Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ows & Sweage

Caricato da

Vyas SrinivasanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ows & Sweage

Caricato da

Vyas SrinivasanCopyright:

Formati disponibili

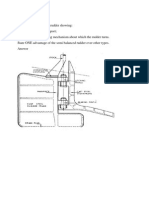

Oily Water Separator and Sewage Plant Guide Book for Marine Engineers OILY WATER SEPARATOR: Principle

of Operation: The principle of operation of OWS is the gravity difference between oil and water. The force acting on an oil globule causing it to move in the water is proportional to the difference in weight between the oil particle and a particle of water of equal volume. Fs = separating force P = density of water Fs = d 3 ( Pw Po) g P = density of oil globule 6 d = diameter of oil globule g = acceleration due to gravity The resistance to the movement of the globule depends on its size and viscosity of the fluid. For small particles moving under stream line flow the relationship between these properties is expressed by Strokes Law: Fr = resistance to movement Filters used in OWS are 2 types = viscosity of fluid 1. Coalescence type: Fr = 3d = terminal velocity of particle Hydrophilic material i.e. glass wool. d = diameter of oil particle Absorbs water rather than oil. When separation of an oil globule in water is taking place, Has to be renewed after certain periods. Fs = Fr 2. Absorption type: g Oleophilic material v= ( Pw Po) d 2 Absorbs oil rather than water. 18 Frequent replacement is not required. High rate of separation is favored by: Large size of oil globule. Elevated temperature of the system ( i.e. lowers viscosity of oil, density of oil-water but oil is higher). Residence time. Avoidance of turbulence or agitation. Laminar or stream line flow. Low viscosity of oil globule. Control Box Power supply Diaphragm Control

SV Oil Sensor Vent

Vent & filling SV O/B TC To Bilge Tank Oil

To Oil Collecting Tank Test cocks Oil

Test Cocks

Filter

Filter Drain

From Bilge Pump

Second stage and Coalescer 1 Hamid

First Stage Md Abdul

Oily Water Separator and Sewage Plant Guide Book for Marine Engineers Non-return spring loaded water discharge valve prevents syphoning as the seperator positioned above the overboard valve. Syphoning is permitted once pumping has stopped. Operation of OWS: The oily water separator is first filled with clean water; the oily water mixture is then pumped through the separator inlet pipe into the coarse separating compartment. Here some oil, as a result of its lower density, will separate and rise into the oil collection space and the purity of this stage is 100 ppm or less. The remaining oily water mixture now flows down into the fine separating compartment and moves slowly between the catch plates. More oil will separate out onto the underside of these plates and travel outwards until it is free to rise into the oil collecting space. The almost oil free water passes into the central pipe and leaves the separator unit. The purity at this point will be 15 ppm or less. An automatically controlled valve releases the separated oil to a storage tank. Air is released from the unit by a vent valve. Steam or electric-heating coils are provided in the upper and sometimes the lower parts of the separator. The water flows in turn through two filter stages and the oil-removed pass to oil collecting spaces. The first stage filter removes physical impurities present and promotes some fine separation. The second stage filter uses coalescer inserts to achieve the final de-oiling and the oil from the collecting spaces is drained away manually as required. Coalescer is the break down of surface tension between oil droplets in an oily water mixture, which causes them to join and increase in size. With respect to Oily Water separation state how following conditions affect separation: a) Oil Density b) Mixture Temperature c) High Pumping Rate d) Oily water interface bellow Test Cocks. a) Oil Density: The principle of separation by which an oily-water separation function is based on difference in density between water and oil. If other separating conditions are constant then high-density difference between oil and water will accelerate the separation. Separation Velocity 0. 95 s.g. of oil 0. 99 s.g. of oil Diameter of oil particle (mm) b) Mixture Temperature: Mixture temperature affects the specific gravity differential of oil and water, and the surface temperature of oil particles. The speed at which oil droplets rise depends on size, the difference in density and the surface tension. Generally, a high rate of separation is favored at elevated temperature of the system. High oil density / low mixture temperature causes: 1) Low density differential between water and oil. 2) Increasing surface tension, thus discourage coalescence. For this reason, low mixture temperature results oil discharged with water. c) High Pumping Rate: The performance of separator depends on residence time of oil-water mixture in the separator, the degree of agitation (affects the droplet size of oil). High pumping rate will cause higher velocity of water in separator, which - Reduce the residence time of water in the separator. - Increase turbulence and disintegration of oil globules. Therefore, high pumping rate can result in oil being discharged.

d) Oily water interface bellow Test Cocks: Oil-water interface below test cock indicates that oil-collecting space is full of oil. At this point, oil is collected and discharged to oil collecting tank automatically or manually. If not discharged, further separated oil will be collected up to the water collected point of the separator. after this condition, more collected oil will be discharged with the water. 2 Hamid Md Abdul

Oily Water Separator and Sewage Plant Guide Book for Marine Engineers Internal Baffles are fitted in OWS due to: Baffles plates are fitted in the 1st stage of oily water separator to improve separation of oil from water. Oily water has to pass through a series of dashed plates before leaving the 1st stage separator. Oil droplets from the plates tend to travel upwards, being collected at the baffles and funneled up to the oil collection space. Coalescers are generally incorporated in OWS due to: Coalescers are generally incorporated in the 2nd stage for bilge water purification towards 15 ppm requirement. The coalescing materials are usually porous and granular or fibrous membra. The coalescer device encourages formation of large oil droplets from the dispersed phase. Small oil droplets come in contact with the coalescer surface and as they congregate, thus join up to form large oil droplets of oil. The oil droplets remain in the coalescer until they have grown large enough to achieve the buoyancy required to break away and float upward. Grill Large oil droplets Small oil droplets Coalescer Element How and why maximum throughput of bilge and ballast water is restricted? The ability of oil to settle in a gravimetric separator will obviously depend on its density, the residence time and the degree of agitation. Throughput of bilge water relates the velocity and residence time. Velocity will be higher due to higher throughput; but higher throughput causes turbulence or agitation, which will disrupt the separation process. Agitation causes re-entrainment. Therefore, maximum throughput of bilge or ballast water is restricted to achieve the optimum velocity and residence time for high rate of separation. High throughput can result in oil discharged with water. Temperature changes: Density / specific gravity / surface tension. Throughput changes: Velocity / turbulence / agitation / residence time

Why positive displacement pump is preferred to centrifugal pump for supply purpose? Centrifugal pump has various disadvantages on separator performance, such as Centrifugal pump churns (moves violently) the supply and produce small oil droplets throughout the water so that 15 ppm requirement can not be met. But a slow speed positive displacement pump enables a much better performance to be achieved from the separator as they do not produce large quantities of small oil droplets. Leakage from seal ring. Re-circulation of liquid in the impeller. Excessive speed of fluid in the volute casing (15 ~ 25 m/sec).

3 Hamid

Md Abdul

Oily Water Separator and Sewage Plant Guide Book for Marine Engineers

SEWAGE PLANT: Vent Wash water C = Clorinator CF = Course Filter Soil inlet

C Float switch Settling tank

CF Aeration tank

Over Board Port side

Collecting tank 60minutes Air Air Comp

Stbd side Shore connection

Pump Biological Sewage Treatment Plant

Sea Water

BOD is a measure of the total amount of oxygen, which will be taken up by the chemical and organic matter in the effluent. This is usually associated with a specific period and that normally taken is 5 days period. The value is written as BOD5, and is determined by incubating one litre sample of sewage at 20oC diluted in sufficiently well oxygenated water. The amount of oxygen absorbed over the 5 days period is measured. Suspended Solids are unsightly and over a period of time can give rise to silting problems. They are usually a sign of malfunctioning of sewage plant. Suspended solids are measured by filtering a sample through a pre-weighed asbestos pad, which is the dried and reweighed. The Ecoliform Count is a family of bacteria, which lives in the human intestine. The can be quantified easily in a laboratory test, the result of which is indicative of the amount of human waste preset in a particular sewage sample ad the count is expressed per 100 ml. Standard sample incubating 48 hrs at 35oC. MARPOL 73/ 78 Annex IV: Regulation for the prevention of pollusion by sewage from ship. This regulation is applicable to Ship of 200 GRT and above. Ship of carrying 10 passenges and above. Sewage can be discharged from ship: When the ship is en-route and not less than 4 knots speed. Comminuted and disinfected sewage 4 nitical miles away from the nearest land. Not comminuted and disinfected seawge notical miles away from the nearest land. Shore Connection for Sewage Plant: Hamid Permissible Discharge Condition: 4 Md Abdul

Oily Water Separator and Sewage Plant Guide Book for Marine Engineers 210 mm OD x 16 mm flange 4 holes x 18 mm dia 170 mm PCD 4 x 16 mm bolts and nuts. Pipe diameter 100 mm acceptable : 6 kg / cm2. Suspended solids : 50 mg / liter Biochemical Oxygen Demand [BOD] : 50 mg / liter E-Coleform count : 2 50 / 100 ml

5 Hamid

Md Abdul

Potrebbero piacerti anche

- PURIFIERSDocumento7 paginePURIFIERSjames dogelioNessuna valutazione finora

- Oily Water SeparatorDocumento5 pagineOily Water SeparatorFe Capricho100% (1)

- Week 2-Oilwater Separators Working PrinciplesDocumento12 pagineWeek 2-Oilwater Separators Working PrinciplesCriswin Malazarte100% (1)

- Marine PurifierDocumento30 pagineMarine PurifierJayDelosSantos100% (1)

- PurifierDocumento14 paginePurifierMohammad Jahid Alam100% (1)

- Oily Water SeparatorDocumento7 pagineOily Water SeparatorVishu Sharma100% (2)

- Crankcase explosions causes and preventionDocumento9 pagineCrankcase explosions causes and preventionSrini VasanNessuna valutazione finora

- Recent MMD QuestionsDocumento49 pagineRecent MMD QuestionsAkash Nair100% (1)

- Why EGE safety valve pressure is greater than auxiliary boiler pressureDocumento3 pagineWhy EGE safety valve pressure is greater than auxiliary boiler pressureKišić SpasojeNessuna valutazione finora

- Scavenge FireDocumento3 pagineScavenge FireVishu SharmaNessuna valutazione finora

- Cargo Oil Pump TurbineDocumento16 pagineCargo Oil Pump TurbineNikolay KirovNessuna valutazione finora

- MEO CLASS IV OralsDocumento25 pagineMEO CLASS IV OralsAnoop Vijayakumar0% (1)

- Created by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneDocumento7 pagineCreated by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneSankash Sood100% (2)

- Tie BoltsDocumento31 pagineTie BoltsMuhammad Nasim AbbasNessuna valutazione finora

- Marine BoilersDocumento16 pagineMarine BoilersPawan Beniwal100% (1)

- MEO Class I OralsDocumento2 pagineMEO Class I OralsGurvindarNessuna valutazione finora

- MEO Class IV Exam Guide on Steering Gear SystemsDocumento8 pagineMEO Class IV Exam Guide on Steering Gear Systemsnarendra rathoreNessuna valutazione finora

- What Are The Steering Gear Motor SafetiesDocumento2 pagineWhat Are The Steering Gear Motor SafetiesRachitNessuna valutazione finora

- Exhaust Valve OverhaulDocumento19 pagineExhaust Valve Overhaulغازي عليNessuna valutazione finora

- Main Engine Shutdowns Marine Two Stroke EnginesDocumento12 pagineMain Engine Shutdowns Marine Two Stroke EnginesUdana Hettiarachchi67% (3)

- Class 4 Frequent Asked Qs Shashwat000Documento168 pagineClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- IMP Main Engine and Aux EngineDocumento37 pagineIMP Main Engine and Aux EngineLOKINessuna valutazione finora

- First Steps in a Ship Blackout SituationDocumento5 pagineFirst Steps in a Ship Blackout Situationmister_no34Nessuna valutazione finora

- FWGDocumento8 pagineFWGSWASTIK MISHRANessuna valutazione finora

- Air Bottle InspectionDocumento1 paginaAir Bottle InspectionSaifful Nasir67% (3)

- Generate Fresh Water at Sea with this GeneratorDocumento13 pagineGenerate Fresh Water at Sea with this GeneratorNandu SNessuna valutazione finora

- MEO Class 4 Oral QuestionsDocumento33 pagineMEO Class 4 Oral QuestionsAnkit Batra50% (2)

- Class 4 Safety Oral Solas & Marpol FileDocumento106 pagineClass 4 Safety Oral Solas & Marpol FileAkash Vimal100% (3)

- Purifier Manual Starting StoppingDocumento3 paginePurifier Manual Starting Stoppingavm4343Nessuna valutazione finora

- CoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyDocumento6 pagineCoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyShaip Sankar100% (1)

- Safety MEO Class 4 Part B - For OralsDocumento11 pagineSafety MEO Class 4 Part B - For Oralslazyreaderr100% (2)

- Procedure For Starting and Stopping of Sewage Treatment Plant On A ShipDocumento4 pagineProcedure For Starting and Stopping of Sewage Treatment Plant On A ShipILHAMNessuna valutazione finora

- Oral Candy Meo Class 4Documento32 pagineOral Candy Meo Class 4deepanck0% (2)

- Master Air Starting Valve ExploredDocumento13 pagineMaster Air Starting Valve Exploredavm4343100% (1)

- 2.steering GearDocumento15 pagine2.steering GearMehedy Masud100% (1)

- MEO Class 2 Orals Function 4 & 6 Q & ADocumento8 pagineMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Class 4 Repeated QSTN Ship ConsructnDocumento19 pagineClass 4 Repeated QSTN Ship ConsructnAshok KumarNessuna valutazione finora

- The Air Starting System How An Engine Starts On AirDocumento6 pagineThe Air Starting System How An Engine Starts On AirBharatiyulamNessuna valutazione finora

- Important Points While Carrying Out Power Balancing of Marine EnginesDocumento5 pagineImportant Points While Carrying Out Power Balancing of Marine EnginesprabhudiwaNessuna valutazione finora

- Second marine engineer duties upon joiningDocumento2 pagineSecond marine engineer duties upon joiningSARATKUMAR RATNALANessuna valutazione finora

- Class4 Question & Answers Ship ConstDocumento48 pagineClass4 Question & Answers Ship ConstNarine100% (2)

- Meo Oral AnsDocumento17 pagineMeo Oral AnsKapil Verma100% (4)

- 200 OralDocumento295 pagine200 OralSamarendu Tiwari100% (7)

- Unmanned Machinery SpacesDocumento20 pagineUnmanned Machinery SpacesRazaq PayapoNessuna valutazione finora

- Met Class 4 Electrical WrittenDocumento83 pagineMet Class 4 Electrical WrittenAjeet Jha86% (7)

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Documento11 pagineBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNessuna valutazione finora

- B&W Maneouvring DiaDocumento16 pagineB&W Maneouvring DiaAjinkya KhamkarNessuna valutazione finora

- Nodular Cast Iron, and A Ram. Each Pair of Cylinders Is Tied Together Axially by A Guide Bar and Adjacent Cylinders AreDocumento10 pagineNodular Cast Iron, and A Ram. Each Pair of Cylinders Is Tied Together Axially by A Guide Bar and Adjacent Cylinders AreKr Manu100% (1)

- Class 4 Safety Oral Ship Construction & Naval FileDocumento72 pagineClass 4 Safety Oral Ship Construction & Naval Fileclinton100% (4)

- 3 Important Calculations Every Marine Engineer Must Know On ShipsDocumento6 pagine3 Important Calculations Every Marine Engineer Must Know On ShipsAayush AgrawalNessuna valutazione finora

- Marine Auxiliary BoilersDocumento31 pagineMarine Auxiliary Boilerskojet90100% (5)

- Ums OperationDocumento27 pagineUms OperationSwarg Vibha0% (1)

- Common Rail Fuel Injection Technology in Diesel EnginesDa EverandCommon Rail Fuel Injection Technology in Diesel EnginesNessuna valutazione finora

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Da EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Nessuna valutazione finora

- New Technologies for Emission Control in Marine Diesel EnginesDa EverandNew Technologies for Emission Control in Marine Diesel EnginesNessuna valutazione finora

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionDa EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionValutazione: 5 su 5 stelle5/5 (1)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsDa EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (3)

- Unit 17 - 03 - Safety & Alarm SystemDocumento16 pagineUnit 17 - 03 - Safety & Alarm SystemAisha Zaheer100% (1)

- Unit 17 - 02 - Starting & ManoeuvringDocumento16 pagineUnit 17 - 02 - Starting & ManoeuvringAisha ZaheerNessuna valutazione finora

- 13 - Man B&W TCDocumento3 pagine13 - Man B&W TCAisha ZaheerNessuna valutazione finora

- 11 - Reversing of Two Stroke EngineDocumento13 pagine11 - Reversing of Two Stroke EngineAisha Zaheer90% (29)

- 12 TurbochargerDocumento14 pagine12 TurbochargerAisha Zaheer100% (5)

- 10 - Starting and ReversingDocumento4 pagine10 - Starting and ReversingAisha Zaheer100% (3)

- 09 Governor 02Documento1 pagina09 Governor 02Aisha ZaheerNessuna valutazione finora

- 08 - Gvernor - 01Documento7 pagine08 - Gvernor - 01Aisha Zaheer100% (2)

- 07 - Stern Tube SealingDocumento2 pagine07 - Stern Tube SealingAisha Zaheer100% (2)

- 08 VibrationDocumento10 pagine08 VibrationAisha Zaheer0% (1)

- 01 IndtroductionDocumento11 pagine01 IndtroductionAisha ZaheerNessuna valutazione finora

- 05 Air ConditioningDocumento6 pagine05 Air ConditioningAisha ZaheerNessuna valutazione finora

- Trans Chapter6 PDFDocumento106 pagineTrans Chapter6 PDFsammar_10Nessuna valutazione finora

- Cane Juice HeatingDocumento85 pagineCane Juice HeatingsenaNessuna valutazione finora

- Turbo Lab 1Documento10 pagineTurbo Lab 1Seng SoonNessuna valutazione finora

- 4 - 3D Ah-5vcmDocumento1 pagina4 - 3D Ah-5vcmMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- Chemical Kinetics1 PDFDocumento13 pagineChemical Kinetics1 PDFNaga Pratyusha DuvvuriNessuna valutazione finora

- PROPERTIES OF SUBSTANCES - PPTDocumento8 paginePROPERTIES OF SUBSTANCES - PPTDarko TrajanovNessuna valutazione finora

- API 650 Tank DesignDocumento1 paginaAPI 650 Tank Designanto3harrish3fdoNessuna valutazione finora

- Polybed PSADocumento2 paginePolybed PSAJeEJyZaNessuna valutazione finora

- Part 2 Fundamentals of Fluid FlowDocumento3 paginePart 2 Fundamentals of Fluid FlowJoren HuernoNessuna valutazione finora

- Expansion Valves - Working PrincipleDocumento3 pagineExpansion Valves - Working PrinciplePradeep Sukumaran100% (1)

- GRAVEL Packer Tool OperationDocumento7 pagineGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- How To Properly Size A Steam TrapDocumento4 pagineHow To Properly Size A Steam TrapJessicalba Lou100% (1)

- Chemical Kinetics Exercise SolutionsDocumento98 pagineChemical Kinetics Exercise SolutionsKivilia EduventuresNessuna valutazione finora

- Rectangular Sharp Crested Weirs - Francis FormulaDocumento8 pagineRectangular Sharp Crested Weirs - Francis FormulaRenvil PedernalNessuna valutazione finora

- Modeling of Gravity Concentration Unit Operations: A. K. MajumderDocumento78 pagineModeling of Gravity Concentration Unit Operations: A. K. MajumderSwarnaRakshitNessuna valutazione finora

- Reverse Osmosis PlantDocumento10 pagineReverse Osmosis PlantBhupender RamchandaniNessuna valutazione finora

- Miscible Gas Injection Report SummaryDocumento9 pagineMiscible Gas Injection Report SummaryAli MahmoudNessuna valutazione finora

- Reverse Osmosis Design With Hydranautics Design Software For Industrial Waste Water ReuseDocumento10 pagineReverse Osmosis Design With Hydranautics Design Software For Industrial Waste Water ReuseMario Antonio Araya MorosoNessuna valutazione finora

- Check List-CHW PUMPSDocumento3 pagineCheck List-CHW PUMPSsarmad009100% (1)

- Double Pipe Heat Exchanger DesignDocumento30 pagineDouble Pipe Heat Exchanger DesignAlif RifatNessuna valutazione finora

- 371 HW 07 SDocumento4 pagine371 HW 07 SSugumar Panneer SelvamNessuna valutazione finora

- Unit 13. Alkylation: Professional Course in English "Fundamentals of Petroleum Refining"Documento43 pagineUnit 13. Alkylation: Professional Course in English "Fundamentals of Petroleum Refining"Abdoul RahimNessuna valutazione finora

- Description of SituationDocumento3 pagineDescription of SituationFikrie MuhdNessuna valutazione finora

- H05899 - H2Zero - Gas Shutoff (Carbonate Formations)Documento5 pagineH05899 - H2Zero - Gas Shutoff (Carbonate Formations)Leopold Roj DomNessuna valutazione finora

- TOTFLEX Catalog PDFDocumento38 pagineTOTFLEX Catalog PDFSuhail EhtishamNessuna valutazione finora

- Centrifugal PumpsDocumento18 pagineCentrifugal Pumpsdania ahmarNessuna valutazione finora

- Steel PipeDocumento1 paginaSteel Pipesafar bahariNessuna valutazione finora

- Methven Nefa Pressure Reducing Valves ReferenceDocumento36 pagineMethven Nefa Pressure Reducing Valves ReferenceLen Salisbury100% (1)

- FM200 ItDocumento10 pagineFM200 ItNguyễn Bửu ThắngNessuna valutazione finora

- Packed Bed AbsorptionDocumento4 paginePacked Bed AbsorptionSenthilNathanNessuna valutazione finora