Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rotary Discharge Machine

Caricato da

MKOZERDEMDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rotary Discharge Machine

Caricato da

MKOZERDEMCopyright:

Formati disponibili

W E

C O N V E Y

Q U A L I T Y

ROTARY DISCHARGE MACHINE

W E

C O N V E Y

CONTENTS

ROTARY DISCHARGE MACHINES

For a variety of applications wherever difficult bulk material needs to be discharged from Rectangular hoppers Open stockpiles Large cylindrical silos All LOUISE Rotary Discharge Machines feature the logarithmically shaped discharge arms and automatic operation including reverse travel.

2 Rotary Discharge Machines 3 Rotary Discharge Machine type RDM-BL 6 Rotary Discharge Machine type RDM-BL 7 Data Sheet 9 Rotary Discharge Machine type RDM-LP 10 Rotary Discharge Machine type RDM-LP with Weigh Feeder 11 Data Sheet 12 Rotating Rotary Discharge Machine type RDM-R 15 Bulk Material testing in our laboratory 16 Components 18 Conversion & Refurbishments 19 After-Sales Service

Three basic alternatives: Block Model type RDM-BL Low Profile Model type RDM-LP Rotating Model type RDM-R

Materials which can be handled: FGD-gypsum Coal Gypsum Limestone Lignite Clay Marl Petcoke

Q U A L I T Y

ROTARY DISCHARGE MACHINE TYPE RDM-BL

Double side discharge for rectangular hoppers The block-type Rotary Discharge Machine is designed for double side discharge. All drive components are located in a solid casing. The machine moves inside a tunnel and reclaims the product from both sides. The hydraulic unit or the frequency controller allows to adjust the reclaim capacity.

W E

C O N V E Y

ROTARY DISCHARGE MACHINE TYPE RDM-BL

hydraulic unit

discharge wheel

bunker table

belt conveyor

Q U A L I T Y

Coal storage and reclaim The Ishikawa power plant, Okinawa - Japan, features four silos with a storage volume of 50,000 m3. These silos, ranging among the largest worldwide, were built by Mitsui Construction Co. Ltd. The coal is discharged by four Rotary Discharge Machines arranged parallel to each other. Each discharge machine travels on rails installed in a concrete tunnel covering the whole length of the silos. This arrangement allows each individual machine to discharge from either one of the four silos. The travel distance exceeds 200 m. The block-type discharge machine is designed in such a way that the coal is reclaimed from bothsides of the shelf. Each machine has a reclaim capacity of 40 t/h 400 t/h and both the discharge wheel and the travel mechanism are hydraulically driven and adjustable. The discharge wheels diameter of 4 m allows to cut deeply into the material column, an important feature to prevent bridging of the stored product. A material guide installed on the RDM serves as dust cover and guides the product onto the belt conveyor located underneath the Rotary Discharge Machine.

Cross section of Denpatsu coal silo

Storage capacity of the 4 silos Diameter of each silo Height of each silo Discharge capacity of each discharge machine Installed power Travel speed Diameter of discharge wheel 50.000 m3 37 m 56 m adjustable from 40 t/h to 400 t/h 37 kW 0.92 to 3.72 m/min 4.000 mm

Denpatsu coal-fired

Shikoku plant

At the Denpatsu coal-fired power plant of Electric Power Development Co. Ltd., the coal storage silos feature 8 Rotary Discharge Machines each reclaiming 1,000 t/h coal from two rows of 4 silos each.

At the Shikoku plant, 8 Rotary Discharge Machines reclaim from 2 rows of 2 silos each.

W E

C O N V E Y

ROTARY DISCHARGE MACHINE TYPE RDM-BL

Coal Handling - American Superior Midwest Energy Terminal, Wisconsin - USA The coal extracted in open-cast mining is stored on an open stockpile during the winter season when shipping service is interrupted due to low temperatures. 6.5 million tons of coal can be stored on this open stockpile until the end of the winter season. A total of 9 Rotary Discharge Machines reclaim the coal from this stockpile. Three machines each work in one unit and achieve a total reclaim capacity of 10,000 t/h. With this capacity and a discharge wheel diameter of 4 m, they range among the best performing reclaimers worldwide. The discharge machines travel on rails inside a tunnel with a cone-shaped roof, continuously discharging the coal onto a belt conveyor also installed in the tunnel. When travelling back and forth, the discharge arms dig deeply into the coal through slots arranged in the tunnel. Each rotary discharge machine is driven by a 2.2 kW motor and travels the distance of 360 m with a velocity of 0.9 m/min. In order to achieve a high torque with only 1 to 10 rpm, the discharge wheels are actuated by hydraulic units with 110 kW electric motor. If the discharge machines encounter high resistance due to the frozen status of the coal, the pressure sensors actuate the reverse mode and restart the machine. The drive unit is installed inside a compact casing with easy access. The machines are in operation since 1976 and demonstrate the high availability of the LOUISE Rotary Discharge Machines.

Storage capacity Stockpile length Discharge capacity of each discharge machine Installed power Rotating speed of discharge wheels Diameter of discharge wheels Travel speed open stockpile, 6.5 million tons 360 m 3.300 t/h 150 kW adjustable from 1 to 10 rpm 4.000 mm 0.9 m/min

Q U A L I T Y

DATA SHEET

Rotary Discharge Machine type RDM-BL

theoretical capacity Q (m3/h) both-sided discharge with wheel speed n (rpm)

range 1:10 circular speed at wheel tip

discharge wheel diameter DR

(mm)

discharge opening height H

(mm)

penetration depth P

(mm)

cone-shaped tunnel width B

(mm)

rail to hopper shelf hopper to belt feeder shelf height height Z

(mm)

max. admissible travel speed V

(m/min)

T

(mm)

U = 0,3 m/s

m/h (m/s)

U = 0,3 m/s

m/h (m/s)

2000 2500 3000 4000 5000

200 250 300 400 500

350 450 700 1000 1150

1300 1600 1600 2000 2700

600 775 775 1030 1030

1000 1100 1100 1200 1200

94 (2,90) 138 (2,28) 225 (1,91) 410 (1,43) 580 (1,14)

940 (29,0) 1380 (22,8) 2250 (19,1) 4100 (14,3) 5800 (11,4)

6,35 6,35 6,35 6,35 6,35

Standard dimensions and capacity. Further dimensions and capacities on request.

W E

C O N V E Y

RDM with single-side discharge Discharge wheel with six arms, each with wear resistant front plate and armoured tip.

View onto discharge wheel

RDM with single side discharge Festoon towing arm Safety limit switch Anti-collision sensor Travel distance sensor Travel distance limit switch Local control box Discharge wheel dust cover

RDM with single-side discharge

RDM with single side discharge and double swivel mechanism

Q U A L I T Y

ROTARY DISCHARGE MACHINE TYPE RDM-LP

RDM with single-side discharge Installed on the belt conveyor supporting structure, the Rotary Discharge Machine moves along the hopper shelf and reclaims the bulk material. The drive unit and electrical package are safely stored inside the dust-tight casing of the machine.

RDM with single swivel drive for single-side discharge Installed on the belt conveyor supporting structure, the Rotary Discharge Machine travels to defined areas of the hopper where it reclaims the bulk material. A high speed mode in the travel drive allows to reach these areas quickly. The main drive with all its components forms a swivel unit installed on the trolley.

RDM with double swivel drive for single side discharge on both sides Installed on the belt conveyor supporting structure, the Rotary Discharge Machine travels to defined areas of the hopper. The discharge wheel swivels between the shelfs on both sides of the hopper. A high speed mode in the travel drive allows to reach these areas quickly. The main drive with all its components forms a swivel unit installed on the trolley.

W E

C O N V E Y

ROTARY DISCHARGE MACHINE TYPE RDM-LP WITH WEIGH FEEDER

Raw material handling in a Cement Plant Three Rotary Discharge Machines are installed underneath a row of hoppers storing a total of 9,000 t of limestone, marl and dolomite. In order to obtain the required mixture directly when reclaiming the different raw materials from the hoppers for subsequent mill feeding, the reclaim capacity of the three discharge machines is controlled by a Weigh Belt Feeder forming part of the mobile discharge machine. The actual volume to be reclaimed by the discharge machine from the three hoppers is determined in the laboratory. Adequate adjustment of the total reclaim capacity is made in the mill control room. The mixture ratio remains unchanged. On account of the homogeneous volumetric reclaim through the hopper openings, an accuracy of +/- 1% can be achieved with the Weigh Feeders.

Storage capacity Material Humidity Capacity of each discharge machine Installed power Rotating speed of discharge wheels Travel speed Weigh belt feeder width 9.000 t limestone and marl of 0 60 mm max. 14% 30 - 180 t/h 20 kW adjustable from 0.5 to 5 rpm 1 and/or 0.45 m/min 800 mm

10

Q U A L I T Y

DATA SHEET

Rotary Discharge Machine - Low Profile Model

theoretical capacity Q (m3/h) single-side discharge with wheel speed n (rpm)

range 1:10 circular speed at wheel tip

discharge wheel diameter

discharge opening height

penetration depth overall width

overall height

track

hopper shelf to rail height

rail to belt feeder height

max. admissible travel speed

DR

(mm)

H

(mm)

P

(mm)

B

(mm)

O

(mm)

V

(mm)

Z

(mm)

T

(mm)

U = 0,3 m/s U = 0,3 m/s

m/h (m/s) m/h (m/s)

V

(m/min)

2000

200

400

2300

1450

1500

600

500

47 (2,90)

470 (29, 0)

6,35

2500

3000

250

300

450

700

2650

3000

1500

1600

1850

2200

650

650

550

700

69 (2,28)

112 (1,91)

690 (22,8)

1120 (19,1)

6,35

6,35

3500

4000

350

400

800

1000

3300

3600

1700

1850

2500

2800

700

750

750

800

151 (1,63)

205 (1,43)

1510 (16,3)

2050 (14,3)

6,35

6,35

Standard dimensions and capacity. Further dimensions and capacities on request.

11

W E

C O N V E Y

ROTATING ROTARY DISCHARGE MACHINE TYPE RDM-R

For large silos with a 5 m to 12 m diameter

The discharge wheel undercuts the material column and guides the material to the central outlet chute. First in / First out Proportional reclaim Simultaneous feeding and discharge Easy access

12

Q U A L I T Y

ROTATING ROTARY DISCHARGE MACHINE

Culley Power Station, Indiana USA

In the coal-fired plant in Indiana the FGD-gypsum, a by-product of the flue gas desulphurisation process, is stored in concrete silos. With an average humidity of 8 10%, sometimes even 15%, the FGD-gypsum is a heavy and sticky material with poor flow characteristics. The exact data of this material were determined by tests carried out in the LOUISE laboratory and the reclaim of each silo is now performed with a rotating rotary discharge machine designed to suite the specific characteristics revealed by these tests. Each machine reclaims a total of 500 t/h, a capacity reached within 15 seconds, and loads onto 20 ton trucks. With normal loading conditions, the material volume of each silo is unloaded within 8 hours. In order to provide easy access, the discharge machine bottom and outlet chute are fitted directly underneath the discharge arms. The bottom rotates with the discharge wheel and the machine may be entered from the side opposite to the discharge arms.

Storage capacity Diameter of each silo Height of each silo Discharge capacity of each discharge machine Installed power Rotating speed of discharge wheel Diameter of discharge wheel 2 silos of 1.000 m3 each 8m 20 m 500 t/h 75 kW adjustable from 0.3 to 3 rpm 4.500 mm

13

W E

C O N V E Y

ROTATING ROTARY DISCHARGE MACHINE TYPE RDM-R

Rotating Rotary Discharge Machine type RDM-R

theoretical capacity Q (m3/h) with wheel speed n (rpm) range 1:10 penetration circular speed at wheel depth tip

diameter silo

diameter discharge wheel

diameter cone

diameter floor ring opening

diameter concrete floor opening

diameter incl. undercut

max. protrusion of cone girder

discharge opening height

D1

(mm)

DR

(mm)

D2

(mm)

D3

(mm)

D4

(mm)

D5

(mm)

A

(mm)

H

(mm)

P

(mm)

u = 0,3

(m/s)

u = 3,0

(m/s)

5000

3000

3600

1200

1950

5140

600

300

700

112 (1,91) 1120 (19,1)

6000

8000 10000

3600

4500 4500

4400

6000 8000

1300

2200 3700

2350

4750 6250

6140

8140 10140

700

900 900

350

450 450

800

1000 1000

155 (1,67) 1550 (16,7)

247 (1,27) 2470 (12,7) 247 (1,27) 2470 (12,7)

12000

4500

10000

5700

8250

12140

900

450

1000

247 (1,27) 2470 (12,7)

Standard dimension and capacity. Further dimensions and capacities on request.

14

Q U A L I T Y

BULK MATERIAL TESTING IN OUR LABORATORY

To determine the physical and mechanical properties and behaviour of specific bulk materials, our laboratory incorporates a large variety of testing equipment. Various test methods allow to determine the correct application of our products, e.g. shear testing.

Jennicke shear cell

Bulk material tests

Ratholing

Core flow

Bridging

Mass flow

15

W E

C O N V E Y

COMPONENTS

5 RDM-R's 10,000/4,500 during assembly in the workshop

Block gear units for RDM-BL

16

Q U A L I T Y

RDM-R discharge wheel, 4,500 mm

Chassis of RDM-R, view onto hydraulic cylinders for rotation

17

W E

C O N V E Y

Retrofitting a heavy Apron Feeder

CONVERSIONS AND REFURBISHMENTS

Upgrading of existing plant components Targeting increased efficiency Higher output Improved higher availability the feasibility and analysis of the bulk materials properties and the technical specifications of the existing plant. Engineered conversions and refurbishments for increased efficiency and output are performed on AUMUND equipment same as well as on equipment of other manufacturers.

With our expert team of engineers planning selective modernization measures we pay special attention to the upgrading of existing plant components, targeting increased efficiency, higher output rates and improved availability. Upgrading of your materials handling and storage equipment to state-of-the-art technology is achieved through a tailor-made refurbishment process under optimum utilization of time and budget. Most of the existing components are re-used in the refurbishment process to save costs. For each project, a system drawing showing how the new components fit into the existing geometry is generated after verification of

Conversion of a Bucket Elevator

18

Q U A L I T Y

AFTER-SALES SERVICE

Supervises assembly and

commissioning jobs

THE AUMUND GROUP

GERMANY

AUMUND-Frdererbau GmbH & Co. KG Saalhoffer Str. 17 47495 Rheinberg Tel.: +49 - 2843 - 72 0 Fax: +49 - 2843 - 6 02 70 e-mail: aumund@aumund.de www.aumund.com AUMUND Frdertechnik GmbH Saalhoffer Str. 17 47495 Rheinberg Tel.: +49 - 2843 - 72 0 Fax: +49 - 2843 - 6 02 70 e-mail: aumund@aumund.de www.aumund.com SCHADE Lagertechnik GmbH & Co.KG Dorstener Strae 360 44653 Herne Tel.: +49 - 2325 - 58 74 0 Fax: +49 - 2325 - 58 74 74 e-mail: info@schade-lagertechnik.de www.schade-lagertechnik.com

Proactive maintenance

AUMUND continues to place high emphasis on the service to the customer also after the successful completion of design, engineering, manufacture, delivery, assembly and commissioning. Thus, after-sales service means for all companies of the AUMUND Group:

SWITZERLAND

AUMUND AG Ober Altstadt 32a, P.O. Box 6301 Zug Tel.: +41 - 41 - 710 10 82 Fax: +41 - 41 - 710 42 02 e-mail: zug@aumund.ch PREMAS AG Loewenstr. 55, P.O. Box 8023 Zrich Tel. +41 - 44 - 2 10 30 05 Fax +41 - 44 - 2 10 31 15 e-mail: info@premas.ch www.premas.ch

Expert consulting in all aspects of the

transport and storage technology

BRAZIL

AUMUND Ltda. Rua Haddock Lobo, 337 - 11. andar 01414-001 So Paulo, SP Tel.: +55 - 11 - 3059 0160 Fax: +55 - 11 - 3059 0161 e-mail: aumund@aumund.com.br

Modification and conversion concepts

for a capacity increase or a modernization Stockkeeping of spare parts Maintenance and inspection services A team of well-experienced field engineers supervises assembly and commissioning jobs. An outstanding feature of the AUMUND after-sales service is the proactive maintenance. Within the frame of a maintenance program, we offer field inspections and maintenance seminars for all products of the AUMUND Group.

USA

AUMUND Corporation 2300 Windy Ridge Parkway Suite 150S Atlanta, GA 30339 Tel.: +1 - 770 - 226 - 95 78 / 80 Fax: +1 - 770 - 953 - 48 44 e-mail: sales@aumundusa.com

THE NETHERLANDS

AUMUND Holding B.V. Spoorstraat 42-52 5911 KJ Venlo Tel.: +31 - 77 - 351 98 75 Fax: +31 - 77 - 320 07 28 e-mail: info@aumund-holding.nl

INDIA

AUMUND Engineering Private Ltd. 2nd Floor, Lakshmi Neela Rite Choice Chambers . 9, Bazulla Road, T. Nagar Chennai - 600 017 Tel.: +91 - 44 - 2815 60 48 / 49 Fax: +91 - 44 - 2815 60 46 e-mail: aumund@vsnl.com

GREAT BRITAIN

B&W Mechanical Handling Ltd. Gemini House Cambridgeshire Business Park, 1 Bartholemew`s Walk, Ely, Cambridgeshire CB7 4EA Tel.: +44 - 1353 - 665 001 Fax: +44 - 1353 - 666 734 e-mail: sales@bwmech.co.uk www.bwmech.co.uk

HONG KONG SAR

AUMUND Asia (H.K.) Ltd. 1301 Oxford House, Taikoo Place, 979 King's Road, Quarry Bay Hong Kong Tel.: +852 - 3695 - 43 33 Fax: +852 - 3695 - 43 11 e-mail: info@aumund-asia.com

FRANCE

AUMUND France S.A.R.L. 53, Rue dHauteville . 75010 Paris Tel.: +33 - 1 - 42 46 72 72 Fax: +33 - 1 - 42 46 72 74 e-mail: aumund@aumund.fr

P.R. CHINA POLAND

AUMUND Polska Representative Office ul. Lektorska 34 G . 44-210 Rybnik Tel.: +48 - 32 - 426 32 11 Fax: +48 - 32 - 426 32 01 e-mail: aumund@post.pl AUMUND (China) Room 909, East Ocean Center, No.24A, Jian Guo Men Wai Street, Chao Yang District . Beijing 100004 Tel.: +86 - 10 - 65 15 58 13 / 14 Fax: +86 - 10 - 65 15 58 15 e-mail: aumund@aumund.cn

2006 by AUMUND Frdertechnik GmbH All rights reserved. Neither this document nor any part of it may be reproduced or stored, processed, duplicated or circulated e.g. by using electronic systems in any form or by any means without the prior authorization of AUMUND Frdertechnik GmbH. In case of infringements the infringing party will be obliged to compensate for all damages incurred.

19

W E

C O N V E Y

Q U A L I T Y

AUMUND Headquarters in Rheinberg, Germany

Your partner for all requirements regarding material handling and storage. We design, engineer, manufacture, erect and service reliable equipment. Reputation and competence proven by more than 10.000 installations in over 100 countries.

www.aumund.com

AU MUND Foerdertechnik GmbH . Saalhoffer Str. 17 . 47495 Rheinberg (Germany)

Tel.: + 49 (0) 28 43-720 . Fax: + 49 (0) 28 43-6 02 70 . e-mail: aumund@aumund.de

GB Technical data subject to change without notice A-GB-010-IV/06-MA

Potrebbero piacerti anche

- The Operation, Care, and Repair of Farm MachineryDa EverandThe Operation, Care, and Repair of Farm MachineryValutazione: 5 su 5 stelle5/5 (1)

- Rotary Discharge MachineDocumento20 pagineRotary Discharge MachineMechatronics EngineeringNessuna valutazione finora

- Rotary Plow FeedersDocumento0 pagineRotary Plow FeedersMallinatha PNNessuna valutazione finora

- High Angle Conveyor Offers Mine Haulage SavingsDocumento27 pagineHigh Angle Conveyor Offers Mine Haulage SavingsJDNessuna valutazione finora

- Caso 6 - Boxhole Boring en El Teniente PDFDocumento6 pagineCaso 6 - Boxhole Boring en El Teniente PDFCésar EstrellaNessuna valutazione finora

- Rocker Shovel LoaderDocumento7 pagineRocker Shovel LoaderDinesh dhakarNessuna valutazione finora

- Maersk Discoverer PDFDocumento12 pagineMaersk Discoverer PDFNoor HadiNessuna valutazione finora

- Stacker and ReclaimerDocumento5 pagineStacker and ReclaimerPhilip Anthony MasilangNessuna valutazione finora

- Maersk DeveloperDocumento12 pagineMaersk DeveloperNoor HadiNessuna valutazione finora

- Lecture 4 - Mine Transportation PDFDocumento48 pagineLecture 4 - Mine Transportation PDFMuhammad Ramzan100% (2)

- RigDocumento12 pagineRigDavid SeowNessuna valutazione finora

- TAKRAF - Scraper Reclaimer TechnologyDocumento6 pagineTAKRAF - Scraper Reclaimer TechnologyEduart GuerreroNessuna valutazione finora

- TAKRAF - Scraper Reclaimer Technology PDFDocumento6 pagineTAKRAF - Scraper Reclaimer Technology PDFEduart GuerreroNessuna valutazione finora

- Scrap Collecting MachineDocumento10 pagineScrap Collecting MachineShailesh RanawareNessuna valutazione finora

- Actual ReportDocumento73 pagineActual ReportEzio3511Nessuna valutazione finora

- Maersk DelivererDocumento12 pagineMaersk DelivererNoor HadiNessuna valutazione finora

- Mobile Drilling and Workover Rig WF 125 SaDocumento8 pagineMobile Drilling and Workover Rig WF 125 Saluciana_gaby100% (1)

- Atlas Copco Utilitary Vehicles - FamilyBrochure - ENGDocumento12 pagineAtlas Copco Utilitary Vehicles - FamilyBrochure - ENGmasterandreis100% (2)

- Belt ConveyorDocumento7 pagineBelt ConveyorPRABIR DATTANessuna valutazione finora

- 1 Conveyorppt Course 2010Documento36 pagine1 Conveyorppt Course 2010sk3146Nessuna valutazione finora

- 10.high Angle Conveyor Offers Mine Haulage SavingsDocumento20 pagine10.high Angle Conveyor Offers Mine Haulage SavingspeyockNessuna valutazione finora

- Stacker Reclaimer 1Documento14 pagineStacker Reclaimer 1Avinash GocherNessuna valutazione finora

- ConveyorDocumento36 pagineConveyorapirakqNessuna valutazione finora

- 47 National Hydraulic Swaging MachinesDocumento1 pagina47 National Hydraulic Swaging MachinesUrip S. SetyadjiNessuna valutazione finora

- ScraperDocumento37 pagineScrapercindyimeldaNessuna valutazione finora

- Vacuum CollectionDocumento4 pagineVacuum CollectionLoganBohannonNessuna valutazione finora

- 3.3.4 Stacker and ReclaimerDocumento13 pagine3.3.4 Stacker and ReclaimerPhilip Anthony MasilangNessuna valutazione finora

- Raw Press AreaDocumento6 pagineRaw Press AreaOsama RehmanNessuna valutazione finora

- Ammann Asphalt Mixing-Plant EasyBatch en PDFDocumento12 pagineAmmann Asphalt Mixing-Plant EasyBatch en PDFWillian MazaNessuna valutazione finora

- Coal MachineriesDocumento7 pagineCoal Machineriesdudealok100% (2)

- Continous Miner and Road HeaderDocumento22 pagineContinous Miner and Road HeaderAhsan AliNessuna valutazione finora

- Polycom HPGRDocumento11 paginePolycom HPGRWilson VicencioNessuna valutazione finora

- Transportable Drilling Workover Rig w100-Dh-tDocumento8 pagineTransportable Drilling Workover Rig w100-Dh-tciucalata88100% (1)

- Complete CatalogueDocumento41 pagineComplete CatalogueRad AlexNessuna valutazione finora

- Pan Conveyors PDFDocumento20 paginePan Conveyors PDFChristian Makande100% (2)

- Continous MinerDocumento27 pagineContinous MinerSohil BakshiNessuna valutazione finora

- Scraper 150509172416 Lva1 App6891Documento46 pagineScraper 150509172416 Lva1 App6891Alin SuarliakNessuna valutazione finora

- Ground Hopper (Polymer Concrete)Documento2 pagineGround Hopper (Polymer Concrete)searun327Nessuna valutazione finora

- Smart Infra Est Internship ProgrammeDocumento9 pagineSmart Infra Est Internship ProgrammeAjay katkarNessuna valutazione finora

- Belt Conveyor by Alok VardhanDocumento30 pagineBelt Conveyor by Alok VardhanLOKENDRA9150% (2)

- Processing Station - Part 1 (Mpob HQ 21711)Documento56 pagineProcessing Station - Part 1 (Mpob HQ 21711)Ameen Zenn100% (2)

- Specification of Grouting EquipmentDocumento6 pagineSpecification of Grouting EquipmentBimal BosmiaNessuna valutazione finora

- Bateman Stacker and ReclaimerDocumento31 pagineBateman Stacker and ReclaimerADITYA_PATHAK100% (2)

- Ashrant Coal Handling PlantDocumento29 pagineAshrant Coal Handling Plantsexyakshay26230% (1)

- Coal Handling Plant: at Heads of CHP MeetDocumento46 pagineCoal Handling Plant: at Heads of CHP MeetMANISH SHARMANessuna valutazione finora

- High Angle Conveyor Offers Mine Haulage SavingsDocumento20 pagineHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- Bolting Products Brochure - rb04 0712 PDFDocumento9 pagineBolting Products Brochure - rb04 0712 PDFEmilio Rodríguez VillarrealNessuna valutazione finora

- Chain Conveyor AngDocumento10 pagineChain Conveyor Angamiraelsaid222Nessuna valutazione finora

- Coal Handling Stacking and ReclaimingDocumento3 pagineCoal Handling Stacking and ReclaimingPhilip Anthony MasilangNessuna valutazione finora

- Mine MachineryDocumento74 pagineMine Machinerymatin shereniNessuna valutazione finora

- Bulk Solids Handling BrochureDocumento20 pagineBulk Solids Handling BrochurefelramNessuna valutazione finora

- PDF Summer Training Report of Shree CementDocumento28 paginePDF Summer Training Report of Shree CementRaghav AroraNessuna valutazione finora

- Articole StiintificeDocumento4 pagineArticole Stiintificebdiaconu20048672Nessuna valutazione finora

- Terex Finlay 863 (English) PDFDocumento4 pagineTerex Finlay 863 (English) PDFsherylinlaNessuna valutazione finora

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocumento10 pagine10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNessuna valutazione finora

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsDa EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNessuna valutazione finora

- Scientific American Supplement, No. 312, December 24, 1881Da EverandScientific American Supplement, No. 312, December 24, 1881Nessuna valutazione finora

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Da EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Nessuna valutazione finora

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDa EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNessuna valutazione finora

- Original Gasket Technology GuideDocumento40 pagineOriginal Gasket Technology GuideAtty AttyNessuna valutazione finora

- Fire Alarm Valve E3 ReliableDocumento4 pagineFire Alarm Valve E3 ReliableMKOZERDEM100% (1)

- DegassingDocumento11 pagineDegassingMKOZERDEMNessuna valutazione finora

- ProductBrochure L110F L120F EN 21C1002738 2009-08Documento32 pagineProductBrochure L110F L120F EN 21C1002738 2009-08MKOZERDEMNessuna valutazione finora

- ESA BAT Bolt Torque For Flanged Connections 2012 JuneDocumento2 pagineESA BAT Bolt Torque For Flanged Connections 2012 JuneMKOZERDEMNessuna valutazione finora

- SKL-SP2 Aerosol English SDS Rev 1.2 2015-11-11Documento10 pagineSKL-SP2 Aerosol English SDS Rev 1.2 2015-11-11MKOZERDEMNessuna valutazione finora

- Hopper Discharge SystemsDocumento8 pagineHopper Discharge SystemsMKOZERDEMNessuna valutazione finora

- Spec GridwireDocumento4 pagineSpec GridwireMKOZERDEMNessuna valutazione finora

- Concrete Repair According To The New European Standard EN 1504Documento10 pagineConcrete Repair According To The New European Standard EN 1504MKOZERDEM100% (1)

- Pan ConveyorsDocumento20 paginePan ConveyorsMKOZERDEM100% (1)

- ZamDocumento60 pagineZamMKOZERDEMNessuna valutazione finora

- Accessories 2010Documento3 pagineAccessories 2010MKOZERDEMNessuna valutazione finora

- Repairing ConcreteDocumento19 pagineRepairing ConcreteMKOZERDEMNessuna valutazione finora

- CentrexDocumento16 pagineCentrexMKOZERDEMNessuna valutazione finora

- VEP Protectors 2010Documento2 pagineVEP Protectors 2010MKOZERDEMNessuna valutazione finora

- Masoneilan 21000 Series Control ValvesDocumento8 pagineMasoneilan 21000 Series Control ValvesMKOZERDEMNessuna valutazione finora

- Flowserve Cavitation Control PDFDocumento20 pagineFlowserve Cavitation Control PDFEric KnowlesNessuna valutazione finora

- Stainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesDocumento4 pagineStainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesMKOZERDEMNessuna valutazione finora

- Uhline 2010Documento2 pagineUhline 2010MKOZERDEMNessuna valutazione finora

- Instalation Instruction 2010Documento20 pagineInstalation Instruction 2010MKOZERDEMNessuna valutazione finora

- Flare 2010Documento22 pagineFlare 2010MKOZERDEMNessuna valutazione finora

- QCLOK QuickConnect 2010Documento6 pagineQCLOK QuickConnect 2010MKOZERDEMNessuna valutazione finora

- HoseStainless 2010Documento4 pagineHoseStainless 2010MKOZERDEMNessuna valutazione finora

- 4026 - revAA - Eng Catalog 2005 CDDocumento6 pagine4026 - revAA - Eng Catalog 2005 CDMKOZERDEMNessuna valutazione finora

- H-500 SERIES: Three-Piece Ball ValvesDocumento10 pagineH-500 SERIES: Three-Piece Ball ValvesMKOZERDEMNessuna valutazione finora

- Edison Ashcroft B TransmitterDocumento2 pagineEdison Ashcroft B TransmitterMKOZERDEMNessuna valutazione finora

- Ag Turbine-Valves en 2010Documento4 pagineAg Turbine-Valves en 2010MKOZERDEMNessuna valutazione finora

- 9340-1131 Turbine Water Induction Protection - TWIPDocumento2 pagine9340-1131 Turbine Water Induction Protection - TWIPMKOZERDEM100% (1)

- Hydrastep Hydratect DS Bp2468Documento8 pagineHydrastep Hydratect DS Bp2468ashwaniv_6Nessuna valutazione finora

- 303-01A+EngineDocumento279 pagine303-01A+EngineP HandokoNessuna valutazione finora

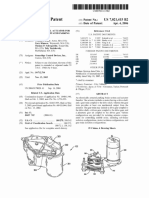

- Electro-Mechancal Actuator For An Electrically Actuated Parking BrakeDocumento13 pagineElectro-Mechancal Actuator For An Electrically Actuated Parking BrakeHassanNessuna valutazione finora

- Finisher SR3120 (D636) 111219Documento54 pagineFinisher SR3120 (D636) 111219william lozadaNessuna valutazione finora

- SSP 605 Audi Occupant Protection Passive Systems II Audi Pre SenseDocumento44 pagineSSP 605 Audi Occupant Protection Passive Systems II Audi Pre Sensestrobo333Nessuna valutazione finora

- Nordstrong Conveyor Idlers CatalogueDocumento51 pagineNordstrong Conveyor Idlers CatalogueAnonymous ntE0hG2TPNessuna valutazione finora

- OF 68029-BGV 4 Manual - InglDocumento24 pagineOF 68029-BGV 4 Manual - InglKevin FloresNessuna valutazione finora

- Belt SwayDocumento3 pagineBelt SwayMuhammad ChabibiNessuna valutazione finora

- Manual Skoda Octavia 1,8 92kWDocumento136 pagineManual Skoda Octavia 1,8 92kWCornea Horatiu SebastianNessuna valutazione finora

- Sidewinder ManualDocumento245 pagineSidewinder ManualkukstrongNessuna valutazione finora

- 7 - Eccentricity, Hydraulic and AerodynamicDocumento13 pagine7 - Eccentricity, Hydraulic and Aerodynamickurniuawan6723Nessuna valutazione finora

- Sunrise CatalogDocumento35 pagineSunrise CatalogKajal MathurNessuna valutazione finora

- Manual Aspiradora BissellDocumento16 pagineManual Aspiradora BissellSetyc MexicoNessuna valutazione finora

- Catalogo Correas Genial PDFDocumento92 pagineCatalogo Correas Genial PDFMarco Antonio Ramirez CornejoNessuna valutazione finora

- Engine Zna RichDocumento40 pagineEngine Zna RichEMILIO “ER NEGRO MECANICO” GONZALEZ100% (9)

- ALDEC G2-95 Decanter & Controls - Operation and Maintenance ManualDocumento250 pagineALDEC G2-95 Decanter & Controls - Operation and Maintenance ManualCentrifugal SeparatorNessuna valutazione finora

- Multi-Level Sand Sieving MachineDocumento53 pagineMulti-Level Sand Sieving MachineRia Joy Cabantao AlimpuyoNessuna valutazione finora

- Man C - 14995Documento394 pagineMan C - 14995RON WUNessuna valutazione finora

- 1.1.4.A PulleyDrivesSprockets FinishedDocumento4 pagine1.1.4.A PulleyDrivesSprockets FinishedJacob DenkerNessuna valutazione finora

- Vishal 35426455tyre Changer Machine NEWDocumento22 pagineVishal 35426455tyre Changer Machine NEWSushant ManeNessuna valutazione finora

- CL2Documento98 pagineCL2Sita MaliNessuna valutazione finora

- WIRTGEN Parts Price List 2-1-19Documento62 pagineWIRTGEN Parts Price List 2-1-19Евсей ЗабродинNessuna valutazione finora

- Upto 2010 KomDocumento36 pagineUpto 2010 KomRajueswarNessuna valutazione finora

- Vibration ProblemsDocumento18 pagineVibration ProblemsKarthick RamNessuna valutazione finora

- Gujarat Technological UniversityDocumento3 pagineGujarat Technological UniversityBhavesh PatelNessuna valutazione finora

- Gates Groundsmaintenance CatalogDocumento818 pagineGates Groundsmaintenance CatalogDiego AvendañoNessuna valutazione finora

- 6000 - Rex-Idlers Belt-Conveyor-Component PDFDocumento27 pagine6000 - Rex-Idlers Belt-Conveyor-Component PDFoscarlopez12345Nessuna valutazione finora

- Te Mech Academic Book PDFDocumento123 pagineTe Mech Academic Book PDFPravinAutadeNessuna valutazione finora

- Rider 111 BDocumento54 pagineRider 111 BHokkanen JaniNessuna valutazione finora

- SKF Belt Alignment Tool TMEB 2: SKF Product Data SheetDocumento0 pagineSKF Belt Alignment Tool TMEB 2: SKF Product Data Sheetiyilmaz1Nessuna valutazione finora

- Arduino 3D Printed CNC Pen PlotterDocumento37 pagineArduino 3D Printed CNC Pen Plotterseynif015Nessuna valutazione finora