder 26 and the ?xed ram 36.

The

spindles carry equal gearwheels 52, 64, meshing

with a pinion 6.6 ?xed to a shaft 68 which carries

employed, the speed of the feed movement is 55 a pulley 60 driven by a belt 62 from an electric

motor

order to

_,

which wiil be referred to as the forward

feed circuit, runs from A through a, b, c, to, 7, switch 896 which is closed at this time, e, 98,

switches 92, so both of which are closed, 9, h, C.

operation or the pressure-sens

es s, a sim

plified arrangement will first be described. In this arrangement the supply of current to the

motor is taken through s reversing switch t6

which is biased into one position by a spring (68 and is moved into thetnther position by an elec

The switch or will be described later; it is a. for ward limit switch and is opened automatically at the end of the welding operation. The switch

96 is an interlock switch on the reverse motor tromagnet The electrornugnet is energised by the closing oi a 'pressiuewgrerated switch 712 ' contactor 95 and is opened when this contactor the pile-e Stiles-ding from the pump cylinder 10 is closed. The closing of the forward contactor 98 sup to the feed cylinder it, the arrange plies current to the motor 66 which rotates in the ineht such that when the pressure in the forward direction, moving the ram'28 to the left cylinders it), rises above a predetermined limit thereby causing the moving head l8 to advance. the switch 72 will be closed and the electromag net energised thereby reversing the direction oi 15 At the same time the interlock switch I90 is

rotation of the motor to, .

closed.

When the switch it opens, the switch St is re

When the work pieces make contact, current

flows in the primary winding of the transformer so, and a relay Hit in the primary circuit will be

energised and. will open one switch I08 and close

turned to its original position by the spring {38 and the arrangement is such that when the

switch is in this position the moving ram 28 is driven towards the left, thereby causing the mov= lug head to be fed forward. At the beginning of

another switch N18. The opening ,of I06 breaks the forward feed circuit through the winding 80, but this winding remains energised by a' circuit the welding operation this forward movement from A by way of a, b, c, 89, a, pressure. switch continues until the cold workpieces come togethe er. in general, ?ashing will not occur immedi-= 25 712, 7:, ml, i, e, so, or, Edit, C. This circuit will bereferred to as the pressure switch circuit." ately mil the feed movement will be opposed to This circuit, however, is almost immediately in such an extent that the rise of liquid pressure terrupted by the opening of the pressure switch in the cylinder to causes. the switch 52 to be vl2 consequent on the mechanical resistance of closed, thereby reversing the motor @563 and driv ing the ram 28 in the reverse direction, that is 30 icred by the cold work pieces. Thus, the wind ing 9c is (lo-energised, the forward contactor 9s to soy, towards the right. This will cause the opens, the switch Mil is opened and the switch moving to more to the right thereby sepo

rating the workpieces. As soon as the work

itd is closed. When 90 is de-energised and .

falls, the switch it opens and the string 68 re 35 H2 will be energised momentarily, the circuit be ing from A by way of a, b, 0, INF, H10, 2, m, H2, turns the reversing switch to its original pcsiu C. The motor will thus reverse momentarily as 'tion, thereby causing the motor to rotate in its

. original direction with theresult that forward This sequence oi opera will res

pieces separate, the pressure in the cylinder to

switch ltd closes the reverse motor contactor coil

-- o result of the closing of so and will then stop.

tions continues ntil the ?ashing temperature is the forward movement will. reached, whereu

continue uniritc ~

The two switches HAF and lidBare operated automatically by the motor, MQF being closed while the motor is running forward-and 53

being closed while the motor is running in re= .3113 because the niechamm : verse. . . cal resistance t. rd feed never reaches When the forward contactor coil 99 was ener the limit at whi 2 .e switch it is closed. After a predetermined travel of the moving head a 45 gised the switch 12 was opened. When 90 is. de=energised, however, switch 902 does not .close so=called butting mechanism comes into opera=

pending on the time of action of the dash-pct, is opened when the pressure rises beyond a brew which is made adjustable. During this heating determined iiniit. Provision is made for a delay, period there is s. possibility. of leakage of pressure the extent oi which can be varied, before the in the cylinder to which might cause the pres= motor is reversed, so that the workpieces re sure switch it to close. The forward contactor in in contact for an appreciable time before coil Qt, however, cannot be ire-energised because separated so that their meeting races 1 seated. The resumotion of forward feed v ' ' at this time the switch It! is open. When the switch m2 ?nally closes, a circuit is about as a result of the drop in welding 60 established from A through a, b,c,'B9, 198,182, to the separation of the workpieces.

*

arrangement whereby the machine is operated 50 Therefore, after the motor has stopped, the work pieces remain in contact, being heated by the and controlled. in this arrangement the nres= passage of current through them, for a time de~ mire-operated switch 32 is normally closed and.

tion automatically to complete the weld and to out oi? the current from the welding transformer. Figure 4 is a circuit diagram of the preferred,

again immediately, being prevented from doing

so by a dash-pot Hit. _ So long as I02 is open, the

reverse contactor coil H2 cannot be energised.

cut is supplied from iii-phase mains A, E. C, trough a main switch id. The operating handle it controls three switches #78, 8d, 82. To

the machine the handle is depressed to close 65 is (is-energised, switch ms opens and switch i596 hes cc and open switch S2. The closing closes. oi switch energises the main contactor coil till, The opening of switch M38 (consequent on drop . the circuit being tron: A through points a, b, c, d, of current in the transformer winding 83) breaks it}, a switch are (normally closed) which will be described later, winding til, C. The enersisation 70 the last-mentioned clrcuitithe reverse contactor

Z, m, M2, C. The energisation of lit-.closesltlfie. reverse contactor 96, the motor starts in reverse, '. the already, pressure the switch work pieces it- closes, separate, if it has windingl?t notclosed

of iil closes switches

transformer 88. .

and

thus supplying

current tokthe primary winding of, the welding

winding M2 is ole-energised, the reverse contactor it opens, the interlock switch so closes and the forward feed circuit, previously referred to, is re

established energising so, causing the motor to The closing of switch 8d completes a circuit through the forward feed contactor coil This 75 run forward until the work pieces come together

again as previously described. This cycle

op

demenergises the reverse contactor coil and closes the interlock switch as". The switch 86 being open, 90 cannot be energised through the forward feed circuit, but the motor-operated con

tacts IHB are now closed and there is a circuit

erations is repeated until the work pieces no long er oppose mechanical resistance at the time the pressure switch circuit is established. In these circumstances the pressure switch 72 remains closed and the pressure switch circuit is main

to rotate forwards. starts in the forward direction, 1 14B opens im On the crosshead 22 is mounted an adjustable cam Ii5._ At a predetermined point in the for l0 mediately thereby de-energising the coil 90, which cannot be re-energised through the forward feed ward feed movement this cam will push down; circuit because 80 is open. This brings the oper wards a pivoted lever I I6 thereby opening a valve ation to an end and no current can flow in any I I8 which allows high pressure oil from an inde of the circuits until the switch 80 is closed by pendent source to enter the forward feed cylinder the handle 16 to initiate the next welding oper l0 and thus drive the moving head I8 forward at an increased speed to butt the work pieces to 15 ation. We claim: gether and complete the weld. At the same time 1. A hydraulic system comprising in combi another valve I20 is opened to connect the re nation hydraulic ram means operable in a for turn cylinder I2 to an oil reservoir I22 to allow the oil displaced by the rapid forward movement 20 ward direction and in the reverse direction, a

of the moving head to escape. -

tained, with the result that the motor continues

from A through a, b, 0, H413, f, e, 90, 92, 94, h, C. The forward contactor 98 closes, the motor

The downward movement of the lever IIGalso opens the switch I26 previously referred closes another switch I24. The opening of I26

mechanically driven reversible pump for supply ing liquid under pressure to said hydraulic means,

reversing means for said pump and a device sen

switches 26 and 86. The welding current is 25 ing means to cause reverse movement as a con thereby cut' off from the primary transformer sequence of rise of liquid pressure above a pre winding 68 and the winding I04 is tie-energised, determined limit and for again actuating said . closing switch I06 and opening switch I06. reversing means to cause forward movement as a consequence of fall of liquid pressure below said When the switch I24 is closed there is a circuit from A through a, b, c, 80, I24, k, IN, ,1, e, 90, 30 limit. 2. A hydraulic system according to claim 1, in- I 62, 04,12, C. The switch I24 is, therefore a shunt across the pressure switch I2 and keeps the, moipr eluding an electric motor to drive saidpump and nmning forwards in spite of I2 being opened by wherein said reversing means includes a revers the high pressure supplied to the cylinder I0 ing switch through which current is supplied to through the valve H0. The oil displaced from said motor and which operates to reverse the di rection of rotation of the motor in response to is cylinder 26 during this movement escapes the rise or fall in pressure of the liquid as More through a relief valve I26 into the reservoir l22.

. The cross-head 30 carries a projection I30 which _

said. '

de-energises the winding 84, thereby opening

sitive to variation in the liquid pressure causing the forward movement for actuating the revers~

presently opens the forward limit switch 62 pre~

viouely referred cause to, the which forward will motor de-energise contacts? coil 66 and

86 to open. This establishes a circuit A, a, b, c, II4_F, I00, 1, m, II2, C. This causes the motor to reverse momentarily and then stop. The weld is now complete and the welded woris pieces are removed from the machine. The , op crating handle 10 is moved back to its original position and the lever H6 is lifted. This comes about owing to the fact that its pivots are ec

centrically mounted on the spindle I32 of the op- _

3. A hydraulic system according to claim 1, in eluding an electric motor to drive said pump and

wherein said reversing mechanism includes a re

versing switch, a pressure actuated switch, and an electromagnet which is energized upon closing of the pressure switch to operate the reversing

switch to a, position in which it operates to re

verse the direction of rotation of the motor in response to the rise in pressure of the liquid aforesaid and to return the reversing switch to its normal position in response to fall in pressure of the liquid.

_ (i. A hydraulic system comprising in combina tion hydraulic rain means operable in a forward direction and in the reverse direction, said means

crating handle 16. Thus, the raising of the han dle 76 depresses the right hand end of the lever I I 6 thereby causing its operative left hand end to be raised by a spring,.not shown. The valves II 0 and I20 are thereby closed, the switches 76, 00, I24 are opened, and the switches Ill, I26 are closed. The closing of 02 energises the reverse contactor coil II 2, the circuit being from A through a, b, c, 82, I44, m, II2, C. The motor

runs in reverse, the pump ram 28 being moved

consisting of two cylinders placed back to back,

one for forward movement and the other for re verse movement, a cross head and tie rods con 'i" the rams, a mechanically driven revers

ihle pump supplying liquid under pressure to said cylinders, reversing means for said pump and a

to the right. A limit stop I36 is provided which arrests the rams I6, 20 at a predetermined posi tion. When this takes place, the pump ram 26 is still moving to the right, displacing oil past a second relief valve I36 into the oil reservoir i212. At the same time the pump cylinder :26 receives oil from the reservoir through a non-return valve

I30. A second nomreturn valve serves in. the same way for the bore in the pump ram nd

device sensitive to variation in the liquid pressure causing the forward movement for actuating the

reversing means to cause reverse movement as a consequence of rise of liquid pressure above a pre~ determined limit and for again actuating said re versing means to cause forward movement as a consequence of fall of liquid pressure below said

mint. 5. A hydraulic system according to claim 4,

the two valves 38 and Mil enable the oil circuit . , wherein said pump consists of a ?xed cylinder, a mechanically driven ram moved within the cylin to be filled in the first place and maintain it full tier and bored to constitute a second cylinder, against any small leakages that might take place. and a, ?xed ram within the second cylinder, the A second projection. M2 on the crossh 38 ?rst pump cylinder being connected to the for ultimately opens a back limit switch its ward cylinder and the second pump cylinder be

5 2,298,051 ing connected to the reverse cylinder of the hycylinder. and the second pump cylinder being con

draullc ram means.

wherein the pump consistspt

.. em according to claim 4, 6. A hydraulic syst a ?xed cylinder, a

nected to the reverse cylinder of the hydraulic ram means, and whereinvthe movable ram is driven by two nuts, carried one on either side

. SAMUEL

mechanically driven ram moved within nder, and. der and bored to constitute a second cyli the ?rst cylinder, a ?xed ram within the second ted to the forward pump cylinder being connec

the cylin- 6 vthereof, and engaging two screw spindles posi

~ tively geared together and mechanically rotated. '_

HUNTER GORDON.

WILLIAM FORBES YOUNG.

Potrebbero piacerti anche

- A New System of Alternating Current Motors and TransformersDa EverandA New System of Alternating Current Motors and TransformersValutazione: 1 su 5 stelle1/5 (1)

- Electric Gas Lighting: How to Install Electric Gas Ignition ApparatusDa EverandElectric Gas Lighting: How to Install Electric Gas Ignition ApparatusNessuna valutazione finora

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Documento5 pagineSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1Nessuna valutazione finora

- Us2585437 PDFDocumento7 pagineUs2585437 PDFbelchior alvaroNessuna valutazione finora

- Us2333680 PDFDocumento8 pagineUs2333680 PDFbelchior alvaroNessuna valutazione finora

- Device For Controlling Clutch Hyd PRDocumento9 pagineDevice For Controlling Clutch Hyd PRRajesh CNessuna valutazione finora

- Welding FBWDocumento13 pagineWelding FBWRakesh SrivastavaNessuna valutazione finora

- JP2020180696A Proportional Solenoid VV in Hyd CKT PDFDocumento12 pagineJP2020180696A Proportional Solenoid VV in Hyd CKT PDFRajesh CNessuna valutazione finora

- Fluid Power Control and Automation PresentationDocumento18 pagineFluid Power Control and Automation PresentationmuthukumaranNessuna valutazione finora

- U.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Documento6 pagineU.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Anonymous a7S1qyXNessuna valutazione finora

- Modul 14 Dan Assetment (Steering Gear)Documento6 pagineModul 14 Dan Assetment (Steering Gear)Nakiri AliceNessuna valutazione finora

- Once Through Boiler Recirculation PumpDocumento6 pagineOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்Nessuna valutazione finora

- Chapter 6 HYDRAULICDocumento93 pagineChapter 6 HYDRAULICShishir GyawaliNessuna valutazione finora

- Us2218760 PDFDocumento3 pagineUs2218760 PDFbelchior alvaroNessuna valutazione finora

- 1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresDocumento5 pagine1,176,784. Patented Mar, 28, 1916.: Walwe Operating Mechanism For LawatoresmarlondijiNessuna valutazione finora

- Industrial Hydraulic Circuits Slide ShareDocumento35 pagineIndustrial Hydraulic Circuits Slide ShareUMIPL HydNessuna valutazione finora

- Section: Illustrated Sou Rcebook Mechanical ComponentsDocumento15 pagineSection: Illustrated Sou Rcebook Mechanical ComponentsparamontNessuna valutazione finora

- United States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentDocumento9 pagineUnited States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentdollarrbillNessuna valutazione finora

- II N The L ' ' Ball Typ Which Is N T 3-ph Se Synchronous M T F He F'lyball Head o I T Con Trol The Guide N Pump Driven Maintain 150 Psi B Ea IngsDocumento20 pagineII N The L ' ' Ball Typ Which Is N T 3-ph Se Synchronous M T F He F'lyball Head o I T Con Trol The Guide N Pump Driven Maintain 150 Psi B Ea IngsCristian GarcíaNessuna valutazione finora

- Work 6 Functional Analysis of A Hydraulic Scheme Piece P.H.40Documento8 pagineWork 6 Functional Analysis of A Hydraulic Scheme Piece P.H.40Tequila AlexNessuna valutazione finora

- Lab ManualDocumento26 pagineLab ManualHEMANTH KUMAR CNessuna valutazione finora

- Us 2109297Documento6 pagineUs 2109297lfilippiniNessuna valutazione finora

- چاشنی کنترل یDocumento4 pagineچاشنی کنترل یs rNessuna valutazione finora

- Rtaa SB 4 - 10011991Documento6 pagineRtaa SB 4 - 10011991alcomech100% (3)

- Industrial Hydraulic CircuitsDocumento16 pagineIndustrial Hydraulic CircuitskingkakingNessuna valutazione finora

- Hydraulic Regenerative and Sequencing CircuitsDocumento9 pagineHydraulic Regenerative and Sequencing CircuitsSanket NirmaleNessuna valutazione finora

- Hydraulic Systems: Hydraulic Mechanism of Acme Cutting MachineDocumento21 pagineHydraulic Systems: Hydraulic Mechanism of Acme Cutting MachineSantha PriyaNessuna valutazione finora

- Ignition SystemDocumento7 pagineIgnition SystemJoel DsouzaNessuna valutazione finora

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Documento8 pagineApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNessuna valutazione finora

- Sequencing of CylindresDocumento5 pagineSequencing of CylindreschtganduNessuna valutazione finora

- Cold Electricity - Amperage Without Voltage Similar To EV Gray TH Moray J BediniDocumento13 pagineCold Electricity - Amperage Without Voltage Similar To EV Gray TH Moray J Bediniqqqq100% (2)

- STN A : Hydraulics and Fluid MechanicsDocumento1 paginaSTN A : Hydraulics and Fluid MechanicsAnshad CpNessuna valutazione finora

- US1306865Documento4 pagineUS1306865Kamal Vijay Ram R SNessuna valutazione finora

- No. 380,100. Patented Mar. 2'7, 1888.: T. A. EdisonDocumento4 pagineNo. 380,100. Patented Mar. 2'7, 1888.: T. A. EdisonAnonymous NcB95G6XwNessuna valutazione finora

- Thermal Analysis of CANDU Nuclear ReactorsDocumento12 pagineThermal Analysis of CANDU Nuclear ReactorskchitharanjanNessuna valutazione finora

- Exercise 13: Conveyor Belt: 1: Problem DescriptionDocumento10 pagineExercise 13: Conveyor Belt: 1: Problem DescriptionyashveerluvNessuna valutazione finora

- Topic 6 1 Phase Controlled DC DriveDocumento8 pagineTopic 6 1 Phase Controlled DC Drivedillon deonathNessuna valutazione finora

- Conveyer Screw Stops Bottles for LabelingDocumento3 pagineConveyer Screw Stops Bottles for LabelingChristian MavarezNessuna valutazione finora

- 210 MW O & M AnualDocumento207 pagine210 MW O & M Anualsenthil031277100% (1)

- Feb. 21, 1967 F. M, Slqan Et Al: Filed Sept. 18, 1964Documento2 pagineFeb. 21, 1967 F. M, Slqan Et Al: Filed Sept. 18, 1964saranyaarulNessuna valutazione finora

- Instructions: 06D Capacity Control Accessory PackagesDocumento6 pagineInstructions: 06D Capacity Control Accessory PackagesSyed Ali KhanNessuna valutazione finora

- Basic Electrical Controls For Fluid PowerDocumento21 pagineBasic Electrical Controls For Fluid PowerSelemon Assefa100% (1)

- Tadano TR 500e 3 00101 ManualDocumento22 pagineTadano TR 500e 3 00101 Manualmichaellittle030786drb100% (120)

- Calculus For Business, Economics, Life Sciences, and Social Sciences 13Th Edition by Raymond A. Barnett (Ebook PDFDocumento23 pagineCalculus For Business, Economics, Life Sciences, and Social Sciences 13Th Edition by Raymond A. Barnett (Ebook PDFmabel.larsen695100% (34)

- UNIT-III-Oil Hydraulic System & Its Componenets Marks 12 PDFDocumento18 pagineUNIT-III-Oil Hydraulic System & Its Componenets Marks 12 PDFChaitanya YengeNessuna valutazione finora

- ElectroHydraulic PracticalDocumento9 pagineElectroHydraulic PracticalXander RamburnNessuna valutazione finora

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Documento5 pagineJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNessuna valutazione finora

- Pumps, Lecture 6Documento29 paginePumps, Lecture 6Guillermo Martinez SanchezNessuna valutazione finora

- Delphi IMVDocumento1 paginaDelphi IMVmdataguy100% (1)

- Hydraulic Circuit Experiment with Double Acting CylinderDocumento20 pagineHydraulic Circuit Experiment with Double Acting CylinderMahesh ANessuna valutazione finora

- Hydraulic CircuitsDocumento25 pagineHydraulic CircuitspriyanthabandaraNessuna valutazione finora

- ACFrOgCZETY1N34f2srrkyR7JgrX4uSur7W4An MpSBkZiq2Us5 ZWkwcsaCvks8HGgRK8kpuFeq8pH9 wG9vwbHWwx74VfQl GbxKWpX50wp2CtiyjOU1HUvScSFKD3otsLYbmBbOJrBJX2Xu31Documento3 pagineACFrOgCZETY1N34f2srrkyR7JgrX4uSur7W4An MpSBkZiq2Us5 ZWkwcsaCvks8HGgRK8kpuFeq8pH9 wG9vwbHWwx74VfQl GbxKWpX50wp2CtiyjOU1HUvScSFKD3otsLYbmBbOJrBJX2Xu31George AcostaNessuna valutazione finora

- Chapter 7Documento21 pagineChapter 7Pink FloydaNessuna valutazione finora

- USRE16126Documento3 pagineUSRE16126seiNessuna valutazione finora

- Central Door LockingDocumento6 pagineCentral Door LockingKelvin WairiNessuna valutazione finora

- A New Concept of Rotary Hydraulic Motor Working With Alternating FlowsDocumento4 pagineA New Concept of Rotary Hydraulic Motor Working With Alternating FlowsalokgobarNessuna valutazione finora

- Hydrostatic Transmission: GonverterDocumento27 pagineHydrostatic Transmission: Gonvertermarabest3Nessuna valutazione finora

- Us2291241 PDFDocumento5 pagineUs2291241 PDFbelchior alvaroNessuna valutazione finora

- Mecha Lab Report (Pneumatics Results and Discussion)Documento3 pagineMecha Lab Report (Pneumatics Results and Discussion)Shamni KarthegesuNessuna valutazione finora

- AMEE310 Lab3Documento15 pagineAMEE310 Lab3Ya HooNessuna valutazione finora

- Bis 6745 Amed 4Documento16 pagineBis 6745 Amed 4Rakesh SrivastavaNessuna valutazione finora

- Is 6137 1993Documento4 pagineIs 6137 1993Rakesh SrivastavaNessuna valutazione finora

- Is 444 2003Documento11 pagineIs 444 2003Rakesh SrivastavaNessuna valutazione finora

- Is 77-2010Documento11 pagineIs 77-2010Rakesh SrivastavaNessuna valutazione finora

- IS 4843 Ferrous CastingDocumento9 pagineIS 4843 Ferrous CastingRakesh SrivastavaNessuna valutazione finora

- Is-4843 CastingDocumento9 pagineIs-4843 CastingRakesh SrivastavaNessuna valutazione finora

- Is 7888 2003Documento19 pagineIs 7888 2003Rakesh SrivastavaNessuna valutazione finora

- Is 3091 99Documento7 pagineIs 3091 99Rakesh SrivastavaNessuna valutazione finora

- Is 2760Documento20 pagineIs 2760Rakesh SrivastavaNessuna valutazione finora

- Is 13411 2003Documento44 pagineIs 13411 2003Rakesh SrivastavaNessuna valutazione finora

- Is 1079 98Documento12 pagineIs 1079 98Rakesh SrivastavaNessuna valutazione finora

- Is-4843 Casting PDFDocumento9 pagineIs-4843 Casting PDFRakesh SrivastavaNessuna valutazione finora

- Is 2334Documento30 pagineIs 2334Rakesh SrivastavaNessuna valutazione finora

- Is 1608-1995Documento24 pagineIs 1608-1995Rakesh Srivastava100% (2)

- Is 4843 68Documento10 pagineIs 4843 68Rakesh SrivastavaNessuna valutazione finora

- Is 5522 92 PDFDocumento6 pagineIs 5522 92 PDFRakesh SrivastavaNessuna valutazione finora

- Iso 14284.1996Documento33 pagineIso 14284.1996Rakesh SrivastavaNessuna valutazione finora

- Whether Corruption Can Be EradicatedDocumento3 pagineWhether Corruption Can Be EradicatedRakesh SrivastavaNessuna valutazione finora

- ReducedDocumento11 pagineReducedRakesh SrivastavaNessuna valutazione finora

- GS Sheet-IS 277 PDFDocumento15 pagineGS Sheet-IS 277 PDFRakesh SrivastavaNessuna valutazione finora

- BS 12385 7 2002Documento18 pagineBS 12385 7 2002Rakesh SrivastavaNessuna valutazione finora

- GS Sheet-IS 277 PDFDocumento15 pagineGS Sheet-IS 277 PDFRakesh SrivastavaNessuna valutazione finora

- Head Hard UicDocumento38 pagineHead Hard UicRakesh SrivastavaNessuna valutazione finora

- SS Fastener-IS1367 Part 14 PDFDocumento25 pagineSS Fastener-IS1367 Part 14 PDFRakesh SrivastavaNessuna valutazione finora

- BS 12385 7 2002Documento18 pagineBS 12385 7 2002Rakesh SrivastavaNessuna valutazione finora

- Short CircuitDocumento27 pagineShort CircuitRakesh SrivastavaNessuna valutazione finora

- Is-4163 NMI in SteelDocumento40 pagineIs-4163 NMI in SteelRakesh SrivastavaNessuna valutazione finora

- DeslaggingDocumento4 pagineDeslaggingRakesh SrivastavaNessuna valutazione finora

- Fracture Cyclic LoadingDocumento9 pagineFracture Cyclic LoadingRakesh SrivastavaNessuna valutazione finora

- 3443 IsDocumento17 pagine3443 IsRakesh SrivastavaNessuna valutazione finora

- Molecules 28 03152 v2Documento17 pagineMolecules 28 03152 v2naziri2008Nessuna valutazione finora

- N173 Iso CD 5149 1 2006Documento47 pagineN173 Iso CD 5149 1 2006heronguyen87100% (1)

- EN - DUPIGET PRECISION - Operation Manual - R15 2019 - BisDocumento36 pagineEN - DUPIGET PRECISION - Operation Manual - R15 2019 - Biskalyan ponnamNessuna valutazione finora

- Open Pan EvaporatorDocumento5 pagineOpen Pan EvaporatorsenthilNessuna valutazione finora

- Gate 1998 PDFDocumento14 pagineGate 1998 PDFVammsy Manikanta SaiNessuna valutazione finora

- Flat Lapping Brochure 2009Documento24 pagineFlat Lapping Brochure 2009kuzhanthaiNessuna valutazione finora

- AMACS Corrugated Grid Packing Web2Documento1 paginaAMACS Corrugated Grid Packing Web2ValiNessuna valutazione finora

- Chapter 3 Past PaperDocumento47 pagineChapter 3 Past PaperAria ElectrobellNessuna valutazione finora

- Contact Angle Phenomena and WettingDocumento16 pagineContact Angle Phenomena and WettingArcha UnniNessuna valutazione finora

- Main Project Part IDocumento7 pagineMain Project Part IBigNessuna valutazione finora

- Investigation of Mixing Behavior of Hydrogen Blended To Natural Gas in Gas NetworkDocumento17 pagineInvestigation of Mixing Behavior of Hydrogen Blended To Natural Gas in Gas NetworkAnonymous y3tPCbVrNessuna valutazione finora

- .Enthuse Major Test Schedule & Syllabus (Med, F, G, H, I, Q, R)Documento1 pagina.Enthuse Major Test Schedule & Syllabus (Med, F, G, H, I, Q, R)335ynesNessuna valutazione finora

- Dalal Engineering Wiped Film Evaporator LeaderDocumento8 pagineDalal Engineering Wiped Film Evaporator LeaderVenkat Giri100% (1)

- Grundfos SB 3 25 ADocumento10 pagineGrundfos SB 3 25 Abuat downloadNessuna valutazione finora

- Pump Types Guide - Find The Right Pump For The JobDocumento6 paginePump Types Guide - Find The Right Pump For The JobShaival JhaNessuna valutazione finora

- 195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0Documento8 pagine195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0leejo100% (1)

- Gas Turbine PhilosophyDocumento55 pagineGas Turbine PhilosophyFreddie Asiedu Larbi100% (1)

- Examples Chapter 11Documento14 pagineExamples Chapter 11Luz HernandezNessuna valutazione finora

- Methods of Purification TechniquesDocumento43 pagineMethods of Purification Techniquespriya sundaramNessuna valutazione finora

- 91JUN085Documento7 pagine91JUN085miguelamenozaNessuna valutazione finora

- T&L Pumps-SignedDocumento11 pagineT&L Pumps-SignedSoumyakanti S. Samanta (Pgdm 09-11, Batch II)Nessuna valutazione finora

- Module 2 - PROPERTIES OF WATER AND TYPES OF SOLIDSDocumento3 pagineModule 2 - PROPERTIES OF WATER AND TYPES OF SOLIDSGabo AlfonsoNessuna valutazione finora

- Score:: Noveleta, Cavite High School Department First Mid-Quarter ExaminationDocumento3 pagineScore:: Noveleta, Cavite High School Department First Mid-Quarter ExaminationTimothyPaul13Nessuna valutazione finora

- Problem Class 2Documento3 pagineProblem Class 2fadum099Nessuna valutazione finora

- Industrial Plant Engineering Elements Review PDF FreeDocumento4 pagineIndustrial Plant Engineering Elements Review PDF FreeRoss AlteaNessuna valutazione finora

- No13 1995 Framo Submerged Cargo Pump - Purging Routine 1ny RevDocumento12 pagineNo13 1995 Framo Submerged Cargo Pump - Purging Routine 1ny RevDaniel Sánchez SoldevillaNessuna valutazione finora

- Budget of Works for Essential Science CompetenciesDocumento28 pagineBudget of Works for Essential Science CompetenciesCALMAREZ JOMELNessuna valutazione finora

- Sitrans Fc430 Hart SM Eng En-UsDocumento100 pagineSitrans Fc430 Hart SM Eng En-UspilperuNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1Sandip Thakur0% (1)

- Cpe Ansi Process Pumps E10431Documento24 pagineCpe Ansi Process Pumps E10431FRANCISCO BADILLONessuna valutazione finora