Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Small Printing Press Home Made

Caricato da

cagedraptorTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Small Printing Press Home Made

Caricato da

cagedraptorCopyright:

Formati disponibili

Food

Living

Outside

Play

Technology

Workshop

Desktop Printing Press

by MU5ICI4N on May 26, 2013 Table of Contents Desktop Printing Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Intro: Desktop Printing Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 1: Materials & Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 2: Cutting Wood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 3: Drilling 5/8th Inch Plywood Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 4: Drilling 1/4th Inch Plywood Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 5: Creating the Swiveling Bolt / Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 6: Begin Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 7: Finishing Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 8: Creating the Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 9: Making the Movable Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Step 10: Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 2 3 3 5 5 6 7 8 8 9

Step 11: Some Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Related Instructables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Advertisements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

http://www.instructables.com/id/Desktop-Printing-Press/

Intro: Desktop Printing Press

In my history class, I recently learned about Johannes Gutenberg and the role he played in the foundations for the Renaissance. I found myself captivated by his invention of the printing press, a revolutionary technology utilizing movable, inked type that could produce hundreds of Identical prints. I found myself asking "What would a modern re-imagining of this classic invention look like?" Before long, I had developed the idea for a desktop-based, "mini" printing press that used flash cards. Combine this with the abilities of 3D printing and laser-cutting technology, and its boundaries are expanded with the introduction of type with different fonts, sizes, and effects, as well as possible decals. Alas, I lack either a 3D-printer or a laser-cutter, forcing me to make improvisations. However, after seeing the Epilog V challenge, I decided to submit this instructible, and hopefully acquire a laser-printer to make this project what it was truly meant to be.

Step 1: Materials & Tools

For this project, you will need: MATERIALS -Masking tape -Strips of adhesive velcro (more than is pictured) -Ink pad (used in stamping) -foam letters (if you have a laser cutter or 3D printer, these are not necessary) -1/2 inch bolt (approx. 5 inches) -1/2 inch nut PLYWOOD -5/8 inch -1/4 inch NOT PICTURED -12 wood screws approx. 1/2 inch long TOOLS -Wood saw (unnecessary if you have a laser-cutter) -Handheld drill -Hot glue gun -Scissors -Screwdriver DRILL BITS -1/2 inch -1 inch NOT PICTURED -Drill bit for 1/2 inch long wood screws

http://www.instructables.com/id/Desktop-Printing-Press/

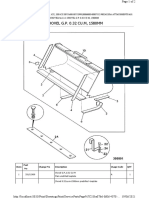

Step 2: Cutting Wood

Begin by cutting: 5/8 INCH PLYWOOD -10 by 3 and 1/8th (1 piece) - 2 and 1/2 by 3 and 1/8th (3 pieces) 1/4 INCH PLYWOOD -5 by 3 (1 piece) -2 and 1/2 by 6 (2 pieces) For this step, you can use a hand saw, or use a laser cutter by creating a vector image.

Image Notes 1. 10 by 3 and 1/8th 2. 2 and 1/2 by 3 and 1/8th 3. 2 and 1/2 by 3 and 1/8th 4. 2 and 1/2 by 3 and 1/8th 5. 5 by 3 6. 2 and 1/2 by 6 7. 2 and 1/2 by 6 8. 2 and 1/2 by 6

Step 3: Drilling 5/8th Inch Plywood Holes

Now, we will drill all of the holes in the wooden pieces. 1. drill a 1/2 inch hole in the center of two of the '2 and 1/2 by 3 and 1/8th' pieces. 2. bore a 1 inch hole into the other '2 and 1/2 by 3 and 1/8th' piece, making sure not to go all the way through. 3. measure and mark the '10 by 3 and 1/8th' piece into quarters. Next, mark two dots 1/2 inch in from the sides of the 2nd quarter. Do this on both sides. (See picture for details) 4. Mark two dots on each '2 and 1/2' side of the two '2 and 1/2 by 3 and 1/8th' pieces, 1/2 inch in from the sides, as before. 5.Drill all of these dots with the drill bit for the wood screws.

http://www.instructables.com/id/Desktop-Printing-Press/

Image Notes 1. 1/2 inch hole 2. 1/2 inch hole

Image Notes 1. 1 inch bored hole

Image Notes 1. 2nd quarter 2. measure on the other side as well

Image Notes 1. 2nd quarter

Image Notes 1. holes drilled 2. holes drilled 3. holes drilled 4. other side as well 5. other side as well 6. other side as well

http://www.instructables.com/id/Desktop-Printing-Press/

Step 4: Drilling 1/4th Inch Plywood Holes

Now, take the two '2 and 1/2 by 6' pieces of 1/4th inch plywood and mark the holes and lines to cut according to the photograph. Next, drill all of these holes and cut out the area in the middle. (drill using the same drill bit for the wood screws)

Step 5: Creating the Swiveling Bolt / Press

In this step, we will be creating the main force behind the printing press; the swiveling bolt and block of wood for pushing down. 1. Drill a hole large enough to accommodate the wooden dowel about 2 inches from the top of the 1/2 inch bolt. (make sure to use proper technique when drilling the steel- lubrication and a steel drill bit are essential) 2.The dowel should now fit nicely through this hole. It will serve as the "handle" for moving the bolt. 3.place the bolt on top of the '2 and 1/2 by 3 and 1/8th' piece of wood with the 1 inch hole bored into it. 4. Next, slide the metal ring down the bolt. 5. Hot glue the ring to the piece of wood, not the bolt. the bolt should now swivel smoothly.

http://www.instructables.com/id/Desktop-Printing-Press/

Step 6: Begin Construction

In this step, we will bring together all of the pieces of wood that were just drilled. 1.Begin by screwing the two '2 and 1/2 by 6' pieces of wood into the '10 by 3 and 1/8th' piece (the base). Make sure that four drilled holes remain above the cut- out piece, and that the cut out piece points towards the long end of the base. 2. Next, after placing the bolt / press flat in between the two '2 and 1/2 by 6' pieces, slide the two other '2 and 1/2 by 3 and 1/8th' pieces (with the 1/2 inch hole drilled in the center) down the bolt, and screw them into their corresponding holes on the '2 and 1/2 by 6' piece.

Image Notes 1. Pretend this is a dowel

http://www.instructables.com/id/Desktop-Printing-Press/

Step 7: Finishing Construction

Now, we will complete construction of the main press by gluing the nut for the bolt to turn through. 1.when the bolt / swiveling press is at a good location, screw the nut on and hot glue it to the wood. 2. your press should now look like the final picture.

http://www.instructables.com/id/Desktop-Printing-Press/

Step 8: Creating the Tray

It is now time to create the tray on which the movable type and flashcard will rest. 1. Take the '5 by 3' piece of plywood and cover it with strips of adhesive velcro. Use the thread-loop variation for this.

Step 9: Making the Movable Type

Finally, it is time to construct the movable type that will be used. I am using foam letters for this, however the exact same steps still apply if you are using laser-cut or 3D printed letters / decals. 1. take a sample of the letters that you want and lay them out, exactly as you would like to see them. 2. Next, take a piece of velcro (the nylon hook variation) enough to cover all of the letters. 3.cut the velcro into pieces just large enough to cover each letter. 4. apply the adhesive side of the velcro to the tops of the letters. 5. turn all of the letters around, and you should see your letters inverted. 6. the movable type is done!

http://www.instructables.com/id/Desktop-Printing-Press/

Step 10: Printing

all of the components have been completed, so it is time to dive into the technique of printing! NOTE- make sure yo cover your work area with newspaper, as ink can ruin any carpet or floor. 1. arrange all of the movable type on top of the tray as desired, completely inverted. 2.using the ink pad, gently apply ink to all of the letters. 3. stick two 5 inch pieces of masking tape halfway on each side of the tray. 4.Next, place the flashcard on top of the tray. 5. wrap the masking tape up onto the flashcard, holding it in place. 6. Finally, press the tray / flashcard in two stages, as the press can only print 1/2 of the flashcard at a time. 7.Enjoy your print! NOTE- as foam letters are a long shot from being the perfect material for movable type, my print may appear grainy and oversized. However, with laser-cut wooden or plastic letters, this could be eliminated, and letters would appear crisp and could be made smaller.

http://www.instructables.com/id/Desktop-Printing-Press/

Step 11: Some Notes

About this project: - This project was the culmination of my growing interest in historic inventions and love of building. I feel that this project could be taken to much further lengths when coupled with laser-cutting technology, as all pieces of wood in the press can be cut using a vector-file, and engraved to ones liking with designs or personalization. I would especially be fascinated to learn how laser-engraved decals would work in this press, and if they would be reminiscent of early woodcut prints. Since this project is potentially an almost completely-laser cut project, it could be a great introduction to laser-cutting and assembling. This is only my second Instructible, so any constructive criticism would be greatly appreciated! Regards, MU5ICI4N P.S. I hope that I have earned your vote!

Related Instructables

Origin of the Species - wall hanging 194x42in. by saul Book Wall Hangings Flatlands - cube by saul

How to make a PocketMod Book - 50+ Pages by icspots

Our Dream Project: Letterpress Print Studio and Stationery Store (video) by riseandshine

Mini Celebrity Pocket Desktop Notebook Monument Planner (Photos) by Daily/Weekly/Monthly randofo on 1 Page by thetoolman

http://www.instructables.com/id/Desktop-Printing-Press/

Advertisements

http://www.instructables.com/id/Desktop-Printing-Press/

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Charlemagne CipherDocumento38 pagineCharlemagne Ciphercagedraptor100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Flexistrut-8 2Documento167 pagineFlexistrut-8 2Lachlan RhodesNessuna valutazione finora

- Downloadfile 52 PDFDocumento565 pagineDownloadfile 52 PDFJoseph nozile0% (1)

- Ask Adult ManualDocumento37 pagineAsk Adult ManualcagedraptorNessuna valutazione finora

- Astm F 835 PDFDocumento6 pagineAstm F 835 PDFDan Dela Peña100% (1)

- Manual Parts 1cx JCBDocumento715 pagineManual Parts 1cx JCBGarcia Cruz100% (2)

- Basics of Short Baton Web1Documento13 pagineBasics of Short Baton Web1cagedraptor100% (1)

- Full Name Contact No. CityDocumento335 pagineFull Name Contact No. CitySatyam TejiNessuna valutazione finora

- Aluminum Fabrication PDFDocumento11 pagineAluminum Fabrication PDFdishku50% (4)

- Sonalika Tractors Parts MRP List PDFDocumento588 pagineSonalika Tractors Parts MRP List PDFkvsj2001100% (1)

- Linbad Duct SupportsDocumento46 pagineLinbad Duct SupportsdreamagiczNessuna valutazione finora

- Canon of Judo by K Mifune PDFDocumento249 pagineCanon of Judo by K Mifune PDFcreanga_ionNessuna valutazione finora

- User's Manual: Assembly and Energizing For Power TransformersDocumento47 pagineUser's Manual: Assembly and Energizing For Power TransformersYudis MercadoNessuna valutazione finora

- Cipher Wheel 3Documento2 pagineCipher Wheel 3cagedraptorNessuna valutazione finora

- Improvised Weaponry - Improvised Munitions Handbook (TM 31-210) PDFDocumento47 pagineImprovised Weaponry - Improvised Munitions Handbook (TM 31-210) PDFJosh Dean0% (1)

- Cipher WheelDocumento2 pagineCipher WheelcagedraptorNessuna valutazione finora

- Coat of ArmsDocumento1 paginaCoat of ArmscagedraptorNessuna valutazione finora

- Small and Large Cipher Disk Cutouts: Encryption and Decryption Pages To Learn How To Use The Cipher Disk CorrectlyDocumento1 paginaSmall and Large Cipher Disk Cutouts: Encryption and Decryption Pages To Learn How To Use The Cipher Disk Correctlycagedraptor100% (1)

- Make Your Own Wallet-Sized Enigma (TM) - Like Machine: Food Living Outside Play Technology WorkshopDocumento10 pagineMake Your Own Wallet-Sized Enigma (TM) - Like Machine: Food Living Outside Play Technology WorkshopcagedraptorNessuna valutazione finora

- Cipher Wheel 1Documento7 pagineCipher Wheel 1cagedraptorNessuna valutazione finora

- Cipher Wheel 1Documento7 pagineCipher Wheel 1cagedraptorNessuna valutazione finora

- Chinese GenericDocumento2 pagineChinese Genericcagedraptor100% (1)

- Cipher Wheel 2Documento2 pagineCipher Wheel 2cagedraptor100% (1)

- Chess BishopDocumento2 pagineChess BishopcagedraptorNessuna valutazione finora

- Caesar Box Cipher: PllptuelhorhceopeirlDocumento1 paginaCaesar Box Cipher: PllptuelhorhceopeirlcagedraptorNessuna valutazione finora

- Chess BaseDocumento1 paginaChess BasecagedraptorNessuna valutazione finora

- Chess CodeDocumento5 pagineChess CodecagedraptorNessuna valutazione finora

- Cart Code Cart Code Abcdefgh A B C D E F G H Ijklmno I J K L M N O Pqrstuv P Q R S T U V Wxyz W X Y ZDocumento2 pagineCart Code Cart Code Abcdefgh A B C D E F G H Ijklmno I J K L M N O Pqrstuv P Q R S T U V Wxyz W X Y ZcagedraptorNessuna valutazione finora

- Chess KnightDocumento4 pagineChess KnightcagedraptorNessuna valutazione finora

- Chess KingDocumento3 pagineChess KingcagedraptorNessuna valutazione finora

- BDMA Kids HandbookDocumento30 pagineBDMA Kids HandbookcagedraptorNessuna valutazione finora

- Black 1 ManualDocumento4 pagineBlack 1 Manualdeputy619Nessuna valutazione finora

- Caesar Box Cipher: PllptuelhorhceopeirlDocumento1 paginaCaesar Box Cipher: PllptuelhorhceopeirlcagedraptorNessuna valutazione finora

- Bunch o LinesDocumento2 pagineBunch o LinescagedraptorNessuna valutazione finora

- CAAM JapaneseNinjaDocumento2 pagineCAAM JapaneseNinjacagedraptorNessuna valutazione finora

- Bruce Lees 1 and 3 Inch PunchDocumento22 pagineBruce Lees 1 and 3 Inch PunchcagedraptorNessuna valutazione finora

- Build A PVC Fig RigDocumento6 pagineBuild A PVC Fig RigcagedraptorNessuna valutazione finora

- The Japanese Arts - Karate, Akeido, Kendo and JudoDocumento89 pagineThe Japanese Arts - Karate, Akeido, Kendo and Judowinegums93Nessuna valutazione finora

- BJJ Pardoel Fig4Documento1 paginaBJJ Pardoel Fig4hikari70Nessuna valutazione finora

- Ub356 Bolted SpliceDocumento4 pagineUb356 Bolted SpliceihpeterNessuna valutazione finora

- Ed Brown 2011 CatalogDocumento36 pagineEd Brown 2011 CatalogMario LopezNessuna valutazione finora

- Installation Instructions PTO Kit For Powershift TransmissionDocumento34 pagineInstallation Instructions PTO Kit For Powershift TransmissionНиколай МироновNessuna valutazione finora

- Europac Eng DatasheetDocumento22 pagineEuropac Eng DatasheetAdrian PowellNessuna valutazione finora

- DP15 To 100 BManualweb 2Documento22 pagineDP15 To 100 BManualweb 2juantecsup0% (1)

- Shop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemDocumento31 pagineShop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemMatias Sanchez100% (1)

- Chave de Fluxo MagnetrolDocumento28 pagineChave de Fluxo MagnetrolAlexandre EmmerickNessuna valutazione finora

- Chamberlain ManualDocumento80 pagineChamberlain ManualClaudioNessuna valutazione finora

- Manual IntercambiadorDocumento48 pagineManual IntercambiadorsaraNessuna valutazione finora

- Arctica Engine KavoDocumento14 pagineArctica Engine KavoHsuan ChenNessuna valutazione finora

- Datasheet T4WA S3Documento20 pagineDatasheet T4WA S3Diego BellanoNessuna valutazione finora

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 13-02 - Oil PumpDocumento5 pagineD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 13-02 - Oil PumpMANUALESNessuna valutazione finora

- LH3000 Operator ManualDocumento38 pagineLH3000 Operator ManualsandroterraNessuna valutazione finora

- Engineering Drawing Abbreviations and Symbols - WikipediaDocumento17 pagineEngineering Drawing Abbreviations and Symbols - Wikipediakader LoiliNessuna valutazione finora

- Remove Honda Civic DashDocumento10 pagineRemove Honda Civic Dashapi-19643285Nessuna valutazione finora

- IS 7152 - Book Room Doors S PDFDocumento14 pagineIS 7152 - Book Room Doors S PDFemanNessuna valutazione finora

- Sistomat-P: 1. Installation InstructionsDocumento1 paginaSistomat-P: 1. Installation InstructionsEric LarrondoNessuna valutazione finora

- ¡ 1/2" Through Bolt With: Temporary Traffic Control PlanDocumento1 pagina¡ 1/2" Through Bolt With: Temporary Traffic Control PlanEliNessuna valutazione finora

- MM313Documento262 pagineMM313zukraf jawaharNessuna valutazione finora

- @surfan - Design3d: Mesin - Fti - UsaktiDocumento2 pagine@surfan - Design3d: Mesin - Fti - UsaktiFawwazNessuna valutazione finora

- MAE322PowerThreads PDFDocumento29 pagineMAE322PowerThreads PDFabbieNessuna valutazione finora