Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6164128

Caricato da

Bilal AhmadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6164128

Caricato da

Bilal AhmadCopyright:

Formati disponibili

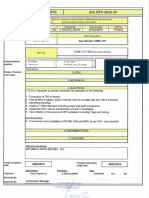

Network Construction - Design Pack

Cover and Contents Sheet

6164128B0002

Issue: 1 Page 1 of 1

DESCRIPTION AND CONTACTS

Title: Location: Remarks: Timing: Designer: TM: PDM: PS: Verifier: Authoriser: Origin:

10018832_78_VIC CSF EPGZ D&C Full Epping Post var

Iqbal, Saadat Baulch, Ian W Rawson, Terry I Walton, Dale Aylmer, Brett T Iqbal, Saadat

TM - Team Manager Ph: Ph: Ph: Ph:

0419 139 081 03 8649 4037

03 6212 8093 03 8633 1578

Fax: Fax: Fax: Fax: Date: Date: 03 6231 3157 03 8633 2353

Signature: Original is signed Signature: Original is signed

NECD31 - VIC Transmission & Switching

PDM - Project Delivery Manager PS - Project Specialist

DISTRIBUTION

[ E ] Email Copy [ P ] Paper copy [ Q ] QM [ T ] TCSS

ASSOCIATED PACKS

PACK NO. ACTIVITY DESCRIPTION

6164128B0001 6164128B0002

10018832_78_VIC CSF EPGZ D&C Full 10018832_78_VIC CSF EPGZ D&C Full

ATTACHMENTS

A B C D E Overview Project Notes Cable Runway Integral Material List Equipment Layout

Issue

1 1 1 1 1

Network Construction - Design Pack

Overview

6164128B0002

Attachment A

Issue: 1 Page 1 of 2

1 1.1

Overview Purpose & Scope

The purpose of this project is to provide CFC SMR Superstructure on the Ground Floor Epping Exchange in accordance with TM00100A02-Exchange Common Infrastructure, CN1234 Superstructure: Cable Only Variant. As per all Cable Only Variant Superstructure, Optical Fibre Ducting is not required for this deployment

Site Name

EPPING

Site Address

BLD 1- 44 COULSTOCK ST EPPING VIC, 3076

FLOOR

Ground

Equip Code

EPGZ

All work to be performed as outlined under the NC H&S Action Plan.

1.2

Integral Details

Network Activity Nos 6164128.0101 6164128.0222 Work Breakdown Structure (WBS) N.10087.03.0004.078.01 N.10087.03.0004.078.22 Description PM Install & Commission

1.3

Timing

The Customer Required By Date is: Refer to PS Schedule.

1.4

Interdependencies

Not Applicable

1.5

Related Documents

Document Not Applicable Interdependencies / Relationships NIL

1.6

Project Quality Plan

For a copy of the quality plan for this project please contact the Project Specialist.

1.7

MOP and Acceptance Procedure

Where necessary, the installer is to supply MOPs and WINs to detail the work covered by this project.

1.8

Hazard Management, Worksite Safety Inspections

The project site was visited. Detected hazards at the site visit are listed in the table below. Project supervisors are required to also assess the site and implement Network Constructions Safety Plan as per CSD22001 (Health and Safety Management in Network Construction). For projects with less than five staff on site, the Take Five Process as described in the Work Pack may be used. In this case risks may be assessed using the quick risk level guide at :http://www.in.telstra.com.au/ism/hse/manageyourrisks.asp .

Network Construction - Design Pack

Overview

6164128B0002

Attachment A

Issue: 1 Page 2 of 2

For projects with five or more staff on site, the construction staff are expected to complete a JSA. The JSA form is supplied by the Project Officer from within the PSHSP (Project Specific Heath & Safety Plan).

Hazard Element None Identified

Possible Hazard Possible Hazards are to be identified during the Pre-Construction Take 5 or JSA process. This should include identifying work areas that may contain asbestos.

1.9

Environmental Clearance

The risks associated with the activity have been deemed negligible by the National EMS Co-ordinator. A national exemption from completing an environmental risk assessment has been applied. A copy of the current Transport & Wireless exemption form is included in the Work Pack.

1.10 Network Hazard Classification

The activities as described in this design are such that the project is classified as Type C Network Hazard. Installer to submit necessary hazard advices.

1.11 Powers and Immunities

Item Powers and Immunities Options Project contains BELOW THE LINE facilities and activities only.

1.12 Health, Safety and Environment Issues

Before commencing work at this site please refer to the on-site Hazards Log to determine whether asbestos is present or not. If any asbestos is found to be present it is to be dealt with in accordance with CSD22110. Beware of any non-registered / concealed hazards. If any property maintenance work is found to be required at the site please notify Sentinar on 1800 622 203 so that they can arrange for the rectification of the site problems found. If site cleaning or grounds maintenance work is found to be required please contact Service Delivery using the Webform found at NonUrgent Service Request - Network Sites or Email ! CD&G Cleaning & Grounds .

1.13 Environmental Management Plan

The basic elements of Environmental Management are set out in the Environmental Handbook document at this link. Environmental Handbook . These should be adhered to when carrying out the work specified in the work package.

1.14 Buildings Requests

Epping Floor Epping Structural Epping Floor Epping Wall Gnd Floor Epping Covering Request.docx Engineer Request.docx Penetration Request.docx Penetration Request.docx Exchange Electrical Bldg Req.docx

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 1 of 11

1 1.1

Project Details Site Details:

Epping BLD 1-44 Coulstock St Epping VIC, 3076 EPGZ VX1055/11

Site Name: Site Address Site ID Drawings

1.2

Scope of Work

The wall between the Maintenance Control and Power & Battery Room will be removed as part of the BES Scope of Work. This is to be completed before Construction begins. The timing of this is to be assessed by the Project Specialist. A Buildings Request has been submitted for new Exchange Flooring to facilitate the NBN area. This work may be actioned by BES Pre-Construction; in this case the Buildings request will not be needed. This is to be assessed by the Project Specialist. A Buildings Request has been submitted for the Pre-Construction removal of existing False Ceiling Mounted Fluoro Lights. A Licensed Electrician is required for this work. This work may be actioned by BES Pre-Construction; in this case the Buildings request will not be needed. This is to be assessed by the Project Specialist. A Buildings Request has been submitted for the removal of a wall mounted GPO on the Northern Wall of the Power & Battery Room. A Licensed Electrician is required for this work. A Buildings Request has been submitted for the relocation of a wall mounted GPO on the Western Wall of the MDF Room where a new Wall mounted Cable Riser will be required. A Licensed Electrician is required for this work. Remove the existing 150mm Wall Mounted Tray on the Northern Wall of the Power & Battery Room that was utilized for the 240V GPO Conduit. Remove the existing Alarm Indicator Panel from the North West corner of the Power & Battery Room. This may be actioned as part of the BES work. Remove the existing section of 2800mm high Wall Bar on the Northern Wall of the Maintenance Control Room. Reduce in length (cut back) the existing Wall Mounted Cantilever Brackets on the Southern Wall of the Power & Battery Room. Establish MID CLEARANCE superstructure & trays for H2 and OMF area for any compliant New Network Equipment. Ensure that the area is compliant with the H2 - suites with 1520mm centre spacing for Mid Clearance, refer to deployment standard 005747-B135 for details. Also ensure that this superstructure is isolated from any existing superstructure. 600mm H - frames shall be used for H2 area. Location of the area: H2 and OMF area shall be located at GD/92 to GD/95. Start building area from rack position 16 Backwards. Augment the existing 150mm Wall Mounted Earth Cable Tray in the South West corner of the MDF Room to provide adequate clearance for the proposed 450mm Cable Riser access to runway. A Buildings Request has been submitted for a Floor Penetration in the South West corner of the MDF Room.

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 2 of 11

A Buildings Request has been submitted for a Wall Penetration in the South East corner of the MDF Room above the existing penetration for the 150mm Earth Cable Tray. Establish a 450mm Wall Mounted Cable Riser in the South West corner of the MDF Room above the new Floor Penetration. Establish a new Wall Mounted 450mm Cable runway on the Southern Wall of the MDF Room that also incorporates the existing 150mm Earth Cable Tray. A Buildings Request has been submitted for an Engineers Report for this activity. Establish a new Ceiling Suspended section of 450mm Cable runway between the wall penetration and the new NBN deployment. A Buildings request has been submitted for an Engineers Report for th is activity. Refer to CADLINK drawing VX1055/11 for floor plan. Ensure all labelling and DBoR entry is completed as part of this project. In CADLINK ensure the superstructure build is identifiable over the rack positions, i.e. I need to be able to see what installed & reserved rack position's have superstructure installed above.

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 3 of 11

2 2.1

Project Notes Installation of CN1234 Superstructure.

Notes:

Drawings in this design pack are not to scale and are to be used as a guide only. The installer is to double check all appropriate measurements within the CFC area prior to starting the installation. If any discrepancies exist, please advise the designer. Refer to Documents & Cadlink Drawings below and Drawings in the Equipment Layout of this Design Pack. Some information in the documents & drawings below have been superseded by document:- Technical Specification TM00100A02 - Exchange Common Infrastructure CN1234 Superstructure: Cable Only Variant. Installation to be in accordance with the following Documents: : Except where approved exemptions apply. o Technical Specification TM00100 & amendments Exchange Common Infrastructure CN1234 Superstructure. o Technical Specification TM00100A01 Exchange Common Infrastructure CN1234 Low Clearance Superstructure. Where Applicable o Technical Specification TM00100A02 Exchange Common Infrastructure CN1234 Superstructure: Cable Only Variant o Technical Specification TM00100A03 Exchange Common Infrastructure CN1234 Mid Clearance Superstructure: Where Applicable o Deployment Standard 005747-335551 Network equipment area Common Infrastructure o New Document 005747-B135 - NBN Co in Telstra Buildings Floor Layout and Common Infrastructure o Technical Specification TM00330A03 Next Generation Common Facilities Alarm Alarm Peripherals & Sensors (For Temperature Sensor Installation). o Document TM00181 Exchange Common Infrastructure Cable Runways. o Design Guidelines For FSAM 576F Cable Runway- ALT-6415 o Deployment Standard 005747- 405602 Telepower & Building Alarms NGCF-AMS Sites o Document 007338 C13-11 - Next generation Common Facilities Alarm Management System (NGCF-AMS) o CN1234-xxx Drawings. Refer to attached list

Drawing List CN1234-COM_1-1 v8.xlsx

2.2

Project Details: Work Required:

Refer to the attached drawings & Cadlink Drawing VX1055/11

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 4 of 11

(i)

Existing 150mm Wall Mounted Tray

Existing 240V GPO and conduit to be removed as per Buildings Request.

Remove the existing 150mm Wall Mounted Tray and mounting Brackets on the Northern Wall of the Power & Battery Room that is utilized for the 240V Conduit.

(ii)

Alarm Indicator Panel

Remove the Alarm Indicator Panel. This may be done by BES during the Building Works.

(iii)

Remove Existing Wall Bar

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 5 of 11

Remove the existing Wall Bar on the Northern Wall of the Maintenance Control Room. (iv) Wall Mounted Cantilever Brackets

Cut back existing Wall Mounted Cantilever Brackets.

(v)

Superstructure - CN1234-MC-11 Install Suite infrastructure in rack positions 11-16 for H2 and 5-16 for ODF. Refer to H2 and ODF superstructure and attached floor plans drawings for additional detail.

Network Construction - Design Pack

Project Notes (vi) (vii) (viii) (ix)

6164128B0002

Attachment B

Issue: 1 Page 6 of 11

Install wall bar at end of suite GD/92-93 and GD/94-95 to support top bars and on both side walls. Install 6 x 600mm (H2 and OMF) and 5 x OMF I-Frames in suite positions 5-16. Install Top Bars between H frames, in each suite GD/92-93 and GD/94-95. Install top bars from the end of rack 16 to the wall bar. Install tie bars from each suite to the wall bars. Ladder - Not Required for CN1234-MC-11 Planar Shelf - Not Required for CN1234-MC-11 Safety Rail- Not Required for CN1234-MC-11 Intra Suite trays & supports H2 Suite GD/92-93 Refer to Drawings:CN1234-MC-11_2-1-2 CN1234-MC-11_2-2-2 CN1234-MC-11_16-1 CN1234-COM_38-1 CN1234-COM_38-2 Plan & elevation View 1520 Suites Overhead Cable Support Isometric View Kit Intra suite Tray & Supports Tray Fibre Cable Drop RHS Tray Fibre Cable Drop LHS

(x)

Install Intra suite tray supports. Install 150mm ST3 tray, for Optical Fibre Sheathed Cable, onto frame support from the inter suite tray. Install a new RHS S/I 353/01587 or LHS S/I 353/01588 (as required) dropper from the new section of O/F tray. Install 2 x 150mm ST3 tray, for DC Power Cable, onto Tie Bar from the inter suite tray. Install 2 x 150mm ST3 tray, for Signal Cable, onto Tie Bar from the inter suite tray. Intra Suite trays & supports OFF/OMF Suite GD/94-95 Refer to TM00100/A02/A03 & drawings for additional details. Refer to Drawings:CN1234-MC-11_2-1-1 CN1234-MC-11_16-1 CN1234-COM_38-1 CN1234-COM_38-2 Plan & Elevation view Kit Intra Suite Tray & Supports Tray Fibre Cable Drop RHS Tray Fibre Cable Drop LHS

Install OMF Intra suite Tray Kits S/I 353/01821 above suites GD/94-95 Positions 5-16. Refer to floor layout and TM00100A03 for additional details. Secure Trays with hold down brackets S/I 353/02407, M8 Hex Head Set Screws S/I 353/02211, M8 Channel Nuts S/I 353/02146 and M8 Flat Washers S/I 353/02271. Install both Uni-Directional Trays. Install a new LHS O/F dropper S/I 353/01588 from the intra suites section of O/F tray. Install a new LHS S/I 353/01588 (as required) from the inter suite section of O/F tray adjacent to suite GD/94-95 refer to CN1234-MC-11 2-1-1.

(xi)

Inter suite trays & supports

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 7 of 11

Refer to TM0100A03 & drawings:CN1234-MC-11_16-2-1 CN1234-MC-11_2-2-2 CN1234-COM_39-2 T Junction (353/01549) CN1234-COM_39-5 Bracket 150mm Infill PC for 353/1549 Inter Suite Cable Frame Overhead Isometric View Bracket 300mm ST3 TRY

Install the inter suite support frames at the end of Suite GD/92-93 and GD/93-94 as per documentation & drawings. Install 450mm ST3 tray, for Optical Fibre Sheathed Cable, onto frame supports. Install a 300mm and 150mm Infill (as required H2 or ODF suite) ST3 T Junction Bracket (353/01549) to join the intra suite O/F tray to the inter suite O/F tray

Network Construction - Design Pack

Project Notes 2.3 Suite Lighting

6164128B0002

Attachment B

Issue: 1 Page 8 of 11

Install suite lighting on Aisle Lighting Kit S/I 353/01625. Kit to be installed in the aisle between suites. Install lights spaced at 1500mm pitch along each lighting conduit. Connect lights to existing circuit if possible, if not an additional lighting pendant will be required in each suite as per Buildings Request. 2.4 240V AC Switched Outlet for Test Equipment Install Test Socket Pendant 151/00799 at end of suite Note the Switched Socket Pendant is to be installed by a licensed electrician. One test socket outlet should be installed, in each of the following locations:- Between Suite GD/92, GD/93-94 and GD/95, 3 metres from the end of the suite measured from rack 1 end of the suite and then every 6 meters. - Socket consists of the following 1 x Test Socket Outlet mounting Bracket 353/01591 and 1 x 240V AC Switched Outlet 151/00796. - Connect socket to pendant with 6 metre preterminated cable 151/00798. Refer to:- Document TM00100A03. Sections 3.1.12 & 3.3.9 Drawings CN1234-COM-44_1-1 and CN1234-COM-44_1-2 2.5 Labelling All labelling is to comply with the relevant documents, including TM00100. For end of suite labelling, refer to CN1234-COM, Sh.46-1 2.6 Rubbish All rubbish, created by the above projects, is to be removed according to Telstras Procedures. 2.7 Dbors All relevant Dbors to be updated. The designer will ensure Cadlink is correct after receiving an As Built from the constructor. The area is to be left clean & tidy. 353/01599 KIT, SUITE END LABEL BRACKET FOR CN1234

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 9 of 11

Double Tie Bars as per CN1234-COM-36-1.

Stanchions.

Wall Bar. Dummy 150mm Signal Tray to facilitate Test Outlet. 240V Superstructure Test Outlet as per TM00100A03. Wieland Pendant Dropper for Test Outlets. Wieland Pendant Dropper for Lights.

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 10 of 11

Utilize Bend Side Plate to reduce the Tray from 450mm to 300mm.

Network Construction - Design Pack

Project Notes

6164128B0002

Attachment B

Issue: 1 Page 11 of 11

Network Construction - Design Pack

Cable Runway

6164128B0002

Attachment C

Issue: 1 Page 1 of 2

Cable Runway Details

Please note: Guidelines for Cable Runways and Risers should be constructed in relation to details from TM00181 and Design Guidelines for FSAM 576F Runway (ALT-6415).

1.1

Project Details: Work Required:

Refer to the attached drawings & Cadlink Drawing VX1055/11 (xii) Re-Route the Existing 150mm Earth Cable Tray

Re-route the existing 150mm Wall Mounted Earth Cable Tray to provide clear access for the new 450mm Cable Runway to the intended Cable Riser and Penetration.

(i)

Provide a new Wall Mounted Cable Tray

Provide a Wall Mounted 450mm Cable Tray. Please see the attached Buildings Request for a Structural Engineers report.

Network Construction - Design Pack

Cable Runway

6164128B0002

Attachment C

Issue: 1 Page 2 of 2

(ii)

Provide a Ceiling Suspended Continuation of the 450mm Cable Runway. Provide a Wall Penetration as per Buildings Request.

Ceiling Suspend a 450mm Cable Tray. Please see the attached Buildings Request for a Structural Engineers report.

Utilize bendside plate to reduce the Tray from 450mm to the 300mm Unidirectional Intra-Suite Tray.

(iii)

Wall Mount a 450mm Cable Riser and Floor Penetration.

Provide a Floor Penetration as per Buildings Request.

Provide a Wall Mounted 450mm Cable Riser. The existing 240V Wall Mounted GPO Outlet needs to be removed or relocated as per Buildings Request.

Network Construction - Design Pack

Integral Material List

Project def. WBS element Network Activity Material 353/01594 353/01799 353/01821 353/01822 353/01626 353/01590 353/01637 353/01650 353/01625 529/00051 353/01591 151/00796 151/00797 151/00798 151/00799 353/00469 353/01561 353/02527 353/02528 353/02526 353/01549 353/02407 353/02146 353/02211 353/02271 353/02405 353/02140 353/02409 353/01797 353/02403 353/02328 353/02329 353/01587 353/01588 353/00451 353/02520 353/02055 353/02270 353/02085 353/02536 353/02532 353/02177 353/02181 353/02179 353/02095 067/00478 353/02318 353/02172 353/02354 353/02322 067/00467 269/00092 269/00099 269/00102 -----N.10087.03 6164128 0001

6164128B0002

Attachment D

Issue: 1 Page 1 of 1

WP20003174 Nat NC CFC 11/12 V/T 10018832_78_VIC CSF EPGZ D&C Full 1. EPPING (EPGZ) Material Rqmts qty 9 EA 3 EA 9 EA 4 EA 4 EA 15 EA 10 EA 1 KIT 10 EA 15 EA 5 EA 5 EA 3 EA 2 EA 6 EA 6 EA 5 EA 8 EA 9 EA 14 EA 2 EA 120 EA 120 EA 120 EA 120 EA 50 EA 200 EA 30 EA 1 EA 3 EA 4 EA 4 EA 2 EA 17 EA 32 EA 4 EA 70 EA 1 EA 250 EA 250 EA 300 EA 16 EA 20 EA 32 EA 80 EA 2 EA 70 EA 20 EA 1 EA 60 EA 4 EA 1 PAC 2 PAC 2 PAC

Material text KIT,WALL BAR 3M CN1234 KIT,STANCHION FOR CN1234 FRAME,INTRASUITE FIBRE CABLE CN1234-MC FRAME,INTERSUITE CABLE CN1234-MC LABEL SET,HOT/COLD AISLE FOR CN1234 BRACKET,CABLE TIE OFF/OMF SUITE CN1234 BRACKET,CABLE HOOP 150MM W FOR ST3 TRAY KIT,SLIT PIPE 50MM FOR CABLE TRAY EDGING KIT,AISLE LIGHTING CONDUIT FOR CN1234 LIGHT UNIT,FLUOR EXCH RACK 40W SINGLE BRACKET,FOR 240V TEST OUTLET CN1234 OUTLET,DUAL 240V FOR CN1234 SUPERSTRUCT CABLE,4M FOR SUPERSTRUCTURE OUTLET CABLE,6M FOR SUPERSTRUCTURE OUTLET SOCKET,PENDANT WIELAND GST CONNECTOR FRAME,SUITE SUPPORT 600MM X 2.4M CN1234 FRAME,OFF/OMF SUITE SUPPORT 2.4M CN1234 TRAY,CABLE ST3 300MM X 3M AUG2A330 PC TRAY,CABLE ST3 450MM X 3M AUG2A345 PC TRAY,CABLE ST3 150MM X 3M AUG2A315 PC BRACKET,T JUNCTION 300MM ST3 TRAY PC BRACKET,HOLD DOWN ST3 TRAY AUG2HDC PC NUT,CHANNEL M8 TAPERED SPRING 1007 VZA SETSCREW,HEX HEAD M8X25 HHS0825 ZA WASHER,FLAT M8 FW08 ZA PLATE,SPLICE ST3 TRAY AUG2PFH PC SCREW,M10x20 & NUT ZA PLATE,LINK ST3 TRAY AUG2PLK PC BRACKET,150MM INFILL PC FOR 353/01549 PLATE,BENDSIDE 3M ST3 TRAY AUG2BS3 PC BRACKET,BRACED CANTILEVER 470MM CL300 ZA BRACKET,BRACED CANTILEVER 635MM CL450 ZA TRAY,FIBRE CABLE DROP RHS CN1234 TRAY,FIBRE CABLE DROP LHS CN1234 CHANNEL,SLOTTED 41X41MM X 3M 10003T CHANNEL,SINGLE 41X41MM X 3M 10003 ZA BRACKET,ANGLE 90 DEG 41X57MM 1068 ZA BRACKET,ANGLE 30 DEG 52X83MM 2101 ZA SETSCREW,HEX HEAD M12X30 HHS1230 ZA NUT,CHANNEL M12 TAPERED SPRING 1010 VZA WASHER,SPRING M12 SW12 ZA PLATE,FLAT 90X40MM 2 HOLE 1065 ZA BRACKET,U SHAPE 186MM 1377 ZA PLATE,FLAT 40X40MM HOLE 14MM 1064 ZA CAP,CHANNEL END 41X41MM 2240 PVC ROD,THREADED 12MM X 1M ZINC PLATED NUT,HEX M12 HN12 ZA CAP,CHANNEL END 2860-10 PVC PLANAR SHELF,150MM X 3M TELTRAY PC WASHER,FLAT M12 FW12 ZA ROD,THREADED 12MM X 3M ZINC PLATED TIE,CABLE SELF-LOCKING UV RES 2.5X100MM TIE,CABLE SELF-LOCKING UV RES 200 X 3.5 TIE,CABLE SELF-LOCKING UV RES 300 X 3.5

Network Construction - Design Pack

Equipment Layout

6164128B0002

Attachment E

Issue: 1 Page 1 of 1

Potrebbero piacerti anche

- Technician's Instructions Estetica E30Documento142 pagineTechnician's Instructions Estetica E30виктор100% (1)

- Method-Statement For Electrical InstallationDocumento31 pagineMethod-Statement For Electrical Installationmozartjr22100% (3)

- CDR Electrical EngineerDocumento13 pagineCDR Electrical Engineerfh63775% (4)

- Managing Successful Projects with PRINCE2 2009 EditionDa EverandManaging Successful Projects with PRINCE2 2009 EditionValutazione: 4 su 5 stelle4/5 (3)

- Method Statement For Installation For Curtain Wall (Unitized)Documento38 pagineMethod Statement For Installation For Curtain Wall (Unitized)Gary Lo79% (29)

- Transmission and Distribution Electrical EngineeringDa EverandTransmission and Distribution Electrical EngineeringValutazione: 4.5 su 5 stelle4.5/5 (31)

- Method Statement For Hot Tapping Rev 0Documento9 pagineMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- Asignment Blanc ChequeDocumento12 pagineAsignment Blanc ChequeFaiz AlwiNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Cable Tray Installation ProcedureDocumento9 pagineCable Tray Installation ProcedureMahmoud Tobala0% (1)

- MS For Electrical InstallationDocumento31 pagineMS For Electrical InstallationPatricia Jackson100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Amino AcidsDocumento17 pagineAmino AcidsSiddharth Rohilla100% (2)

- Cable Tray BKM 7105Documento8 pagineCable Tray BKM 7105Utku Can KılıçNessuna valutazione finora

- RFP RefDocumento31 pagineRFP RefHicham MedgazNessuna valutazione finora

- Electrical Design & Implementation Engineer CV WordDocumento6 pagineElectrical Design & Implementation Engineer CV WordAlamgeer Abdul RazzaqueNessuna valutazione finora

- Clarification 6Documento6 pagineClarification 6Biniyam BENessuna valutazione finora

- Conduit BKM 7102Documento9 pagineConduit BKM 7102Utku Can Kılıç100% (1)

- PO6 (Delta Mesh Network) Project: Prepared BY: Eng. Amal Abd EL Hafeez BakryDocumento17 paginePO6 (Delta Mesh Network) Project: Prepared BY: Eng. Amal Abd EL Hafeez Bakrytarekyehia009Nessuna valutazione finora

- Method Statement For Cable Conduit & Tray Installation PDFDocumento5 pagineMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (1)

- MOS ELectrical Sub StationDocumento10 pagineMOS ELectrical Sub Stationecstacy7Nessuna valutazione finora

- EPM PM19 Structured Cabling Specification Nov2014Documento24 pagineEPM PM19 Structured Cabling Specification Nov2014MekaNo1DNessuna valutazione finora

- EntryDetails - IMI2022 TCE GI 2022 0050562Documento5 pagineEntryDetails - IMI2022 TCE GI 2022 0050562sayak banerjeeNessuna valutazione finora

- Rev - Resource Plan SubstationDocumento22 pagineRev - Resource Plan SubstationKukuborNessuna valutazione finora

- Job List 11-15-2023Documento4 pagineJob List 11-15-2023Thanh DoNessuna valutazione finora

- 2014 Underground Electric Construction StandardsDocumento53 pagine2014 Underground Electric Construction StandardsJosé Martín Peña TorresNessuna valutazione finora

- Structured Cabling System Specification: Section 271010-Telephone and Data Distribution 11/2017Documento27 pagineStructured Cabling System Specification: Section 271010-Telephone and Data Distribution 11/2017gate 2012Nessuna valutazione finora

- KP-00+++-CY712-BKM7103 Rev. B CONDUITDocumento8 pagineKP-00+++-CY712-BKM7103 Rev. B CONDUITUtku Can KılıçNessuna valutazione finora

- Work Procedure For CCB Proposed Inside Staircase Working PlatformDocumento24 pagineWork Procedure For CCB Proposed Inside Staircase Working PlatformResearcherNessuna valutazione finora

- Method Statement For Duct InstallationDocumento7 pagineMethod Statement For Duct InstallationShaikh MateenNessuna valutazione finora

- Method Statement For Block PavingDocumento7 pagineMethod Statement For Block Pavingjohng5697Nessuna valutazione finora

- Technical Report - WMB Electrical LTDDocumento8 pagineTechnical Report - WMB Electrical LTDAreej ShahbazNessuna valutazione finora

- Aqua MCA Queries Clarifications - 2 - (2) - MEICA Comments V1R2 - DP PDFDocumento4 pagineAqua MCA Queries Clarifications - 2 - (2) - MEICA Comments V1R2 - DP PDF3238NDNessuna valutazione finora

- Ronald Talisay CV Telecom EngineerDocumento6 pagineRonald Talisay CV Telecom EngineerRonald AllanNessuna valutazione finora

- JPK-056-07-Q-0794 - Rev 1Documento84 pagineJPK-056-07-Q-0794 - Rev 1aibekNessuna valutazione finora

- Application For: The HR ManagerDocumento6 pagineApplication For: The HR ManagerAbhilash P PaulNessuna valutazione finora

- Ronald Allan Talisay 2017 v2Documento16 pagineRonald Allan Talisay 2017 v2Ronald AllanNessuna valutazione finora

- Method Statement Bottom Up Roof Slab Concreting: Page 1 of 10Documento10 pagineMethod Statement Bottom Up Roof Slab Concreting: Page 1 of 10J. Kumar Infraprojects LtdNessuna valutazione finora

- ConduitDocumento77 pagineConduitkamlNessuna valutazione finora

- 1.2) MSO Fitting-Out Guide - v2017 June (Non A&A)Documento50 pagine1.2) MSO Fitting-Out Guide - v2017 June (Non A&A)KUNG HIM CHANNessuna valutazione finora

- MM ZTK 1A ONEP ELE PRC 0002 - Electrical Installation ProcedurDocumento18 pagineMM ZTK 1A ONEP ELE PRC 0002 - Electrical Installation ProcedurAbdelaziz Abdelaziz100% (1)

- P7512PB2000G0198Documento12 pagineP7512PB2000G0198SUJITH.K.S.Nessuna valutazione finora

- 33kV Indoor Connection Guide - Version 18Documento50 pagine33kV Indoor Connection Guide - Version 18Khalid HameedNessuna valutazione finora

- HSE Plan - HB2NP Habeeb (New)Documento81 pagineHSE Plan - HB2NP Habeeb (New)nsadnanNessuna valutazione finora

- 132kV Connection Guide Version 9Documento44 pagine132kV Connection Guide Version 9ElwanNessuna valutazione finora

- SOP For WiMAX CPE Installation 1Documento17 pagineSOP For WiMAX CPE Installation 1Mohammad Faisal AzizNessuna valutazione finora

- P S S C Sez O F - P: Roject Cope TatementDocumento9 pagineP S S C Sez O F - P: Roject Cope Tatementnafis haiderNessuna valutazione finora

- Proposed Network RehabilitationDocumento5 pagineProposed Network RehabilitationRic SaysonNessuna valutazione finora

- Key CompetenciesDocumento4 pagineKey CompetenciesAmandeep SinghNessuna valutazione finora

- 1390-Twi 552 Elec Rev.3 Sep 5Documento11 pagine1390-Twi 552 Elec Rev.3 Sep 5Joel AlcantaraNessuna valutazione finora

- ICT Structured Cabling GuidelinesDocumento37 pagineICT Structured Cabling GuidelinesSylvester Muzendah100% (1)

- Wasim CVDocumento5 pagineWasim CVWasim IqbalNessuna valutazione finora

- 18 11 2018 Glastonbury House Fire Safety Z251 - Project Execution PlanDocumento25 pagine18 11 2018 Glastonbury House Fire Safety Z251 - Project Execution PlanEdward Chan AcostaNessuna valutazione finora

- Wasim Ahmed Electrical EngineerDocumento2 pagineWasim Ahmed Electrical EngineerWasim AhmedNessuna valutazione finora

- Techno Commercial Proposal 4500kwDocumento13 pagineTechno Commercial Proposal 4500kwcapankajabuNessuna valutazione finora

- Email:: Contact No: 09396711437,9885616495Documento6 pagineEmail:: Contact No: 09396711437,9885616495Suresh PentapatiNessuna valutazione finora

- Infrastructure Cabling Works SECTION 27 13 23: Part 1 - General 1.1 Related DocumentsDocumento14 pagineInfrastructure Cabling Works SECTION 27 13 23: Part 1 - General 1.1 Related DocumentsGamal Ahmed100% (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDa EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNessuna valutazione finora

- The Complete Guide to Getting Certified Cisco CCNA 200-301: Complete Your CCNA Exam Training and Preparation with 400 Exam Level Practice QuestionDa EverandThe Complete Guide to Getting Certified Cisco CCNA 200-301: Complete Your CCNA Exam Training and Preparation with 400 Exam Level Practice QuestionNessuna valutazione finora

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresDa EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNessuna valutazione finora

- List Pol Parties With AddressesDocumento9 pagineList Pol Parties With AddressesBilal Ahmad0% (1)

- Convergence and Next Generation NetworkDocumento63 pagineConvergence and Next Generation Networkhlong1604Nessuna valutazione finora

- Next Generation Network ReportDocumento27 pagineNext Generation Network Reportharit_ec100% (1)

- Decommissioning Guidance 0Documento22 pagineDecommissioning Guidance 0Bilal AhmadNessuna valutazione finora

- Form-A For Enlistment in Voter ListDocumento1 paginaForm-A For Enlistment in Voter ListNaveed ShaheenNessuna valutazione finora

- SYC - University ProgramDocumento1 paginaSYC - University ProgramBilal AhmadNessuna valutazione finora

- IeltsDocumento5 pagineIeltsBilal AhmadNessuna valutazione finora

- Decommissioning Guidance 0Documento22 pagineDecommissioning Guidance 0Bilal AhmadNessuna valutazione finora

- Area 1 PROBLEM SET #2Documento10 pagineArea 1 PROBLEM SET #2JC YabisNessuna valutazione finora

- Nammcesa 000008 PDFDocumento197 pagineNammcesa 000008 PDFBasel Osama RaafatNessuna valutazione finora

- App Guide EntelliGuard - G 09 - 2020 AplicacionDocumento100 pagineApp Guide EntelliGuard - G 09 - 2020 AplicacionjeorginagNessuna valutazione finora

- Contoh Reflection PaperDocumento2 pagineContoh Reflection PaperClaudia KandowangkoNessuna valutazione finora

- Advances in Agronomy v.84Documento333 pagineAdvances in Agronomy v.84luisiunesNessuna valutazione finora

- Ideal Discharge Elderly PatientDocumento3 pagineIdeal Discharge Elderly PatientFelicia Risca RyandiniNessuna valutazione finora

- Unsaturated HydrocarbonsDocumento84 pagineUnsaturated HydrocarbonsHey itsJamNessuna valutazione finora

- Inside The Earth NotesDocumento2 pagineInside The Earth NotesrickaturnerNessuna valutazione finora

- Canfield FairDocumento3 pagineCanfield Fairapi-546463844Nessuna valutazione finora

- Mental Health & TravelDocumento18 pagineMental Health & TravelReyza HasnyNessuna valutazione finora

- 2013 Casel GuideDocumento80 pagine2013 Casel GuideBobe MarinelaNessuna valutazione finora

- CASE 1. Non-Cash Assets Are Sold For P 580,000Documento3 pagineCASE 1. Non-Cash Assets Are Sold For P 580,000Riza Mae AlceNessuna valutazione finora

- Emergency War Surgery Nato HandbookDocumento384 pagineEmergency War Surgery Nato Handbookboubiyou100% (1)

- 5 Keto Pancake RecipesDocumento7 pagine5 Keto Pancake RecipesBai Morales VidalesNessuna valutazione finora

- Concrete and Its PropertiesDocumento24 pagineConcrete and Its PropertiesAmila LiyanaarachchiNessuna valutazione finora

- Infographic Humanistic PsychologyDocumento2 pagineInfographic Humanistic Psychologyvivain.honnalli.officialNessuna valutazione finora

- SPKT Thiet Ke Co Khi 1Documento33 pagineSPKT Thiet Ke Co Khi 1Chiến PhanNessuna valutazione finora

- Week 2 - ValEdDocumento30 pagineWeek 2 - ValEdBernadette MacalindongNessuna valutazione finora

- Diplomate Course and Conferment RequirementsDocumento1 paginaDiplomate Course and Conferment Requirementsabigail lausNessuna valutazione finora

- Ethical Consideration in Leadership and ManagementDocumento6 pagineEthical Consideration in Leadership and ManagementGlizzle Macaraeg67% (3)

- Director's Update Our StudentsDocumento23 pagineDirector's Update Our StudentsAdrian MojicaNessuna valutazione finora

- CNA Candidate HandbookDocumento57 pagineCNA Candidate HandbookSummerNessuna valutazione finora

- Dirty Dozen List of Endocrine DisruptorsDocumento4 pagineDirty Dozen List of Endocrine DisruptorsMariuszNessuna valutazione finora

- NHT Series High-Throughput Diffusion PumpsDocumento12 pagineNHT Series High-Throughput Diffusion PumpsJosé Mauricio Bonilla TobónNessuna valutazione finora

- Entrepreneurship Paper 2Documento3 pagineEntrepreneurship Paper 2kisebe yusufNessuna valutazione finora

- 168 Visual Perceptual SkillsDocumento3 pagine168 Visual Perceptual Skillskonna4539Nessuna valutazione finora

- MPSI OverviewDocumento15 pagineMPSI OverviewZaqee AlvaNessuna valutazione finora

- Maxs AdultDocumento1 paginaMaxs Adultclark lopezNessuna valutazione finora