Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Schedule - Power, Chemicals & Utilities

Caricato da

Chandresh YadavDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Schedule - Power, Chemicals & Utilities

Caricato da

Chandresh YadavCopyright:

Formati disponibili

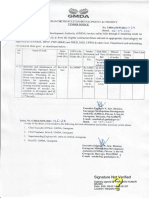

Technical Schedule Power, Chemicals & Utilities Delivered Rates in Rs.

/ Unit Daily Consumpsion

Chemical Utilities Gas Chlorine Dewatering Polyelectrolyte

Units Kg/Day Kg/Day

DATA SHEETS FOR ELECTRICAL ITEMS Sl. No A 1 2 3 4 5 DESCRIPTION POWER TRANSFORMERS Manufacture/ Type Application Standard Type of Cooling Rated KVA Rated Voltage of HV winding (KV) LV winding (KV) Voltage Ratio at different tabs Related Frequency Temperature rise Of oil by Thermometer (OC) Of winding by resistance (OC) No. of Phases Vector Group reference Guaranteed no load losses at 75 degree Centigrade, rated frequency at rated voltage (KW) Total losses at normal ratio, rated frequency and maximum attainable temperature at site (KW) Tolerance no losses Percentage impedance of winding at rated current, rated frequency at 75 degree centigrade (%) Efficiency at rated voltage, rated frequency at 75????? Centigrade (%) Noise level, Db Overall dimensions (L * B * H) Crane lift required (mm) Complete transformer weight (kg) Are radiators detachable (Yes/No) Are all the fittings as per enquiry Specifications Provided on the transformer? (Yes/No) HT PANEL BOARD General Manufacturer/Type Bus Bar VALUE

6 7 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 B 1 A B

C D

E F

2 A B C

E F G H I

3 A B C D E F

Material (Al/Cu) Continuous rating, A Short time ( one second) withstand rating KA (rms) Clearances Between phase, mm Between live part and earth, mm One minute power frequency withstand voltage KV (rms) Thickness of steel sheey Frame, mm Door, mm Cover, mm Dimensions of cubicle (MM) Draw out space required in front (mm) Weight of heaviest cubicle (kg) Circuit Breaker Manufacturer/ Type Rated voltage, v Rated current for various circuit breakers Normal, A De-rating factor for site conditions, A When installed within cubicles,A Method of closing Normal Emergency Type of closing Mechanism Normal rating of closing Mechanism (V/W) Type of tripping Mechanism Normal rate of tripping mechanism Spring changing motor details Output rating (KW) Rated voltage (V) FUSES (FOR PTS) Manufacturer Type Rated voltage (V) Rated current, A Category of duty Rupturing capacity (prospective current), KA

C 1 A B

MCC General Manufacture/Type Whether single front or double front

C D

2 A B C

E F G H I

4 A C 5 A B C D E F G H I J

Fully draw out semi-draw out/fixed type Bus Bar Material (Al/Cu) Continuous rating, A Circuit Breaker Manufacture/Type Rated voltage (V) Rated current for various circuit breakers Normal, A De-rating factor for site conditions, A When installed within cubicles,A Method of closing Normal Emergency Type of closing Mechanism Normal rating of closing Mechanism (V/W) Type of tripping Mechanism Normal rate of tripping mechanism (V/W) Spring changing motor details Output rating (KW) Rated voltage (V) Spring changing time (sec) Isolating Switches Manufacture Type No. of poles Rated voltage (V) Rated continuous current ,A Manufacture FUSES (FOR PTS) Manufacture Rated voltage & current, (V) Motor Contactors Manufacture Type Utilization Category No. of poles Rated voltage for main contacts Rated voltage of coil, v Rated voltage of auxiliary contacts, v Rated (thermal) current, A Rated duty Rated making capacity, KA (rms)

D A B C D E F

LIGHTING FIXXTURES Manufacture/Type Normal working voltage, V Power loss per ballast at nominal working voltage and frequency, W Temperature witnin fixture housing (0C) Guaranteed maximum hot spot temperature of ballast case under site condition (0C) Average total light output per fixture as percentage of combined lamp light output at nominal working voltage and frequency in still air ambient temperature of 45 0C (%)

E 1 A B C D

E 2 A B C D

E 3 A B C D

POWER & CONTROL CABLES 11KV Earthed Grade Power Cables Manufacture Type Rated voltage Continuos current rating with cable laid in air under specified ambient temperature for specified maximum conductor temperature, A Specify various applicable Derating factors 1100V Grade Power Cables Manufacture Type Rated voltage Continuos current rating with cable laid in air under specified ambient temperature for specified maximum conductor temperature, A Specify various applicable Derating factors 1100V Grade Power Cables Manufacture Type Rated voltage Conductor Material Core section, mm2 No. of dia. Of strands

F 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

17

18

19 20 21 22 23

24

25 26

MOTORS Make & type Type of frame size Degree of protection Rotor shaft (solid/hollow) Mounting Rated output Rated voltage and range No. of phases and frequency Load cycle Synchronous RPM Full load speed Starting current Full load current Starting torque in % of full load torque Breakdown torque in % of full load torque Locked rotor withstand time Under hot condition Under cold condition Starting time at minimum starting voltage With load Without load Number of starts permissible Under hot condition Under cold condition Locked rotor with stand time at minimum permissible starting voltage Locked rotor with stand time at 110% voltage Max permissible running time with full load at minimum allowable voltage Method of starting Power factor At full load At load Efficiency At full load At load At load At load Insulation Class Material treatment Tropical & fungicidal treatment Temperature rise over an ambient of 450C while delivering rated output

RPM RPM A A

27 28

29

30 31

32

33 34 35

36 37 38

By resistance method By thermometer method Maximum allowable temperature rise over an ambient of 450C Stator winding Connection Type and nos. of terminal brought out Resistance per phase in ohms at 20 0C Make and no. of embedded temperature detector per phase Range of temperature as per class of insulation Range of temperature Terminal and terminal size for R.T.D Space heater Number Location Capacity Voltage Direction of rotation viewed from driving end Bearing Driving end Non driving end Recommended lubricant a. Type b. Quantity Anticipated bearing life Bearing housing temperature detection arrangement for bearing temperature Terminal boxes for stator winding Phase segregated or not Number provided Fault level up to which terminal; box can be used Location of terminal box viewed from driving end Cable gland size Terminal boxes for Space heater Number provided Location Cable size Cable entry GD2 of motor Critical speed Total weight of motor Weight of stator Weight of rotor

G 1 2 3 4 5 6 7 8

9 10 11 12

13 14

POWER FACTOR IMPROVEMENT CAPACITOR Manufacture Reference specification Type Rated capacity Rated continuos voltage Rated frequency Rated line current Formatting of capacitor Element Shape of element Type of PP/Film/Paper Nos. of capacitor element In series In parallel Type of die electric used Whether unit fuse provided Method of internal connections Maximum operating temperature Type of discharge service Formation of bank Total nos. of capacitor unit per bank Nos. of unit in series per phase Nos. of unit in parallel per phase Dimension of complete bank Whether foot insulators required Whether bus bar material for bank required Whether inter task insulation included Whether interconnecting material included Whether any other item required for erection and commissioning of the bank, if so details and price thereof Tangent of loss angle i.e. lan delta Mounting details of capacitor bank Structural section Dimensions of each unit ( W * D * H ) Weight of each capacitor unit Cable entry box with cable and gland for 3 core cable of the required size Type of neutral displacement protection device provided

KVAR KV A

0C

MM3

RVT/NCT

H 1

DATA SHEET FOR ISOLATOR Manufacturer

2 3 4 5 6 7 8 9

10 11 12 13 14 15

16 17 18 19 20 21

Modal Standard F Rated voltage (KV) Rated current (A) Frequency Nos. of poles Short time withstand current and duration Short time withstand current and peak withstand current type test certificate or report enclosed (YES/NO) Nos. of break in circuit per pole Total length of break per pole Type of contacts Whether indoor or outdoor Whether oil or air break Minimum clearance in air Between poles and Between live parts & earth Type of operation including details of mechanism Weight of insulator and operating mechanism Operating time for opening Operating time for closing Type of interlocks Whether provided with earth switch or not, if provided: details of the earth switch

Electric Load List 1 2 Sr. No. Drive for For Sewage pumping station 1 2 3 Total 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Mechanical coarse screen Conveyor for coarse screen Raw sewage [pumps 3 4 5 6 7 Nos. Nos. Operating Drive operating standby hrs/day rating KW 9 Guaranteed consumed power per day KWH

Total nos.

Mechanical fine screen Fine screen conveyor Grit separator mechanism Grit separator classifier Grit separator organic return pump Air blowers for SBR units RAS Pumps SAS Pumps Sludge sump blower Centrifuge feed pumps Centrifuge Chlorine booster pump DWPE tank agitator DWPE tank dosing pump Other (Valves, Plant Lighting, Electric Hoists etc.)

Total of sewage treatment plant

Grand total

SEWAGE TREATMENT PLANT OPERATING DETAILS Sr. No. I. 1 2 3 4 5 6 II. 1 2

ITEM ELECTRICAL Loads Total connected load Maximum running load Average running load Average power factor Daily average power requirement Annual average power requirement Chemical usage Average dose for chlorine Maximum dose for chlorine Average dose for Dewatering Polyelectrolyte Maximum dose for Dewatering Polyelectrolyte

UNIT KVA KW KW KWH/day KWH/year

VALUE

Mg/l Mg/l Mg/l Mg/l

ESTIMATED NUMBERS OF STAFF AND LABOUR TO BE PROVIDED DURING COMMISSIONING Sr. No. 1 2 3 4 5 6 7 8 9

DESCRIPTION Engineer Chemist Skilled erector Skilled fitter Skilled electrician Skilled instrument technician Foreman Semi-skilled labour Unskilled labour

NOS.

Man Month

ESTIMATED NUMBERS OF STAFF AND LABOUR TO BE PROVIDED DURING O & M Sr. No. 1 2 3 4 5 6 7 8 9 Amount in Rs. Per man month

DESCRIPTION Engineer Chemist Skilled erector Skilled fitter Skilled electrician Skilled instrument technician Foreman Semi-skilled labour Unskilled labour

NOS.

Man Month

Potrebbero piacerti anche

- Alternator Data SheetDocumento6 pagineAlternator Data Sheetnagraj204100% (1)

- LT Cable SizingDocumento12 pagineLT Cable SizingPramod B.WankhadeNessuna valutazione finora

- FGD - Technical DiaryDocumento61 pagineFGD - Technical DiaryanmohieyNessuna valutazione finora

- Technical Schedule: Section - Vi-EDocumento7 pagineTechnical Schedule: Section - Vi-EAnonymous 7ZYHilDNessuna valutazione finora

- DS - 6.6kV HT SWGRDocumento22 pagineDS - 6.6kV HT SWGRcherif yahyaoui0% (1)

- MTU10V1600DS550 550kVA Standby FuelOptDocumento4 pagineMTU10V1600DS550 550kVA Standby FuelOptlcsandovalr989Nessuna valutazione finora

- Fire Water Make Up PumpDocumento7 pagineFire Water Make Up PumpAlvin SmithNessuna valutazione finora

- Load Calculation and Design Sheet for PV SystemDocumento13 pagineLoad Calculation and Design Sheet for PV SystemSanju BabaNessuna valutazione finora

- COVER SHEET FOR LV MOTORS DATASHEETDocumento7 pagineCOVER SHEET FOR LV MOTORS DATASHEETjaikolangaraparambilNessuna valutazione finora

- G3516 (975 Ekw 1218 kVA)Documento7 pagineG3516 (975 Ekw 1218 kVA)Antwon CharlesNessuna valutazione finora

- Technical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedDocumento3 pagineTechnical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated Saturatedkarimakki100% (1)

- 32/7 kV yard componentsDocumento31 pagine32/7 kV yard componentsHarsh TanwarNessuna valutazione finora

- Kohler Marine 500KW 500EOZCDocumento4 pagineKohler Marine 500KW 500EOZCnathandemNessuna valutazione finora

- Lecture Notes - Transformer Installation PDFDocumento28 pagineLecture Notes - Transformer Installation PDFYuvraj Gogoi100% (1)

- 2009 02 M HD 319 0Documento5 pagine2009 02 M HD 319 0ZoebairNessuna valutazione finora

- 1.2 Data Schedule LTB245E1Documento2 pagine1.2 Data Schedule LTB245E1Jose Alberto Jorge JiménezNessuna valutazione finora

- Data Sheet For Power TransformerDocumento3 pagineData Sheet For Power TransformerNakkolopNessuna valutazione finora

- 350EOZC - Gerador KOHLER - Marítimo - Uso Comercial-ServiçosDocumento4 pagine350EOZC - Gerador KOHLER - Marítimo - Uso Comercial-Serviçosgeraldo gilNessuna valutazione finora

- Reozjc: Standard Features Ratings RangeDocumento4 pagineReozjc: Standard Features Ratings RangePapi CruzNessuna valutazione finora

- Big Blue Air Pak: The Power of BlueDocumento4 pagineBig Blue Air Pak: The Power of BlueRaul Izquierdo MoralesNessuna valutazione finora

- C9300ekwStandbyTier3 EMCP4Documento6 pagineC9300ekwStandbyTier3 EMCP4CAR6Nessuna valutazione finora

- Detroit Diesel 8063-7405Documento4 pagineDetroit Diesel 8063-7405Francisco CanidoNessuna valutazione finora

- AHU 20sep11Documento36 pagineAHU 20sep11Tạ Tuấn CườngNessuna valutazione finora

- Comprehensive specifications and ratings for Kohler 10RY/RZ natural gas generator modelsDocumento4 pagineComprehensive specifications and ratings for Kohler 10RY/RZ natural gas generator modelsBianka HernandezNessuna valutazione finora

- Kohler 150kw Prime Gas OilfieldDocumento4 pagineKohler 150kw Prime Gas OilfieldnathandemNessuna valutazione finora

- Datasheet TachogeneratorDocumento4 pagineDatasheet TachogeneratorNurulHidayatNessuna valutazione finora

- 850 KVAR 400v.doc - 400V Capacitor Bank - SpecDocumento10 pagine850 KVAR 400v.doc - 400V Capacitor Bank - Specdeepthik27Nessuna valutazione finora

- Kcn463hag BXXXDocumento4 pagineKcn463hag BXXXPawan SehrawatNessuna valutazione finora

- 0.37 KWDocumento9 pagine0.37 KWManoj KumarNessuna valutazione finora

- EPA-Certified Tier 4 Final Towable GeneratorDocumento4 pagineEPA-Certified Tier 4 Final Towable GeneratorDaniel MorganNessuna valutazione finora

- 10P01 1a e 604 R00 - HCSD - Pump - MotorDocumento17 pagine10P01 1a e 604 R00 - HCSD - Pump - Motorsuleman247Nessuna valutazione finora

- Model: 32EOZD 27efozd: 60 HZ 50 HZ 1-Phase DieselDocumento4 pagineModel: 32EOZD 27efozd: 60 HZ 50 HZ 1-Phase DieselyjmhuguesNessuna valutazione finora

- Untitled Presentation PDFDocumento79 pagineUntitled Presentation PDFshivam choudharyNessuna valutazione finora

- 9-1 Inverter Specifications 9-2 Specifications of Accessories 9-3 Option SpecificationsDocumento26 pagine9-1 Inverter Specifications 9-2 Specifications of Accessories 9-3 Option SpecificationsAlejandro HernandezNessuna valutazione finora

- DC - Traction Motor 752RS1A-Final Test ReportDocumento5 pagineDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNessuna valutazione finora

- ABB Datasheet LV MotorDocumento1 paginaABB Datasheet LV MotorAdam Mukhriz0% (1)

- Technical Data Sheet: Solar PV Module S. No. Description SpecificationDocumento4 pagineTechnical Data Sheet: Solar PV Module S. No. Description Specificationarul skpNessuna valutazione finora

- Datasheet of Equipment - ANNAMDocumento8 pagineDatasheet of Equipment - ANNAMhuyly34Nessuna valutazione finora

- Technical Data 11kV AIS VHIHDocumento6 pagineTechnical Data 11kV AIS VHIHSelvin Francis100% (2)

- Synchro N MotorDocumento18 pagineSynchro N MotorDong BachNessuna valutazione finora

- Model: J300K Diesel GensetDocumento5 pagineModel: J300K Diesel GensetJorge CarrascoNessuna valutazione finora

- Technical Particulars for Punjab Paint Colour and Varnish worksDocumento1 paginaTechnical Particulars for Punjab Paint Colour and Varnish worksRaja ManiNessuna valutazione finora

- Centrifugal PUMP SPECIFICATIONDocumento6 pagineCentrifugal PUMP SPECIFICATIONAlvin Smith100% (1)

- Document No PCPL-0532-4-407-04-12-1 Battery Charger Data Sheet Section - 4 PAGE: 1 of 7 Data Sheet A-1Documento7 pagineDocument No PCPL-0532-4-407-04-12-1 Battery Charger Data Sheet Section - 4 PAGE: 1 of 7 Data Sheet A-1tceterexNessuna valutazione finora

- Please Upload Your Data As Soon As Possible Please For Mechanical Workshop/ N.E.Railway GorakhpurDocumento5 paginePlease Upload Your Data As Soon As Possible Please For Mechanical Workshop/ N.E.Railway GorakhpurANUNAY KUMARNessuna valutazione finora

- Abb GisDocumento17 pagineAbb GisluangkokNessuna valutazione finora

- Technical Bid Evaluation for Electrical WorksDocumento14 pagineTechnical Bid Evaluation for Electrical WorksNavneet SinghNessuna valutazione finora

- Residential & small commercial AC solutionsDocumento2 pagineResidential & small commercial AC solutionsYorgos J. Ramirez PNessuna valutazione finora

- Kohler 20RES SpecsDocumento4 pagineKohler 20RES Specsginger1951Nessuna valutazione finora

- Data Sheet-HV MotorsDocumento4 pagineData Sheet-HV MotorsPramod B.WankhadeNessuna valutazione finora

- 245kV Circuit Breaker GTPDocumento4 pagine245kV Circuit Breaker GTPTejaswi ShuklaNessuna valutazione finora

- Manual Kholer 2000reozddDocumento4 pagineManual Kholer 2000reozddVictorNessuna valutazione finora

- Taylor Power SystemsDocumento4 pagineTaylor Power SystemsTeresa CarterNessuna valutazione finora

- C1100 D5Documento2 pagineC1100 D5anon_568723957100% (1)

- KohlerDocumento4 pagineKohlerAngga ClevneztNessuna valutazione finora

- G5523 KD33Documento4 pagineG5523 KD33Binh NguyenNessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignDa EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNessuna valutazione finora

- Store Deta Elect 10.8Documento2 pagineStore Deta Elect 10.8Chandresh YadavNessuna valutazione finora

- Signature Not Verified: Digitally Signed by PARVEEN KUMAR Bajwa Date: 2021.09.02 14:18:35 IST Location: Haryana-HRDocumento1 paginaSignature Not Verified: Digitally Signed by PARVEEN KUMAR Bajwa Date: 2021.09.02 14:18:35 IST Location: Haryana-HRChandresh YadavNessuna valutazione finora

- CP Fittings Inventory ReportDocumento16 pagineCP Fittings Inventory ReportChandresh YadavNessuna valutazione finora

- Store Deta Elect 10.8Documento2 pagineStore Deta Elect 10.8Chandresh YadavNessuna valutazione finora

- Tendernotice 1Documento1 paginaTendernotice 1Chandresh YadavNessuna valutazione finora

- 21 Candlestick Patterns Every Trader Should KnowDocumento83 pagine21 Candlestick Patterns Every Trader Should KnowAlex Dela RosaNessuna valutazione finora

- Schedule of Rates - RUIDP - 2017Documento575 pagineSchedule of Rates - RUIDP - 2017nimm196267% (3)

- SBR ManualDocumento27 pagineSBR ManualbjhamnaniNessuna valutazione finora

- 13-Annexure 2a - Experience Certificate For Large Diameter Sewer LineDocumento2 pagine13-Annexure 2a - Experience Certificate For Large Diameter Sewer LineChandresh YadavNessuna valutazione finora

- SBR ManualDocumento27 pagineSBR ManualbjhamnaniNessuna valutazione finora

- Technical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCDocumento183 pagineTechnical Analysis: PDF Generated At: Wed, 02 Feb 2011 16:50:34 UTCb87208582100% (12)

- SBR ManualDocumento27 pagineSBR ManualbjhamnaniNessuna valutazione finora

- Enquiry StatusDocumento2 pagineEnquiry StatusChandresh YadavNessuna valutazione finora

- ExperienceDocumento9 pagineExperienceChandresh YadavNessuna valutazione finora

- ExperienceDocumento9 pagineExperienceChandresh YadavNessuna valutazione finora

- Sonipat Data SheetsDocumento35 pagineSonipat Data SheetsChandresh YadavNessuna valutazione finora

- Payment ReceiptDocumento2 paginePayment ReceiptChandresh YadavNessuna valutazione finora

- Instrumentation Data SheetsDocumento28 pagineInstrumentation Data SheetsChandresh YadavNessuna valutazione finora

- Wastewater Treatment MethodsDocumento8 pagineWastewater Treatment MethodszzzamrNessuna valutazione finora

- 012 08808aDocumento19 pagine012 08808asrNessuna valutazione finora

- Unit 1 Electromagnetic Radiation-1Documento23 pagineUnit 1 Electromagnetic Radiation-1Saif YounusNessuna valutazione finora

- DR NTTPSDocumento41 pagineDR NTTPSnagasuresh100% (1)

- 300+ TOP ELECTROSTATIC Multiple Choice Questions and Answers PDFDocumento36 pagine300+ TOP ELECTROSTATIC Multiple Choice Questions and Answers PDFjeet joshiNessuna valutazione finora

- Mth517 WK 10 Matlab: Differential CalculusDocumento2 pagineMth517 WK 10 Matlab: Differential CalculusShavin ChandNessuna valutazione finora

- Capacitance and Esr Meter Using Pic16f873aDocumento74 pagineCapacitance and Esr Meter Using Pic16f873aJ_renoNessuna valutazione finora

- Voltage Protection Relay 900VPR-2: FeaturesDocumento2 pagineVoltage Protection Relay 900VPR-2: FeaturesRahul PallipparaNessuna valutazione finora

- Relief Design SizingDocumento9 pagineRelief Design SizingDark KnightNessuna valutazione finora

- Final Electrostatic Precipitator (Esp)Documento46 pagineFinal Electrostatic Precipitator (Esp)Akshay Shebe100% (1)

- Chapter 8 - GravitationDocumento14 pagineChapter 8 - Gravitationspt007Nessuna valutazione finora

- Phy Lab Manual 2nd SemDocumento34 paginePhy Lab Manual 2nd SemMukesh ChawlaNessuna valutazione finora

- Battery Charger User Manual SEO Optimized TitleDocumento24 pagineBattery Charger User Manual SEO Optimized TitlePhang KumwingNessuna valutazione finora

- Ats 1 Afst Paper 1Documento14 pagineAts 1 Afst Paper 1Aryan GuptaNessuna valutazione finora

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocumento2 pagineMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongNessuna valutazione finora

- 2ndLE Lecture 27 - R10 Rotational DynamicsDocumento22 pagine2ndLE Lecture 27 - R10 Rotational DynamicsMark ReyesNessuna valutazione finora

- How A Current To Pressure Transducer (I - P) Works - Learning Instrumentation AnDocumento2 pagineHow A Current To Pressure Transducer (I - P) Works - Learning Instrumentation AnLeDuNessuna valutazione finora

- Hvdc-Light Technology: Presented byDocumento15 pagineHvdc-Light Technology: Presented bypodila lavanya lavanyaNessuna valutazione finora

- Generator Protection Class DefinedDocumento18 pagineGenerator Protection Class Definedamitbharadwaj7Nessuna valutazione finora

- Korean Embassy Energy Audit ReportDocumento7 pagineKorean Embassy Energy Audit ReportEdeki MondayNessuna valutazione finora

- Experiment No. 3b Particle Size Hydrometer Analysis of SoilDocumento9 pagineExperiment No. 3b Particle Size Hydrometer Analysis of Soilhey cuteNessuna valutazione finora

- Case Study - Line Capacitors - MSEDCLDocumento9 pagineCase Study - Line Capacitors - MSEDCLKordofanNessuna valutazione finora

- Langmuir Probes Experiment GuideDocumento11 pagineLangmuir Probes Experiment GuideAli SafdariNessuna valutazione finora

- Mathcad Solutions To The Chemical Engineering Problem SetDocumento29 pagineMathcad Solutions To The Chemical Engineering Problem SetFelipe ChicrallaNessuna valutazione finora

- Mechanical Properties of FluidsDocumento27 pagineMechanical Properties of Fluidsanon_42348947Nessuna valutazione finora

- Datasheet - Solargiga 560W JMPV-X1 72Documento2 pagineDatasheet - Solargiga 560W JMPV-X1 72tacianoNessuna valutazione finora

- EXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitDocumento9 pagineEXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitCHERUYIOT IANNessuna valutazione finora

- Igcse 22 ElectricchargeDocumento21 pagineIgcse 22 ElectricchargeHany ElGezawy0% (2)

- PUMPS SELECTION GUIDEDocumento82 paginePUMPS SELECTION GUIDEHailu Fekadu100% (1)

- SizingTransformers PDFDocumento1 paginaSizingTransformers PDFNaveen ReddyNessuna valutazione finora

- SPM Physics Paper3 NotaDocumento52 pagineSPM Physics Paper3 Notanlweing100% (2)