Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 Modelling of Air Pollution Control Equipment

Caricato da

bappabatliboiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3 Modelling of Air Pollution Control Equipment

Caricato da

bappabatliboiCopyright:

Formati disponibili

Available online at http://www.urpjournals.

com

Advanced Engineering and Applied Sciences: An International Journal

Universal Research Publications. All rights reserved

ISSN 23203927

Original Article Modelling of Air Pollution Equipment (ESP)

Anil Sharma1 and Omprakash Sahu2 Department of Chemical Engineering, ITGGV, Bilaspur, India Correspondence author Email:ops0121@gmail.com, Tel:+919752610957 Received 01 May 2013; accepted 21 May 2013 Abstract Performance of Electrostatic Precipitator (ESP) deteriorates over the years and they are not able to meet the required emission standard. In the present paper we discuss the performance of ESPs in a power plant, which is situated right in the centre of a mega city. As the power plant is surrounded by densely populated area of the city the other emission control methods like flu gas treatment with SOx/NOx cannot be applied due to a further risk of pollution. Pulse charging method has also limited scope of further enhancing the particulate collection efficiency of ESPS. The decision was taken to put additional unit of ESP along with existing unit of ESP. Performance Guarantee (PG) tests were carried out for the whole ESP systems. Samples were collected from the inlet and outlet of the each ESP systems. The collection efficiencies were determined for individual and for the whole set of ESPs. The results indicate a significant deterioration of collection efficiency old ESP unit at the level of (90-93%) against designed value of more than 99%. The new ESP unit, which was put ahead of old ESP unit, was operating in the range of (93-96) % of collection efficiency. The overall Collection efficiency of the system exceeded all the time more than 99%. 2013 Universal Research Publications. All rights reserved Keywords: Pollutant, Suspended particulate matter, Sulphur Oxides, Nitrogen Oxide. Therefore, a more rigorous control of SPM is necessary and 1. INTRODUCTION: The concern with the environment is becoming more and the electrostatic precipitator (ESP) stands out as an air more present in the daily life of everyone. An increasing cleaning equipment with high removal efficiency in a wide involvement with the environmental issue is demanded size range, including sub-micron particles [8]. Although from the governments, companies and, eventually, from the relatively well studied, the behaviour of the electrostatic society as a whole. Conscious decisions need to be taken to precipitators lacks experimental data on their performance preserve the ecosystems with minimum interference in the due to the high number of influential parameters, which development of the nations. These ideas are contained in include: particle properties (density, electrical resistivity, the Declaration of Rio on the Environment and size distribution, etc.), process variables (gas velocity, Development approved in the ECO92 [1], which assumes particle concentration, etc.), construction and geometrical as a principle the acquisition and improvement of the elements (electrode type and geometry, space between the necessary scientific knowledge for promoting the plates and electrodes, etc.), and operational variables sustainable development. Of the several aspects involved in (applied potential, corona polarity, dc and pulse the study of air pollution, the presence in the atmosphere of energization, cleaning frequency, etc). Attempting to particles smaller than 2.5 m in diameter is becoming a maximize the performance of the precipitators, many matter of great concern. These particles, known as PM2.5 researchers [8-14] have addressed the problem of or high risk respirable particles have been proved to be very quantifying the influence of some of these variables. harmful to the human health, especially to the children, the However, the quantity of experimental data on the elderly and the sick [2-4]. These particles possess a high performance of electrostatic precipitators is still relatively superficial area, thus favouring the adsorption of toxic scarce, even more in SPM size range [15, 16]. The present substances and increasing the potential harmful effects to work evaluates experimentally the influence of the gas the human organism [5, 6]. SPM is directly associated to velocity, the field strength, the diameter of the discharge asthma, bronchitis, loss of the breathing capacity and has electrodes and of the distance between them in the been pointed as responsible for the decrease of the life performance of a plate-wire precipitator operating in the expectation in some areas [7]. removal of very fine particles. Theoretical predictions are Advanced Engineering and Applied Sciences: An International Journal 2013; 3(2): 21-23

21

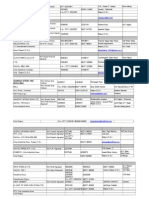

presented and discussed. 2. METHODOLOGY: The basic formula describing ESP performance is the Deutsch equation [17], The ESP collection efficiency, , is defined as: = 1-Zo/Zi (1) Where, Zi and Zo represent the dust concentrations at the inlet and outlet of the ESP. General information provided by ESP manufacturers often calculate ESP efficiency as: = 1- exp -ktotal (2) Where, ktotal is known as the total efficiency factor, which can be calculated as: ktotal = kd k1....kn (3) Where, kd is the efficiency factor in design conditions and k1...kn are several correction factors accounting for operating deviations of the gas and ash flow characteristics. The value of kd is determined by the constructive characteristics of the ESP, mainly the design of its electrodes, its R/T control system, and its rapping system. Correction factors usually refer to volumetric gas flow rate, gas temperature, coal moisture and sulfur content, unburned coal in fly ash, and dust concentration at the ESP inlet. These factors are strongly dependent on the performance of the equipments upstream the ESP (mainly boiler and gas-air preheaters), some global operation criteria (such as excess air), or they are imposed by strategic reasons (e.g., the composition of the coal blend being fired). Equation (2) is just a simplified form of the Deutsch equation: = 1- exp( -w A/Q) (4) Where, w is the migration velocity (m/s), A is the effective collection area (m2), and V is the volumetric gas flow rate (m3/s). White (1977a) and Riehle & Loffler (1992) present interesting studies about the limitations and significance of the Deutsch formula [18-20]. 3. RESULT AND DISCUSSION: (CALCULATION FOR EFFICIENCY OF ESP) The test program at the NTPC Korba Power Station was the test personnel were more experienced with the test equipment. The test program consisted of both mass loading and particle size distribution measurements. Internal inspections and gas velocity distribution measurements were planned for a later date. The ESP upgrade options considered for NTPC. The mass indicate that the ESP is not in as good condition. The model calibration does not provide as good since the specific collecting electrode area is for NTPC. For the worst case coal condition, the upgrade options were rerun the NTPC, This means that the NTPCs ESP must be repaired and brought to a good condition, before the upgrade options will provide the full measure of improvement. Present ESP installed in NTPC Korba which have 98% efficient, now theoretical collection efficiency of ESP is calculating by the Deutsch Anderson equation [21]. It can be used for both tubular and plate type precipitator. This expressed in terms of =1-exp (-Ws x A/Q) Where, A- Area of plate/wire

Ws- Migration Velocity Q- Gas Flow Rate From NTPC Power Station we find, A= Area of the plate=18.55 m2 Q=Gas flow rate inlet=287.28m3/s Ws=Migration velocity of gaseous=59.0m/s Then, =1-exp (-59.0 x 18.55/278.28) =98% Now velocity of the gas can be calculated by the equation v=Q/A =15.48 m/s Volume of the precipitator can calculate by, A/V=2/S Where, S is the distance between the two plates. The specific consumption gas rates 0.82ton/MW/hr. It required the electric load 39MW. From the quality parameter of coal we find that, it contains ash will appox. 0.625 i,e. 62.5% Fly Ash=0.92=92% Now the inlet dust concentration can be calculated, Inlet dust concentration= (39*1000000*0.82*0.92*0.625)/3600*287.78 =17.870gm/m3 Out dust concentration Dust collection efficiency can be define as Ratio of difference in the load to inlet load, and calculated by the equation, From the table no 4.5 & 4.6 we get, Dust collection efficiency = (Inlet-Outlet)/Inlet = (17.87*1000-347.78)/17.87*1000 =98% To determine the pollutant level in chimney probe is used to take the sample. It was observation that the in sample SPM 350g/m3, SOx 165g/m3 and NOx 155g/m3 respectively. But According to Central Pollution Control Board the permissible limit of pollutant in Industrial area are 250g/m3, SOx 150g/m3 and NOx 150g/m3. So it was cross the permissible limit. Now we modified the area of same ESP Our conclusion for NTPC Korba -Efficiency of ESP is defined as the Deusch Anderson equation. =1-exp(-A*Ws/Q) e= exponential factor A= Area=21.8 m (if we are change the area of plate then) Q=Gas flow rate=287.28m/s Ws=migration velocity=59.0m/s For the gas velocity v=Q/A =15.48 Efficiency=1-exp(-59.0 x 21.8/278.28) =99% By applying our modification we get the SPM 200g/m3 , SOx 65g/m3 and NOx 55g/m3 the pollutants level which is under permissible limit. The efficiency of was observed 99%. From the above we find that pollutant level is much low than pollution control board norms. 4. CONCLUSION: The Over-all collection efficiencies for particulate have been improved by putting two ESPs in series. Further improvement is possible on adopting following steps. Plugging of leakage in the boiler / ESP system up to

22

Advanced Engineering and Applied Sciences: An International Journal 2013; 3(2): 21-23

stack. This will minimize infiltration as well as make ID fans operation suitable to create adequate suction in the furnace. Operating the boiler at stable load with minimum fluctuation. Increasing current level of collecting electrodes of NTPC ESPs with lower current in initial fields and higher current in final fields. ACKNOWLEDGE: Authors acknowledge to department chemical engineering ITGGV, Bilaspur and Pollution control department NTPC Korba for providing facilities. REFERENCE: 1. UNEP, United Nations Environment Program, http:// www. unep. org/ Documents. Multilingual, 2005. 2. Ferin, J., G. Oberdrster, D.P. Penney, S.C. Soderholm, R. Gelein and H.C. Pipier, Increased Pulmonary Toxicity of Ultrafine Particles I. Particle Clearance Translocation, Morphology, Journal of Aerosol Science, 21, 381-384 (1990). 3. Oberdrster, G., J. Ferin, G. Finkelstein, P. Wade and N. Corson, Increased Pulmonary Toxicity of Ultrafine Particles II. Lung Lavage Studies, Journal of Aerosol Science, 21, 384-387 (1990). 4. Pui, D.Y.H. and D.R. Chen, Nanometer Particles: a New Frontier for Multidisciplinary Research, Journal of Aerosol Science, 28, 539-544 (1997). 5. Donaldson, K., X.Y. Li and W. MacNee, Ultrafine (Nanometer) Particle Mediated Lung Injury, Journal Aerosol Science, 29, 553-560 (1998). 6. Harrison, R.M. and J. Yin, Particulate Matter in the Atmosphere: Which Particle Properties are Important for its Effects on Health, Science of the Total Environment, 249, 85-101 (2000). 7. US-EPA, U.S. Environmental Protection Agency, Quality Assurance Project Plan for EPA Particle Matter Supersite: PM2.5 Technology Assessment and Characterization Study in New York, http://www.epa.com. (2000). 8. Parker, K.R., Why an Electrostatic Precipitator, Applied Electrostatic Precipitation, K.R. Parker (ed.), London, Blackie Academic, 1-9 (1997). 9. Triantafyllou A.G., PM10 Pollution Episodes As A Function Of Synoptic Climatology In A Mountainous Industrial Area, Environmental Pollution 2001;

112 (3):491-500. 10. James K.B. Bishop: The Correction and Suspended Particulate Matter Calibration of Sea Tech Transmissometer Data. Deep Sea Research Part-A, Oceanographic Research Papers, 2003; 33(1):121-134. 11. Donald J. OConnor and John P. Connolly, The Effect Of Concentration Of Adsorbing Solids On The Partition Coefficient, 2003; 14(10):1517 -1523. 12. Chandra A., Particulate Reduction Using A Series Of ESPs In A Coal Based Thermal Power Plant. Centre For Energy Studies, Indian Institute of Technology Delhi, Jun 2004. 13. Ruilin G., Wenlin M., Jinhua K., Jianbin K., Sizing And Design Of Electrostatic Precipitators For Iron Ore Sinter Band, ICESP X Australia 2006. 14. Huntera P.D., Tylera A.N., Kovacsband A.W., Prestonc T., Spectral Discrination of Phytoplankton Colour Groups: The Effect Of Suspended Particulate Matter and Sensor Spectral Resolution, 2007. 15. Kocik, M., J. Dekowski and J. Mizeraczyk, Particle precipitation efficiency in an electrostatic precipitator, Journal of Electrostatics, 63, 761-766 (2005). 16. Bacchiega, G., I. Gallimbertia, E. Sani, R. Sala, V. Arrondel, M. Hamlil and E. Christensen, Experimental study of the mass balance in a pilot industrial electrostatic precipitator, Journal of Electrostatics, 64, 297309 (2006). 17. Matts S., Ohnfeldt P-O. Efficient gas cleaning with the SF electrostatic precipitator. Flakt Review, Vol. 6/7, 105, 1963/1964. 18. Bart D. Ostro: Air pollution and morbidity revisited: A specification test 1. U.S. Envirinmental Protection Agency, Washington, D.C.,USA , 24thJuly 2008. 19. Sumit Sharma, Avinash Chandra: Simullation of Air Quality using an ISCST3 Dispersion Model. Online Available 25thJan 2008. Volume 36, Issue 1, Pages 118-124. 20. Marieke A. Elevelda, ReinoldPasterkampa and Julie D: Remotely seasonality in the spatial distribution of seasurface suspended particulate matter in the southern North Sea. 2008. 21. Hongli Liu, Changxi Li: Prediction of The Concentration And Diameter Distribution Of Indoor Suspended Particulate Matter. 2009, Kybernetes, Vol.38, Iss:3/4, Pages 381-387.

Source of support: Nil; Conflict of interest: None declared

23

Advanced Engineering and Applied Sciences: An International Journal 2013; 3(2): 21-23

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Air Forces 2016Documento12 pagineAir Forces 2016bappabatliboi100% (6)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 4as Lesson PlanDocumento3 pagine4as Lesson PlanLenette Alagon100% (3)

- BMath3 ProjectDocumento6 pagineBMath3 ProjectRainbow VillanuevaNessuna valutazione finora

- Discovery Issues Resolution Naga NotesDocumento7 pagineDiscovery Issues Resolution Naga NotesNagaPrasannaKumarKakarlamudi100% (1)

- Yaskawa Product CatalogDocumento417 pagineYaskawa Product CatalogSeby Andrei100% (1)

- Ebook PDF Elementary Algebra 4th Edition by Michael III SullivanDocumento41 pagineEbook PDF Elementary Algebra 4th Edition by Michael III Sullivansean.cunningham518Nessuna valutazione finora

- Jump in A Teachers BookDocumento129 pagineJump in A Teachers BookShei QuinterosNessuna valutazione finora

- Paper 3A1 PDFDocumento13 paginePaper 3A1 PDFavmurugan87Nessuna valutazione finora

- Farthest Galaxy Known in The Universe SpottwsDocumento2 pagineFarthest Galaxy Known in The Universe SpottwsbappabatliboiNessuna valutazione finora

- MIUI 6 ManualDocumento53 pagineMIUI 6 ManualbappabatliboiNessuna valutazione finora

- Tips To Improve PC Performance in Windows 10 - Windows HelpDocumento19 pagineTips To Improve PC Performance in Windows 10 - Windows HelpbappabatliboiNessuna valutazione finora

- Biomass Cofiring - New Challenges For ESPDocumento6 pagineBiomass Cofiring - New Challenges For ESPbappabatliboiNessuna valutazione finora

- Audio File SizeDocumento2 pagineAudio File SizebappabatliboiNessuna valutazione finora

- Pickup Velocity For Pneumatic ConveyingDocumento2 paginePickup Velocity For Pneumatic ConveyingbappabatliboiNessuna valutazione finora

- Gas Cleaning Efficiency Requirements For Different PollutantsDocumento5 pagineGas Cleaning Efficiency Requirements For Different PollutantsbappabatliboiNessuna valutazione finora

- CRC Press Math CatalogueDocumento116 pagineCRC Press Math CataloguebappabatliboiNessuna valutazione finora

- Easeus Partition Master User GuideDocumento33 pagineEaseus Partition Master User Guideamineki7639Nessuna valutazione finora

- AOSmith Hse Ses - LeafletDocumento2 pagineAOSmith Hse Ses - LeafletbappabatliboiNessuna valutazione finora

- Book 1Documento4 pagineBook 1bappabatliboiNessuna valutazione finora

- DSD Database - Sheet1Documento2 pagineDSD Database - Sheet1bappabatliboiNessuna valutazione finora

- Samsung Universal Print Driver 2 - User's GuideDocumento15 pagineSamsung Universal Print Driver 2 - User's GuidebappabatliboiNessuna valutazione finora

- 1962 10468053Documento5 pagine1962 10468053bappabatliboiNessuna valutazione finora

- Ipad User GuideDocumento135 pagineIpad User Guidehdave32Nessuna valutazione finora

- Toshiba DVD RecorderDocumento2 pagineToshiba DVD RecorderbappabatliboiNessuna valutazione finora

- Super Audio CD Player With Usb-Dac: WWW - Marantz.EuDocumento2 pagineSuper Audio CD Player With Usb-Dac: WWW - Marantz.EubappabatliboiNessuna valutazione finora

- 1962 10468053Documento5 pagine1962 10468053bappabatliboiNessuna valutazione finora

- Irdac Manual Sh255 e F D N Es R 2Documento12 pagineIrdac Manual Sh255 e F D N Es R 2bappabatliboiNessuna valutazione finora

- Marantz Whitepaper PC-Audio NA-11S1Documento13 pagineMarantz Whitepaper PC-Audio NA-11S1bappabatliboiNessuna valutazione finora

- DSD Database - Sheet1Documento2 pagineDSD Database - Sheet1bappabatliboiNessuna valutazione finora

- Installation WinESP DemoDocumento4 pagineInstallation WinESP DemobappabatliboiNessuna valutazione finora

- Abhishek Steel Industries LTD.: Ganga Steel Re-RollingDocumento14 pagineAbhishek Steel Industries LTD.: Ganga Steel Re-RollingbappabatliboiNessuna valutazione finora

- Belkin Surge ProtectorDocumento2 pagineBelkin Surge ProtectorbappabatliboiNessuna valutazione finora

- Scan - V. CardDocumento1 paginaScan - V. CardbappabatliboiNessuna valutazione finora

- Operation & Maintenance Instructions For Electrostatic PrecipitatorDocumento3 pagineOperation & Maintenance Instructions For Electrostatic PrecipitatorbappabatliboiNessuna valutazione finora

- State Bank of Ndia: Aper TokeDocumento1 paginaState Bank of Ndia: Aper TokebappabatliboiNessuna valutazione finora

- Rebecca Wilman 17325509 Educ4020 Assessment 3Documento6 pagineRebecca Wilman 17325509 Educ4020 Assessment 3api-314401095Nessuna valutazione finora

- Spectrofotometru SpectroDirect (De La Lovibond)Documento360 pagineSpectrofotometru SpectroDirect (De La Lovibond)FlaviusNessuna valutazione finora

- Decision Making Techniques: How To Make Good DecisionsDocumento10 pagineDecision Making Techniques: How To Make Good DecisionsParanthaman RamanNessuna valutazione finora

- Verification ofDocumento14 pagineVerification ofsamuel-kor-kee-hao-1919Nessuna valutazione finora

- Approaches On Gender Equality in Development Cooperation A Comparison Between The International, National and Project LevelsDocumento69 pagineApproaches On Gender Equality in Development Cooperation A Comparison Between The International, National and Project LevelsMzee KodiaNessuna valutazione finora

- Advanced Signal Multi-ScannerDocumento8 pagineAdvanced Signal Multi-ScannerneerajupmanyuNessuna valutazione finora

- Activity Based Costing No.1Documento3 pagineActivity Based Costing No.1joint accountNessuna valutazione finora

- Learning StylesDocumento10 pagineLearning Stylesrose marie RegalaNessuna valutazione finora

- The Role of Youth in ForthDocumento17 pagineThe Role of Youth in ForthSamuel EmmanuelNessuna valutazione finora

- 11 Technical Analysis & Dow TheoryDocumento9 pagine11 Technical Analysis & Dow TheoryGulzar AhmedNessuna valutazione finora

- Medical Technology ScheduleDocumento2 pagineMedical Technology ScheduleCara Veronica MendozaNessuna valutazione finora

- A Lady of Fashion: Report INVALSIDocumento1 paginaA Lady of Fashion: Report INVALSINicole BalboNessuna valutazione finora

- Regional Directorate General of Public Finance of BucharestDocumento8 pagineRegional Directorate General of Public Finance of BucharestAnna MarissNessuna valutazione finora

- Appendix F Sample Erosion and Sediment Control PlanDocumento11 pagineAppendix F Sample Erosion and Sediment Control Planjhj01Nessuna valutazione finora

- Muhammad Adnan Sarwar: Work Experience SkillsDocumento1 paginaMuhammad Adnan Sarwar: Work Experience Skillsmuhammad umairNessuna valutazione finora

- Eng 105 S 17 Review RubricDocumento1 paginaEng 105 S 17 Review Rubricapi-352956220Nessuna valutazione finora

- Sequential Circuit Description: Unit 5Documento76 pagineSequential Circuit Description: Unit 5ramjidr100% (1)

- Genogram and Eco GramDocumento5 pagineGenogram and Eco GramGitichekimNessuna valutazione finora

- Essay Plan and StructureDocumento3 pagineEssay Plan and StructureNinaNCNessuna valutazione finora

- Catalogo Molas PratoDocumento176 pagineCatalogo Molas Pratocassio_tecdrawNessuna valutazione finora

- Attachment 4A Security Classification GuideDocumento42 pagineAttachment 4A Security Classification GuidepingNessuna valutazione finora

- Reformer Tube Inspection: Leo - ScanDocumento5 pagineReformer Tube Inspection: Leo - ScanAnonymous 5odj1IcNessuna valutazione finora

- Thesis Chapter IiiDocumento6 pagineThesis Chapter IiiJohn Rafael AtienzaNessuna valutazione finora

- Angular With Web ApiDocumento32 pagineAngular With Web ApiAnonymous hTmjRsiCp100% (1)