Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MMA136 Dat1b

Caricato da

Paulson JosephTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MMA136 Dat1b

Caricato da

Paulson JosephCopyright:

Formati disponibili

Kattegatt Design

MANUAL

PROJECT NO. DOC. NO.

P1114-00 P1114-00-040-MA-001

CLIENT:

Chalmers Tekniska Hgskola

PROJECT NAME:

MMA136 Ship Geometry and Hydrostatics

SUBJECT:

Design Assignment Guidance

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 2 JBz

CONTENTS

1 1.1 1.2 1.3 2 2.1 2.1.1 2.1.2 2.2 2.2.1 2.2.2 2.3 2.3.1 2.3.2 3 3.1 3.1.1 3.1.2 3.1.3 3.1.4 3.1.5 3.1.6 3.1.7 3.1.8 3.1.9 3.2 3.2.1 3.2.2 3.2.3 3.2.4 3.3 3.3.1 3.3.2 3.3.3 3.3.4 3.3.5 INTRODUCTION .............................................................................................................. 3 Objective ....................................................................................................................... 3 Purpose ......................................................................................................................... 3 Hull Modelling and Stability Analysis Exercise in General ................................................ 3 BASIC SHIP GEOMETRY ................................................................................................... 4 Ships Lines .................................................................................................................... 4 Lines and Body Plan ..................................................................................................................4 Reference System .....................................................................................................................7 Main Particulars ............................................................................................................. 8 Datum Points ............................................................................................................................8 Moulded Dimensions ................................................................................................................8 Freeboard and WT Integrity ............................................................................................ 9 Buoyant Hull..............................................................................................................................9 WT Subdivision....................................................................................................................... 10 COMPUTER AIDED NAVAL ARCHITECTURAL DESIGN WORK ............................................11 Hull Modelling Basics using Autoship .............................................................................11 General................................................................................................................................... 11 Control Points ........................................................................................................................ 11 Edit Points .............................................................................................................................. 12 Surfaces .................................................................................................................................. 13 Rows and Columns ................................................................................................................. 13 Knuckles and Chines............................................................................................................... 14 Degree of Curvature............................................................................................................... 14 Direction................................................................................................................................. 14 Ship Hull Assembly and Analyses ........................................................................................... 15 Subdivision and Compartment definition in Modelmaker ...............................................16 General................................................................................................................................... 16 Parts, Components and Shapes ............................................................................................. 16 Command Script Files ............................................................................................................ 17 Modelmaker Cmd-File Example ............................................................................................. 19 Hydrostatic and Stability Analyses in Autohydro ............................................................22 General................................................................................................................................... 22 Run Script Files for Hydrostactics .......................................................................................... 22 Run Script Files for Intact Stability Analysis ........................................................................... 23 Autohydro Hydrostatics Example........................................................................................... 25 Autohydro Loading Condition Stability Evaluation Example.................................................. 27

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 3 JBz

1 1.1

Objective

INTRODUCTION Objective

The course of Ship Geometry and Hydrostatics includes one exercise in Hull Modelling and Stability Analysis. The objective is to provide understanding of and some experience in using modern computer software in naval architectural design work.

1.2

Purpose

Purpose

The purpose of this document is to constitute guidance to the execution of a Hull Modelling and Stability Analysis task, using the naval architectural computer software tools Autoship, Modelmaker and Autohydro. Furthermore, this document presents specifications of the Vessels to be modelled and analysed within the exercise.

1.3

Supervision

Hull Modelling and Stability Analysis Exercise in General

The design workshop classes will be in the Ritsalen according to schedule, and will be supervised by: Jan Bergholtz Kattegatt Design AB jan.bergholtz@kattegattdesign.se Ana Sanz Kattegatt Design AB ana.sanz@kattegattdesign.se

Exercise moments

The exercise will be carried out as five moments: 1. 2. 3. 4. 5. Hull Modelling Verification of Hydrostatic Properties Modelling of Compartments Intact Stability Analysis, two Loading Conditions Damage Stability Probabilistic Assessment Autoship Autoship & Autohydro Modelmaker Autohydro Autohydro / MS Excel

For approval all five tasks must be fulfilled, a written report shall be established comprising Hydrostatic Tables, Tank Capacities and Stability Analyses of two Loading Conditions, e.g. Full Load Departure and Ballast Condition Departure, and finally an adequate documentation of the Probabilistic Damage Stability Assessment.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 4 JBz

2 2.1 2.1.1

BASIC SHIP GEOMETRY Ships Lines Lines and Body Plan

The exterior shape of a ships hull is a curved surface defined by the Ships Lines. Precise and unambiguous means are needed to describe this surface, as the ships form must be configured to accommodate all internal volumes, must meet buoyancy and stability constraints, must show acceptable speed power, seakeeping and manoeuvring characteristics and finally must be buildable.

Lines

Hence, the Lines consist of orthographic projections of the intersections of the hull form with three mutually perpendicular sets of planes, see Figure 2.1.1.

Figure 2.1.1

Ship Lines Plan

Normally ships have only one plane of symmetry, the centreplane, which constitutes a principal vertical plane of reference. The shape of a ship cut by this plane is known as the profile, see Figure 2.1.2. Vertical sections parallel to the centreplane, spaced for convenient definition of the hull form and identified by their distance to the centreplane, are called buttocks.

Centreplan, Profile

Figure 2.1.2

Centreplane, Profile

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 5 JBz

A waterline plane is a plane perpendicular to the centreplane, selected as a principal horizontal reference plane, Figure 2.1.3.

Waterline Plane

Figure 2.1.3

Waterline plane

The Design Water Line, DWL, represents the waterline near which the fully loaded ship is intended to float. The waterlines are defined by their height over the base line. A Plane perpendicular to both the centreplane and the waterline plane is defined as a transverse plane, which normally exhibits symmetry around the Centre Line, Figure 2.1.4.

Transverse Plane

Figure 2.1.4 Frames

Transverse Plane

The transverse sections are often referred to as the frames. The distance between the frames is depending on what purpose the frames are intended to fulfill. For hydrostatic calculations the length between perpendiculars divided into a set of 21 equidistant frames, #0 - #20, and a more dense spacing towards the forward and aft ends are normally considered to be sufficient. During the production phase, however, each building frame must of course be defined.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 6 JBz

Body Plan

A drawing comprising a set of frames is often referred to as the Body Plan where the Fore Body is represented on the right hand side of the centre line and the After Body on the left hand side, Figure 2.1.5.

Figure 2.1.5

Body Plan

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 7 JBz

2.1.2

Coordinate System

Reference System

The coordinate system, most commonly used, has its datum point, origo, at the intersection between the centreplane, the Base Line which is the longitudinal horizontal line parallel to the waterline plane at the upper surface of the keel plating and the transverse plane through the axis of the rudder stock, see Figure 2.1.6. The longitudinal axis is positive from stern towards bow, the transverse axis is positive from centre line, CL, towards the starboard side, SB, and the vertical axis is positive from base line, BL, and upwards. Z

Positive Directions

AP Y LPP FP X

Figure 2.1.6

Coordinate System

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 8 JBz

2.2 2.2.1

Main Particulars Datum Points

For practical reasons the waterlines, buttocks and frames are evenly spaced and datum points are needed to start from. A longitudinal reference point at the fore end of the ship is provided by the intersection of the Design Water Line, DWL, and the bow contour. The line through this point, perpendicular to the DWL, is called the Forward Perpendicular, FP. The Aft Perpendicular is often taken as the axis through the rudder stock or the intersection of the DWL and the transom profile, Figure 2.2.1.

Fwd and Aft Perpendic.

AP

Figure 2.2.1 Forward and Aft Perpendiculars

FP

The distance between these two reference lines is referred to as the Length between Perpendiculars, LPP.

2.2.2

Moulded Draught Moulded Depth

Moulded Dimensions

The Moulded Draught is the perpendicular distance in a transverse plane from the top of the keel plate to the Design Water Line, if unspecified it refers to amidships. The Moulded Depth is the perpendicular distance in a transverse plane from the top of the keel plate to the underside of the deck plating at the ships side, if unspecified it refers to amidships. The Moulded Breadth extreme is the maximum horizontal breadth of any frame section. The terms Breadth and Beam are synonymous.

Moulded Breadth

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 9 JBz

2.3 2.3.1

Freeboard and WT Integrity Buoyant Hull

For all ships a required freeboard is determined in accordance with the IMO Load Lines resulting in a minimum allowable distance between the load water line and the deck to which the watertight (WT) integrity is maintained. The freeboard grants a minimum amount of reserve buoyancy as composed by the buoyant hull limited by the freeboard deck, see Figure 2.3.1.

Buoyant Hull

ER-Vent

Main Deck / Freeboard Deck

AP

Figure 2.3.1 Flooding Points Freeboard and Buoyant Hull

FP

Any opening leading into the buoyant hull must terminate at a minimum threshold distance above the freeboard deck or be fitted with an adequate closing appliance. o o A Watertight, WT, closing appliance must withstand a specified hydrostatic pressure and is then considered to be a part of the WT-integrity. A Weathertight, WeT, closing appliance is considered closed for the purpose of righting arm calculations but can not withstand any hydrostatic pressure and may thus not be submerged at equilibrium. An Unprotected Opening is considered as a flooding point through which progressive flooding may occur if the opening is immersed. Hence, stability calculations, e.g. righting arm curves, shall terminate as soon a flooding point is reached. A typical unprotected flooding point is represented by the Engine Room ventilation.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 10 JBz

2.3.2

WT Subdivision

WT Subdivision

Below the freeboard deck the ship is subdivided in an adequate number of compartments separated by WT-bulkheads. The compartments may be arranged as machinery spaces, void spaces, cargo spaces or tanks containing consumables or ballast etc. The subdivision is arranged such as to provide reserve buoyancy and residual stability also after suffering a stipulated damage to the hull shell.

Permeability In order to account for un-floodable volumes inside a compartment, such as structural

steel members and various equipment a volumetric filling rate, permeability, is required. For the purpose of the subdivision and damage stability calculations in accordance with regulations the permeability for general compartments shall be applied as follows: o o o o o Stores Accommodation and Public Spaces Machinery Room Void Spaces Tanks intended for Liquids 0.60 0.95 0.85 0.95 0 or 0.95*)

*) which ever results in more sever requirements

However, when establishing various load conditions a more deterministic approach for calculating a true permeability of e.g. Tanks is applied. The deduction for structural members inside a Tank can in general be set to 1.5% of the gross volume, hence a permeability for Tanks of 0.985 can normally be applied.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 11 JBz

3 3.1 3.1.1

NURBS

COMPUTER AIDED NAVAL ARCHITECTURAL DESIGN WORK Hull Modelling Basics using Autoship General

Autoship is a 3D hull modelling software using non-uniform rational B-splines (NURBS) curves and NURBS-surfaces for the representation of the hull. The B-spline curves are made up of continuous end-to-end segments, joined at knots or knot vectors. This means that hull surface is defined and controlled by a number of mathematical entities called control points in the 3D space surrounding the object.

3.1.2

Control Points

Control Points

The control points can be compared to polynomial coefficients. Hence, when defining a curve or a surface, the order, degree, of the polynomial must first be determined, i.e. how many control point must be used in order to provide a good representation of the shape. The control points are organised in rows and columns, each of which having a positive direction. This means that all surfaces have a positive and a negative side, which must be considered when calculating an enclosed volume. Figure 3.1.1 shows how Autoship control points are represented on the screen.

Control Points

Figure 3.1.1

Control Points along a curve

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 12 JBz

Control point can be moved, deleted, added to a curve, and manipulated using the software Select and Edit mode tools. Autoship bends the curve towards a control point, but does not make the curve to coincide with a control point. When one control point is moved, no other control points of the entity are moved. Figure 3.1.2 shows the effect of moving two control points governing the curve.

Figure 3.1.2

Effect of moving Control Points

3.1.3

Edit Points

Edit Points

Autoship also provides edit points for shaping curves. Edit points are shown as small, unfilled squares on the curve, see Figure 3.1.3. If an edit point is moved, its neighbouring points also move, and the curve is redrawn through the new location of the edit points, see Figure 3.1.4.

Edit Points

Figure 3.1.3

Edit Points on a curve

Figure 3.1.4

Moving Edit Points

Edit point are derived from control points, there is one edit point for each control point. When moving an edit point it is actually the control point which is being relocated.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 13 JBz

3.1.4

Surfaces

Surfaces

One frequently used method of creating a surface in Autoship is to, based on a curve, extrude the surface in one direction or along another curve. Often one fore body surface and one after body surface are extruded from the midship section curve, see Figure 3.1.5, and then modified in order to represent the intended shape of the forward and aft parts of the hull.

Figure 3.1.5

Extruded Surface based on a Midship curve

3.1.5

Rows and Columns

In Autoship, a surface is built-up by a mesh of i x j control (or edit) points, a matrix having i rows, Figure 3.1.6 and j columns, Figure 3.1.7. Hence, the number of Columns must be the same on every Row and vice versa, the number of Rows must be the same on every Column along a surface.

Rows

Figure 3.1.6 Columns

Rows

Figure 3.1.7

Columns

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 14 JBz

3.1.6

Knuckle

Knuckles and Chines

A Knuckle is a sharp discontinuity on a curve, e.g. the tangent-point at the transition from a bilge radius to a flat bottom or flat side on a midship curve, Figure 3.1.8.

Knuckle Points

Figure 3.1.8 Chine

Knuckle Point on a midship curve

Turning a control point into a Knuckle point will result in turning the complete row or column, which ever is activated, into a discontinuity, a Chine, along the surface.

3.1.7

Degree of Curvature

Degree of Curvature

When creating a curve in Autoship, you must specify its maximum degree. The degree of a curve is the order, power, of the polynomial used to define the entity. Degree 1 is linear, degree 2 uses a quadratic polynomial and degree 3 uses a cubic polynomial. Autoship allows up to degree 5. The degree of curvature is related to how many control points are needed to define a curve. There is always one control point more than the degree of curvature. Thus, a 1 degree curve is a straight line between two control points, a degree 2 curve is composed of at least three control points, etc. A degree 5 curve composed of at least six control points can be used to create smooth and very complex surfaces. However, a high degree surface is very difficult to manipulate locally in a controlled way.

Number of Control Points

3.1.8

Direction

Direction

All Autoship curves, rows and columns have a positive direction. On a curve this direction is indicated by a small arrow at the beginning of the curve, Figure 3.1.9.

Figure 3.1.9

Positive Direction of Curve

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 15 JBz

Surface Inand Outside

The existence of a positive or negative direction of a curve results in a defined inside and a defined outside of a surface. This must be considered when executing analyses of an enclosed volume, ship hull. If not, strange hydrostatic properties will be generated.

3.1.9

Hull Group

Ship Hull Assembly and Analyses

When all surfaces required to describe the hull are created a group is assembled. This hull group can now be immersed and analysed with regard to basic hydrostatic properties such as displacement, geometrical coefficients, centre of buoyancy and flotation etc. Autoship is also used to define the number, the location and spacing of frames used for hydrostatic calculations. Furthermore frames, buttocks and waterlines used for visualisation of the hull shape can be defined. The modelling work in Autoship is stored as a project file, *.pr3. The hull surface created in Autoship is exported to Modelmaker and Autohydro through a geometry-file (*.gf#; # = any arbitrary number for identification of file version). Note that the *.gf# does not comprise the surface but only a numerical representation of the defined frames. An administrative rule of thumb is to separately define the ships moulded bare hull and save the geometry file as *.gf0, and then define the appended hull and save it as *.gf1, etc.

Calculation Frames

Project File Geometry File *.gf#

File Adm.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 16 JBz

3.2 3.2.1

Subdivision

Subdivision and Compartment definition in Modelmaker General

The hull geometry, i.e. the outer boundary of the vessel, represented by the frames as defined in Autoship is imported into Modelmaker for further definition of the subdivision into compartments such as tanks, cargo holds, machinery spaces, accommodation etc. When importing the hull geometry by loading a *.gf# file the frames may have to be cleaned from excessive coordinate points which are not needed. As mentioned above, the hull shape is only represented by frames, i.e. a surface is no longer available at this stage. The cleaned bare hull geometry-file should then be saved, preferably by overwriting the old bare hull geometry file. The subdivision can be created by using the application menus and commands or by writing a script file (*.cmd). It is strongly recommended to apply the script writing method, even though this method requires knowledge about application specific commands and may seem time consuming, since script are easy to duplicate e.g. for starboard and port tanks etc. Furthermore, checking and / or modification of compartment coordinates are much quicker when using the script method. Finally, alterations in compartmentation can easily be done by just introduce the desired changes in the Command File and re-run the commands.

Cleaning of Frames

Script Files *.cmd

3.2.2

Parts, Components and Shapes

In order to handle the complexity of a vessel geometry model, a hierarchical data structure is used. The model is broken up into Parts, Components and Shapes. The vessel, with its buoyant appendages and superstructure, normally consists of one Part. Each Part is made up of one or more Components (e.g. HULL = hull + skeg + superstructure) and each Component is composed of a Shape.

Parts

A Part is a group of one or more Components. Each Part is identified by a name, has a description and a class designation of either: o o o o o Hull Appendage Superstructure Sail Tank

Tank parts have, in addition, a side designation, a substance name and specific gravity, a capacity and optional sounding tube definitions. More than one component may refer to the same shape. This saves computer memory and disk space when identical shapes are involved (as in port and starboard tanks).

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 17 JBz

Components

Each component is identified by a name (which may be unique only within the referencing part) refers to one shape by name. Side specifies whether the shape is to be reflected about its own centerplane to the opposite side. Also included are the permeability (for containers) or effectiveness factor (for displacer) and a flag indicating whether the component adds to or deducts from the part volume. Finally, the component gives the shape a specific location on the vessel by means of the shift vector, although this is frequently 0,0,0, indicating that the shape is defined in Ship Coordinates.

3.2.3

Command Script Files

The Script Files comprises various Commands of which the most commonly used are defined below.

Clear

Every Command Script File should start with the Clear command, ensuring that any previous geometries, settings and commands are cleared prior to running an updated command file. read *.gf#. The geometry file which is currently located in modelmaker will be removed and the specified geometry file, *.gf#, will be loaded. create [Part Name/]Component Name Marks the start of a block of component creation information and provides the name of the component and part to be created. The part name can be used to identify an existing part or if the name does not exist, a new part will be created. The component name should not identify an existing component. If only a component name is given, modelmaker will assume that the part and component have the same name. The component creation information is terminated and a component is created at either a forward slash of a component parameter.

Read

Create

Contents

cont Description <spgr> Is used to set the default contents of a tank and the specific gravity of the specified liquid. ModelMaker and Autohydro recognizes the following abbreviations: DO FO FW GAS HO KER LO SEW SW DIESEL OIL FUEL OIL FRESH WATER GASOLINE HYDR OIL KEROSENE LUBE OIL SEWAGE SEA WATER

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 18 JBz

Permeability

perm <p> Specifies the permeability factor between 0 and 1.0 of a container component (it will also set the effectiveness factor of a displacer component). Default value is: 0.985 (1.0 for displacers) or the same as the first component of the part. ends L1, L2 Defines the longitudinal locations of the forward and aft boundary L1 and L2 of the components. top V1 [@ L1, V2 @ L2] Defines the height of the top of a box shaped compartment. The top may be sloped by specifying differing heights at 2 different longitudinal locations. bot V1 [@ L1, V2 @ L2] Defines the height of the bottom of a box shaped compartment. The bottom may be sloped by specifying differing heights at 2 different longitudinal locations. in T1 [@ L1, T2 @ L2] The Inboard command specified the inboard side location of a box shaped compartment. This side may be sloped by specifying different halfbreadths at different longitudinal locations. out T1 [@ L1, T2 @ L2] The Outboard command specifies the outboard side location of a box shaped compartment. This side may be sloped by specifying different halfbreadths at different longitudinal locations. loc @ L [=T1,V1, T2,V2, ....., Tn,Vn] Results in an explicit section curve at the shape longitudinal location L. The curve is represented by transverse-vertical coordinate pairs running in the counterclockwise direction looking forward. The first point is considered to follow the last point. If only the L parameter is given, a section is interpolated at that location from the other shape data given. One Locus statement is needed for each section. The final shape is the intersection of the shape defined by the Locus statements and the volume bounded by the Top, Bottom, Inboard and Outboard statements. fit [Component Name] The fit command uses the current component creation information and fits this new component to the specified part. The most common use of this command is the case where a tank is fit to the hull. opp [Part Name] The opposite command generates a new Part and copies all of the existing components from the original part into the newly created part. The opposite command is used after the create command. The create command identifies the part to be created and the original part is identified by the opposite parameter. The part name should therefore be the name of an existing part. write [*.gf#] Writes the geometry file out to disk. A drive and path specification may be included in the filespec. If the path is not specified, the file will be written to the current modelmaker directory. NB! The Hull including the defined compartments and tanks shall preferably be saved under a new file name, e.g. *.gf2, in order not to overwrite the bare hull geometry file *.gf1

Ends

Top

Bot

Inboard

Outboard

Locus

Fit

Opposite

Write

NB!!!

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 19 JBz

3.2.4

Clear

Modelmaker Cmd-File Example

Read Test.gf1 create HULL\Rudder.c ends 1.6a, 0.8f top 5.0 @ 1.6a, 5.0 @ 0.8f bot 0.3 out 0.2 /

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 20 JBz

create Forepeak.c cont SW perm = 0.975 ends 152f, 165f top 7.5 bot -1 fit Hull /

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 21 JBz

create Fuel_Tk.s cont FO perm = 0.975 ends 80f, 89.6f locus @ 80f = 15, 7.5, 10, 7.5, 10, 4.75, 8, 4.75, 8, 2, 15, 2 locus @ 89.6f = 15, 7.5, 10, 7.5, 10, 4.75, 8, 4.75, 8, 2, 15, 2 fit Hull / create Fuel_Tk.p opposite Fuel_Tk.s /

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 22 JBz

3.3 3.3.1

Hydrostatic and Stability Analyses in Autohydro General

Hydrostatic The application Autohydro is used for hydrostatic and stability analyses of hull shapes and Stability and associated compartment definitions. Hence, analyses are performed on the loaded Analyses geometry file *.gf# (in our case *.gf2 which comprises bare hull and compartments).

The application includes a report generator used for the establishing of stability booklets.

Accuracy

Autohydro works as a true floating simulator solving the condition equilibrium including the effect of free surfaces etc. However, the hull shape and the compartment definition are only represented by frames. Hence, the accuracy of the results is highly dependent on the quality and resolution (number of calculation frames) of the geometry file. The analyses can be executed by using the application menus and commands or by writing a script file (*.run). Again, it is strongly recommended to apply the script writing method, even though this method requires knowledge about application specific commands and may seem time consuming, since script are easy to duplicate e.g. for multiple Loading Conditions and various Damage Cases etc. Furthermore, checking and / or modification of Conditions, Damage Cases and Criteria etc are much quicker when using the script method. In order to limit the computing time, it may be wise to write separate run file for various purposes, e.g. one file for the Hydrostatics HS.run, one file for Intact Stability Analysis INTACT.run and one file for Damage Stability Analysis DAM.run etc. The Run Files comprises various Commands of which the most commonly used are defined below.

Script Files *.run

3.3.2

Read

Run Script Files for Hydrostactics

Read *.gf#. The geometry file which is currently located in Autohydro will be removed and the specified geometry file, *.gf#, will be loaded. Units MT Sets the units to metric units (meters and tonnes). Every Run File should start with the Clear Report command, ensuring that previously executed calculations are cleared and a blank report is started prior to running an updated command file. Report Header [Header Text] and Report Footer [Footer Text] creates a report header and footer including the stated texts respectively. Water <Spgr> Sets the ambient water specific gravity to specified value, in general 1.025 for seawater and 1.000 for freshwater.

Units Clear Report

Report Header / Footer Water

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 23 JBz

LBP

LBP L1, L2 Sets the longitudinal position of the forward and aft termination to be considered when calculating trim, coefficients etc. If FP and AP are used then the Length between Perpendiculars will be used as reference length. If no calculation length is defined Autohydro uses the LWL and specifies the trim in degrees. ghs draft @ L = d1, d2, , dn calculates the General Hydrostatic Properties on the specified drafts d1, d2, , dn using a constant draft increment corresponding to d2 d1. Disk [File Name.rtf] Saves the current report in the current computer folder. The extension *.rtf provides a MS Word Rich Text Format which can be edited and printed using MS Word.

ghs

Disk

3.3.3

Read

Run Script Files for Intact Stability Analysis

Read *.gf#. The geometry file which is currently located in Autohydro will be removed and the specified geometry file, *.gf#, will be loaded. Units MT Sets the units to metric units (meters and tonnes). Every Run File should start with the Clear Report command, ensuring that previously executed calculations are cleared and a blank report is started prior to running an updated command file. Report Header [Header Text] and Report Footer [Footer Text] creates a report header and footer including the stated texts respectively. Limit Off Clears any activated Stability Evaluation Criteria. Water <Spgr> Sets the ambient water specific gravity to specified value, in general 1.025 for seawater and 1.000 for freshwater. LBP L1, L2 Sets the longitudinal position of the forward and aft termination to be considered when calculating trim, coefficients etc. If FP and AP are used then the Length between Perpendiculars will be used as reference length. FldPt (n) [Description] L, T, V defines the location of a Flooding Point through which progressive down flooding can occur. An arbitrary number of Flooding Points can be defined. Limit Title [Name] defines a Title of a set of Stability Evaluation Criteria as defined below (IMO A167): Limit (1) area from 0 to 30 > .055 Limit (2) area from 0 to 40 or Fld > .09 Limit (3) area from 30 to 40 or Fld > .03 Limit (4) RA at 30 or Max > .2 Limit (5) Angle from 0 to Max > 25 Limit (6) GM at Equil > .15

Units Clear Report

Header / Footer Limit off Water

LBP

FldPt

Limit

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 24 JBz

Note

Note [Text] Sets a title of the forthcoming calculations, e.g. note Light Ship will set the title Light Ship for the Loading Condition. Del All Weights Command, deletes all previously defined Fixed Weights except the Light Ship Weight. Type (*) Intact Sets all Tanks to Intact Condition. Load (*) 0 Sets the Contents in all Tanks to zero, making sure that any previously Tank Loads are reset prior to running a Stability Evaluation of the Condition. Weight [Mass, L, T, V] Sets the Light Ship Weight and defines the Centre of Gravity longitudinal, transverse and vertical for the Light Ship Weight. Add [Name, Mass, L, T, V] Adds a Fixed Weight at a defined Centre of Gravity. An arbitrary number of Fixed Weights can be added. Load (Tank) <percentage> Sets the Contents in the specified Tank to the specified filling percentage. This command is repeated for all Tanks used in the requested Loading Condition. Solve Finds the equilibrium floating status for the defined Loading Condition. Status Provides the status of the current Loading Condition with regard to Floating Status, Fixed Weights Status, Tank Status etc. Status Cartoon Provides a graphical presentation of the Tank Status. Ra /Lim /Notes Computes righting arms and produces tabular and graphical output at one or more heel angles and evaluates the stability against the current stability criteria, displaying limit margins. The extension /Notes turns on an extra column that identifies key angles such as the equilibrium point, maxRA, second intercept, etc Page Forces a page break to separate the current Loading Condition from the following Condition. The next and following Loading Conditions are defined and evaluated by repeating the Commands from the Command Note.

Delete

Type Load

Weight

Add

Load

Solve Status

Status Cartoon Ra

Page

Disk

Disk [File Name.rtf] Saves the current report in the current computer folder. The extension *.rtf provides a MS Word Rich Text Format which can be edited and printed using MS Word.

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 25 JBz

3.3.4

Autohydro Hydrostatics Example

delete all weights load(*) 0 ghs draft @ MS = 0.5,1.0,...,5.0

Hydrostatic Properties Draft is from Baseline. No Trim, No heel, VCG = 0.000 Draft at Displ LCB 1.834f (MT) (m) (m) 0.500 210.793 2.552a 1.000 493.328 1.786a 1.500 803.803 1.441a 2.000 1135.400 1.256a 2.500 1486.664 1.174a 3.000 1858.041 1.173a 3.500 2250.598 1.240a 4.000 2665.385 1.366a 4.500 3102.474 1.541a 5.000 3560.214 1.728a Water Specific Gravity = 1.025. VCB (m) 0.279 0.552 0.823 1.095 1.369 1.646 1.926 2.211 2.499 2.789 LCF (m) 1.466a 0.995a 0.825a 0.837a 1.017a 1.342a 1.797a 2.322a 2.849a 3.106a TPcm (MT/cm) 5.23 5.97 6.43 6.83 7.22 7.63 8.07 8.51 8.96 9.34 MTcm (MT-m /deg) 1688.67 2266.91 2685.93 3089.52 3537.90 4064.57 4690.66 5415.27 6213.96 6924.16 KML (m) 458.951 263.255 191.436 155.891 136.336 125.325 119.403 116.396 114.746 111.422 KMT (m) 24.240 13.056 9.424 7.785 6.940 6.484 6.243 6.132 6.108 6.144

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 26 JBz

Hydrostatic Properties at Trim = 0.00, Heel = 0.00

5.0a LCB m LCF m VCB m Displ.MT MT/cm Imm. Mom/Deg Trim KML KMT 4.0a Long. Location in m 3.0a 2.0a 1.0a 5.0 D r a f t @ 3.0 1 . 8 3 4 f

4.0

2.0

1.0

VCB m x 1 Displ.MT x 1000 MT/cm Imm. x 1 Mom/Deg Trim x 1000 KML x 100 KMT x 10

0.0 0.0 5.0 1.0 1.0 2.0 6.0

1.0 1.0 7.0 3.0 2.0 1.0 4.0 3.0 2.0

2.0 3.0 8.0 5.0 2.0 6.0 4.0 9.0 7.0

3.0 4.0 10.0 8.0 5.0

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 27 JBz

3.3.5

clear report

Autohydro Loading Condition Stability Evaluation Example

Fldpt (1) "Opening No1 Stb" 29f 7s 23 Limit title IMO A.167 Limit (1) area from 0 to 30 > .055 Limit (2) area from 0 to 40 or Fld > .09 Limit (3) area from 30 to 40 or Fld > .03 Limit (4) RA at 30 or Max > .2 Limit (5) Angle from 0 to Max > 25 Limit (6) GM at Equil > .15 Weight 1200, 1.173a, 0, 4.23 note Full Load Condition Add "Crew and Effects" 2 15f 0 12 Add "Stores" 3.2 12f 0 5 Add "Pay Load" 1.4 0.5a 0 3.3 Load (FRESHW.S) 1 Load (FRESHW.P) 1 Load (DB#3.C) .98 Load (DB#3.S) .98 Load (DB#3.P) .98 Load (DB#4.C) .98 Load (SETTLING.S) .98 Load (SETTLING.P) .98

so status status cartoon ra /lim /notes

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 28 JBz

Full Load Condition Floating Status Draft FP Draft MS Draft AP Trim LCG 2.386 m 2.498 m 2.609 m aft 0.15 deg. 1.514a m Heel Equil Wind Wave VCG zero Yes 0.0 kn No 3.668 m GM(Solid) F/S Corr. GM(Fluid) KMT TPcm 3.277 m 0.248 m 3.029 m 6.945 m 7.24

Loading Summary

Item

Light Ship Deadweight Displacement Fixed Weight Status Item LIGHT SHIP CREW AND EFFECTS PAY LOAD STORES Total Fixed: Tank Status FRESH WATER (SpGr 1.000) Tank Name FRESHW.P FRESHW.S Subtotals: FUEL OIL (SpGr 0.870) Tank Name SETTLING.P SETTLING.S DB 3.C DB 3.P DB 3.S DB 4.C Subtotals: Displacer Status Item HULL SubTotals:

Weight (MT) 1 200.00 290.26 1 490.26

LCG (m) 1.173a 2.921a 1.514a

TCG (m) 0.000 0.000 0.000

VCG (m) 4.230 1.346 3.668

Weight (MT) 1 200.00 2.00 1.40 3.20 1 206.60

LCG (m) 1.173a 15.000f 0.500a 12.000f 1.110a

TCG (m) 0.000 0.000 0.000 0.000 0.000

VCG (m) 4.230u 12.000u 3.300u 5.000u 4.244u

Load (%) 100.00% 100.00% 100.00%

Weight (MT) 27.42 27.42 54.85

LCG (m) 16.808a 16.808a 16.808a

TCG (m) 4.616p 4.616s 0.000

VCG (m) 2.830 2.830 2.830

Perm 0.950 0.950

Load (%) 98.00% 98.00% 98.00% 98.00% 98.00% 98.00% 66.41%

Weight (MT) 9.31 9.31 66.53 37.82 37.82 68.03 228.81

LCG (m) 20.178a 20.178a 5.963f 5.370f 5.370f 6.190a 0.027f

TCG (m) 3.869p 3.869s 0.000 4.486p 4.486s 0.000 0.000

VCG (m) 2.949 2.949 0.625 0.697 0.697 0.612 0.834

Perm 0.950 0.950 0.950 0.950 0.950 0.950

Status Intact

Spgr 1.025

Displ (MT) 1 490.64 1 490.64

LCB (m) 1.519a 1.519a

TCB (m) 0.000 0.000

VCB (m) 1.372 1.372

Eff /Perm 1.000

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 29 JBz

Fluid Legend Fluid Name FRESH WATER FUEL OIL Righting Arms vs Heel Angle Heel Angle (deg) 0.00 5.00s 10.00s 15.00s 20.00s 25.00s 30.00s 35.00s 40.00s 45.00s 47.44s 50.00s 55.00s 60.00s Trim Angle (deg) 0.15a 0.14a 0.11a 0.08a 0.03a 0.02f 0.07f 0.13f 0.22f 0.30f 0.33f 0.36f 0.39f 0.38f Origin Depth (m) 2.503 2.485 2.435 2.351 2.230 2.053 1.815 1.534 1.232 0.896 0.719 0.529 0.147 -0.252 Righting Arm (m) 0.000 0.281 0.574 0.878 1.190 1.455 1.663 1.805 1.863 1.890 1.895 1.889 1.850 1.779 Area Flood Pt Height (m-Rad) (m) 0.000 20.572 (1) 0.012 19.887 (1) 0.050 19.058 (1) 0.113 18.093 (1) 0.203 17.005 (1) 0.319 15.825 (1) 0.455 14.568 (1) 0.607 13.225 (1) 0.768 11.778 (1) 0.932 10.267 (1) 1.012 9.515 (1) 1.097 8.712 (1) 1.260 7.116 (1) 1.419 5.495 (1) Notes Equil Legend Weight (MT) 54.85 228.81 Load% 100.00% 66.41%

MaxRa

Unprotected Flood Point Name (1) Opening No1 Stb L,T,V (m) 29.000f, 7.000s, 23.000 Height (m) 20.572

Kattegatt Design

Doc. No.: Project: Subject: Issued By:

P1114-00-040-MA-001 Rev: 00 MMA136 - Ship Geometry and Hydrostatics Design Assignment Guidance Jan Bergholtz

Proj: Date: Page: Author:

P1114-00 31 Aug 11 30 JBz

IMO A.167 Limit (1) Area from 0.00 deg to 30.00 (2) Area from 0.00 deg to 40.00 or Flood (3) Area from 30.00 deg to 40.00 or Flood (4) Righting Arm at 30.00 deg or MaxRA (5) Angle from 0.00 deg to MaxRA (6) GM at Equilibrium Min/Max >0.0550 m-R >0.0900 m-R >0.0300 m-R >0.200 m >25.00 deg >0.150 m Actual 0.455 0.768 0.312 1.895 47.44 3.029 Margin 0.400 0.678 0.282 1.695 22.44 2.879 Pass Yes Yes Yes Yes Yes Yes

Righting Arms v s. Heel

0.0s Righting Arm R. Area Equi librium GMt 10.0s Heel angle (Degrees) 20.0s 30.0s 40.0s 50.0s 60.0s 2.0 A r m s i n m

1.5

1.0

0.5

0.0

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Rhino Ship Hull TutorialDocumento32 pagineRhino Ship Hull TutorialMark Pavkov100% (27)

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullDocumento10 pagine(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarNessuna valutazione finora

- 02 - Individual Benefits - GoldDocumento2 pagine02 - Individual Benefits - GoldPaulson JosephNessuna valutazione finora

- Esvagt+carpathia 2010a PDFDocumento1 paginaEsvagt+carpathia 2010a PDFPaulson JosephNessuna valutazione finora

- BV Damage Zones ModelDocumento1 paginaBV Damage Zones ModelPaulson JosephNessuna valutazione finora

- Mastech ShowReport2011Documento7 pagineMastech ShowReport2011Paulson JosephNessuna valutazione finora

- Monthly Calendars 2013-2014Documento12 pagineMonthly Calendars 2013-2014Paulson JosephNessuna valutazione finora

- Design 1: Akshay ChandranDocumento2 pagineDesign 1: Akshay ChandranPaulson JosephNessuna valutazione finora

- Monthly Calendars 2013-2014Documento12 pagineMonthly Calendars 2013-2014Paulson JosephNessuna valutazione finora

- Quasi-Efficiency PropulsionDocumento31 pagineQuasi-Efficiency PropulsionWafaà WafaNessuna valutazione finora

- LoadlineDocumento4 pagineLoadlinePaulson JosephNessuna valutazione finora

- Leaflet SOLAS 2009 - Damage Stability - V12Documento10 pagineLeaflet SOLAS 2009 - Damage Stability - V12Mohamed ChelfatNessuna valutazione finora

- Med Network ListDocumento19 pagineMed Network ListPaulson JosephNessuna valutazione finora

- Guidelines For Marine Crane LiftsDocumento25 pagineGuidelines For Marine Crane LiftsPaulson JosephNessuna valutazione finora

- FORM No. 1&2 Memorandum of Marriage Solemnization-Blank FormDocumento4 pagineFORM No. 1&2 Memorandum of Marriage Solemnization-Blank FormPaulson JosephNessuna valutazione finora

- External Forces & AccDocumento9 pagineExternal Forces & AccPaulson JosephNessuna valutazione finora

- Publication 1Documento1 paginaPublication 1Paulson JosephNessuna valutazione finora

- Leading Australian Supplier of Pipes, Valves and FittingsDocumento1 paginaLeading Australian Supplier of Pipes, Valves and Fittingsdragos_aeroNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- FFFDocumento57 pagineFFFlucasNessuna valutazione finora

- US Navy Preliminary Supplemental Inquiry Into USS Fitzgerald CollisionDocumento41 pagineUS Navy Preliminary Supplemental Inquiry Into USS Fitzgerald Collisionjared_keller_2100% (1)

- Activity Sheet 16 SEA 204 B1Documento5 pagineActivity Sheet 16 SEA 204 B1Arch AstaNessuna valutazione finora

- Seam 2 Module 1Documento21 pagineSeam 2 Module 1Adrian Carranza SimNessuna valutazione finora

- How To Draw Starship Deck PDocumento5 pagineHow To Draw Starship Deck PGlobulin MasterNessuna valutazione finora

- Training Manual: EASA Part-66 53 Level 3Documento22 pagineTraining Manual: EASA Part-66 53 Level 3Luis Enrique La Font FrancoNessuna valutazione finora

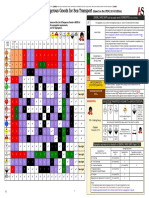

- Segregation of Dangerous Goods For Sea Transport: (Based On The IMDG 2016 Edition)Documento2 pagineSegregation of Dangerous Goods For Sea Transport: (Based On The IMDG 2016 Edition)Elton PintoNessuna valutazione finora

- Ng8038 Valve Name Tag List (9 Mar 20)Documento18 pagineNg8038 Valve Name Tag List (9 Mar 20)thova weeNessuna valutazione finora

- Technical Regulations On The Safety of Sea Transport Items - Part1Documento15 pagineTechnical Regulations On The Safety of Sea Transport Items - Part1strijelavremena100% (1)

- Damage Control Plan PDFDocumento21 pagineDamage Control Plan PDFasdsddsNessuna valutazione finora

- NES 109 Stability Standards For Surface ShipsDocumento50 pagineNES 109 Stability Standards For Surface ShipsJEORJENessuna valutazione finora

- 300 DWT UNMANNED BARGE by SNNCDocumento4 pagine300 DWT UNMANNED BARGE by SNNCEdi sonNessuna valutazione finora

- Case Study About Incidents Related To Hatches, Watertight DoorsDocumento3 pagineCase Study About Incidents Related To Hatches, Watertight Doorsjin harrenz dela cruzNessuna valutazione finora

- Ship Construction TermsDocumento41 pagineShip Construction TermsMitanshu ChadhaNessuna valutazione finora

- MSC 1-Circ 1572-Rev 1Documento13 pagineMSC 1-Circ 1572-Rev 1DujeKnezevicNessuna valutazione finora

- 600 NR - 2018 11Documento199 pagine600 NR - 2018 11mainNessuna valutazione finora

- Segregating of Dangerous GoodsDocumento47 pagineSegregating of Dangerous GoodsAbdel Nasser Al-sheikh YousefNessuna valutazione finora

- Rudder and Manoeuvring Arrangement DetailsDocumento11 pagineRudder and Manoeuvring Arrangement DetailsaminNessuna valutazione finora

- Failure of Titanic PDFDocumento26 pagineFailure of Titanic PDFAkshay BhaleraoNessuna valutazione finora

- Question Bank - Naval ArchitectureDocumento42 pagineQuestion Bank - Naval ArchitectureAnkit MauryaNessuna valutazione finora

- Intact ship data sourcesDocumento57 pagineIntact ship data sourcesasit_kgpNessuna valutazione finora

- Explosion FPSO Cidade de Sao Mateus Investigation Report Brasilian NavyDocumento43 pagineExplosion FPSO Cidade de Sao Mateus Investigation Report Brasilian NavyTim HopperNessuna valutazione finora

- MS Act - Stability RegulationsDocumento13 pagineMS Act - Stability RegulationsSudhakar MnsNessuna valutazione finora

- Freeboard: A. DefinitionsDocumento9 pagineFreeboard: A. DefinitionsFairuzNessuna valutazione finora

- Strength of ShipsDocumento94 pagineStrength of ShipsT VigneshwarNessuna valutazione finora

- 04 Watertight and Weather Tight DoorsDocumento12 pagine04 Watertight and Weather Tight DoorsLucky Boat100% (1)

- Structure and Main Parts of The ShipDocumento10 pagineStructure and Main Parts of The ShipromazNessuna valutazione finora

- Damage Stability: Principles of Naval Architecture The Management of Merchant Ship Stability, Trim & StrengthDocumento28 pagineDamage Stability: Principles of Naval Architecture The Management of Merchant Ship Stability, Trim & StrengthAnwarul Shafiq AwalludinNessuna valutazione finora

- Close this Damaged Stability DocumentDocumento59 pagineClose this Damaged Stability DocumentMrithyunjayanRathnamNessuna valutazione finora

- Ship Framing Systems and Construction DetailsDocumento12 pagineShip Framing Systems and Construction DetailsTruculent TrinoyNessuna valutazione finora