Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kinematic Coupling 3groove Design

Caricato da

thulasi_krishnaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Kinematic Coupling 3groove Design

Caricato da

thulasi_krishnaCopyright:

Formati disponibili

Screwforce.

xls To determine lifting force from a screw By Alex Slocum 3/8/01, last modified 2/12/04 by Alex Slocum Enter numbers in BOLD, results in RED Be consistant with units! (in, lb or N, m or N, mm) Applied torque (input) 50 Turning speed (rpm) 100 Dthrustbearing 12 Dpitch 5 Lead 1.25 alpha, cos(alpha) 30 0.8660254 Coefficients of friction muthrustbearing 0.2 muthreads 0.2 beta 0.25 To RAISE a load screwthread efficiency, etaraise 25.16% Without thrust bearing Force (output) 63.2 With thrust bearing Force (output) 25.1 Linear speed (mm/sec) 2.08 To LOWER a load screwthread efficiency, etalower 54% Without thrust bearing Force (output) 134.6 With thrust bearing Force (output) 31.8

Diameter of thrust bearing Pitch diameter Distance traveled in one turn A typical bolt screwthread has alpha = 30 degrees

required

F desired D Bolt _ head _ or _ thrust _ bearing F desired 2 2

thrust _ bearing

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

A B C D E Kinematic_Coupling_3Groove_Design.xls To design three groove kinematic couplings Written by Alex Slocum. Last modified 10/27/2004 by Alex Slocum Metric units only! Enters numbers in BOLD, Results in RED Standard 120 degree equal size groove coupling? (contact forces are inclined at 45 to the XY plane. For non standard designs, enter geometry after results section) TRUE System geometry (XY plane is assumed to contain the ball centers) Dbeq (mm) = 15 Equivalent diameter ball to contact the groove at the same points Rbminor (mm) = 5 "Ball" minor radius Rbmajor (mm) = 500 "Ball" major radius Rgroove (mm) = 1.00E+06 Groove radius (negative for a trough) Costheta = TRUE Is ball major radius along groove axis? Dcoupling (mm) = 250 Coupling diameter Fpreload (N) = -100 Preload force over each ball Xerr (mm) = 0.0 X location of error reporting Yerr (mm) = 0.0 Y location of error reporting Zerr (mm) = 0.0 Z location of error reporting Auto select material values (enter other_4 to the right)

Appendix F A

Material properties User defined material aluminum Yield stress plastic 3.45E+07 RC 62 Steel 1.72E+09 CARBIDE 2.76E+09 user defined 2.76E+08 Elastic modulus plastic 2.07E+09 RC 62 Steel 2.04E+11 CARBIDE 3.10E+11 user defined 6.80E+10 Poisson ratio plastic 0.20 RC 62 Steel 0.29 0.30 0.29

Matlabball = 4 Enter 1 for plastic, 2 for steel, 3 for carbide, 4 for user defined, 5 CARBIDE Matlabgroove = 4 where each ball and groove is defined individually user defined Min. yield strength (Pa, psi) 2.76E+08 40,000 Largest contact ellipse major diameter (mm) 2.964 Largest contact ellipse major diameter (mm) 0.162 Largest contact stress ratio 0.666 Max Hertz shear stress/Material's max shear stress (tensile yield/2) RMS applied force F (N) 17.32 RMS deflection at F (micron) 0.095 RMS stiffness (N/micron) 182.88 Applied force's Z,Y,Z values and coordinates Coupling centroid location FLx (N) = 10.00 XL (mm) = 0 xc (mm) 0.000 FLy (N) = 10.00 YL (mm) = 0 yc (mm) 0.000 FLz (N) = 10.00 ZL (mm) = 100 zc (mm) 0.000 Results: Hertz stresses and deformations Error displacements at the point of interest (micron) DeltaX -5.34E-08 DeltaY -5.44E-08 DeltaZ Groove normal forces (N) Fbnone Fbntwo Ball-Groove 2 Groove normal forces (N) Fbnthree Fbnfour Ball-Groove 3 Groove normal forces (N) Fbnfive Fbnsix Contact stress (Pa) 7.68E+01 sigone 6.74E+01 sigtwo Contact stress (Pa) 6.49E+01 sigthree 6.15E+01 sigfour Contact stress (Pa) 6.33E+01 sigfive 7.62E+01 sigsix

Max shear stress/(ult. tensile/2)

XL (m) = YL (m) = ZL (m) =

3.06E+08 2.93E+08

Deflection (+into ball) (m) 0.666 delone 0.637 deltwo Deflection (m) 0.630 delthree 0.618 delfour Deflection (m) 0.624 delfive 0.664 delsix

1.54E-07 -8.47E-08

2.90E+08 2.84E+08

-1.49E-07 -2.40E-07

2.87E+08 3.05E+08

-1.92E-07 1.37E-07

-5.61E-08 Contact ellipse Rmajor (m) 1.48E-03 1.42E-03 Contact ellipse Rmajor (m) 1.40E-03 1.38E-03 Contact ellipse Rmajor (m) 1.39E-03 1.48E-03

Results: Error motions Error motions are at X,Y,Z coordinates: deltaX (m) -5.34E-08 deltaY (m) -5.44E-08 deltaZ (m) -5.61E-08 EpsX (radian) 5.50E-07 EpsY (radian) -5.47E-07

0.000 0.000 RMS delta (m) 9.47E-08 Homogenous Transformation Matrix: 1.00E+00 -1.12E-10 1.12E-10 1.00E+00 5.47E-07 5.50E-07

0.000

-5.47E-07 -5.50E-07 1.00E+00

Page 3

-5.34E-08 -5.44E-08 -5.61E-08

55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109

A B C D E Appendix F A EpsZ (radian) 1.12E-10 0.00E+00 0.00E+00 0.00E+00 Generic data entry for non-120 degree couplings NOTE! For calculation of angular errors, the coupling is assumed to lie in the XY plane. Ball 1 must lie in quadrants 1 0r 2, and Balls 2 & 3 must lie in quadrants 3 and 4 Enter X,Y,Z coordinates and alpha, beta, gamma direction cosines for Ball 1 Dball (m) 0.0150 Dcoupling (m) 0.250 Contact point 1 Contact point 2 Xba = 0.005303 Xbb = -0.005303 Yba = 0.125000 Ybb = 0.125000 Zba = -0.005303 Zbb = -0.005303 Aba = -0.707107 Abb = 0.707107 Bba = 0.000000 Bbb = 0.000000 User values if matlabs = Gba = 0.707107 Gbb = 0.707107 Enter characteristics for groove 1 and ball 1 5 Egone = 6.80E+10 Groove material elastic modulus, or enter value (mm): vgone = 0.29000 Groove material Poisson ratio, or enter value (mm): Rgone = 1000 Groove radius of curvature Ebone = 6.80E+10 Ball material elastic modulus, or enter value (Pa): vbone = 0.29 Ball material Poisson ratio, or enter value (Pa): Eeone = 3.71E+10 Equivelent modulus Dbone = 1.50E-02 Equivelent diameter ball that would contact the groove at the same points Rpone = 0.5 "Ball" major radius of curvature, or enter value (mm): Raone = 0.005 "Ball" minor radius of curvture, or enter value (mm): Reone = 0.004950471 Equivelent radius ctone = 0.980198118 Cos(theta) theta_1 = 0.19933681 alpha_1 = 5.959934734 beta_1 = 0.325084666 lambda_1 = 0.342741271 Sone = 2.76E+08 Allowable Hertz stress, or enter value: Enter X,Y,Z coordinates and alpha, beta, gamma direction cosines for Ball 2 Contact point 3 Contact point 4 Xbc = -0.110905 Xbd = -0.105602 Ybc = -0.057907 Ybd = -0.067093 Zbc = -0.005303 Zbd = -0.005303 Abc = 0.353553 Abd = -0.353553 Bbc = -0.612372 Bbd = 0.612372 User values if matlabs = Gbc = 0.707107 Gbd = 0.707107 Enter characteristics for groove 2 and pin 2 5 Egtwo = 6.80E+10 Groove material elastic modulus, or enter value (mm): vgtwo = 0.29000 Groove material Poisson ratio, or enter value (mm): Rgtwo = 1000 Groove radius of curvature Ebtwo = 6.80E+10 Ball material elastic modulus, or enter value (Pa): vbtwo = 0.29 Ball material Poisson ratio, or enter value (Pa): Eetwo = 3.71E+10 Equivelent modulus Dbtwo = 1.50E-02 Equivelent diameter ball that would contact the groove at the same points Rptwo = 0.5 "Ball" major radius of curvature, or enter value (mm): Ratwo = 0.005 "Ball" minor radius of curvture, or enter value (mm): Retwo = 0.004950471 Equivelent radius cttwo = 0.980198118 Cos(theta) theta_2 = 0.19933681 alpha_2 = 5.959934734 beta_2 = 0.325084666 lambda_2 = 0.342741271

Page 4

G 1.00E+00

110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164

A B C Stwo = 2.76E+08 Allowable Hertz stress Enter X,Y,Z coordinates and alpha, beta, gamma direction cosines for Ball 3 Contact point 5 Xbe = 0.105602 Xbf = Ybe = -0.067093 Ybf = Zbe = -0.005303 Zbf = Abe = 0.353553 Abf = Bbe = 0.612372 Bbf = Gbe = 0.707107 Gbf =

Appendix F A

User values if matlabs = Enter characteristics for groove 3 and ball 3 5 Egthree = 6.80E+10 Groove material elastic modulus, or enter value (mm): vgthree = 0.29000 Groove material Poisson ratio, or enter value (mm): Rgthree = 1000 Groove radius of curvature Ebthree = 6.80E+10 Ball material elastic modulus, or enter value (Pa): vbthree = 0.29 Ball material Poisson ratio, or enter value (Pa): Eethree = 3.71E+10 Equivelent modulus Dbthree = 1.50E-02 Equivelent diameter ball that would contact the groove at the same points Rpthree = 0.5 "Ball" major radius of curvature, or enter value (mm): Rathree = 0.005 "Ball" minor radius of curvture, or enter value (mm): Rethree = 0.004950471 Equivelent radius ctthree = 0.980198118 Cos(theta) theta_3 = 0.19933681 alpha_3 = 5.959934734 beta_3 = 0.325084666 lambda_3 = 0.342741271 Sthree = 2.76E+08 Allowable Hertz stress Preload forces' X,Y,Z components and coordinates Fpxone = 0 Fpxtwo = 0 Fpxthree = 0 Fpyone = 0 Fpytwo = 0 Fpythree = 0 Fpzone = -100 Fpztwo = -100 Fpzthree = -100 Xpone = 0 Xptwo = -0.108253175 Xpthree = 0.108253175 Ypone = 0.125 Yptwo = -0.0625 Ypthree = -0.0625 Zpone = 0.03 Zptwo = 0.03 Zpthree = 0.03 Calculations: Build Force Moment equilibrium matrices: AF = B (Equations 1-6) Matrix A Fbn1 Fbn2 Fbn3 Fbn4 Fbn5 Fbn6 -7.07E-01 7.07E-01 3.54E-01 -3.54E-01 3.54E-01 -3.54E-01 0.00E+00 0.00E+00 -6.12E-01 6.12E-01 6.12E-01 -6.12E-01 7.07E-01 7.07E-01 7.07E-01 7.07E-01 7.07E-01 7.07E-01 8.84E-02 8.84E-02 -4.42E-02 -4.42E-02 -4.42E-02 -4.42E-02 0.00E+00 0.00E+00 7.65E-02 7.65E-02 -7.65E-02 -7.65E-02 8.84E-02 -8.84E-02 8.84E-02 -8.84E-02 8.84E-02 -8.84E-02 Res. Forces with applied loads Res forces with preload only fbnone 76.84 fone 70.71 fbntwo 67.41 ftwo 70.71 fbnthree 64.93 fthree 70.71 fbnfour 61.48 ffour 70.71 fbnfive 63.29 ffive 70.71 fbnsix 76.17 fsix 70.71 Original ball corrdinates xboneO 0.0000000 xbtwoO -0.1082532 xbthreeO 0.1082532 yboneO 0.1250000 ybtwoO -0.0625000 ybthreeO -0.0625000 zboneO 0.0000000 zbtwoO 0.0000000 zbthreeO 0.0000000 New ball coordinates (=original + ball deflection*direction cosines)

Page 5

Contact point 6 0.110905 -0.057907 -0.005303 -0.353553 -0.612372 0.707107

Matrix F Fbn1 Fbn2 Fbn3 Fbn4 Fbn5 Fbn6

B with loads -1.00E+01 -1.00E+01 2.90E+02 1.00E+00 -1.00E+00 0.00E+00

165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219

A B xboneN -0.00000008432 yboneN 0.1250000 zboneN 0.0000000 Ball centers' deflections dxone -8.43E-08 dyone 0.00E+00 dzone 2.45E-08 Theory applicability check: Initiial dist. between balls LotI ############# LttI ############# LtoI ############# Change in length/distance between balls 1.20E-07 3.44E-07 4.64E-07

C xbtwoN ybtwoN zbtwoN dxtwo dytwo dztwo Final dist. between balls LotN LttN LtoN

D E -0.1082532 xbthreeN -0.0625000 ybthreeN -0.0000001 zbthreeN ############ dxthree ############ dythree ############ dzthree Difference 0.2165063249 DLotI 0.2165062766 DLttI 0.2165064514 DLtoI Deflection/ball radius 2.05E-05 3.21E-05 2.56E-05

Appendix F A 0.1082531 -0.0625001 0.0000000 -5.82581249E-08 -1.00906032E-07 -1.94155344E-08

2.60E-08 7.44E-08 -1.00E-07 Ratio (should be >5) 1.71E+02 9.33E+01 5.53E+01

Coupling centroid is assumed to be at intersection of coupling triangle's angle bisectors Initial centroid Distance from ball to centroid Error motion at centroid from weighted ball motions xci 0.000000000 Dcone 0.125000000 dxc -5.34E-08 yci 0.000000000 Dctwo 0.125000000 dyc -5.44E-08 zci 0.000000000 Dcthree 0.125000000 dzc -5.61E-08 Original angles between balls Original altitude lengths Angone ############# angle at ball 1 Aone 0.1875 Ball 1 to side 2 3 Angtwo ############# angle at ball 2 Atwo 0.1875 Ball 2 to side 1 3 Angthree ############# angle at ball 3 Athree 0.1875 Ball 3 to side 2 1 New angles between balls Original sides' angle with X axis AngoneN 60.0000 angle at ball 1 Aot 60 Side opposite ball 3 AngtwoN 60.0000 angle at ball 2 Att 0 Side opposite ball 1 AngthreeN 60.0000 angle at ball 3 Ato 120 Side opposite ball 2 New sides' angle with X axis AotN 60.00002671 Side opposite ball 3 0 AttN -1.93142E-05 Side opposite ball 1 0 AtoN 119.9999926 Side opposite ball 2 Original altitudes' slope angles and Y intercepts AmtwoO 30 AbtwoO 0 AmthreeO 150 AbthreeO 0 Rotation about opposite side (radians) Ttt 1.30E-07 rotation about side 23 due to Z motion at ball 1 Tto -7.35E-07 rotation about side 13 due to Z motion at ball 2 Tot -1.04E-07 rotation about side 12 due to Z motion at ball 3 Coupling error rotations EpsX 5.50E-07 EpsZ1 6.75E-07 Z rot from ball 1 EpsY -5.47E-07 EpsZ2 2.58E-07 Z rot from ball 2 EpsZ 1.12E-10 EpsZ3 -9.32E-07 Z rot from ball 3 Coupling HTM Point of interest 1.00E+00 -1.12E-10 -5.47E-07 -5.34E-08 Xerr 0 1.12E-10 1.00E+00 -5.50E-07 -5.44E-08 Yerr 0 5.47E-07 5.50E-07 1.00E+00 -5.61E-08 Zerr 0 0.00E+00 0.00E+00 0.00E+00 1.00E+00 1 1 Error displacements at the point of interest DeltaX -5.34E-08 DeltaY -5.44E-08 DeltaZ -5.61E-08 0

Page 6

Potrebbero piacerti anche

- JUAS 2019 - Tutorial 2: 1.) S-ParametersDocumento6 pagineJUAS 2019 - Tutorial 2: 1.) S-Parameterssultan1786Nessuna valutazione finora

- Chapter #19 Solutions - Engineering Economy, 7 TH Editionleland Blank and Anthony TarquinDocumento15 pagineChapter #19 Solutions - Engineering Economy, 7 TH Editionleland Blank and Anthony TarquinMusa'bNessuna valutazione finora

- FBS Back CalcDocumento4 pagineFBS Back Calcnzgreg82Nessuna valutazione finora

- Gear CalcDocumento8 pagineGear CalcChetan PrajapatiNessuna valutazione finora

- Exam 2 F10 SolDocumento8 pagineExam 2 F10 SolAlejandro AguirreNessuna valutazione finora

- BOOK Ugural 15 Mechanical Design of Machine ComponentsDocumento95 pagineBOOK Ugural 15 Mechanical Design of Machine ComponentsLeonel Bejar VelardeNessuna valutazione finora

- A A A A A A A A A A A: Exercise Solutions EX12.1Documento15 pagineA A A A A A A A A A A: Exercise Solutions EX12.1Luis AntonioNessuna valutazione finora

- Questions On MatlabDocumento27 pagineQuestions On MatlabnainaNessuna valutazione finora

- Project Title: Exercise 1Documento2 pagineProject Title: Exercise 1tfvnjyNessuna valutazione finora

- Base Plate Design for W6X25 ColumnDocumento54 pagineBase Plate Design for W6X25 ColumnMuhammadIqbalMughalNessuna valutazione finora

- TST56 Welded Joints Examples 12.13 EditDocumento56 pagineTST56 Welded Joints Examples 12.13 EditDaniyal AhmadNessuna valutazione finora

- Ce04 Exam3Documento3 pagineCe04 Exam3woi mariaNessuna valutazione finora

- Tension Members PDFDocumento21 pagineTension Members PDFMaribeth Salvador50% (2)

- Be First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' SchemeDocumento43 pagineBe First Year Engineering Semester 1 2019 December Engineering Mechanics Emrev 2019'c' Schemesinghsitturaj78Nessuna valutazione finora

- Transverse Shear Stresses in BeamsDocumento6 pagineTransverse Shear Stresses in BeamsMijhael Anatholi Romero MamaniNessuna valutazione finora

- 7 1Documento24 pagine7 1khrid3Nessuna valutazione finora

- BEAM DESIGN AND INVESTIGATIONDocumento45 pagineBEAM DESIGN AND INVESTIGATIONNikka KayeNessuna valutazione finora

- Arithmetic for ComputersDocumento67 pagineArithmetic for ComputersJahangir AlamNessuna valutazione finora

- EEE3405Tut1 5QSDocumento10 pagineEEE3405Tut1 5QSArjunneNessuna valutazione finora

- 3d-Ex ProbsDocumento9 pagine3d-Ex ProbsArvind MNessuna valutazione finora

- Prof. Abousleiman N. Younane Email: Yabousle@ou - Edu Office: SEC, Suite P119Documento57 pagineProf. Abousleiman N. Younane Email: Yabousle@ou - Edu Office: SEC, Suite P119Christopher AyresNessuna valutazione finora

- GP 1 A 70 RDocumento7 pagineGP 1 A 70 RNguyen Phuoc HoNessuna valutazione finora

- Chapter - Bode PlotsDocumento22 pagineChapter - Bode PlotsRicardo VillalongaNessuna valutazione finora

- Example 5.1. Axial Force Resistance of Member With Square Hollow SectionDocumento1 paginaExample 5.1. Axial Force Resistance of Member With Square Hollow SectionimotalpNessuna valutazione finora

- Module 5 Structural Steel Design 1Documento19 pagineModule 5 Structural Steel Design 1Rich Lenard L. MagbooNessuna valutazione finora

- Provide A Screenshot of The Beam in Wireframe View in SWS. Ensure That The LC's and BC's Are Clearly Indicated in The Screenshot. AnsDocumento12 pagineProvide A Screenshot of The Beam in Wireframe View in SWS. Ensure That The LC's and BC's Are Clearly Indicated in The Screenshot. AnsSagnik ChakrabortyNessuna valutazione finora

- How To Import Staad Model To XsteelDocumento11 pagineHow To Import Staad Model To XsteelBenchNessuna valutazione finora

- Industrial Instrumentation Assesment 1 Copy 1Documento11 pagineIndustrial Instrumentation Assesment 1 Copy 1MARVIN NAMANDANessuna valutazione finora

- Plate RectangularDocumento7 paginePlate RectangularReyginald MarronNessuna valutazione finora

- Industrial Instrumentation Assesment 1 Copy 1Documento11 pagineIndustrial Instrumentation Assesment 1 Copy 1MARVIN NAMANDANessuna valutazione finora

- Fundamentals Wagoner&Chenot ProblemSolutionsDocumento169 pagineFundamentals Wagoner&Chenot ProblemSolutionsVishweshRaviShrimali100% (1)

- Topographic Survey Lab Report by Students at University XDocumento37 pagineTopographic Survey Lab Report by Students at University XMaria mokdadNessuna valutazione finora

- MOMENT INFLUENCE LINESDocumento23 pagineMOMENT INFLUENCE LINESgeomatik100% (1)

- FUNDRAX1Documento6 pagineFUNDRAX1kannan100% (1)

- Plate 2 2Documento15 paginePlate 2 2Cainoa Nicko CappalNessuna valutazione finora

- Torsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionDocumento26 pagineTorsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionHafiezul HassanNessuna valutazione finora

- Static EquilibriumDocumento4 pagineStatic EquilibriumNORLIN BINTI NADZRIN KM-PensyarahNessuna valutazione finora

- Ec9 Ex44 Bending Trapez Class 4Documento7 pagineEc9 Ex44 Bending Trapez Class 4imotalpNessuna valutazione finora

- Medium Length Line ExampleDocumento2 pagineMedium Length Line ExamplepecworldNessuna valutazione finora

- 112 116Documento10 pagine112 116Monica Jones100% (1)

- Simple ConstructionDocumento6 pagineSimple ConstructiontmssorinNessuna valutazione finora

- Lab 3.2Documento2 pagineLab 3.2Chii PufNessuna valutazione finora

- GP1A70R/GP1A71R: OPIC Photointerrupter With Encoder FunctionsDocumento6 pagineGP1A70R/GP1A71R: OPIC Photointerrupter With Encoder FunctionsToai NguyenNessuna valutazione finora

- Lab Title: Objectives: Material Required:: Sinusoidal Steady StateDocumento11 pagineLab Title: Objectives: Material Required:: Sinusoidal Steady Stateahmed shahNessuna valutazione finora

- Y 240 (3.47) P K Y F PaDocumento3 pagineY 240 (3.47) P K Y F PaANER MOHAMEDNessuna valutazione finora

- Assignment 1-ADocumento9 pagineAssignment 1-AHassan YounasNessuna valutazione finora

- Foundation Engg Module 3 Square Footing With Axial Load OnlyDocumento8 pagineFoundation Engg Module 3 Square Footing With Axial Load Onlyjc gelacioNessuna valutazione finora

- Solutions November 2001 SUBJECT 106 - Actuarial Mathematics IIDocumento14 pagineSolutions November 2001 SUBJECT 106 - Actuarial Mathematics IIShivamGuptaNessuna valutazione finora

- Vernier caliper and micrometer measurementsDocumento9 pagineVernier caliper and micrometer measurementsHassan YounasNessuna valutazione finora

- Equations Eg 341Documento30 pagineEquations Eg 341lopesisnotdamanNessuna valutazione finora

- R & RDocumento16 pagineR & Razadsingh1Nessuna valutazione finora

- Column ComputationDocumento5 pagineColumn ComputationPoppy MooreNessuna valutazione finora

- Non-Worked Out Solutions To ELEC3114 Sample Final Exam Paper ADocumento5 pagineNon-Worked Out Solutions To ELEC3114 Sample Final Exam Paper AkikikikemNessuna valutazione finora

- Mathematical Tables: Tables of in G [z] for Complex ArgumentDa EverandMathematical Tables: Tables of in G [z] for Complex ArgumentNessuna valutazione finora

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDa EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNessuna valutazione finora

- Feedback Control Performance MeasuresDocumento37 pagineFeedback Control Performance MeasuresmrkmatNessuna valutazione finora

- Simulation CellierDocumento65 pagineSimulation Cellierthulasi_krishnaNessuna valutazione finora

- CarboTherm TB2 0213 R02Documento2 pagineCarboTherm TB2 0213 R02thulasi_krishnaNessuna valutazione finora

- Mil DTL 38999 Series IIIDocumento10 pagineMil DTL 38999 Series IIIthulasi_krishnaNessuna valutazione finora

- Expense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total ExpensesDocumento9 pagineExpense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total Expensesthulasi_krishnaNessuna valutazione finora

- Seal Design Considerations Using Kalrez PartsDocumento4 pagineSeal Design Considerations Using Kalrez Partsthulasi_krishnaNessuna valutazione finora

- Chinese Baby Gender Chart - Lunar Month of ConceptionDocumento6 pagineChinese Baby Gender Chart - Lunar Month of Conceptionthulasi_krishnaNessuna valutazione finora

- Modelica Thermal ModelingDocumento4 pagineModelica Thermal Modelingthulasi_krishnaNessuna valutazione finora

- Model Based Systems Engineering For Aircraft Systems - How DoesDocumento9 pagineModel Based Systems Engineering For Aircraft Systems - How DoesAlmas QasimNessuna valutazione finora

- Economic and Product Design Considerations in Machiningchapter 24Documento38 pagineEconomic and Product Design Considerations in Machiningchapter 24احمد عمر حديدNessuna valutazione finora

- Seals and Gaskets: 3.0 Table of ContentsDocumento40 pagineSeals and Gaskets: 3.0 Table of Contentsthulasi_krishnaNessuna valutazione finora

- FastenersDocumento178 pagineFastenersthulasi_krishna100% (6)

- Project Status Dashboard Xl2007Documento22 pagineProject Status Dashboard Xl2007Jkjiwani AccaNessuna valutazione finora

- Valve Sizing CalculationsDocumento20 pagineValve Sizing Calculationsask_friend100% (3)

- LaminateDocumento3 pagineLaminatethulasi_krishnaNessuna valutazione finora

- F 4Documento9 pagineF 4thulasi_krishnaNessuna valutazione finora

- Technical Manual - O-Ring Gland Design InformationDocumento31 pagineTechnical Manual - O-Ring Gland Design InformationplaunieNessuna valutazione finora

- Gearmotor size estimator spreadsheetDocumento2 pagineGearmotor size estimator spreadsheetS C GaurNessuna valutazione finora

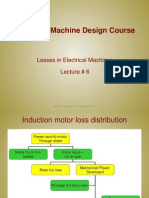

- Lecture6 - Losses in Electric MachinesDocumento24 pagineLecture6 - Losses in Electric Machinesthulasi_krishnaNessuna valutazione finora

- Brushless DC Motor Phase Poles Lot ConfigurationsDocumento17 pagineBrushless DC Motor Phase Poles Lot Configurationsthulasi_krishnaNessuna valutazione finora

- Lecture1 - History & IntroductionDocumento20 pagineLecture1 - History & Introductionramaswamykama786100% (1)

- Electromagnetic Design of DC MotorsDocumento24 pagineElectromagnetic Design of DC Motorsthulasi_krishna100% (1)

- Bolt DesignDocumento18 pagineBolt Designthulasi_krishnaNessuna valutazione finora

- Lecture3 - Three Phase Power Converter Control Strategies For Three Machine TypesDocumento26 pagineLecture3 - Three Phase Power Converter Control Strategies For Three Machine Typesthulasi_krishnaNessuna valutazione finora

- Projectto Dolist1Documento2 pagineProjectto Dolist1Vikas PhatakNessuna valutazione finora

- Lecture1 - History & IntroductionDocumento20 pagineLecture1 - History & Introductionramaswamykama786100% (1)

- Lecture2 - Basic Electric Motor & Generator TheoryDocumento21 pagineLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNessuna valutazione finora

- Calendar 2014: January February MarchDocumento4 pagineCalendar 2014: January February Marchthulasi_krishnaNessuna valutazione finora

- Random Vibration - An Overview - BarryControlsDocumento15 pagineRandom Vibration - An Overview - BarryControlsGuru75Nessuna valutazione finora

- Lecture2 - Basic Electric Motor & Generator TheoryDocumento21 pagineLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNessuna valutazione finora

- Remeha Gas 310 ECO: Technical InformationDocumento59 pagineRemeha Gas 310 ECO: Technical InformationAdrian Blazquez MolinaNessuna valutazione finora

- MCP HistoryDocumento18 pagineMCP HistoryStanciu VladNessuna valutazione finora

- Design and Development of Swashplate-Less HelicopterDocumento68 pagineDesign and Development of Swashplate-Less HelicopterNsv DineshNessuna valutazione finora

- ABS Thickness Measurement Requirement For Ship in Operation PDFDocumento2 pagineABS Thickness Measurement Requirement For Ship in Operation PDFMohd Fouzi AbdullahNessuna valutazione finora

- Well Control - Fundamental - W2 - Well Control PrincipleDocumento17 pagineWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoNessuna valutazione finora

- Performance of tuned mass dampers under wind loadsDocumento13 paginePerformance of tuned mass dampers under wind loadsDhirendra Kumar PandeyNessuna valutazione finora

- Engineering Drawing Solution All Year First Part Ioe NotesDocumento31 pagineEngineering Drawing Solution All Year First Part Ioe Notesई. सन्तोष शर्माNessuna valutazione finora

- Design of Connetiomn Chankara AryaDocumento21 pagineDesign of Connetiomn Chankara AryaMohamed AbdNessuna valutazione finora

- Solar Desalination PlantDocumento28 pagineSolar Desalination PlantAnonymous TETH310% (1)

- Maintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksDocumento441 pagineMaintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksMigue Angel Rodríguez Castro100% (2)

- A967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFDocumento25 pagineA967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFKiran KumarNessuna valutazione finora

- System ConfigurationDocumento13 pagineSystem ConfigurationEdlyn Estopa BuenoNessuna valutazione finora

- 7 Inch Liner Cementing ProgramDocumento44 pagine7 Inch Liner Cementing ProgramMarvin OmañaNessuna valutazione finora

- Fundamentals of Ship ConstructionDocumento18 pagineFundamentals of Ship ConstructionWAREKARNessuna valutazione finora

- SPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityDocumento18 pagineSPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityYovaraj KarunakaranNessuna valutazione finora

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Documento352 pagine03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94Nessuna valutazione finora

- Performance-Creative Design Concept For Concrete InfrastructureDocumento11 paginePerformance-Creative Design Concept For Concrete InfrastructureTuan PnNessuna valutazione finora

- Thomson VTH 7090 VCR ManualDocumento33 pagineThomson VTH 7090 VCR ManualTrickyDicky2Nessuna valutazione finora

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocumento13 pagineEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNessuna valutazione finora

- ATHENAEUMDocumento4 pagineATHENAEUMShubhra PatraNessuna valutazione finora

- Presentation - Slides Holmes Lever 221215Documento33 paginePresentation - Slides Holmes Lever 221215Ralitsa OlevaNessuna valutazione finora

- Simatic Hmi Wincc V7.0 Sp3 Setting Up A Message SystemDocumento123 pagineSimatic Hmi Wincc V7.0 Sp3 Setting Up A Message Systemalrighting619Nessuna valutazione finora

- Applications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDocumento14 pagineApplications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDian PsdNessuna valutazione finora

- Thermal Arc 161 STL 201 Ts Inverter Welder SM PDFDocumento96 pagineThermal Arc 161 STL 201 Ts Inverter Welder SM PDFduyNessuna valutazione finora

- Improved M16A2 - A3 - A4 Zero TargetDocumento6 pagineImproved M16A2 - A3 - A4 Zero Targetbeetho1990Nessuna valutazione finora

- Motivation and Leadership in Engineering ManagementDocumento24 pagineMotivation and Leadership in Engineering ManagementChen Marie DyNessuna valutazione finora

- 02 - Heat ExchangersDocumento88 pagine02 - Heat ExchangerssanjaysyNessuna valutazione finora

- Mount EFS Across VPCs and Availability ZonesDocumento12 pagineMount EFS Across VPCs and Availability Zonesbiswajit patrasecNessuna valutazione finora

- Haffmans DPT: Dew Point TesterDocumento2 pagineHaffmans DPT: Dew Point TesterLaura Elianne QuirogaNessuna valutazione finora

- Python Question Paper Mumbai UnivercityDocumento5 paginePython Question Paper Mumbai UnivercityRahul PawarNessuna valutazione finora

![Mathematical Tables: Tables of in G [z] for Complex Argument](https://imgv2-2-f.scribdassets.com/img/word_document/282615796/149x198/febb728e8d/1699542561?v=1)