Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Removal of Congo Red Fron Solution by Adsorption

Caricato da

Jacob BennettsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Removal of Congo Red Fron Solution by Adsorption

Caricato da

Jacob BennettsCopyright:

Formati disponibili

1

Removal of anionic dye Congo Red from aqueous solution by adsorption

Abstract The removal of Congo Red (CR) dyes from wastewater effluents is an important topic due to the health and environmental risks if left untreated. In lot of developing areas in the world removal of CR dyes by conventional means is still expensive. This has been motivation for research to be carried out in order to find low cost alternatives. The use of agricultural wastes as adsorbents has shown to be a promising avenue to remove dyes such as CR. This report investigates results of four different studies on the low cost adsorbents: Chitosan Hydrogel Beads, Bagasse Fly Ash, Cattail Root and Bael Shell Carbon. Conclusions are then drawn from the results of these studies. 1. Introduction Dyes have been used by humans for thousands of years to colour fibrous materials such as fabrics. Prior to 1856 humans were only using dyes from natural sources, until the discovery of synthetic dyes was made (Clark 2011, 3). The aim of a dye is to uniformly colour a substrate permanently, hence the dye should also be resistant to such things as moisture, light, heat and washing methods once applied (Chatwal 2009). According to the Britannica encyclopaedia the dyeing process places the dye molecules within the microstructure of the substrate via various mechanisms depending on the specific dye and substrate. Congo Red (CR) also known as Direct Red 28 is a synthetic, anionic benzidine based dye, with the chemical formula . CR can metabolize to benzidine which is a known human

carcinogen. CR is also known to be toxic to plants and animals which is another reason why CR effluents entering wastewater streams is a major environmental, ecological and health concern (Ahmad and Kumar 2010). There are several immediate dangers to CR exposure, which are as follows: Eye irritation and the possibility of chemical conjunctivitis or corneal damage. Skin irritation (possibly burns) with the possibility of an allergic reaction, which would become evident upon re-exposure to CR. If ingested (large quantity) CR may cause gastrointestinal irritation with nausea, vomiting and diarrhoea. If inhaled respiratory tract irritation may result. Olfactory fatigue may occur and possibly delayed pulmonary edema (Congo Red MSDS. 2005). The long term health risks are much more dangerous, some of these are: Possibility to cause adverse reproductive effects (fetotoxicity, female and male fertility) and birth defects (teratogenic developmental abnormalities) based on animal data. May cause genitic mutations based on animal

data. Congo Red is a benzidine-based dye and benzidine has been classified by IARC as Group 1 carcinogen (Congo Red MSDS. 2005). Some of the environmental impacts of CR effluents in wastewater are: negativily affecting photosynthetic processes of aquatic plants, reducing the oxygen levels in water and in some extreme cases suffocating of aquatic ora and fauna has occurred (Chatterjee et al. 2009). According to Mall et al. (2005) CR euents are most commonly produced from textiles, printing and dyeing, paper, rubber and plastics industries however because of the structural stability of CR it can be dicult to biodegrade. This being the case there are still various ways to treat the CR wastewaters so that the associated risks can be reduced. CR dye wastewater can still be treated by conventional means such as coagulation and occulation membrane separation, activated carbon adsorption, electrochemical removal and photochemical degradation (Hu et al. 2010). According to Gupta and Suhas (2009) biological treatment is the most common and wide spread technique used in dye wastewater treatment. Biological treatments can be aerobic, anaerobic or combined aerobicanaerobic, which can offer flexibility for treating a range of dyes and reasonably cost effective (Gupta and Suhas 2009). However this method isnt very effective for dyes such as CR that have low biodegradability also it requires a large area of land and requires a long time to ferment which means it cannot be done on a continuous process. Chatterjee et al. (2009) explains that activated carbon is the most common adsorbent used for removing dye from waste water, however it is difficult to to dispose of and regenerate. Mall et al. (2005) also states that granular activated carbon is a very popular and successful adsorbent, but costly too. The main problem the methods mentioned above have is that they can be quite costly and are therefore too expensive to be used in a lot of developing countries. This has been motivation for research into low cost adsorbents that can be used to treat wastewaters containing CR (Ahmad and Kumar 2010). Some of the research has looked into the use of low-cost agricultural adsorbents such as: coir pith, anaerobic granular sludge, hazelnut shells, bottom ash and de-oiled soya, carbon slurry, hen feathers along with other waste materials however the adsorption capacities of most of the materials mentioned are limited (Hu et al. 2010). Other low cost agricultural adsorbents have greater adsorption capacities, which could be promising, such as: Pine dust, chitosan, rice husks, activated clay and cane pith, all with different contact times and pH (Gupta and Suhas 2009).

Darwood and Sen (2012) along with many others believe adsorption to be superior to other separation techniques in terms of initial cost, simplicity of design, ease of operation and insensitive to toxic substances. According Sen (2013) adsorption is defined as the selective retention of one or more components of a mixture on a solid surface (pore wall). There are two types of adsorption, physical or physisorption and chemical or chemisorption. The attractive forces occurring in physisorption between adsorbed molecules and the solid surface are van der Waals forces. These forces are usually weak which can allow in reversible adsorption. Attraction forces in chemisorption are generally stronger than physisorption, hence it is difcult to remove chemisorbed species from the solid surface (Sen 2013). In the case of anionic dyes such as CR electron transfer between the adsorbent and adsorbate take place to form chemical bonds. Good adsorbents should have the following characteristics, high surface area (increases the adsorption capacity), small particle size, time taken for adsorption equilibrium should be as short as possible, good affinity for solute and correct pH which will affect the degree of ionisation.

According to Gupta and Suhas (2009) some common adsorbents used to remove dyes from waste water are: Alumina, which is a synthetic porous crystalline gel, available in the form of granules of different sizes having surface area ranging from 200 to 300 m2g-1. Silica Gel, prepared by the coagulation of colloidal silicic acid results in the formation of porous and non-crystalline granules of different sizes. Silica Gel has a higher surface area than to alumina, ranging from 250 to 900 m2g-1, however it is an expensive option. Zeolites, are micro porous adsorbents, which can be found naturally and prepared synthetically also. They are also considered as selective adsorbents and show ion exchange properties. Activated carbon, very effective, normally has a very porous structure with a large surface area ranging from 500 to 2000 m2g-1. However time and expensive are required to first activate the carbon through and then regenerate it after it has been exhausted.

2. Previous Research As previously mentioned there is a great need for CR dyes to be removed from wastewater because of the risks associated however many conventional methods of removal can be expensive for developing countries. This section of the report will investigate previous research done on low cost adsorption solutions for the removal of CR dyes. Chitosan Hydrogel Beads Chatterjee et al. (2009) investigated the effectiveness of using Chitosan hydrogel beads impregnated with nonionic or anionic surfactants. Chitosan (CS), is a linear biopolymer of glucosamine that exhibits a high adsorption capacity towards many classes of dyes especially anionic dyes because of its high amino and hydroxyl functional group content (Chatterjee et al. 2009). CS can be obtained at an industrial level by chemical de-acetylation of crustacean chitin (a major component of exoskeletons of crustaceans such as crayfish, prawns and crabs, also on insects), which is the second most abundant biopolymer in nature. In their report Chatterjee et al. (2009) investigated the effect of impregnation of CS beads with two surfactant types, non-ionic [triton X-100 (TX-100)] and anionic [sodium dodecyl sulphate (SDS)], for the removal of anionic dye CR from aqueous solution. Table 1 below shows the properties of the different beads used for the study, notice the very similar physical properties.

Table 1: General properties of different types of beads (Chatterjee et al. 2009)

Figure 1 below shows that CS/TX-100 increases in equilibrium absorption capacity, increasing surfactant concentration of beads up to 0.02 % where increases

(mg/g), with

slowly decreases. CS/SDS also

but starts to decrease rapidly at about 0.01 % surfactant concentration.

4

Figure 1: Effect of Surfactant Impregnation on CR adsorption with initial concentration of 500mg/l (Chatterjee et al. 2009) Figure 2 below shows how the equilibrium absorption capacity solution with all bead types. , decreases with initial pH of

Figure 2: Effect of pH on CR adsorption with initial concentration of 500 mg/l (Chatterjee et al. 2009). Through their experiments Chatterjee et al. (2009) found that not only could CS beads be an effective adsorbent for CR dye but surfactant impregnation at a low dosage could greatly improve performance. With an initial CR concentration of 500 mg/l, the experiments showed a maximum adsorption (mg/g) of CS, CS/TX-100 and CS/SDS beads to be, 160.19, 302.05 and 223.35

respectively. All beads reached maximum adsorption capacity between 480-600 minutes with CS/TX-100 beads having the highest mass transfer rate also. These findings by Chatterjee et al. (2009) are quite promising however no costing estimates were included in their study.

Bagasse Fly Ash Mall et al. (2005) performed a study to examine the effectiveness of bagasse fly ash (BFA) as an adsorbent for CR dye removal in comparison to boilers, activated carbons of commercial grade (ACC) and laboratory grade (ACL). BFA is a waste product from the sugarcane industry and can be obtained from the particulate collection equipment attached upstream to the stacks of bagasse (fibrous remains of sugarcane stalks) fired boilers. Results from the study showed that CR colour removal increases, as adsorbent dosage increases, up to a certain limit and then it remains almost constant with the optimum for BFA, ACC and ACL dosages being 1, 20 and 2 g of adsorbents per litre of dye solution, respectively. Figure 3 shows the results of initial CR concentration for the various adsorbates at pH= 7, temperature = 30C and time= 4 h, demonstrating that effectiveness of adsorbents decreases with increasing initial CR concentration.

Figure 3: Effect of initial adsorbate concentration on the adsorption of CR at optimum dosages (Mall et al. 2005) Figure 4 below demonstrates how the mass of CR adsorbed per unit mass of adsorbent, qt (mg/g), increases over time.

Figure 4:

(mg/g), over a 4 h period, pH= 7, temperature = 30C (Mall et al. (2005).

Summarising the study by Mall et al. (2005) it can be seen that BFA may be an effective low cost adsorbent for the removal of CR dye from aqueous solutions and more effective than the ACC and ACL used. The main advantage of using BFA is its low cost, which according to Gupta and Suhas (2009) is less than $0.1 US/ per kg.

6

Cattail Root Hu et al. (2009) investigated the removal of CR dye by cattail root from aqueous solution. Cattail root is an aquatic plant with a porous structure and a large surface area, which can be utilized as adsorbent to treat wastewater containing dyes such as CR. For their study Hu et al. (2009) used cattail root sourced from a local pond in Hefei, China. The root was first washed with tap water to remove soil and dust then sprayed with distilled water, and dried to a constant weight at 75C. The dry cattail root was ground and sieved to obtain particle sizes of 0.25 -0.40mm as adsorbent, and then stored in desiccators for use. The results of the study showed that when increasing adsorbent dosage from 0.5 to 10.0 g/L, the removal of CR increased from 14.4 to 98.4% in less than 180 minutes for high dosages, see Figure 5 below.

Figure 5: Effect of adsorbent dosage and contact time on CR removal (cattail dosage: , 0.5 g/L; , 1.0 g/L; 3.0 g/L; , 5.0 g/L; , 7.0 g/L; , 10.0 g/L. CR 50 mg/L, initial pH = 7 and temperature = 20C (Hu et al. (2009)) Figure 6 below shows the effect of pH on removal efficiency of CR with a cattail dosage of 5 g/L, CR concentration of 50 mg/L and a temperature of 20C.

Figure 6: Effect of pH on the removal of CR by cattail root (Hu et al. 2009).

7

In summary the investigation by Hu et al. (2009) produces the following results. Removal efficiency of CR increased with increasing adsorbent dosage and decreased with increasing temperature from 20 to 40C. The equilibrium time was about 16 h, depending on the adsorbent dosage. Over a pH range of 5.5 10.0, the removal efficiency was independent of pH at CR concentration of 50mg/L and adsorbent dosage 5.0 g/L with a pH of 2.5 producing the best results. The maximum adsorption capacities of CR on cattail root were 38.79, 34.59 and 30.61mg/g at 20, 30 and 40C, respectively. These results suggest that cattail root is a potential low-cost adsorbent for the dye removal from industrial wastewater (Hu et al. (2009).

Bael Shell Carbon Ahmad and Kumar (2010) investigated the use of Bael shell carbon (BSC) as a low cost adsorbent for the removal of CR dye from aqueous solution. Looking into the effect of different parameters such as pH, temperature, contact time and initial dye concentration. Bael is a fruit that is grown throughout Southeast Asian countries such as India, Sri Lanka, Pakistan, Bangladesh, Burma, and Thailand. The hard shell of the fruit is a waste product. For the study the bael shell was collected locally in India after which it was washed with distilled water and dried in sun light for 10 days. The dried shell was crushed and sieved to the appropriate particle size then it was carbonized for 1 h at 450C in a muffle furnace. The carbonized sample was washed with hot distilled water and dried at 60 C for 24 h after which it was used for experiments (Ahmad and Kumar (2010). Figure 7 below is an example of one of the results from the study performed by Ahmad and Kumar (2010) and shows how the adsorption capacity at equilibrium, , increases with temperature.

Figure 7: Effect of temperature on CR adsorption onto BSC (Ahmad and Kumar 2010).

Other results from the study are as follows were the adsorption of CR onto BSC was strongly pH dependent. The maximum adsorption (92%) was observed at pH 3. The maximum adsorption capacity or CR using BSC was 98.03 mg/g which can be seen in table 4 below along with the comparisons to other carbons used for CR removal. Overall it can be said that BSC could be an effective low cost adsorbent for the removal of CR dyes from wastewater.

Table 2: Comparison of maximum monolayer adsorption capacity of various carbons for CR removal (Ahmad and Kumar 2010).

3. Conclusion Each of the four adsorbents reviewed have potential to be good low cost adsorbents. Simply comparing the maximum equilibrium adsorption capacities of CS/TX-100, BFA, Cattail root and BSC gives the following results respectively, 302.05, 10, 38.79, 98.03 mg/g, which shows CS/TX100 to be the most effective adsorbent. However the adsorption capacities are not the only factor to choose when evaluating options for low cost adsorbents. Factors such as: Cost of obtaining the resource, cost and time in preparing the adsorbent for use, complexity of process, space required, availability of resource, dye removal time, batch or continuous process, concentration of CR in solution and temperature must also be considered.

10

4. References

Ahmad, Rais, and Rajeev Kumar. "Adsorptive Removal of Congo Red Dye from Aqueous Solution Using Bael Shell Carbon." Applied Surface Science 257, no. 5 (12/15/ 2010): 1628-33. Chatterjee, Sudipta, Dae S. Lee, Min W. Lee, and Seung H. Woo. "Congo Red Adsorption from Aqueous Solutions by Using Chitosan Hydrogel Beads Impregnated with Nonionic or Anionic Surfactant." Bioresource Technology 100, no. 17 (9// 2009): 3862-68. Chatwal, Gurdeep R., and Madhu Arora. Synthetic Dyes. Mumbai, IND: Global Media, 2009. Clark. Handbook of Textile and Industrial Dyeing, Volume 2 - Applications of Dyes. 2011. Gupta, V. K., and Suhas. "Application of Low-Cost Adsorbents for Dye Removal a Review." Journal of Environmental Management 90, no. 8 (6// 2009): 2313-42. Hu, Zhenhu, Hui Chen, Feng Ji, and Shoujun Yuan. "Removal of Congo Red from Aqueous Solution by Cattail Root." Journal of Hazardous Materials 173, no. 13 (1/15/ 2010): 29297. Mall, Indra Deo, Vimal Chandra Srivastava, Nitin Kumar Agarwal, and Indra Mani Mishra. "Removal of Congo Red from Aqueous Solution by Bagasse Fly Ash and Activated Carbon: Kinetic Study and Equilibrium Isotherm Analyses." Chemosphere 61, no. 4 (10// 2005): 492-501. Sen, Tushar Kanti. 2013 Lecture 4: Adsorption. Power Point lecture notes.

https://lms.curtin.edu.au/bbcswebdav/pid-2558151-dt-content-rid8200158_1/courses/313760-FacSciEng-1821132224/Adsorption_4.pdf

10

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- HighpuritysealsDocumento6 pagineHighpuritysealstuannhocutNessuna valutazione finora

- State ManagementDocumento16 pagineState Managementnegikamal703Nessuna valutazione finora

- CLS 747 200Documento158 pagineCLS 747 200Rodrigo Adam100% (8)

- User'S Manual: Capstone MicroturbineDocumento56 pagineUser'S Manual: Capstone MicroturbinemassimocalviNessuna valutazione finora

- G270han01 V0Documento26 pagineG270han01 V0NemkoNessuna valutazione finora

- PNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners TypeDocumento28 paginePNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners Typec_lucian2004Nessuna valutazione finora

- Softening Point of AsphaltDocumento2 pagineSoftening Point of AsphaltMuhammad Rizal RamliNessuna valutazione finora

- Iec60092-350 (Ed2 0) enDocumento7 pagineIec60092-350 (Ed2 0) enAzad RahmanNessuna valutazione finora

- FL-02-01 PM SheetDocumento12 pagineFL-02-01 PM SheetBikas SahaNessuna valutazione finora

- GM Passlock II SystemDocumento14 pagineGM Passlock II Systemalmia tronicsNessuna valutazione finora

- FR-8x Editor Eng01 WDocumento8 pagineFR-8x Editor Eng01 WRadulian Daniel100% (1)

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDocumento18 pagineBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNessuna valutazione finora

- Antikythera MechanismDocumento25 pagineAntikythera MechanismchetansergiurazvanNessuna valutazione finora

- Man 2563XX 07Documento232 pagineMan 2563XX 07trance1313Nessuna valutazione finora

- TD Quintolubric 888 68Documento2 pagineTD Quintolubric 888 68Haitham YoussefNessuna valutazione finora

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocumento11 pagine4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Documento7 paginePG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNessuna valutazione finora

- TDS Sadechaf UVACRYL 2151 - v9Documento5 pagineTDS Sadechaf UVACRYL 2151 - v9Alex MacabuNessuna valutazione finora

- BKLT DeaeratorDocumento24 pagineBKLT Deaeratormalikgaurav01Nessuna valutazione finora

- Asgmnt HECRASDocumento7 pagineAsgmnt HECRASShahruzi MahadzirNessuna valutazione finora

- Wiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRDocumento2 pagineWiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRSivan Raj50% (2)

- The Right Stuff PDFDocumento4 pagineThe Right Stuff PDFNeelank Tiwari100% (1)

- The Difference Between The Internet and World Wide WebDocumento3 pagineThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- GIS Project Management GIS Project Management: Quality Issues Quality IssuesDocumento1 paginaGIS Project Management GIS Project Management: Quality Issues Quality IssuesLeo DobreciNessuna valutazione finora

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocumento6 pagineSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNessuna valutazione finora

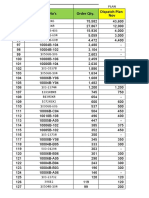

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 pagineOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNessuna valutazione finora

- Differences Between VSI and CSI Converter Operation Modes.Documento1 paginaDifferences Between VSI and CSI Converter Operation Modes.Sushil NamoijamNessuna valutazione finora

- Jacky Smith Resume Project ManagerDocumento1 paginaJacky Smith Resume Project ManagerGrey GrayNessuna valutazione finora

- Justine J. Beroy: Career ObjectivesDocumento5 pagineJustine J. Beroy: Career ObjectivesJustine BeroyNessuna valutazione finora