Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Match Treatment

Caricato da

Erik WeeksCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Match Treatment

Caricato da

Erik WeeksCopyright:

Formati disponibili

TECHNICAL PAGES

Match treatment type to carbon type

The universal adsorbent media comes from different raw materials.

Activated carbon filter media is commonly used in point-of-use/point-of-entry (POU/POE) water treatment applications. It can be used either by itself, such as to remove chlorine from tap water, or in combination with other water treatment processes such as reverse osmosis (RO), ultraviolet (UV) and ion exchange for treatment of more complex water streams containing various contaminants. Activated carbon is known as the universal adsorbent because it has the capacity to adsorb a myriad of compounds and remove them from a liquid or vapor stream. It is commonly used in water filters in granular form or in block form (made from powdered activated carbon) to remove taste- and odor-causing chemicals and additives such as chlorine or chloramine. It works both as an adsorbent, adsorbing organic compounds such as chloroform or geosmin from water, and as a catalyst, such as reacting with chlorine to break the chemical bond producing chloride ions as a result. The block form of carbon filter also acts as a mechanical filter and can be rated as 1-micron, 5-micron, etc. Carbon blocks are made from coal, coconut shell and wood powdered carbons, and each manufacturer has its own guarded recipe for block-making. According to ASTM D 2652, Standard Terminology Relating to Activated Carbon, activated carbon is defined as: a family of carbonaceous substances manufactured by processes that develop adsorptive properties. Activated carbon is a general term to describe a family of adsorbents that have been manufactured from a variety of carbonaceous base materials. Each base material results in an activated carbon with unique physical characteristics that determine its suitability for water treatment applications. Carbonaceous substances are the raw materials used to make activated carbon, and the most common are: Wood (hardwood and softwood) Peat Coal (lignite, sub-bituminous and bituminous) Palm shell Coconut shell. Other types of raw materials used to a lesser extent include fruit pits, nut shells, and agricultural waste such as rice hulls. The most common types used for water treatment carbon are coal, coconut shell and wood.

Activation yields surface area

By Ken Schaeffer

Ken Schaeffer has over 25 years experience in the activated carbon industry and is president of Carbon Resources, LLC, based in Oceanside, CA. He has a BA in biology and an MS in environmental science from the University of Texas at Dallas, is an officer on ASTM D28 Committee on Activated Carbon, and is on the Pacific Water Quality Association Board of Directors. He can be reached at ken@carbon resources.com or (760) 630-5724.

The standard process used to manufacture steam-activated carbon involves putting the carbonaceous substance through a manufacturing process that heats the raw material, creates a char and then is activated in a furnace at high temperatures of 1,700 to 1,800 degrees F with steam in the absence of oxygen. In the steam-activation process, all volatile compounds in the carbon material evacuate the particle, and the following steam-carbon reaction C + H2O = H2 + CO

MORE INFORMATION

ONLINE Visit www.watertechonline.com and type in search keyword(s): carbon.

The carbon family

removes excess carbon and enlarges the pores, leaving behind a carbon skeleton. Some wood-base carbons are made using a chemical activation process that uses heat and phosphoric acid. This activation process results in the creation of an enormous surface area on the order of 600 to 1,200 square meters per gram (m2/g), depending upon the raw material and process dynamics. A good-activity carbon with a surface area of 1,000 m2/g would have 125 acres of surface area per pound. Granular activated carbons are sized using particle size distribution according to ASTM D 2862, and typical sizes include 20 x 50, 12 x 40, 8 x 30 and 8 x16 mesh. Activated carbon used in POU/POE

Important: porosity type

Copyright 2008 Grand View Media Group. Reprinted with permission from Water Technology magazine. For free subscription to Water Technology magazine call (800) 390-2946 / www.watertechonline.com

TECHNICAL PAGES

the main application, then either type of carbon will do because chlorine removal is a surface reaction and not adsorption. The three coal-base materials lignite, sub-bituminous, and bituminous each result in an activated carbon with different physical characteristics. If you consider that some coal carbons are direct-activated and some are reagglomerated and activated, then even more differences are apparent. Lignite coal granular carbons are not typically used in POU/POE applications due to their lower attrition resistance, higher ash content and lower activity level (surface area) compared with other coal carbons, but lignite powdered activated carbon (PAC) is commonly used by municipal water treatment plants for seasonal taste and odor control. Comparing attrition resistance and activity, sub-bituminous and bituminous coals produce similar activated carbons, but bituminous carbons have lower total ash, and reagglomerated bituminous carbon is a bit more dense and is more macro-porous. Coconut shell activated carbon has the greatest density, highest hardness, lowest

(Continued from prior page)

Contrasting the carbons

A good-activity carbon with a surface area of 1,000 m 2 /g would have 125 acres of surface area per pound.

ash and highest activity level in the activated carbon family tree. If the application is to remove larger molecules such as color, then a coal base or wood base PAC is probably the best choice. If your concern is chlorine and some low-level suspended solids, then a carbon block type filter may be required and it could be made with coal or coconut shell carbon. If activated carbon has been in service for chlorine removal and the local municipality changes from adding chlorine to adding chloramine to the water (to reduce disinfection byproducts such as trihalomethanes [THMs]), the options are to increase the amount of carbon, reduce the flow rate to increase contact time, switch to a higher-surface-area carbon or replace the regular carbon with an enhanced-surface-area carbon (for higher catalytic capability). In some cases a carbon with antimicrobial properties may be needed, and some special carbons are marketed for that purpose. They use impregnants such as silver or iodine to curb bacterial growth in the carbon filter. To obtain the best performance from activated carbon media, do some investigation about the desired results for the water treatment system. Match the type of activated carbon that will provide the needed activity (surface area and pore size distribution), attrition resistance (abrasion or hardness number), total soluble ash level, particle size and density. Since activated carbon pricing has been escalating, it is critical to talk to your activated carbon supplier and make a knowledgeable decision on carbon type and WT grade for the application.

Water treatment carbon selection

Lignite, sub-bituminous, and bituminous coal and chemically activated woodbase carbons are manufactured in the United States and also imported, because domestic production cannot meet the demand for product. All coconut shell activated carbon is imported because there is no domestic production. When buying activated carbon cartridge filters or in bulk for a specific POU/POE application, you need to know the carbon base material in order to select the proper carbon for the job: If the main carbon function is chlorine removal, then either a coal base or coconut shell base carbon will suffice, but

Pore Size Comparison

Not just any carbon will do

Copyright 2008 Grand View Media Group. Reprinted with permission from Water Technology magazine. For free subscription to Water Technology magazine call (800) 390-2946 / www.watertechonline.com

Potrebbero piacerti anche

- Environmentally Benign Approaches for Pulp BleachingDa EverandEnvironmentally Benign Approaches for Pulp BleachingNessuna valutazione finora

- Activated Remove Oil MistDocumento9 pagineActivated Remove Oil MistCanh LuongtienNessuna valutazione finora

- What Is Activated CarbonDocumento6 pagineWhat Is Activated CarbonAustroCarbonNessuna valutazione finora

- Activated CarbonDocumento14 pagineActivated CarbonAbhisesh ThakurNessuna valutazione finora

- Activated CarbonDocumento16 pagineActivated Carbonjcoppala44760% (1)

- Properties of Activated Carbon: Iodine NumberDocumento11 pagineProperties of Activated Carbon: Iodine Numbervyas reddyNessuna valutazione finora

- Activated Carbon: Too Many Sections Considering Its Overall LengthDocumento16 pagineActivated Carbon: Too Many Sections Considering Its Overall LengthMuhaimin SelawiNessuna valutazione finora

- Poweder Activated Carbon Treatment (Pact)Documento10 paginePoweder Activated Carbon Treatment (Pact)Harish GowdaNessuna valutazione finora

- Production: Activated Carbon, Also Called Activated Charcoal or Activated Coal Is A Form of Carbon ThatDocumento13 pagineProduction: Activated Carbon, Also Called Activated Charcoal or Activated Coal Is A Form of Carbon ThatShanmugam RameshNessuna valutazione finora

- Activated CarbonDocumento3 pagineActivated CarbonhabtamuNessuna valutazione finora

- Activated CarbonDocumento10 pagineActivated CarbonMurugesh100% (2)

- Carbon Filter Questions and Answers: Technical BriefDocumento2 pagineCarbon Filter Questions and Answers: Technical BriefMinh Nguyen VanNessuna valutazione finora

- Activated Charcoal Preparation, Characterization andDocumento6 pagineActivated Charcoal Preparation, Characterization andMadhanNessuna valutazione finora

- Activated Carbon FiltrationDocumento0 pagineActivated Carbon FiltrationIrhamNessuna valutazione finora

- Activated Carbon FilterDocumento9 pagineActivated Carbon Filtersanabilbaig100% (1)

- Waterprofessionals: All About Activated Carbon FiltersDocumento2 pagineWaterprofessionals: All About Activated Carbon FiltersMCg GozoNessuna valutazione finora

- Active CharcoalDocumento12 pagineActive CharcoalMitko100% (1)

- Activated Carbon Manufacturing Plants: Aswath KC Reg No: 16022654 Jacob Abraham Ajith KumarDocumento32 pagineActivated Carbon Manufacturing Plants: Aswath KC Reg No: 16022654 Jacob Abraham Ajith KumarAbhiram KNessuna valutazione finora

- Norit Ac Beverage BrochureDocumento9 pagineNorit Ac Beverage BrochuredeepthipasumarthyNessuna valutazione finora

- HomeWaterFilter BrochureDocumento6 pagineHomeWaterFilter Brochurevaglohrd100% (1)

- Vol7no3 2Documento4 pagineVol7no3 2Dyah Ratri RahadiniNessuna valutazione finora

- Preparation and Characterization of Waste-Derived Activated CarbonsDocumento37 paginePreparation and Characterization of Waste-Derived Activated CarbonsarulazzikriNessuna valutazione finora

- 14 Tu Carbonresources 0312WQPDocumento2 pagine14 Tu Carbonresources 0312WQPCleverSeyramKetekuNessuna valutazione finora

- Method and Installation DescriptionDocumento3 pagineMethod and Installation DescriptionBeerappa RamakrishnaNessuna valutazione finora

- Mike o Pedia Carbon EBCTDocumento4 pagineMike o Pedia Carbon EBCTMario KonsachristianNessuna valutazione finora

- ArtigoDocumento9 pagineArtigo1986crisNessuna valutazione finora

- Protection of Soil, Surface Water and Ground Water From Industrial & Chemical PollutionDocumento2 pagineProtection of Soil, Surface Water and Ground Water From Industrial & Chemical PollutionAnonymous i3lI9MNessuna valutazione finora

- "Treatability Study of Low Cost Adsorbents For Waste Water Treatment" Gujarat Technological UniversityDocumento56 pagine"Treatability Study of Low Cost Adsorbents For Waste Water Treatment" Gujarat Technological UniversityDEVESH SINGHNessuna valutazione finora

- Carbon FiltersDocumento18 pagineCarbon FiltersAnabelle FernandezNessuna valutazione finora

- Edp ContentDocumento22 pagineEdp ContentJohn Kenneth SenatoNessuna valutazione finora

- Adsorption ReviewDocumento7 pagineAdsorption ReviewLESLI RODRIGUEZ BENDEZUNessuna valutazione finora

- Carbon Block Buyer's Guide: Developing Specifications and Selecting A SupplierDocumento6 pagineCarbon Block Buyer's Guide: Developing Specifications and Selecting A SupplierMohamed El-HarrasNessuna valutazione finora

- Bleaching Techniques in PulpDocumento16 pagineBleaching Techniques in PulphussainNessuna valutazione finora

- Activated Carbon Treatment of Drinking WaterDocumento6 pagineActivated Carbon Treatment of Drinking WaterHaimwant DhanieNessuna valutazione finora

- Comparision of Household Grey Water Treatment Using Slow Sand Filter and Slow Sand Aided With Activated Charcoal FilterDocumento3 pagineComparision of Household Grey Water Treatment Using Slow Sand Filter and Slow Sand Aided With Activated Charcoal FilterInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Carbon FilteringDocumento15 pagineCarbon Filteringasma71Nessuna valutazione finora

- Activated CarbonDocumento18 pagineActivated CarbonArvind Singh KasanaNessuna valutazione finora

- Civil Activated Carbon Adsorption ReportDocumento20 pagineCivil Activated Carbon Adsorption ReportChethan RavikumarNessuna valutazione finora

- Activated Carbon and Its ApplicationDocumento16 pagineActivated Carbon and Its ApplicationErik Weeks100% (2)

- Article Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsDocumento10 pagineArticle Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsHonguito WebNessuna valutazione finora

- Bandosz2015-Spent Coffee-Based Activated CarbonsDocumento7 pagineBandosz2015-Spent Coffee-Based Activated CarbonsUjak Kimia100% (1)

- Pirolisis 1Documento7 paginePirolisis 1CRISTIANNessuna valutazione finora

- Organic RemovalDocumento4 pagineOrganic RemovalErika Andrea Mendez RodriguezNessuna valutazione finora

- Treatment of Brewery Wastewater Effluent PDFDocumento14 pagineTreatment of Brewery Wastewater Effluent PDFMahmoud ElsayedNessuna valutazione finora

- Carbon FilterDocumento6 pagineCarbon FilterFreddy YugchaNessuna valutazione finora

- Aqua-Silencer: BY Yash A. Lad 1719ME30006Documento21 pagineAqua-Silencer: BY Yash A. Lad 1719ME30006Amrit singhNessuna valutazione finora

- Coconut Vs CoalDocumento3 pagineCoconut Vs CoalHaris KokkinisNessuna valutazione finora

- Activated Carbon: A. IntroductionDocumento18 pagineActivated Carbon: A. IntroductionSRINAAS CHEMICALS AND PHARMACEUTICALSNessuna valutazione finora

- Production and Applications of Activated Carbons As Adsorbents From Olive StonesDocumento28 pagineProduction and Applications of Activated Carbons As Adsorbents From Olive Stonesİlayda ÖzdilNessuna valutazione finora

- Project Report On Activated Carbon (Granular and Powder)Documento9 pagineProject Report On Activated Carbon (Granular and Powder)EIRI Board of Consultants and Publishers100% (1)

- Porous Activated Carbon From Agro-Food Waste: Low Cost, Eco-Friendly For Sustainable Green EnergyDocumento6 paginePorous Activated Carbon From Agro-Food Waste: Low Cost, Eco-Friendly For Sustainable Green Energykhalood mohamedNessuna valutazione finora

- GMB June 25 NotesDocumento2 pagineGMB June 25 NotesGlorie Mae BurerosNessuna valutazione finora

- Activated CarbonDocumento47 pagineActivated Carbonsrinijagan100% (2)

- Final - PPT On Aqua SilncerDocumento35 pagineFinal - PPT On Aqua SilncerPravin PatilNessuna valutazione finora

- Coconut Shell Versus Bituminous Coal Activated CarbonDocumento6 pagineCoconut Shell Versus Bituminous Coal Activated Carbonnermeen ahmedNessuna valutazione finora

- Activated Carbon For Waste Water Treatment v2 NDocumento8 pagineActivated Carbon For Waste Water Treatment v2 NMohammed A. Helal100% (1)

- Properties of Coated and Uncoated Biomass Aggregates and Their Effects On The Strength and Water Permeability of Pervious Geopolymer ConcreteDocumento8 pagineProperties of Coated and Uncoated Biomass Aggregates and Their Effects On The Strength and Water Permeability of Pervious Geopolymer ConcreteDavid BoroviczNessuna valutazione finora

- Norit Ac Potable Water BrochureDocumento9 pagineNorit Ac Potable Water BrochureNermeen ElmelegaeNessuna valutazione finora

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocumento4 pagineCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22Nessuna valutazione finora

- Chemical ProcessDocumento18 pagineChemical ProcessErik WeeksNessuna valutazione finora

- Chemical Engineering ThermodynamicsDocumento35 pagineChemical Engineering ThermodynamicsErik WeeksNessuna valutazione finora

- ChE Objective Type Questions Compilation-Dean MedinaDocumento171 pagineChE Objective Type Questions Compilation-Dean MedinaErik WeeksNessuna valutazione finora

- The Legend of The Coconut Tree (Edited)Documento2 pagineThe Legend of The Coconut Tree (Edited)Erik WeeksNessuna valutazione finora

- Chemical Engineering ThermodynamicsDocumento35 pagineChemical Engineering ThermodynamicsErik WeeksNessuna valutazione finora

- Canteenstandardization 140404093606 Phpapp01Documento112 pagineCanteenstandardization 140404093606 Phpapp01Erik WeeksNessuna valutazione finora

- MEMODocumento1 paginaMEMOErik WeeksNessuna valutazione finora

- Che CHM QuestionsDocumento82 pagineChe CHM QuestionsErik WeeksNessuna valutazione finora

- Corn CobsDocumento2 pagineCorn CobsErik WeeksNessuna valutazione finora

- Leadership Is A Potent Combination of Strategy and Character. But If You Must Be Without One, Be Without The Strategy. - Norman SchwarzkopfDocumento4 pagineLeadership Is A Potent Combination of Strategy and Character. But If You Must Be Without One, Be Without The Strategy. - Norman SchwarzkopfErik WeeksNessuna valutazione finora

- Water QualityDocumento11 pagineWater QualityErik WeeksNessuna valutazione finora

- Coconut HuskDocumento4 pagineCoconut HuskErik WeeksNessuna valutazione finora

- Water Quality Requirement For Different UsesDocumento8 pagineWater Quality Requirement For Different UsesErik WeeksNessuna valutazione finora

- 1032 1025 1 PBDocumento9 pagine1032 1025 1 PBErik WeeksNessuna valutazione finora

- Energy and Mass IncinerationDocumento11 pagineEnergy and Mass Incinerationnuti_srinivasNessuna valutazione finora

- Corn CobsDocumento2 pagineCorn CobsErik WeeksNessuna valutazione finora

- Comparative Simulation of The Purification of Wet Phosphoric Acid by TBP Mibk and A Mixture Mibk TBP 2157 7048.1000134Documento4 pagineComparative Simulation of The Purification of Wet Phosphoric Acid by TBP Mibk and A Mixture Mibk TBP 2157 7048.1000134Erik WeeksNessuna valutazione finora

- 1 s2.0 S1878535211003030 MainDocumento8 pagine1 s2.0 S1878535211003030 MainErik WeeksNessuna valutazione finora

- Proximate Composition-Coconut HuskDocumento4 pagineProximate Composition-Coconut HuskErik WeeksNessuna valutazione finora

- Activated CarbonDocumento69 pagineActivated CarbonSaheed Adewale100% (2)

- A 121 Z 1 P 86Documento4 pagineA 121 Z 1 P 86Erik WeeksNessuna valutazione finora

- Material and Energy Balance in Industrial PlantDocumento26 pagineMaterial and Energy Balance in Industrial Plantconan45Nessuna valutazione finora

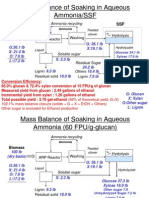

- Mass Balance of Ammonia Treatment at Room TempDocumento3 pagineMass Balance of Ammonia Treatment at Room TempErik WeeksNessuna valutazione finora

- Calorific Values and Proximate Analysis ofDocumento13 pagineCalorific Values and Proximate Analysis ofErik WeeksNessuna valutazione finora

- Activated Carbon UsesDocumento3 pagineActivated Carbon UsesErik WeeksNessuna valutazione finora

- Concept PaperDocumento1 paginaConcept PaperErik WeeksNessuna valutazione finora

- Activated Carbon From BambooDocumento19 pagineActivated Carbon From BambooErik WeeksNessuna valutazione finora

- Green FinanceDocumento16 pagineGreen FinanceErik WeeksNessuna valutazione finora

- Raw MaterialsDocumento14 pagineRaw MaterialsErik WeeksNessuna valutazione finora

- ADAT Optical Audio Data Generator and Encoder V1401Documento8 pagineADAT Optical Audio Data Generator and Encoder V1401mylitalindaNessuna valutazione finora

- Absorption of Gamma RaysDocumento9 pagineAbsorption of Gamma RaysRachit KanchanNessuna valutazione finora

- ASME B1.16 - B1.16M - 1984 (Reaffirmed 2006) PDFDocumento184 pagineASME B1.16 - B1.16M - 1984 (Reaffirmed 2006) PDFKristin Jones100% (1)

- Training Manual A 319/320/321: ATA 30 Ice and Rain ProtectionDocumento46 pagineTraining Manual A 319/320/321: ATA 30 Ice and Rain ProtectionHansraj Kayda100% (1)

- AmdDocumento14 pagineAmdObed Andalis100% (1)

- 9702 w22 QP 36 PDFDocumento16 pagine9702 w22 QP 36 PDFsangdeepNessuna valutazione finora

- Applications of 8086Documento38 pagineApplications of 8086Ajay PeterNessuna valutazione finora

- Rules of MixtureDocumento37 pagineRules of MixtureRahmaF.PuspitaNessuna valutazione finora

- Final PPT of Carbon NanotubesDocumento29 pagineFinal PPT of Carbon Nanotubesmkumar_5481450% (2)

- Lehmann Et Al 2013 PDFDocumento13 pagineLehmann Et Al 2013 PDFJack HamiltonNessuna valutazione finora

- 06 Strengthening MechanismsDocumento63 pagine06 Strengthening MechanismsMURALIGOCAM_29070605100% (1)

- Power Amplifiers: Ranjith Office Level 4 - Building 193 - EEE BuildingDocumento19 paginePower Amplifiers: Ranjith Office Level 4 - Building 193 - EEE BuildingArambya Ankit KallurayaNessuna valutazione finora

- AirCheck Detail Report - PK8AP01Documento116 pagineAirCheck Detail Report - PK8AP01Trion Ragil NugrohoNessuna valutazione finora

- The Chemistry Maths Book: Erich SteinerDocumento16 pagineThe Chemistry Maths Book: Erich SteinerDewi MariyamNessuna valutazione finora

- Effect of Altitude On Audible Noise Generated by AC Conductor CoronaDocumento68 pagineEffect of Altitude On Audible Noise Generated by AC Conductor CoronaAhsan MahmoodNessuna valutazione finora

- 3BSE039838R201 en Compact Control Builder SV 4.1 Getting StartedDocumento160 pagine3BSE039838R201 en Compact Control Builder SV 4.1 Getting StartedPatricia MansanoNessuna valutazione finora

- Us 20060145019Documento11 pagineUs 20060145019Raymond100% (4)

- Earthing Transformer and Its Application To The Power SystemDocumento34 pagineEarthing Transformer and Its Application To The Power SystemRathinaKumar100% (1)

- Activities InterventionDocumento2 pagineActivities InterventionDonabel Villasaya CariosNessuna valutazione finora

- DMSM10 Espinosa Fiche de Stage Parachute GBDocumento2 pagineDMSM10 Espinosa Fiche de Stage Parachute GBHasan Junaid HashamNessuna valutazione finora

- Analog Communications-Notes PDFDocumento110 pagineAnalog Communications-Notes PDFjyothimunjam100% (1)

- Chapter 1-Thermodynamic-Merged-CompressedDocumento60 pagineChapter 1-Thermodynamic-Merged-CompressedAina SyafiqahNessuna valutazione finora

- Powerflex 750-Series Ac Drives: Technical DataDocumento242 paginePowerflex 750-Series Ac Drives: Technical DataJosé Santiago Miranda BernaolaNessuna valutazione finora

- ESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayDocumento20 pagineESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayBenNessuna valutazione finora

- Question 197: (Forces Moments) : (At The 50cm Mark)Documento8 pagineQuestion 197: (Forces Moments) : (At The 50cm Mark)ekjon1Nessuna valutazione finora

- Heinrich Maximilian TE Finalsubmission2015august MAScDocumento213 pagineHeinrich Maximilian TE Finalsubmission2015august MAScWilliam Jaldin CorralesNessuna valutazione finora

- 10 People and 10 HatsDocumento1 pagina10 People and 10 HatsCassandra JohnsonNessuna valutazione finora

- RF10 (A4)Documento4 pagineRF10 (A4)Dewa Made Astika YathaNessuna valutazione finora

- Digital Control Engineering 2nd Edition Fadali Solution Manual - Doc254405506Documento23 pagineDigital Control Engineering 2nd Edition Fadali Solution Manual - Doc254405506chyntia50% (4)

- Electricity & Thermal PhysicsDocumento59 pagineElectricity & Thermal Physicsapi-3743896Nessuna valutazione finora