Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cryocooler Analysis

Caricato da

Rohit PansaraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cryocooler Analysis

Caricato da

Rohit PansaraCopyright:

Formati disponibili

DC FLOW ANALYSIS OF PULSE TUBE CRYOCOOLER

Prepared by: ROHIT H. PANSARA (B.E. MECHANICAL)

INDEX SR NO. Chapter 1

1.2 1.1

CONTENT Introduction of cryogenics

PAGE NO. 1-11

2

Application of Cryogenic temperature

Limitation of vapour compression Refrigeration system 1.3 Classification of cryocooler 1.3.1 1.3.2 1.3.3 Sterling cryocooler Gifford Mc-Mahon cryocooler pulse tube cryocooler 2 4 5 7 10

Chapter 2

2.1

Pulse tube cryocooler

Working mechanism of pulse tube cryocooler

12-18

12 12 12 14

2.2

conditions of working 2.3 principle of pulse tube cryocooler

2.4

types of pulse tube cryocooler 2.4.1 2.4.2 2.4.3

basic pulse tube cryocooler(BPTC) 14 orifice pulse tube cryocooler(OPTC) 15

double inlet pulse tube cryocooler (DIPTC) 17

2.4.4

inertance type pulse type cryocooler (IPTC) 18

Chapter 3

3.2 3.3

Various loose in pulse tube cryocooler

3.1 Loss due to regenerative ineffectiveness Temperature swing loss Loss due to pressure drop in regenerator

19-23

19 20 21

3.4

Conduction loss

21 2

3.5

Losses due to DC flow

22

Chapter 4

Modeling of DC flow losses

4.1 4.2 The assumption for developing model Governing equation for calculation

24-28

25 27

SR NO.

CONTENT

PAGENO.

Chapter 5

5.1

Result and Discussion

Result for variation in pulse tube cold end Temperature 5.2 5.3 Result for different average pressure Result for different frequency

29-34

29 31 32

CHAPTER 1 INTRODUCTION OF CRYOGENICS

In a Greek language Cryogenics means Creation or Production by means of cold.Cryogenics is a science dealing with low temperature. The low temperature is the governing parameter in any cryogenics application. The temperature range of cryogenic is 0K to 123K. This range separates it from the temperature range generally used in refrigeration engineering.

Cryogenics, the science of producing and maintaining low temperatures, had its beginning in the later half of last century. It is concerned with design and development of cryocoolers that are capable of producing and maintaining low temperature. It is a branch of low temperature physics concerned with the effects of very low temperature was first investigated by Michael Faraday who demonstrated that gases could be liquefied leading to the production of lowtemperature around 173 K.

The first cryogenic temperature system was primarily developed for the solidification of carbon dioxide (CO2) and the liquefaction of a subsequent fractional distillation of gases such as air, O2, N2, H2 and He. Oxygen (O2) was liquefied in 1877 by Coilletet and Pietet. H2 was liquefied in 1898 by Dewar using Joule Thomson expansion gases. The liquid Oxygen boils at 90.2K and liquid Hydrogen at 20.4K.The liquefaction of He (Helium) was accomplished in 1908 by H.Kamerlingh in the famous cryogenic lab of university of LAIDEN. Initially, by evaporation of liquid He (Helium) under high vacuum, the temperature as low as 1.1K was obtained. But by making improvements in apparatus, a temperature of 0.7K was reached by the year 1928.

In term cryocooler is generally used for refrigerators of small size which are capable of reaching temperature below 123K (-150 C). 4

1.1. APPLICATIONS OF CRYOGENIC TEMPERATURE

(1) Cooling infrared sensors used on satellites and in missile guidance, night vision and rescue, atmospheric studies involving ozone hole and green house effect, low noise amplifiers. (2) Commercial purpose such as cryopump for semiconductor fabrication, superconductor for cellular phone station, voltage standards, high-speed computer and process monitoring. (3) Medical purpose like cooling super conducting magnets for MRI (magnetic Resonance and process monitoring). System, SQUIDs (Superconducting Quantum Infrared Device) magnetometer for heart and brain studies, Croyogenic catheter and cryosurgery. (4) Cryogenics Temperature also wildly used in Expansion Fitting, Cryobiology,

Semen Preservation, Cryosurgery, Space Research, Computer Engineering, Cryogenic for under Ground Power Lines, Miscellaneous Uses.

1.2. LIMITATION OF VAPOUR COMPRESSION REFRIGERATION SYSTEM The solidification temperature of the refrigerants limits the use of VCR system for the production of low temperature inherently. The following Table 1.1 shows the freezing temperature of commonly used refrigerants in VCR. Table 1.1: Freezing Temperature of Refrigerants Used in VCR

R-717 (NH3) R-744 (CO2) R-764 (SO2)

Refrigerants Freezing Temp (K)

R-11

R-12

R-21

R-22

R-30

R-40

R-113

162

215.5 138

113

176.4

175.5

238

195.2

216.3

197.4

The refrigerants used must have a freezing temperature well below the required temperature to be obtained. Thus the refrigerants R-113, NH3, CO2 and SO2 cannot be used for low temperature refrigeration systems.

(a) The pressure required to be maintained in the evaporator for the required temperature is far below atmospheric pressure and it is difficult to maintain such high vacuum in the evaporator. The pressure required to be maintained in the evaporator for maintaining 213K for different refrigerants is given below in Table 1.2

REFRIGERANTS R-12 R-22 NH3

VACUUM PRESSURE mm of Hg 590 480 595 Bar 0.776 0.631 0.782

Table 1.2: Evaporator Pressures of Different Refrigerants

b) The specific volumes of the refrigerants at such a low temperature are extremely high and it is difficult to operate the compressors efficiently under such low pressure when large volumes of the gases are to be pumped. c) With decrease in temperature, the compression ratio required may be as high as 200 and it still increases with decrease in evaporator temperature. The desired high compression ratio reduces the volumetric efficiency of the compressors and also results in high temperature of discharge gas leaving the compressor. The single stage reciprocating compressors are limited to compression ratio of 12. As the volume displacements of the reciprocating compressors are very low, they are not used at all for low temperature application. d) The Horse Power (HP) required per ton of refrigeration increase in evaporating temperature. The performance is very poor at low temperature refrigeration system when single stage compressor is used. The COP (Coefficient of Performance) of the VCR is very low for the 6

production of low temperature. Below 173 K the COP of a single stage VCR system is lower than cop of air refrigeration system in the same range of temperature. e) Multistage compressor system can be used to overcome few difficulties but the major drawback of multistage system is that the oil may not return to high-pressure compressor. Oil may accumulate in one of the compressor, starving others. Suitable means as traps equalizing float controls are required to prevent this.

1.3. CLASSIFICATION OF CRYOCOOLERS Device which is use to produce cryogenics low temperature is called as cryocoolers. The term cryocooler has generally been used for refrigerator of small and intermediate size, which is capable to obtain and maintain temperature below 123K. Crocoolers, invented in early 1960, are mainly classified in to two groups. a) Recuperative b) Regenerative The Recuperative types utilize a continuous flow of the cryogen in the one direction, analogous to a DC electrical system. The recuperative coolers use only recuperative heat exchanger and operate with a steady flow of cryogen through the system the compressor operates with a fixed inlet and outlet pressure. If the compress is reciprocating type, it must have inlet and outlet valves to provide steady flow. The uses of valves in compressor needed for recuperative cryocoolers limits the efficiency of the compression process about 50% and significantly limit the overall efficiency of recuperative cryocooler. In the Regenerative cycles the cryogen undergoes an oscillating pressure analogous to an AC electrical system. The compressor or pressure oscillator for the regenerative cycles needs no inlet or outlet valve. However, an oscillating pressure can be generated from a valve compressor by using another set of valves to switch between the high and low pressure sides of the compressor, as is done in the Gifford-McMahon cryocooler. The regenerator has only one flow

channel and the heat is stored for a half-cycle in the regenerator matrix, which must have a high heat capacity (>98%). Expansion type cryocoolers are mainly of three types: 1) Stirling Cryocooler 2) Gifford-McMahon Cryocooler 3) Pulse tube cryocooler 1.3.1 Stirling Cryocooler The cycle consists of four stages as shown in Figure 1. The Figure 2 shows Pressure vs. Volume diagram and temperature profile respectively. The sequence of operations for the Stirling cryocooler is as follows:

Phase 1: During this process the gas is compressed isothermally. During the compression pressure is increase and as the process is isothermal the volume is decreased. For making the process isothermal the heat generated, as the result of compression is removed by heat exchanger at ambient temperature.

Phase 2: During this process the volume of fluid is constant. As fluid passes through the regenerator it been cooled (because the effect of the cold fluid, when it is passed through regenerator during 4 th process). Here also as the temperature decreases, by the constant volume, the pressure is also decreases.

Phase 3: 9

During this process as the displacer is moving part it work freely and displace towards left and fluid get expand. As the fluid is expanded the pressure is decreasing slightly and the volume is increasing. Here we get expansion effects of fluid. As whatever the cooling effects produced is used for making the evaporator at the required temperature, the process is been isothermal expansion. At point D we get maximum cooling effect. Phase 4: During this process, the displacer forced the fluid towards right. The fluid gets hot as it passes through regenerator from left to right. As the volume is been constant the pressure is increasing. Thus, by repetition of these all four phases from 1 to 4 we get the useful and continuous cooling at point D. Stirling cycle cryocooler operate on a closed thermodynamic cycle with two external heat exchange processes and two internal constant volume regenerative processes. It is well known that an ideal Stirling cycle has the same efficiency as that of the Carnot cycle and thus the Stirling system is potentially very efficient. The actual refrigeration available to cool thermal load is that available in an ideal case less the thermal and pneumatic losses in the system. The practical realization of the Stirling cycle has only become possible with the development of efficient regenerator. 1.3.2. Gifford-McMahon Cryocooler: Because of the pressure oscillates everywhere within the Stirling cryocooler, excess void volumes must be minimized to maintain a large pressure amplitude for a given swept volume of the piston. Thus oil removal equipment cannot be tolerated which means that the moving piston and displacer must be oil-free. But long lifetime then becomes difficult to achieve. In the mid of 1960s Gifford and McMahon showed that the pressure oscillation for cryocoolers could be generated by the use of a Distribution Valve that switches between high and low pressure sources. 10

The G-M cryocooler has the same low temperature parts as the Stirling cryocooler. The irreversible expansion through the valves significantly reduces the efficiency of the process, but the advantage of this approach is that it allows for an oil-lubricated compressor with oil-removal equipment on the high side to supply the high and low pressure sources. Oil-lubricated compressors were readily available at low cost from the air-conditioning industry by the mid 1960s with continuous operation. To maintain a 1 to 3 years lifetime for the PTFE based seals on the displacer and the Distribution Valve, G-M used low speeds of 1 Hz to 2 Hz for those two components in the cold head. The cold head could be placed quite some distance from the compressor and connected by flexible lines for the high and low-pressure gas. The G-M cryocoolers are now manufactured at a rate of about 20,000 per year for use in cryo-pumps. Schematic of the Gifford-McMahon cryocooler is shown in Figure1.5

This system consists of a compressor, a cylinder closed at both ends, a displacer within the cylinder and a regenerator. Here no work is transferred from the system during the expansion process. The displacer serves the purpose of moving the gas from one expansion space to another 11

and would do zero work in the ideal case of zero pressure drops in the regenerator. The temperature vs. entropy diagram for G-M cryocooler is shown in Figure 1.6.

The sequence of operations for the Gifford-McMahon Cryocooler is as follows:

Process 1-2: With the displacer at the bottom of the cylinder, the inlet valve is opened and the pressure within the upper expansion space is increased from lower pressure P1 to a higher pressure P2. The volume of the lower expansion space is practically zero during this process because the displacer is at its lowest position. Process 2-3: During this the inlet valve still open and the exhaust valve closed, the displacer is moved to the top of the cylinder. This action moves the gas that was originally in the upper expansion space down through the regenerator to the lower expansion space. Because the gas is cooled as it passes through the regenerator, it will decrease in volume so that gas will be drawn in through the inlet valve during this process to maintain a constant pressure within the system. Process 3-4:

12

With the displacer at the top of the cylinder, the inlet valve is closed and the exhaust valve is opened. Thus by redirecting the 3-way valves and allowing the gas within the lower expansion space for expand to the initial pressure Pi. During this the gas passes through the evaporator and gives the cooling. Process 4-5: The low temperature gas is forced out of the lower expansion space by moving the displacer downward to the bottom of the cylinder. This cold gas flows through a heat exchanger in which heat is transferred to the gas from low temperature sources. Process 5-1: The gas flows from the heat exchanger through the regenerator, in which the gas is warmed back to near ambient temperature.Thus the cycle is repeated in this way and we get the cooling effect.

1.3.3. Pulse tube cryocooler: In Stirling Cryocoolers, the pressure of moving part in the cold region gives rise to vibration, friction, wears and tears problems, which are its main drawbacks. A major advantage of the G-M system is the ease with which several units may be multistage to achieve temperature as low as 15 K to 20 K. The Pulse tube cryocooler develops by Gifford and Longworth derives cooling from the compression and expansion of gas. As the Pulse Tube contains no moving parts in the cold region, it has greater reliability and lifetime than the former ones. The only obstacle to its wide applications is relatively low refrigeration performance as compared to other types. The minimum temperature attained by one stage was much higher than 79 K so 2 or 3 stages are necessary to reach very low temperature. Pulse tube refrigeration is based on the cyclic process such that a gas column with cold and warm end temperatures, Tc and Tw, respectively, is compressed, displaced towards the warm end, expanded, and re-displaced towards the cold end.

13

The process is realized by feeding adequate gas flows to both ends of the tube. Those flow rates must be different in size and in phases. The various types of pulse tube refrigerators differ mainly by the performance of the phase shifter which can by realized by use of passive or active elements. Using those flow rates as basic quantities, alternative types of operational diagrams for describing the differences and the common features of various types of pulse tube refrigerators, are derived. They provide simple means for the basic layout and for its optimization. Those results will be compared with more detailed numeric simulations and also with experiments from the literature. The single stage VCR system for the different refrigerants is limited to an evaporator temperature of 234 K.

14

CHAPTER 2 PULSE TUBE CRYOCOOLER

2.1 WORKING MECHANISM OF PULSE TUBE CRYOCOOLER Pulse Tube Cryocooler was built by Gifford and Longworth [1] in 1960s. It has no moving part in low temperature region and is inherently simple and reliable, with low vibration and long lifetime. Mikulin et al [2] invented Orifice Pulse Tube Cryocooler. He has reached 3.6K with 3stage Orifice Pulse Tube Cryocooler. It uses modest pressure and pressure ratio. It has low refrigeration rate per unit mass flow. In 1989, Shaowei introduced the double inlet method. They obtained the lowest temperature of 132k using Double Pulse Tube Cryocooler while it was 175k obtained from Orifice Pulse Tube under the same operating conditions. S.Zhu built the latest development in the field of Pulse Tube Cryocooler. It has higher efficiency than the previous types.

2.2

CONDITIONS FOR WORKING There are three conditions that are necessary for the Pulse Tube Cryocooler to work:

1. The gas must reach the low temperature point without carrying a lot of heat (as measured by the enthalpy flow in the regenerator). 2. The amplitude of the gas flow and pressure oscillation in the Pulse Tube section must be large enough to carry away (by enthalpy flow) the heat applied to the cold heat exchanger. 3. The phase relationship between the pressure the gas flow in the Pulse Tube section must be appropriate to carry heat away from the cold point (by enthalpy flow from cold end to the hot end). 15

2.3 PRINCIPLE OF PULSE TUBE CRYOCOOLER When a gas at room temperature is admitted to one end of tube (shown in Figure 2.1), closed at far end, so that pressure in tube is raised, there will be a tendency for a temperature gradient to be established within part of the tube.

Figure 2.1: Principle of Pulse Tube Cryocooler

This gradient will be most pronounced if the gas enters with plug flow, without turbulent mixing in tube and with minimal heat transfer to the wall. Then all gas initially within the tube will undergo isentropic compression and its temperature T can be given by relationship:

16

[ ]

This gas is displaced towards the closed end of the tube. Between, gas at hot end region that is at higher temperature due to isentropic compression and the gas at the open end of the tube, which is still at T0, a temperature gradient will be established in the tube. If heat is rejected in the region of closed end (hot end) of the tube to restore the gas temperature to near To and the pressure suddenly released through the opened end of the tube, the gas will be expanded by a near isentropic process back to its original pressure and will reoccupy most of the tube. This gas will be at the temperature below T0, and there for will be capable of performing refrigeration. In the field of cryogenics Pulse Tube Cryocooler is attractive as a high reliability and low vibration cryocooler because there is no moving part at the cold section. Also due to improved thermodynamic efficiency the Pulse Tube Cryocoolers are now getting more importance.

2.4

TYPES OF PULSE TUBE CRYOCOOLER

2.4.1 Basic Pulse Tube Cryocooler (BPTC) The basics Pulse Tube Cryocooler was originally developed by Gifford and Longsworth [1]. It consists of compressor, flow reversing valve, regenerator and an open tube as shown in Figure 2.2. The flow-reversing valve is located after the compressor and controls the pressure in the Pulse Tube.

Operation of the Pulse Tube Cryocooler begins by opening an inlet valve, which permits highpressure gas to flow through the regenerator, where transferring energy to the regenerator cools it. The gas then enters open end of the Pulse Tube where the first heat exchanger is located. The heat exchanger raises the temperature of the gas at constant pressure. This partially heated gas behaves like a gas piston, adiabatically compressing the gas already in the tube. This compression results in a temperature rise of the gas inside the tube and forces the gas to the second heat exchanger.

17

In the second heat exchanger, to maintain a constant temperature the gas is cooled by exchanging heat with cooling water. Once the pressure in the reaches a specified level, the inlet valve closes and the exhaust valve opens, allowing expansion of the gas inside the tube accompanied by a cooling effect. The temperature of the gas leaving the Pulse Tube is lowers that the temperature at which it entered, creating the refrigeration effect. The expanding gas flows back through the exit valve.

Once the original low-pressure level in the pulse tube is reached, the exit valve close, the gas is recompressed polytropically and the process begins again. The lower half of figure 2.1 depicts a temperature versus position graph for the entire refrigeration cycle. By cycling the gas back and forth many times per minute, large temperature gradient can be achieved and maintain.

Figure2.2: Basic Pulse Tube Cryocooler (BPTC)

2.4.2 Orifice Pulse Tube Cryocooler (OPTC) 18

The minimum temperature attained by BPTC was limited to 100K and to go below this temperature it requires multistage. This barrier has been overcome by the important breakthrough made during the last few years.

In 1984, Mikulin et al [2] installed an orifice and gas reservoir at the top of the Pulse Tube to allow some gas to pass in to and out of large reservoir volume. This type of Cryocooler called an Orifice Pulse Tube Cryocooler (OPTC), as shown in figure 2.3. It is capable of reaching much lower temperature than the basic type. Mikulin et al [2] have attained low temperature of 79K.

Figure 2.3:Orifice Pulse Tube Cryocooler (OPTC)

Advantages of OPTC over BPTC are as follows:

a) Only one moving part and that is also at room temperature It uses modest pressure and pressure ratios. It is possible to achieve works on ideal gas, which implies one fluid for all temperature. 19

b) Large orifice will not collect impurities at high temperature part of cycle. c) It has good intrinsic efficiency. d) It can be operate with several stages from the same pressure wave generator.

In OPTC, the available phase angle of gas displacement at the hot end of Pulse Tube corresponding to piston motion is restricted between 00 and 900. Thus OPTC cannot achieve optimum phase angle, which is between 900 and 1800. The other disadvantage is the low refrigeration rate per unit mass flow, which means that the better regenerators are required.

2.4.3 Double Inlet Pulse Tube Cryocooler (DIPTC) S. Zhu et al [3] introduced the double inlet method, which further improved the performance. It was found that due to another inlet at the hot end of the P.T., mass flow from cold end to hot end could be reduced. In other words, refrigeration power per unit mass flow rate through the regenerator will be increased. This type of Pulse Tube cryocooler as shown in Figure 2.4 can be called as DIPTC. The lowest temperature was 132K with DIPTC and 175K using OPTC under same operating conditions.

The experiment also showed that the rate of temperature drop in DIPTC was greater than OPTC, which means increased gross refrigeration.

The main contribution of double inlet Pulse Tube is to adjust the phase shift between the pressure wave and mass flow in the Pulse Tube and to increase their amplitude. It was found that the improvement achieved with DIPTC could be explained by their capability to reach phase angle beyond 900.

20

Figure 2.4: Double Inlet Pulse Tube Cryocooler (DIPTC)

2.5.4. Inertance Type Pulse Tube Cryocooler (IPTC) The earliest use of an IPTR appears to be that reported by Kanao. They measured performance as a function of the diameter and length of the tube, as well as of frequency. They concluded that neither the single orifice nor the double inlet configuration provided better performance than the inertance configuration. The first detailed analysis of the IPTR was reported by Zhu et al [3]. They called the inertance tube the "long neck tube", and carried out computer calculations providing the performance as a function of the diameter and length of the tube. The calculations were verified by an experiment in which a long tube was connected directly between the reservoir and the compressor volume. The inertance tube is placed between the pulse tube proper and the reservoir. For proper values of its length and diameter, this arrangement conceivably results in improved performance, when compared with other arrangements. This is because the inertance tube offers a good deal of flexibility, potentially resulting in oscillating velocity and pressure with a phase relationship similar to that in Stirling refrigerator. Present work comprises of design, development and testing of the inertance type of pulse tube cryocooler. 21

Figure 2.5: Inertance Type Pulse Tube Cryocooler (IPTC)

CHAPTER 3 VARIOUS LOSSES IN PULSE TUBE CRYOCOOLER

It can be revealed from the literature that the pulse tube cryocooler operates on a cycle similar to Stirling cycle. Refrigeration capacity of a cryocoolers decreases due to the losses like regenerator ineffectiveness, shuttle heat conduction, temperature swing, pumping action, instantaneous pressure drop, heat conduction through various solid parts etc. Dead volumes also give rise to losses and should be reduced to minimum. If the effects of all individual losses identified are combined, as they are in the real situation, then the net refrigerating power is substantially reduced from that pertaining to the ideal case. The loss analysis of a cryocooler is very important to estimate the efficiency and realistic performance. 3.1 Loss Due to Regenerator Ineffectiveness: In pulse tube cryocooler the amount of gas that passes through the regenerator is quite large and consequently the load on regenerator is also large. Hence, the regenerator is a critical component that influences the performance of pulse tube cryocooler and the regenerator

22

efficiency is critical to the overall performance. The regenerator performance varies with different mesh structures used and also with properties of mesh matrix material. The incoming gas is cooled to a slightly higher temperature than to which it can, in the regenerator due to its ineffectiveness and thereby causing loss of refrigeration power. As suggested by Miyabe [6] this loss can be calculated as under: ( ) ( ) (13)

The fractional time is the effective fraction of total cycle time during which the steady flow of gas enters into the pulse tube through regenerator. If the effect of pressure change during the gas flow through the regenerator is considered than the above equation can be rewritten as

} .(14)

To calculate this loss on a cyclic basis, the effectiveness is to be calculated for each fractional time in the regenerator. The loss due to ineffectiveness of the regenerator for every interval is to be calculated and summed up to cumulative value of this loss.

3.2

Temperature Swing Loss:

Temperature swing loss accounts for the temperature changes in the matrix of the regenerator during the cycle. It is the heat taken up by the matrix due to its finite capacity. The drop in the temperature of regenerator matrix all along the length due to the single flow of the gas should be calculated as described by Martini [8]. Temperature swing of the regenerator matrix material can be obtained as;

23

) (

.(15) The temperature swing loss is calculated when the gas moves through the regenerator during pressurization process during the cycle and therefore, is equal to

(16)

3.3

Loss Due To Pressure Drop In The Regenerator:

Due to pressure drop in the regenerator and other parts the actual pressure in the pulse tube will be lower than the supply pressure. During the expansion process the gas cant be expanded in the pulse tube to the lowest possible pressure due the same reason. This results in reduction of p-v area of gas III and hence reduction of the refrigeration power. It is dependent of flow acceleration and core friction. The flow acceleration term can be ignored for full cycle. To estimate this loss, first of all the pressure drop is to be estimated based on viscosity of gas, density of gas, mass velocity, Reynolds number and friction factor as under; ( ( )( ) ) .(17) To calculate this loss, the refrigerating effect with this pressure drop is to be subtracted from that obtained without considering pressure drop i.e. the gross refrigeration power.

3.4

Conduction Losses: 24

This loss is basically due to heat conduction from high temperature region to low temperature region. It occurs through the pulse tube, regenerator tube liner and regenerator matrix. These losses also reduce the net refrigeration power and can be calculated from the basic heat transfer equations in the cyclic manner

(i)

Conduction through Pulse tube ( ) ..(18)

(ii)

Conduction through Regenerator Liner ( ) ..(19)

(iii)

Conduction through Matrix ( ) ..(20)

The conductivity of matrix (k Matrix) can be obtained as;

( ( ) )

..(21) The factor KX can be obtained as;

( ( ) )

..(22) Net refrigeration power is calculated by subtracting all the losses from the gross refrigeration power. 3.5 Losses due to dc flow 25

Adding second orifice valve between the hot end of pulse tube and the compressor, according to the opening of the orifice valve dc flow is established in the pulse tube. When the mass flow is counter clockwise from cold end of regenerator to the cold end heat exchanger is called positive dc flow and mass flow is in the clockwise cold end heat exchanger to the regenerator cold end is called negative dc. Complete explanation of the DC flow is in the chapter 4.

CHAPTER-4 MODELLING OF DC FLOW LOSSES

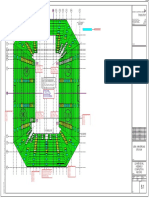

Adding a second orifice valve between the hot end of the pulse tube and the compressor significantly improves the performance by decreasing the mass flow rate through the regenerator that does not contribute to the actual cooling power generation. However, this new configuration also introduces a possibility for unbalanced, unidirectional flow, analogous to direct current in an electrical circuit. Figure 4.1 shows a schematic diagram of a G-M type double-inlet pulse tube refrigerator. During the compression process, high pressure gas flows out of the compressor and is divided into two flow streams one to the hot end of the regenerator, and the other to the hot heat exchanger through the orifice valve. Flow resistances of the regenerator and the double-inlet orifice valve determine the ratio of the mass flow rates into the system. During the expansion process, mass flows from the regenerator and the hot heat exchanger back to the compressor. However, the flow resistance for gas that returns to the compressor can be different from that for the gas coming out of the compressor. Typically orifice valves have directional characteristics, i.e. the mass flow rate at the same pressure ratio may be different when the orifice valve is installed in the reverse direction. Also, in the regenerator, the pressure drop that is represented as 26

flow resistance is a function of the pressure difference between the regenerator ends, as well as the temperature, density and other fluid dynamic values such as velocity. The pressure drop can be different for the compression and expansion process. This potential imbalance in flow resistance can generate a unidirectional net mass flow rate in a pulse tube system. The net mass flow is zero for an ideal balance of flow resistances. However, in actual conditions, the net mass flow can be counterclockwise (i.e., a positive DC flow through the cold heat exchanger) or clockwise (i.e., a negative DC flow through the cold heat exchanger) in figure 4.1 If the system has a positive DC flow, more cold gas flows from the cold end of the regenerator to the cold end of the pulse tube with the result that the gas temperature can be lower during the expansion process. In other words, the system ideally produces more cooling power. However, a positive DC flow also increases the mass flow rate through the regenerator and the pressure drop in the regenerator. The mass flow rate in the regenerator is also unbalanced. On the other hand, a negative DC flow increases the heat load to the cold end of the pulse tube. As the mass flow from the hot end to the cold end of the pulse tube is increased, higher temperature gas may reach the cold end of the pulse tube and this additional mass flow decreases the cooling power of the system. As mentioned above, DC flow causes several different effects and its impact on the system performance is not obvious. In the G-M type pulse tube refrigerator, valves (V1~V4) perform the function of the double-inlet orifice valve. Therefore the system has the possibility for DC flow. The numerical cycle simulation described above can evaluate the direction and amount of DC flow. In present work DC flow in Pulse tube cryocoolers is modeled using MATLAB software. Effect of frequency, cold end temperature, orifice and double inlet opening on DC flow and hence on performance of the system can be studied using the present model. The model is explained in following section. The assumption made to develop the model is listed below.

4.1 The assumption for developing model:

1. Helium, the working gas, behaves as a perfect gas (an ideal gas with constant specific heat). 27

2. Flow in the system is one dimensional, so that there is no velocity component normal to the walls in each component.

3. The effectiveness of the regenerator is unity and the regenerator wall temperature distribution is constant.

4. The pressure drops in the regenerator and connection tubings are neglected. The pressure in the regenerator, pulse tube and heat exchangers are the same at any time.

5. In the cold and hot heat exchangers, the gas temperature is the same as that of the wall temperature of the heat exchanger, which is constant, i.e., heat transfer is perfect in the heat exchanger.

6. In the pulse tube, the flow is adiabatic

7. Flow through the orifice valves is adiabatic.

8. The temperature of the reservoir is isothermal.

28

Figure 4.1 G-M type pulse tube cryocooler

4.2 Governing equation use for calculation. For calculation of mass flow through orifice 3, 4 and 5 we are using nozzle equation because there is needle valve which outlet area is not equal inlet area but it is variable.

29

( ( )( ) ( ) ( ( [ ) ( ) (

) )

]

.. (4.1)

The value of

and

are calculated using above equation of the orifice valve.

Now these values of the mass flow are put in the equation of change in pressure with respect to time dP/dt as below.

]]

.. (4.2)

In above equation

and

are primary flow and it is negligible for calculation of

DC losses so it not use in calculation purpose. Now calculating the mass flow in the regenerator respective equation for mass conservation in regenerator, For mass conservation we are dividing regenerator in to the 5 discrete part because for different part there is different temperature of the part as shown in the figure 4.1.

)

.. (4.3) 30

)

...... (4.4)

)

...... (4.5)

)

.... (4.6)

)

.... (4.7)

And finally we are putting the value of the mr5 in given below equation and we get the value of losses due to DC flow.

*h Where h=Enthalpy of helium at that temperature

.... (4.8)

...... (4.9)

CHAPTER-5 RESULT AND DISCCUSION

31

5.1 Results for variation in pulse tube cold end temperature The present model is used to understand the DC flow losses at various operating parameters. As discussed in earlier section DC flow is harmful but inevitable in pulse tube crycoolers. DC flow is affecting the overall performance of the G-M type pulse tube cryocoolers. Temperature 40 50 60 70 80

0.9017 7.2278 7.4276 1.3235 7.6496 7.0058 1.8076 8.1338 6.5216 2.3497 8.6759 5.9795 2.9464 9.2725 5.3829 Table 5.1 Effect of cold end temperature on cooling power

4.0111 4.7101 5.3609 5.9730 6.5534

Graph 5.1

32

Graph 5.2 Effect of DC flow loss & other losses at different temperature are predicted from model. The result of DC flow loss at cold end temperature is shown in graph 5.1 & net refrigeration power at cold end temperature is shown in graph 5.2.As shown in graph 5.1 cold end temperature increase heat loss due to the DC flow is increase & according to the graph 5.2 as cold end temperature increase net refrigeration power is decrease.

Graph 5.3

33

Graph 5.4 The results are tabulated in table 5.1 regenrator mass flow at various temperature are calculated and shown in graph 5.3 & effect of regenrator mass flow rate on DC flow losses is shown in graph 5.4.In graph 5.3 shows that as cold end temperature increases mass flow through the regenrator increases, and graph 5.4 shows that as mass flow increases DC flow heat loss also increase.

5.2 Results for different average pressure Effect of avarage pressure is studied and results are shown in graph 5.5 & 5.6 for DC loss and refrigeration power respectivly model predicts that lower avarage pressure results in lower losses and higher refrigeration power. The results are tabulated in table 5.2. Pressure 13 14 15 16 17

2.8008 2.9464 3.0858 3.2204 3.3510

9.1269 9.2725 9.4119 9.5465 9.6772

5.5285 5.3829 5.2435 5.1089 4.9783

6.2295 6.5534 6.8634 7.1628 7.4534

Table 5.2 Effect of average pressure on cooling power

34

Graph 5.5

Graph 5.6 As shown in graph 5.5 which is Vs average pressure which is indicated that as average

pressure is increase DC flow loss is also increse, and in graph 5.6 indicate that as average pressure increase net refrigeration power is decreases.

5.3 Resuls for different frequances Effect on DC flow losses and net refrigeration power at different frequency are predicated from the model. The results are tabulated in table 5.3.The resuls of DC losses at different frequency shown in graph 5.7 and net refrigeration power at different frequency as shown in graph 5.8. Frequency 1 4.8562 11.1823 3.4731 10.8012 35

2 3 4 5

4.7176 4.6900 4.6802 4.6756

11.0437 11.0161 11.0063 11.0017

3.6117 3.6393 3.6491 3.6537

10.4928 10.4315 10.4097 10.3995

Table 5.3 Effect of frequancy on cooling power

Graph 5.7

Graph 5.8 In graph 5.7 shows frequency Vs DC loss graph as frequency increases DC losses are decreases and as shown in graph 5.8 shows graph of frequency Vs Qnet as frequency increases net refrigeration power also increases.

36

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Mecha World Compendium Playbooks BWDocumento12 pagineMecha World Compendium Playbooks BWRobson Alves MacielNessuna valutazione finora

- Circular ConvolutionDocumento3 pagineCircular Convolutionseeksudhanshu1Nessuna valutazione finora

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDocumento18 pagineIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamNessuna valutazione finora

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocumento2 pagineLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahNessuna valutazione finora

- Federalist Papers 10 51 ExcerptsDocumento2 pagineFederalist Papers 10 51 Excerptsapi-292351355Nessuna valutazione finora

- Ch-10 Human Eye Notes FinalDocumento27 pagineCh-10 Human Eye Notes Finalkilemas494Nessuna valutazione finora

- 444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16Documento1 pagina444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16whatisNessuna valutazione finora

- Manuel SYL233 700 EDocumento2 pagineManuel SYL233 700 ESiddiqui SarfarazNessuna valutazione finora

- Quotation of Suny PDFDocumento5 pagineQuotation of Suny PDFHaider KingNessuna valutazione finora

- Active Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023Documento119 pagineActive Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023jagdeepchkNessuna valutazione finora

- How Chargers WorkDocumento21 pagineHow Chargers WorkMuhammad Irfan RiazNessuna valutazione finora

- Work Breakdown StructureDocumento8 pagineWork Breakdown StructurerenshagullNessuna valutazione finora

- 02 Object Modeling TechniqueDocumento50 pagine02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdNessuna valutazione finora

- WWW Studocu Com in N 29646569 Sid 01682568219Documento1 paginaWWW Studocu Com in N 29646569 Sid 01682568219Nivetha SelvamuruganNessuna valutazione finora

- Answers For Some QuestionsDocumento29 pagineAnswers For Some Questionsyogeshdhuri22Nessuna valutazione finora

- CATaclysm Preview ReleaseDocumento52 pagineCATaclysm Preview ReleaseGhaderalNessuna valutazione finora

- Instant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdDocumento17 pagineInstant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdLance CorreaNessuna valutazione finora

- SDSSSSDDocumento1 paginaSDSSSSDmirfanjpcgmailcomNessuna valutazione finora

- Information Systems and Supply Chain ManagementDocumento2 pagineInformation Systems and Supply Chain Managementvipinkandpal86Nessuna valutazione finora

- IM1 Calculus 2 Revised 2024 PUPSMBDocumento14 pagineIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoNessuna valutazione finora

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocumento3 pagineTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louNessuna valutazione finora

- Grade 7 Nap MayDocumento6 pagineGrade 7 Nap Mayesivaks2000Nessuna valutazione finora

- Ateneo de Manila University: Submitted byDocumento5 pagineAteneo de Manila University: Submitted byCuster CoNessuna valutazione finora

- 3400 MD IomDocumento52 pagine3400 MD IomIhabNessuna valutazione finora

- State Space ModelsDocumento19 pagineState Space Modelswat2013rahulNessuna valutazione finora

- Case Study - Suprema CarsDocumento5 pagineCase Study - Suprema CarsALFONSO PATRICIO GUERRA CARVAJALNessuna valutazione finora

- NHD Process PaperDocumento2 pagineNHD Process Paperapi-203024952100% (1)

- 0012 Mergers and Acquisitions Current Scenario andDocumento20 pagine0012 Mergers and Acquisitions Current Scenario andJuke LastNessuna valutazione finora

- BBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)Documento2 pagineBBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)NinaNessuna valutazione finora

- Financial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyDocumento3 pagineFinancial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyAsh imoNessuna valutazione finora