Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shell & Tube Allowable External Pressure

Caricato da

J.SIVIRA100%(1)Il 100% ha trovato utile questo documento (1 voto)

1K visualizzazioni3 pagineThis document contains calculations for determining allowable external pressure (Pa) for shell and tube components of a vessel. It provides dimensions and material properties, then calculates ratios and uses charts in the ASME code to find factors A and B for each component. These factors and the material yield strength are used to calculate the allowable pressures of 60.87 psi for the shell and 1758.53 psi for the tube.

Descrizione originale:

Titolo originale

UG-28.xlsx

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains calculations for determining allowable external pressure (Pa) for shell and tube components of a vessel. It provides dimensions and material properties, then calculates ratios and uses charts in the ASME code to find factors A and B for each component. These factors and the material yield strength are used to calculate the allowable pressures of 60.87 psi for the shell and 1758.53 psi for the tube.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

1K visualizzazioni3 pagineShell & Tube Allowable External Pressure

Caricato da

J.SIVIRAThis document contains calculations for determining allowable external pressure (Pa) for shell and tube components of a vessel. It provides dimensions and material properties, then calculates ratios and uses charts in the ASME code to find factors A and B for each component. These factors and the material yield strength are used to calculate the allowable pressures of 60.87 psi for the shell and 1758.53 psi for the tube.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

External Pressure allowable, Pa

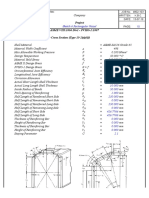

SHELL SIDE SHELL Do = Outside Diameter of Vessel t = Shell Plate Thickness Di = Inside Shell Inside Diameter L = Shell length Temp.F = Ratios DO/T = L/Do = 92.00 4.85 46 0.5 45 222.9375 440 in in in in

[UG-28]

Fig. G in Subpart 3 of Section II A= 3

Check

x .00001 = 0.00003 x .0001 = 0.0003 x .001 = 0.003 x .01 = 0.03

Pa =

60.87

psi

x .1 = 0.3 Material chart - Subpart 3 of Section II, Part D B= 4200

TUBE CALCULATIONS TUBE t = Wall Thickness Do = Outside Diameter of Tube L = Tube length Yield Stress =

(Sec.II, Part D of ASME Code-Subpart 3 -Page 564)

0.109 1 222.9375 21,200.00 Temp.F = 500

in in in psi

Ratios DO/T = L/Do = 9.17 222.94

Fig. G in Subpart 3 of Section II A= 9.8

Check

x .00001 = 0.000098 x .0001 = 0.00098 x .001 = 0.0098 psi x .01 = 0.098 x .1 = 0.98

Pa =

1758.53

Do /t value <10: Pa1 = 1850.13 Pa2 = 3706.06

psi psi

Material chart - Subpart 3 of Section II, Part D B= 12100

FACTOR A

Fig. G in Subpart 3 of Section II

FACTOR B

Material chart - Subpart 3 of Section II, Part D

For values of L/Do greater than 50, enter the chart at a value of L/Do = 50.

a

For values of L/Do less than 0.05, enter the chart at avalue of L/Do = 0.05.

Do /t value <10:

Potrebbero piacerti anche

- Thickness Calculation of Pressure Vessel ShellDocumento22 pagineThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- TUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1Documento5 pagineTUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1J.SIVIRA100% (2)

- TUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1Documento5 pagineTUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1J.SIVIRA100% (2)

- TUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1Documento5 pagineTUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1J.SIVIRA100% (2)

- Nozzle Loads WRC 107 Ver 1.1Documento5 pagineNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Documento14 pagineASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (1)

- Asme Viii D Table 2aDocumento16 pagineAsme Viii D Table 2aJohakim974100% (1)

- Fiber elongation calculations for pressure vesselsDocumento1 paginaFiber elongation calculations for pressure vesselsJ.SIVIRA100% (1)

- Seal Chamber Pressure PDFDocumento10 pagineSeal Chamber Pressure PDFJ.SIVIRA50% (2)

- Datum Compressor Cut PDFDocumento1 paginaDatum Compressor Cut PDFJ.SIVIRANessuna valutazione finora

- Pd5500 Flange CalculationDocumento6 paginePd5500 Flange CalculationMakrand SakpalNessuna valutazione finora

- WRC-107 Calculations for Cylindrical Vessel NozzleDocumento4 pagineWRC-107 Calculations for Cylindrical Vessel NozzleSakthi VelNessuna valutazione finora

- Pvelite OutputDocumento44 paginePvelite OutputRam MurtyNessuna valutazione finora

- WRC 297Documento9 pagineWRC 297akisdassas100% (1)

- Skirt Support Analysis Per en 13445Documento13 pagineSkirt Support Analysis Per en 13445karthik1amarNessuna valutazione finora

- WRC Input InstructionDocumento2 pagineWRC Input InstructionpandiangvNessuna valutazione finora

- EMINENT - Quick Release HooksDocumento17 pagineEMINENT - Quick Release HooksJ.SIVIRANessuna valutazione finora

- Skirt To Dish Joint PDFDocumento64 pagineSkirt To Dish Joint PDFPrajwal ShettyNessuna valutazione finora

- WRC Data-ModifiedDocumento40 pagineWRC Data-ModifiedGovindan KrishnamoorthybashyamNessuna valutazione finora

- Flange Pad CalcsDocumento4 pagineFlange Pad CalcstomNessuna valutazione finora

- Sample FLG CalcDocumento6 pagineSample FLG CalcameyyammaiNessuna valutazione finora

- AES Type Heat ExchangerDocumento8 pagineAES Type Heat ExchangerSudhanshu67100% (1)

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocumento1 paginaNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191Nessuna valutazione finora

- PIPEMILL - Piping Engineering Design and Analysis Pipe Support Shoe Heat TransferDocumento1 paginaPIPEMILL - Piping Engineering Design and Analysis Pipe Support Shoe Heat TransferPhornlert Wana100% (1)

- WRC Check List CriteriaDocumento1 paginaWRC Check List CriteriaAlvin Smith100% (1)

- Calcu Nozzle NeckDocumento15 pagineCalcu Nozzle Necksachmaya0% (1)

- 7-12-0024 Rev 7Documento1 pagina7-12-0024 Rev 7cynideNessuna valutazione finora

- Pipe Cap Thickness Calculation for ASME Section VIIIDocumento9 paginePipe Cap Thickness Calculation for ASME Section VIIILcm TnlNessuna valutazione finora

- Weir Plate or Baffle Plate CalculationDocumento2 pagineWeir Plate or Baffle Plate CalculationamaNessuna valutazione finora

- Nozzle Load AnalysisDocumento2 pagineNozzle Load Analysisvm153748763Nessuna valutazione finora

- WRC For NozzleDocumento43 pagineWRC For NozzleSachin55860% (1)

- Saddle CalculationDocumento10 pagineSaddle Calculationpharis_chrisNessuna valutazione finora

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocumento1 paginaCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNessuna valutazione finora

- Nozzle Design Tool AnalysisDocumento2 pagineNozzle Design Tool AnalysisArt G. EnziNessuna valutazione finora

- WRC 297Documento94 pagineWRC 297joshuamaagNessuna valutazione finora

- Rectangular Tubesheet Design Guideline by HEIDocumento6 pagineRectangular Tubesheet Design Guideline by HEIm5416Nessuna valutazione finora

- Reinforcement Pad DesignDocumento3 pagineReinforcement Pad DesignAkshat JainNessuna valutazione finora

- Cálculo Flange ASME VIII 1 Apendice 2Documento10 pagineCálculo Flange ASME VIII 1 Apendice 2jowarNessuna valutazione finora

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Documento25 pagineEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNessuna valutazione finora

- Calculo Brida Ejemplo PV - EliteDocumento8 pagineCalculo Brida Ejemplo PV - ElitePedro Montes MarinNessuna valutazione finora

- Flange calculation as per ASME Section VIIIDocumento9 pagineFlange calculation as per ASME Section VIIIDarshan PanchalNessuna valutazione finora

- Data Sheet Buffer Tank 60-BT-01 - Rev0.1Documento4 pagineData Sheet Buffer Tank 60-BT-01 - Rev0.1bandithaguru6338Nessuna valutazione finora

- FLANGEDocumento1 paginaFLANGEscrbdgharavi50% (2)

- WRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)Documento1 paginaWRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)miteshpatel191Nessuna valutazione finora

- Nozzle Load As Per MegyesyDocumento3 pagineNozzle Load As Per MegyesyamaNessuna valutazione finora

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 paginePV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNessuna valutazione finora

- "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Documento4 pagine"Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNessuna valutazione finora

- EJMA Bellows CalculatorDocumento6 pagineEJMA Bellows Calculatorsammar_10Nessuna valutazione finora

- Trunnion Check - Node 710Documento13 pagineTrunnion Check - Node 710Prashant ChauhanNessuna valutazione finora

- Manhole DavitDocumento2 pagineManhole DavitgaratetaNessuna valutazione finora

- AD 2000 Head Under Intenal PressureDocumento3 pagineAD 2000 Head Under Intenal Pressuremechengg01Nessuna valutazione finora

- Nozzle Calculations: Understanding Asme Code Calculations-Pressure VesselsDocumento28 pagineNozzle Calculations: Understanding Asme Code Calculations-Pressure VesselsRamakrishnan SrinivasanNessuna valutazione finora

- Universal Nozzle Calculator Ver 3 0Documento10 pagineUniversal Nozzle Calculator Ver 3 0madodandembeNessuna valutazione finora

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Mo ZeroNessuna valutazione finora

- External Pressure allowable calculationDocumento4 pagineExternal Pressure allowable calculationKim JungdaeNessuna valutazione finora

- ASME Design of Buoy For FRP Pipe TestingDocumento5 pagineASME Design of Buoy For FRP Pipe TestingarkadjyothiprakashNessuna valutazione finora

- Steam Drum, Water Wall & Evaporator - VWHA054Documento36 pagineSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNessuna valutazione finora

- Pipeextp-Asme Ug 28Documento1 paginaPipeextp-Asme Ug 28alvinchuanNessuna valutazione finora

- Thrust Block Design JNT450Documento15 pagineThrust Block Design JNT450p_ignatiusNessuna valutazione finora

- Air Compressor Pipe Thickness CalculationDocumento2 pagineAir Compressor Pipe Thickness CalculationDang Hieu NguyenNessuna valutazione finora

- CalculationDocumento37 pagineCalculationParomita Mukherjee Misra100% (1)

- WindDocumento2 pagineWindrameshkaaNessuna valutazione finora

- Lug Support DesignDocumento3 pagineLug Support DesignSajal KulshresthaNessuna valutazione finora

- Mold Design Fundamental Calculation BATTERY COVERDocumento10 pagineMold Design Fundamental Calculation BATTERY COVERBoby SaputraNessuna valutazione finora

- Thickness CalculationsDocumento6 pagineThickness Calculationsvijayunity100% (1)

- ASME B31.3 - 2008 PipeCalculationDocumento6 pagineASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Horizontal Vessel Volume Calculator - Preliminary Sizing SheetDocumento1 paginaHorizontal Vessel Volume Calculator - Preliminary Sizing SheetJ.SIVIRANessuna valutazione finora

- Back Up RingsDocumento10 pagineBack Up RingsJ.SIVIRANessuna valutazione finora

- Api 682 Update PDFDocumento5 pagineApi 682 Update PDFJ.SIVIRANessuna valutazione finora

- Turbine Parts DescriptionsDocumento9 pagineTurbine Parts DescriptionsJ.SIVIRANessuna valutazione finora

- The Illusion of Explanatory DepthDocumento1 paginaThe Illusion of Explanatory DepthJ.SIVIRANessuna valutazione finora

- Process Check List For Columns VesselsDocumento4 pagineProcess Check List For Columns VesselsJ.SIVIRANessuna valutazione finora

- What Is NPSHDocumento10 pagineWhat Is NPSHgyousafNessuna valutazione finora

- Metering Pumps - The Lowdown On TurndownDocumento7 pagineMetering Pumps - The Lowdown On TurndownJ.SIVIRANessuna valutazione finora

- Fluid Viscosity EffectsDocumento4 pagineFluid Viscosity Effectschris110Nessuna valutazione finora

- Big Tapping Chart PDFDocumento1 paginaBig Tapping Chart PDFJ.SIVIRANessuna valutazione finora

- January 2013: Mon, Jan 7 - Sun, Jan 13Documento6 pagineJanuary 2013: Mon, Jan 7 - Sun, Jan 13slv_prasaadNessuna valutazione finora

- ASME Impact Test RequirementDocumento6 pagineASME Impact Test RequirementJ.SIVIRANessuna valutazione finora

- Specifications Standards For Shafts AlignmentDocumento20 pagineSpecifications Standards For Shafts AlignmentJ.SIVIRANessuna valutazione finora

- Semi Elliptical Head Specs PDFDocumento2 pagineSemi Elliptical Head Specs PDFJ.SIVIRANessuna valutazione finora

- Equipment Specifications PDFDocumento10 pagineEquipment Specifications PDFJ.SIVIRANessuna valutazione finora

- Tank Heat LossDocumento25 pagineTank Heat Lossdanmaltais100% (3)

- Taller Comercio C.A. Heat Exchanger Design CalculationsDocumento1 paginaTaller Comercio C.A. Heat Exchanger Design CalculationsJ.SIVIRANessuna valutazione finora

- Insulation Calc I PDFDocumento2 pagineInsulation Calc I PDFJ.SIVIRANessuna valutazione finora

- Calculate volume and weight of ellipsoidal headDocumento3 pagineCalculate volume and weight of ellipsoidal headJ.SIVIRANessuna valutazione finora

- Storage Tank Basic Training Rev 2Documento97 pagineStorage Tank Basic Training Rev 2erikoh100% (1)

- Centrifugal PumpsDocumento82 pagineCentrifugal PumpsMd KalamuddinNessuna valutazione finora

- Pump AlignmentDocumento69 paginePump AlignmentJ.SIVIRA100% (1)

- Propane Gas and Liquefied GasDocumento10 paginePropane Gas and Liquefied GasJ.SIVIRANessuna valutazione finora