Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6827 c00740

Caricato da

Rohan JindalDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6827 c00740

Caricato da

Rohan JindalCopyright:

Formati disponibili

Advantages of Film Coating with a Novel Modified Starch vs.

HPMC on the Disintegration Time and Dissolution Profile of Tablets Containing Polyphenolic Actives

Xavier Parissaux1, Ashish A. Joshi2, and Gregory Le Bihan1 1. Roquette Freres, Lestrem, FRANCE; 2. Roquette America Inc., Keokuk, IA 52632

Introduction

Antioxidant supplements are gaining popularity due to their various health benefits such as anticancer effects, reducing cardiovascular and stroke risk, lowering LDL cholesterol as well as increasing metabolism and weight reduction. Many of these antioxidants are available as conventional film-coated tablets. Cellulosic polymers such as HPMC are widely used in film coating of these tablets, but suffer from drawbacks such as - Strong unwanted taste/odor and yellowish color to the solution - Difficulty in solubilization due to lumping and foam formation - Bearding on spray nozzles causing frequent production stops for cleaning - High coating cost per tablet due to longer coating times HPMC has a strong tendency to interact with antioxidant polyphenolic actives, resulting in formation of a sticky gel, which significantly increases tablet disintegration time (DT).

Green-Tea Tablet Formulation

Table 1: Core Tablet Formulation & Parameters Microcrystalline Cellulose Green Tea Extract (80% polyphenols) Partially Pregel Starch Fumed Silica Magnesium Stearate Tablet Shape Tablet Diameter Tablet Thickness Compression Force Tablet weight (uncoated) Tablet Hardness (uncoated) Friability Disintegration Time 48.5% 40.0% 9.5% 1.0% 1.0% Concave 10 mm 4.61 0.08 mm 9.3kN 300 10 mg 108 20 N 0.01 %

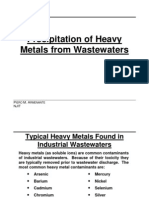

HPMC Forms a Sticky Gel with Polyphenols

Figure 4: Interaction of HPMC & LYCOAT Solutions with Green Tea Extract

HPMC Polyphenol Interaction

Figure 6: Quantitative Precipitate Formation with HPMC and Green Tea Extract 5% Green Tea Extract (1.5 mL)

LYCOAT 2.5%

LYCOAT 1%

HPMC 2.5%

HPMC 1%

Water Control

10 mL

10% HPMC soln 10% LYCOAT soln

A novel pregelatinized, hydroxypropyl starch polymer (LYCOAT), ensures 27 min minimal interaction with polyphenolic actives and does not prolong DT of coated tablets. Core tablets containing 95.17mg theoretical polyphenol content were prepared on a FETTE Exacta 21 single punch tabletting machine and parameters This study presents data supporting the superior compatibility of LYCOAT in evaluated using standardized tests. aqueous film coating of tablets with polyphenolic actives, resulting in minimal changes in DT of LYCOAT coated tablets and significantly faster polyphenol dissolution profiles compared to HPMC.

1.5 mL

10% Green Tea Extract

LYCOAT with Green Tea

HPMC with Green Tea

HPMC forms a sticky gel on addition of Green Tea Extract LYCOAT exhibits instant mixing and complete solubilization

Green Tea extract generates visible precipitate with 2.5% or 1% HPMC compared to LYCOAT

Experimental Methods

Preparation of Dispersions: HPMC and LYCOAT based ready to use film-coating formulations were dispersed in water at room temperature using a paddle stirrer. Viscosity measurements were performed using a Physica MCR 301 Anton Paar rheometer. Tableting and Coating: Tablets (300mg, 10mm concave, 110N, 0.01% friability) containing 40% green tea extract were prepared on a Fette exacta 21 tablet press using MCC and pregelatinized starch. Tablets were film coated (3.2% weight gain) in a RWKA coating equipment with Binks 460 spray-gun. Tablet hardness, friability, and in-vitro DT were measured using appropriate Erweka equipment and USP/EP methods. Polymer-Polyphenol Interaction studies: SOTAX equipment with paddles was used to study tablet dissolution profile in 900 ml water at 37oC. The level of dissolved polyphenols was quantified using the Folin-Ciocalteu colorimetric assay at 780nm. Physical interaction between polyphenols and polymers was studied by adding 1.5ml green tea extract (10%) to 10mL aqueous polymeric solutions (10%) and visually observing the precipitate before and after mixing. Free polyphenol levels in the supernatant were quantified colorimetrically after adding 1.5ml of 5% green tea extract to 1% and 2.5% solutions of HPMC or LYCOAT.

LYCOAT Coating Does NOT Increase Green Tea Tablet Disintegration Time

Table 2: Coating Parameters For Ready to Use LYCOAT & HPMC Coatings

Parameters Solids content Inlet Air temp Tablet bed temp Atomization pressure Mean % weight gain

HPMC is Incompatible with Polyphenols

Figure 5: Qualitative Demonstration of Gel Formation with HPMC & Green Tea Extract

HPMC Quantitatively Reduces Solubilization of Polyphenolic Actives

0.9

% Polyphenols in Supernatant Gallic Acid equivalents

0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0

LYCOAT

20% 50oC 37oC 2 bars 3.2 %

HPMC

20% 52oC 42oC 2 bars 3.2 %

Ready to use aqueous film coating products containing LYCOAT or HPMC were used in a RWKA conventional coating equipment with Binks 460 spray-gun.

Table 3: Evaluation of Film Coated Tablets

Weight (mg) Uncoated Tablets LYCOAT coated tablets HPMC coated tablets 298 310 311 Hardness (N) 108 117 137 Disintegration Time (DT) minutes 27 29 68

10 mL HPMC soln (10%) + 1.5 mL Green Tea Extract (10%)

HPMC significantly increases tablet hardness after film coating (Table 3) HPMC & Green Tea form a Sticky gel-like precipitate despite thorough mixing This gel layer significantly increases tablet DT and release of polyphenol actives

O LYC

1% AT

M HP

C1

LYC

OA

% 2.5 T

MC HP

2.5

L R O Tea NT n CO Gree 5%

LYCOAT coating enables faster dissolution of polyphenols vs. HPMC

- Complete miscibility of LYCOAT with green tea extract without precipitation or gelling - Minimal binding of polyphenols by LYCOAT

Unlike HPMC film-coating,

LYCOAT

does NOT increase DT of green-tea tablets

Ease of Dispersion & Low Viscosity

350 300 Viscosity (m Pa.s) 250 200

LYCOAT Coating Does Not Delay Polyphenol Release from Tablets

Figure 3: Comparative Dissolution Profiles of LYCOAT vs. HPMC coated Green Tea Tablets

100 90

Polyphenol Quantitative Analysis Method

5% Green Tea Extract 1% & 2.5% soln of HPMC or LYCOAT

Summary and Conclusions

By definition, an excipient is an inert and inactive substance used as a carrier for the active ingredients of a medication This study shows that HPMC coating excipient interacts with polyphenolic actives The gel-like precipitate with HPMC acts as a barrier, resulting in prolongation of the tablet disintegration and active dissolution time

LYCOAT (25%) HPMC (10%)

% Polyphenols Released

150 100 50 0 20 30 40 50 60 Temperature (C) 70 75

80 70 60 50 40 30 20 10 0 0 0.5 1 1.5 2 2.5 Uncoated Tablets LYCOAT Coated Tablets HPMC Coated Tablets

- SOTAX Paddle Equipment - 900 mL distilled water at 37oC - Polyphenols quantified by Folin-Ciocalteu colorimetric absorption at 760 nm

Mix thoroughly & centrifuge

A novel hydroxypropyl starch coating excipient (LYCOAT) exhibits inertness with a broad range of actives with polyphenolic moieties (e.g. phytosterols) and does not increase the DT of tablets or prolong dissolution of actives. The inertness of LYCOAT along with additional benefits related to the ease of use, high solids content coating solution and quicker coating process, makes it an ideal excipient for tablet coating (Ref. 1)

Supernatant Folin-Ciocalteu Reagent

Figure 1: Ease of Dispersing LYCOAT vs. HPMC

Figure 2: Viscosity of LYCOAT vs. HPMC

Despite higher solids level, the low viscosity and granular nature of LYCOAT enables fast dispersion in water within 10 min at room temp using only a magnetic stirrer, without any lumps or foam formation (Fig. 1). Previous stability studies (6 months) on coated placebo tablets showed DT of 102 sec (68% increase) of HPMC coated tablets vs. only 50 sec (29% increase) with LYCOAT compared to the uncoated cores. The higher viscosity of HPMC even at low solids level and tendency to swell may result in delay of tablet DT upon storage (Fig. 2).

ACKNOWLEDGEMENTS

Measure Colorimetric Absorption at 760nm

The authors want to thank JM Roturier, Th Delecroix and G Le Bihan from Roquette for the analytical work as well as Biogrund (Germany) for providing the HPMC and Lycoat based ready to use coating systems.

REFERENCE

Calculate % Polyphenols in Supernatant In equivalents of Gallic Acid

1. Xavier Parissaux, Ashish Joshi, Cecile Dusautois, Gregory Le Bihan, and Philippe Lefevre., Functional advantages of a novel modified starch over HPMC in aqueous film coating of tablets. Proc. AAPS Pharm Sci. Vol. 8, No. S2, Abstract W4104 (2006)

Time (hours)

LYCOAT coating allows 60% polyphenol release in 30 min vs. only 5% with HPMC coating

Potrebbero piacerti anche

- Auguste Comte - PPT PresentationDocumento61 pagineAuguste Comte - PPT Presentationmikeiancu20023934100% (8)

- The Conservative Reaction: Auguste ComteDocumento19 pagineThe Conservative Reaction: Auguste ComteRohan JindalNessuna valutazione finora

- Techfest10 PDFDocumento2 pagineTechfest10 PDFRohan JindalNessuna valutazione finora

- Dynamic Programming - Set 1 (Overlapping Subproblems Property) - GeeksforGeeks PDFDocumento5 pagineDynamic Programming - Set 1 (Overlapping Subproblems Property) - GeeksforGeeks PDFRohan JindalNessuna valutazione finora

- BioRes 08 4 6087 Chen ZSQ Comb Glyoxal Chitosan Crosslink Paper Wet Strength 4489 PDFDocumento10 pagineBioRes 08 4 6087 Chen ZSQ Comb Glyoxal Chitosan Crosslink Paper Wet Strength 4489 PDFRohan JindalNessuna valutazione finora

- cl1 Course3 DBProgramming PDFDocumento2 paginecl1 Course3 DBProgramming PDFRohan JindalNessuna valutazione finora

- Article1404813310 - Marin Et Al PDFDocumento11 pagineArticle1404813310 - Marin Et Al PDFRohan JindalNessuna valutazione finora

- MCHRGRDocumento4 pagineMCHRGRRohan JindalNessuna valutazione finora

- Netaji Subhas Institute of TechnologyDocumento1 paginaNetaji Subhas Institute of TechnologyRohan JindalNessuna valutazione finora

- Lactospore Booklet PDFDocumento44 pagineLactospore Booklet PDFRohan JindalNessuna valutazione finora

- Curriculum: What You Will Be Able To Achieve During This CourseDocumento5 pagineCurriculum: What You Will Be Able To Achieve During This CourseRohan JindalNessuna valutazione finora

- SQTDocumento6 pagineSQTRohan Jindal100% (1)

- Cls06 2Documento43 pagineCls06 2Engr SaikatNessuna valutazione finora

- Cisco Certified Network Associate: CurriculumDocumento4 pagineCisco Certified Network Associate: CurriculumRohan JindalNessuna valutazione finora

- ProeDocumento1 paginaProeRohan JindalNessuna valutazione finora

- OracleDocumento6 pagineOracleRohan JindalNessuna valutazione finora

- Color Brochure PlasticsDocumento157 pagineColor Brochure PlasticsRohan Jindal100% (3)

- Learning On Internet C++, JavaDocumento9 pagineLearning On Internet C++, JavaRohan JindalNessuna valutazione finora

- DotnetDocumento4 pagineDotnetRohan JindalNessuna valutazione finora

- Deepan Chakravarthi K B e Cse M A M College of Engg Trichy Pubilshed Bjarne Stroustrup S C TutorialDocumento21 pagineDeepan Chakravarthi K B e Cse M A M College of Engg Trichy Pubilshed Bjarne Stroustrup S C TutorialRohan JindalNessuna valutazione finora

- Lec 17Documento27 pagineLec 17Rohan JindalNessuna valutazione finora

- Guidelines FOR Internship Semester: (Deemed University)Documento22 pagineGuidelines FOR Internship Semester: (Deemed University)Anubhav MittalNessuna valutazione finora

- IPU ProcedureDocumento2 pagineIPU ProcedureVipul KumarNessuna valutazione finora

- Marks InformationDocumento3 pagineMarks InformationRohan JindalNessuna valutazione finora

- Schedule Training Evaluation Cse 2013Documento4 pagineSchedule Training Evaluation Cse 2013Rohan JindalNessuna valutazione finora

- List of Facilitation Centres For Clarifying Doubts About Jee (Main)Documento4 pagineList of Facilitation Centres For Clarifying Doubts About Jee (Main)Tanisha JindalNessuna valutazione finora

- Press Release0001 Jee Main13 2012Documento2 paginePress Release0001 Jee Main13 2012kumar_samsameerNessuna valutazione finora

- Faqs Jee MainsDocumento5 pagineFaqs Jee MainsAbhinav AggarwalNessuna valutazione finora

- Formulab ImageflyerDocumento4 pagineFormulab ImageflyerRohan JindalNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Mcrobio Cell MembraneDocumento8 pagineMcrobio Cell MembraneResty De Guzman SoteloNessuna valutazione finora

- Advances of Ag, Cu, and Ag-Cu Alloy Nanoparticles SynthesizedDocumento29 pagineAdvances of Ag, Cu, and Ag-Cu Alloy Nanoparticles SynthesizedThamirisAgmNessuna valutazione finora

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Documento5 paginePREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1Nessuna valutazione finora

- 140070H1 TIFF YELLOW - United States-EnglishDocumento10 pagine140070H1 TIFF YELLOW - United States-Englishdedi munardiNessuna valutazione finora

- BenzeneDocumento17 pagineBenzeneMitko100% (1)

- Organic Polyelectrolytes in Water TreatmentDocumento24 pagineOrganic Polyelectrolytes in Water TreatmentCamille Nunes LeiteNessuna valutazione finora

- Exact Brochure ForYourPreciseNeedsDocumento8 pagineExact Brochure ForYourPreciseNeedsJulio GarcíaNessuna valutazione finora

- Dosage Form PDF 4 TabletsDocumento55 pagineDosage Form PDF 4 TabletsShumaila QadirNessuna valutazione finora

- TDS Hydrazine HydrateDocumento1 paginaTDS Hydrazine HydrateMarthinus BoxyNessuna valutazione finora

- Salino MeterDocumento13 pagineSalino MeterVyas SrinivasanNessuna valutazione finora

- PHARMACOKINETICS MCQDocumento10 paginePHARMACOKINETICS MCQyan219100% (1)

- Nitowrap FRC-Indonesia PDFDocumento2 pagineNitowrap FRC-Indonesia PDFlilik riyantiNessuna valutazione finora

- Reaksi Alkali Silika Sekam PadiDocumento4 pagineReaksi Alkali Silika Sekam PadiBakri FnuNessuna valutazione finora

- 01 1127Documento1 pagina01 1127nandhini_lgcNessuna valutazione finora

- Route Evaluation and Analytical HPLC Method Development of Buprenorphine, Naloxone, and Comparison OverallSJFN - ms.ID.000105Documento19 pagineRoute Evaluation and Analytical HPLC Method Development of Buprenorphine, Naloxone, and Comparison OverallSJFN - ms.ID.000105Drkrishnasarma pathyNessuna valutazione finora

- HPLC Lab ManualDocumento7 pagineHPLC Lab ManualRakesh Kumar ChaudharyNessuna valutazione finora

- 1 s2.0 S0109564122001944 MainDocumento12 pagine1 s2.0 S0109564122001944 MainDANTE DELEGUERYNessuna valutazione finora

- Role of Nitrogen Cycle Nitrification and Denitrification: Prepared by Bibek Pardhe BhattaraiDocumento20 pagineRole of Nitrogen Cycle Nitrification and Denitrification: Prepared by Bibek Pardhe BhattaraiBibek BhattaraiNessuna valutazione finora

- Adhesive Companies ListDocumento3 pagineAdhesive Companies ListRajneesh SehgalNessuna valutazione finora

- EPC 312 JUNE 2017 Final ExamDocumento11 pagineEPC 312 JUNE 2017 Final Examkalasa royd100% (1)

- Chapter 9-Alkynes 7 Unsaturations 9 Unsaturations 5 UnsaturationsDocumento19 pagineChapter 9-Alkynes 7 Unsaturations 9 Unsaturations 5 Unsaturations張湧浩Nessuna valutazione finora

- Jeffrey 1975Documento4 pagineJeffrey 1975abbasalisu1234Nessuna valutazione finora

- Ingevity Capa CoatingsDocumento4 pagineIngevity Capa CoatingsKanagarajan VijayakumarNessuna valutazione finora

- LS - 0 - 2 - 2d3125 - 0251db4d7f43d-Aromaticity (IIT JAM)Documento2 pagineLS - 0 - 2 - 2d3125 - 0251db4d7f43d-Aromaticity (IIT JAM)Hamit RanaNessuna valutazione finora

- Chem 101 Lab Report 4Documento8 pagineChem 101 Lab Report 4ArvindVishakNessuna valutazione finora

- Assignment 1 Unit 1Documento8 pagineAssignment 1 Unit 1pastpaperscollectorNessuna valutazione finora

- 36 1 93 96 Jakovac enDocumento4 pagine36 1 93 96 Jakovac enDewi WulandhariNessuna valutazione finora

- General Procedure For The Systematic Analysis of A Simple SaltDocumento6 pagineGeneral Procedure For The Systematic Analysis of A Simple SaltDrGaurav Rajput50% (10)

- AP Chem CH 6 Practice QuizDocumento3 pagineAP Chem CH 6 Practice Quizprin ppNessuna valutazione finora