Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rockmatez-Portable Hardness Tester

Caricato da

durim-fcb4435Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rockmatez-Portable Hardness Tester

Caricato da

durim-fcb4435Copyright:

Formati disponibili

Rockmate

Portable Press-and-Read Hardness Tester

with Rockwell Method Operation

Portable Press-and-Read Hardness Tester

Many thousands of Newage Pressand-Read testers have been sold since their introduction in the early 1950s. During that time they have proven to be versatile, accurate, and dependable. The newest model, the Rockmate, is the most advanced, light load, portable metal hardness tester made. It can be used to test parts as small as a watch spring, or as large as a huge die block or airplane wing. These testers produce accurate readings even by unskilled operators through the use of a practical test method and a highly sensitive and unique loading system. One smooth motion applies a minor and major load, and measures the test result back to the minor load. Operators cannot overload the tester. TOP-LOAD, ROCKWELL-PRINCIPLE OPERATION These testers use a lighter load (approx. 5 kg.) and proportionately smaller indenters than standard Rockwell testers, but the same basic test principle is used (preload, full load, and reading back at pre-load). Also, the Rockmate applies both preload and full load from a single side, so there is no need for a C-clamp design. NOT AFFECTED BY SHAPE OR SIZE OF PARTS The Rockmate can test on parts with thin walls, or operate upside-down - unlike some other testers. MEETS ASTM B-724 Rockmate is the only tester that meets this demanding standard for testing aerospace grades of aluminum. COMPACT SIZE & LIGHT WEIGHT The MRDR test head measures only 514 tall and has a 134 x 212 base. It weighs only 112 Ibs. The electronics can be clipped to the operators belt. PRESS AND READ OPERATION The entire test is performed by pressing down on the test head, releasing it, and reading the result. ELECTRONICS The Rockmates advanced electronics provide sophisticated capabilities for statistics, data storage, print out, and custom functions. READOUTS IN MANY SCALES All units read in equivalent Rockwell C, B, A, E, Vickers, Brinell HB30, HB5 scales or optional scales . OPTIONAL TEST STAND AVAILABLE An optional test stand, Model MRD-T, is available for testing very small parts, and for fixturing.

Rockmate

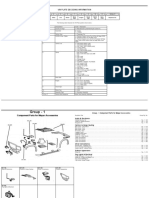

The Rockmate can be placed in the MRD-T test stand for testing small parts and high production. (below)

The Rockmate comes in a carrying case which holds the tester, accessories, battery charger/power supply. (below)

The electronics pack can be belt mounted for extra portability. (above)

Benefits of the Rockmate

ACCURACY

Easy-calibration. Due to the unique, top-loaded operation, The Rockmate can be checked for calibration on test blocks and even recalibrated within a limited range for point-splitting accuracy. Rockwell-principle correlation. Since the Rockmate uses a Rockwell type method, the test results correlate very closely with standard Rockwell test results. It also conforms to ASTM B724. Self-checking for proper operation. The Rockmate electronic system detects improper operating conditions and alerts the operator to retest. Compensates for deflection. Since this tester uses a very light load, it would ordinarily be very sensitive to conditions like part deflection resulting from vibration, dirt on the underside of the test sample, or inadequate support under the specimen. However, the exclusive test-surface-reference feature compensates for these conditions to produce reliable test results. Readings unaffected by part size. Many portable testers are sensitive to parts with a small mass. The Press-and-Read testers are completely insensitive to mass and can test parts as thin as .003". Accurate, consistent loads. The Press-and-Read testers are designed to transmit only their specified load, regardless of the operator strength. Tests large and small parts. The only size limitation is the thickness of the specimen. (.003 at HRC 60.) Very small parts may be tested with the optional bench adaptor. A vee grove in the base enables testing on rounds. Provides printouts with statistics. When used with a standard RS-232 printer, the Rockmate produces X-Bar & R charts, histograms, statistics, etc. It stores up to 2800 results. (See specifications and sample print outs.) The Rockmate can even be used out in the field and later produce hard copy results back in the office. Many electronic functions. Automatic averaging of every N number of results, scale conversion, security code control of functions, lot numbers, tolerances, and large memory capacity. Powered by battery or standard AC power. The Rockmate uses either type of power. New battery life is 5-6 hours continuous operation and rechargeable with the standard charger. If the power is cut off, the results in memory are still saved. Easy to use. Operators can use the Rockmate with very little training. The reading is automatically displayed when the test is complete.

DURABILITY

A history of reliable operation. The Press-and-Read Series of testers has been in use for 50 years. Some early models are still mechanically sound and can be upgraded to digital models. Protected indenter. The tester base and indenter shroud protect the indenter during operation or when being transported. Reduced calibration service. The tester has a passwordprotected calibration routine so there is less need for service.

CAPABILITY

Operates in any orientation. The testers top-load mechanism is insensitive to the tester orientation. It may be used in any direction - even upside down - without confusing compensation factors No clamping required. The top load mechanism and testsurface referencing make it possible to test in the middle of large areas where clamp-type testers are incapable of operation.

Model MR-DR, Rockmate Digital Portable Metal Hardness Tester

Features: Testing with Rockwell-type method using approximately 5 kg full load and 1.0 kg preload. Digital readout in values corresponding to Rockwell C, B, A, Brinell HB30, and Brinell HB5. Press-and-Read operation; self calibration; top loading; test surface referencing; RS232 output; meets ASTM B-724 for testing on aluminum in aerospace applications. Software functions: Security code control of functions, time-at-load indication, adjustable tolerances, Hl/LO/OK indication of results, electronic calibration, minimum thickness, scale conversion of test results, clear last result, clear all results, automatic averaging of 2-10 tests, average and standard deviation of values for all current test results, 2800 result memory. Print functions: print memory, print during testing, select individual results to print during testing, print histogram; print X-Bar & R chart; print statistics of all results in memory including number of tests, tolerances, number and percent Hl/LO/OK, min. and max. result, range, average, Cpk, Z-table scores, variance, and standard deviation. Complete system includes: Tester and battery powered digital readout unit, AC/DC power converter, belt clip attachment, test blocks for Rockwell C and B, snap-on anvil base for flat and small diameter round surfaces, adjustable base for testing non-regular surfaces; base for testing larger rounds; 212 long x 114 diameter extension for testing recessed areas, carrying case, pocket hardness conversion chart, instructions.

OPTIONS

MR-X2A Semi-Custom Programming Option for minor programming like name of company on printouts, etc. MR-X3 Custom Internal Programming for Non-Standard Testing Capabilities Call for details. MRD-70X Custom Scale Calibration Includes scale readout and optional test block customized to test a specific material. MRD81 Rockmate Diamond Indenter MRD98 Serial Printer Cable MRD-T Test Stand Precision testing on small parts with lever actuation. Vertical capacity: 75mm, Horizontal reach: 60mm. Includes flat anvil, vee anvil, convex anvil and vinyl cover. MRPG-DI Prolongator Extension Kit MR-PR Serial Printer with Cable

SPECIFICATIONS

Tester Dimensions Test time Tester Weight Gross weight in case Scales Minimum thickness Test accuracy Surface preparation

514 high 134 wide x 212 long (test head); 3" high x 5" wide x 9" long (electronics) 2 to 3 seconds 112 pounds (head only) 9 pounds Rockwell C, B, A, E, Vickers, Brinell HB30, HB5 (optional custom scales) HRC60 .003; HRC25 .011 ; HRB85 .016"; HRB33 .024" 1 point Rockwell C; 1.5 points Rockwell B 110 RA or 125 RMS or better recommended

Rockmate is a registered trademark of Newage Testing Instruments, Inc; Newage Testing Instruments, Inc. 2003; Printed in USA Specifications subject to change without notice.

OTHER ROCKWELL SCALE TESTERS FROM NEWAGE

Versitron Rockwell Scale Tester for the Toughest Applications

Indentron Rockwell ME-2 Rockwell Scale Tester for the Scale Tester - an Lowest GR&R Economical Choice

Rockman Portable - Heavier Loads with Press-and Read Capability

Represented by:

147 James Way, Southampton, PA 18966 USA Tel: 800-806-3924 or 215-526-2200; Fax: 215-526-2192 email: info@newage1.com website: www.hardnesstesters.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- As 4811-2006 Employment ScreeningDocumento7 pagineAs 4811-2006 Employment ScreeningSAI Global - APAC0% (1)

- SITXHRM006Documento10 pagineSITXHRM006ajay80% (5)

- 380 KV Gis - AbbDocumento25 pagine380 KV Gis - AbbInsan Aziz100% (1)

- Man - 6020 Photometric AnalyzerDocumento92 pagineMan - 6020 Photometric AnalyzerNaser JahangiriNessuna valutazione finora

- Create An SSH Tunnel For MySQL Remote AccessDocumento4 pagineCreate An SSH Tunnel For MySQL Remote Accessleonard1971Nessuna valutazione finora

- IPU Pressure Equipment Directive Handbook 2017 02Documento32 pagineIPU Pressure Equipment Directive Handbook 2017 02kanhuNessuna valutazione finora

- Storage-Sc2000 Deployment Guide En-UsDocumento112 pagineStorage-Sc2000 Deployment Guide En-UsDragos CalinescuNessuna valutazione finora

- GRCA SpecificationDocumento15 pagineGRCA SpecificationfaisaltmNessuna valutazione finora

- Lenovo Ideapad S145-15iil LCFC Nm-c711 Gs44d Gs54dDocumento60 pagineLenovo Ideapad S145-15iil LCFC Nm-c711 Gs44d Gs54dJulián ToméNessuna valutazione finora

- CB Type and Ratings PDFDocumento84 pagineCB Type and Ratings PDFMarlou RabinaNessuna valutazione finora

- User's Guide To Mini6410 Linux - 041611Documento265 pagineUser's Guide To Mini6410 Linux - 041611Cristina Glez. LoboNessuna valutazione finora

- Temper Calib Isocal6Documento3 pagineTemper Calib Isocal6catolinNessuna valutazione finora

- Internship FormDocumento6 pagineInternship FormHOD Department of Mechanical EngineeringNessuna valutazione finora

- UMTS Nastar FeaturesDocumento10 pagineUMTS Nastar FeaturesajaykkaushikNessuna valutazione finora

- Preconfigured Htaccess - Joomla! DocumentationDocumento3 paginePreconfigured Htaccess - Joomla! Documentationuomomedicina.itNessuna valutazione finora

- Track Busway Plug in Units - Domestic 6Documento68 pagineTrack Busway Plug in Units - Domestic 6TBS Máy Phát ĐiệnNessuna valutazione finora

- Scope and Limitations of The StudyDocumento6 pagineScope and Limitations of The Studyjon rey lumayag100% (1)

- Theory of EstimationDocumento2 pagineTheory of EstimationSushil Rana MagarNessuna valutazione finora

- MetelistaDocumento2 pagineMetelistaLuca Marius CristianNessuna valutazione finora

- D 5426 - 03 Rdu0mjyDocumento6 pagineD 5426 - 03 Rdu0mjyJuanNessuna valutazione finora

- Manual Central de Incendios Edificio 43 Notifier AFP-100Documento142 pagineManual Central de Incendios Edificio 43 Notifier AFP-100haedo86Nessuna valutazione finora

- Cisco - Assingment 1Documento9 pagineCisco - Assingment 1Amirul AidilNessuna valutazione finora

- Tempconversion PDFDocumento6 pagineTempconversion PDFPravat TiadiNessuna valutazione finora

- 757N1 Bank Risk Management Final Report 2023 - 2024 - 388583943Documento4 pagine757N1 Bank Risk Management Final Report 2023 - 2024 - 388583943harisNessuna valutazione finora

- USP 2010 SWS: Ballast Distributing and Profiling MachineDocumento1 paginaUSP 2010 SWS: Ballast Distributing and Profiling MachineRohit BaliNessuna valutazione finora

- Simple Object Access Protocol (SOAP) : in This ChapterDocumento34 pagineSimple Object Access Protocol (SOAP) : in This ChapterSuraj JathannaNessuna valutazione finora

- Iso9001 Iqa EtaDocumento171 pagineIso9001 Iqa EtaKanan AgarwalNessuna valutazione finora

- Installation Guide Hebel Slab Panel 08.20lDocumento18 pagineInstallation Guide Hebel Slab Panel 08.20lmuchlis prayogaNessuna valutazione finora

- 2006 LX PartsDocumento859 pagine2006 LX PartsJon Scot Garrison100% (2)