Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tomcotechtips: Engine Computer Controls

Caricato da

tipo3331Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tomcotechtips: Engine Computer Controls

Caricato da

tipo3331Copyright:

Formati disponibili

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

TomcoTechtips

Engine Computer Controls

TM

ISSUE 15

second. The computer uses this information to control air/fuel mixture, EGR flow and timing. Mass Air Flow Sensors In order to make a fuel injection system work most effectively we need to have the proper air to fuel ratio. The computer has to be able to calculate the mass of incoming air so it can inject the proper amount of fuel. An efficient way of determining the mass of incoming air is a system that uses a mass air flow sensor (MAF). The

Ford MAP Sensor

In the last issue of Tech Tips, we looked at a type of MAP sensor that sent a varying voltage to the computer in response to pressure changes. Ford's EEC IV systems use a different style MAP sensor called a frequencygenerating pressure sensor. These sensors send a frequency signal to the computer in response to pressure changes. The computer sends a reference voltage to the sensor. This reference voltage is converted to a frequency signal by a solid state switching device inside the sensor. The frequency signal changes in response to sensed pressure differences. This change in frequency is monitored by the computer. At low manifold pressure (high vacuum) the sensor produces a frequency of 92 cycles per second. At wide open throttle (low vacuum) the sensor produces a frequency of 162 cycles per

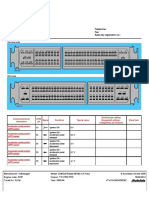

Housing

Circuit Board

Heated Film Ceramic Resister Housing

mass air flow sensor is located in the intake air duct between the air filter and the throttle body. It directly measures the mass of air flowing into the engine. The MAF sensor then sends a proportional signal to the computer. There are different types of mass air flow sensors in use today. We will use the

continued on page 3

Tomco, Inc. 1992

Tomco Tech Tips #15

Electronics 101

RT =

RT =

R1 x R2 R1 + R2

In Figure A this means 10 x 10 = 100 = 5 ohms 20 20

VT 12V

10 ohms R1

10 ohms R2

If we have three or more loads there are two different formulae we can use. The first method of calculating resistance is: RT = 1 1 + 1 + 1 R1 R2 R3

A parallel circuit is a circuit that has more than one path for current to flow on. The loads or electrical devices in this type circuit are placed side by side. In a parallel circuit if one electrical device fails, the other device(s) will continue to work. This is an advantage over the series circuit, in which if one device fails the other one would be inoperative. There are some rules for parallel circuits that we need to take a look at: 1. The voltage drop across each load is the same. 2. The sum of the currents in the circuit is equal to the total circuit current. 3. Loads having different resistance values will have currents that are proportionally different. 4. The total resistance of the total circuit is less than the resistance value of the smallest path. Lets look at some formulae to calculate resistance for parallel circuits. If we have two loads in a parallel circuit we can use the product over the sum method. This formula states that the total resistance is equal to the product of the two resistances divided by the sum of the resistances.

Or, stated another way: 1 RT = 1 + 1 + 1 R1 R2 R3

3R1 I1 VT 12V

In figure B we can calculate the total resistance: RT= 1 1+1+1 3 6 2 RT = 1 ohm = 1 = 1 =1 ohm 4+2+6 12 12 12 12 12

The second method of calculating resistance with three or more loads follows this procedure:

6R2 I2

2R3 I3

Tomco Tech Tips #15

1. Find the individual currents in each of the circuits. 2. Add the currents to get the total current. 3. Divide the total source voltage by the total current to determine total resistance. In Figure B, lets apply this procedure, using Ohms Law: E = I R or I = E R Find individual currents: I1 = V R1 I2 = V R2 I3 = V R3 I1 = 12 = 4 amps 3 I2 = 12 = 2 amps 6 I3 = 12 = 6 amps 2 Figure C's resistance would be calculated as follows: RT= R (of one circuit path)=12= 3ohms N (number of loads) 4 need to do is take the resistance load of one part of the circuit and divide it by the total number of resistances.

12 ohms

12 ohms

12 ohms

12V

Mass Air Flow Sensors

GM AC type mass air flow sensor to continue our discussion. The AC MAF sensor has a cylindrical housing through which intake air is passed. The air first passes over a ceramic resistor which measures the air's temperature. The incoming air is then directed over a heated film. This film is heated to and kept at a temperature of 75o C above the temperature of the incoming air as measured by the ceramic resistor. As air flow is increased or colder air is introduced into the sensor, more power will be required to keep the film heated to 75o C above the incoming air temperature. The extra electrical power needed to keep the film heated is a measure of mass air flow. This extra electrical power is changed to a digital signal which is sent to the computer as a frequency signal. The frequency of a MAF sensor will range from 30 cycles per second to 150 cycles per second.

Add currents to get total current: IT = I1 + I2 + I3 IT = 4 + 2 + 6 IT = 12 amps Using the formula for Ohms Law we can now determine the total resistance: ET 12 1 ohm = RT = IT RT = 12 RT

So the total resistance would be 1 ohm, the same answer we derived from our first formula. These examples also follow our parallel circuit rules: the voltage drop across each load is 12 volts, the sum of the currents is equal to the total current and the total resistance is less than the resistance of the smallest path. If all resistances are equal there is an easier way to figure these values. All we

Inside the computer there are lookup tables which have pre-programmed information. The computer compares the signal from the MAF sensor with these tables to find the air flow rate in grams per second. The computer uses this reading plus engine RPM and air temperature to correctly adjust the air/fuel ratio.

"Masked" Air Flow Sensor

Most GM vehicles from 1985 to 1989 with a 2.8 "W" engine use this AC type mass air flow sensor. This OEM sensor has a high failure rate and has become the source of many driveability problems, including stalling, idling problems and hard starting. This has led to many technical service bulletins (TSBs) from GM to try to correct this problem. One such TSB which came out concerned the 1987-88 "W" engines. This bulletin consists of changing the MAF system back to a speed density system. In this repair the PROM or MEMCAL is updated with a new chip. This PROM change ignores the signals from the MAF sensor and uses signals from the MAP sensor to control fuel supply. MAP sensors are usually not used on MAF sensor systems. These particular vehicles (with 1987-88 "W" engines) have a MAP sensor to help control spark advance and aid the MAF sensor in fuel control. This repair does not include the removal of the MAF sensor. On these

vehicles the MAF sensor contains an air charge temperature sensor which must be used by the speed density system. So, by first glance it may still look like a mass air flow sensor system. The question is: how can we tell if we are dealing with a vehicle that has been converted from a mass air flow system to a speed density system? When this bulletin is performed, the MAF power relay is supposed to be disconnected or removed. This relay is located under the hood by the left front strut tower. The problem is that this repair will still work even if the relay is not removed or disconnected. The best way to tell if the speed density conversion has been performed is to check the system with a scan tool. The scan tool readings will be erratic if the system has been converted. Look at the coolant temperature sensor reading. If the system has been converted, the coolant temperature system reading will stay at -40o C. Next take a look at the elapsed time reading. If the elapsed time does not change or updates in four minute increments, the system has been changed to speed density. Don't get fooled by the masked bandit. Tomco has developed a MAF sensor with a superior design to the OEM sensor. We have redesigned the circuit board to solve the high OEM failure. Tomco's MAF sensor is a quick and lasting fix for the troublesome OEM sensor.

TTT15 Printed in the U.S.A. USA 3.00

Potrebbero piacerti anche

- LG4HKED-WE-VN53 - Engine Control System 4HK1Documento404 pagineLG4HKED-WE-VN53 - Engine Control System 4HK1tuannholtt100% (8)

- 6 L 80Documento8 pagine6 L 80Transmisiones Guero75% (4)

- Electronic Injection Diagnostic Ebook PDFDocumento65 pagineElectronic Injection Diagnostic Ebook PDFscan soft100% (1)

- Fluke - Troubleshooting Auto Electrical SystemsDocumento23 pagineFluke - Troubleshooting Auto Electrical SystemsWesley YoungNessuna valutazione finora

- Automotive Electronics - Vol 2Documento40 pagineAutomotive Electronics - Vol 2Victor Balas100% (14)

- Ranger Drifter Overhaul Manual F161!20!99aDocumento118 pagineRanger Drifter Overhaul Manual F161!20!99aMrSmooth Smooth100% (3)

- Cab&Chaissis ElectricalDocumento323 pagineCab&Chaissis Electricaltipo3331100% (13)

- Automotive Electronic Diagnostics (Course 2)Da EverandAutomotive Electronic Diagnostics (Course 2)Valutazione: 4 su 5 stelle4/5 (2)

- An Intro To Subaru TuningDocumento46 pagineAn Intro To Subaru Tuningkai_isman100% (6)

- ISUZU 4JJ1 Function, Structure, Operation of EngineDocumento40 pagineISUZU 4JJ1 Function, Structure, Operation of EnginePHÁT NGUYỄN THẾ100% (14)

- Engine PDFDocumento254 pagineEngine PDFtipo333194% (18)

- Timming BeltDocumento878 pagineTimming BeltLaila IghaniNessuna valutazione finora

- Marine Electrics Made Simple or How to Keep the Batteries ChargedDa EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNessuna valutazione finora

- Warning & Alarming Instrument 5 & 6Documento28 pagineWarning & Alarming Instrument 5 & 6VivekDhameliyaNessuna valutazione finora

- Codigos Obd RENAULTDocumento1 paginaCodigos Obd RENAULTedsononoharaNessuna valutazione finora

- EGR Valve Emulator EML810/23 Installation Guide: Step ADocumento4 pagineEGR Valve Emulator EML810/23 Installation Guide: Step ASembeiNorimakiNessuna valutazione finora

- PDF Bosch Motronic Me75 18t Aum Pinout DLDocumento14 paginePDF Bosch Motronic Me75 18t Aum Pinout DLSergio AlvarezNessuna valutazione finora

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10Da EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10Nessuna valutazione finora

- 1996 Mazda MPV Workshop Manual - 1501-10-95iDocumento983 pagine1996 Mazda MPV Workshop Manual - 1501-10-95impvclub50% (2)

- Translator DSM 1GDocumento5 pagineTranslator DSM 1Gtcbikerguy6100% (1)

- Sfi SystemDocumento96 pagineSfi SystemWawan SatiawanNessuna valutazione finora

- Exhaust TemperatureDocumento53 pagineExhaust TemperatureSahariar Bin Shafique100% (3)

- 6t70 ATRADocumento6 pagine6t70 ATRAfulltransmission100% (1)

- InstrumentationDocumento8 pagineInstrumentationtingpaduNessuna valutazione finora

- Electrical Online CalculationsDocumento5 pagineElectrical Online Calculationsdarsh2001patelNessuna valutazione finora

- 00 Altima ECU PinoutDocumento8 pagine00 Altima ECU PinoutJimmy Aleman67% (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Conf08presentation SMDocumento333 pagineConf08presentation SMVASEKNessuna valutazione finora

- Sentra 2004 Inmo PDFDocumento20 pagineSentra 2004 Inmo PDFtipo3331100% (2)

- Microsquirt Hardware 3.3Documento152 pagineMicrosquirt Hardware 3.3Amin Rolando Barraza LauraNessuna valutazione finora

- Testing NotesDocumento12 pagineTesting NotesJigar TakoliaNessuna valutazione finora

- VW Passat Sistem InjectieDocumento126 pagineVW Passat Sistem InjectieIulian Doru Mîță100% (1)

- Unit 4-AEEDocumento92 pagineUnit 4-AEEMrs G Hemalatha PSG-PTCNessuna valutazione finora

- Unit 4-AEEDocumento92 pagineUnit 4-AEEMrs G Hemalatha PSG-PTCNessuna valutazione finora

- Optimizer2008 - 2 Calculo de PararrayosDocumento278 pagineOptimizer2008 - 2 Calculo de PararrayosshfedericoNessuna valutazione finora

- Instrumentation Training Tutorial Part4Documento11 pagineInstrumentation Training Tutorial Part4Gary8Nessuna valutazione finora

- ttt3 PDFDocumento4 paginettt3 PDFtipo3331Nessuna valutazione finora

- ttt3 PDFDocumento4 paginettt3 PDFtipo3331Nessuna valutazione finora

- ECU Pin-Out 90-93 MTDocumento1 paginaECU Pin-Out 90-93 MTAkis AlmasidisNessuna valutazione finora

- Manufacturer: Opel/Vauxhall Model: Astra-G 1,8 Engine Code: Z18XE Output: 92 (125) 5600 - Tuned For: R-Cat Year: 2000-06 V9.200Documento4 pagineManufacturer: Opel/Vauxhall Model: Astra-G 1,8 Engine Code: Z18XE Output: 92 (125) 5600 - Tuned For: R-Cat Year: 2000-06 V9.200Danny Alexander Bodegas pinedaNessuna valutazione finora

- API 20.1 Liquid Allocation Measurement 1995Documento7 pagineAPI 20.1 Liquid Allocation Measurement 1995wellington88100% (1)

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Basic GoverningDocumento24 pagineBasic GoverningMohamed RashidNessuna valutazione finora

- IntrvwDocumento67 pagineIntrvwER Balram YadavNessuna valutazione finora

- SenserDocumento2 pagineSenserNurul Huda SobariNessuna valutazione finora

- Automotive Electronics System: GaugesDocumento8 pagineAutomotive Electronics System: Gaugeshadush gebreNessuna valutazione finora

- RE500 Air ManifoldDocumento14 pagineRE500 Air ManifoldAbhishek SrivastavaNessuna valutazione finora

- Em MissionsDocumento3 pagineEm Missionsภูเก็ต เป็นเกาะNessuna valutazione finora

- Instrumentation Training Tutorial4 PDFDocumento11 pagineInstrumentation Training Tutorial4 PDFchdiNessuna valutazione finora

- Project - Arduino MPPT Solar Charge Controller - HackadayDocumento43 pagineProject - Arduino MPPT Solar Charge Controller - Hackadaybazoka fransiskusNessuna valutazione finora

- Power Plant InstrumentsDocumento4 paginePower Plant InstrumentssseshaNessuna valutazione finora

- SCB Article UpdatedDocumento13 pagineSCB Article Updatedjaygee1954Nessuna valutazione finora

- Temperature Control at 19MW On MS5001Documento4 pagineTemperature Control at 19MW On MS5001chdi100% (1)

- 1.8V 0.18 M CMOS Novel Successive Approximation ADC With Variable Sampling RateDocumento5 pagine1.8V 0.18 M CMOS Novel Successive Approximation ADC With Variable Sampling RateMiguel BrunoNessuna valutazione finora

- Chapter 1 Introduction Control SysDocumento52 pagineChapter 1 Introduction Control SysHaliza MatsaniNessuna valutazione finora

- Tomcotechtips: Egr Valve Position SensorsDocumento4 pagineTomcotechtips: Egr Valve Position Sensorstipo3331Nessuna valutazione finora

- P !"#$ P& P P& P) !"#$Documento4 pagineP !"#$ P& P P& P) !"#$Thea AlfonzoNessuna valutazione finora

- HW3.1-5 TU-DelftDocumento4 pagineHW3.1-5 TU-DelftLucho GutierrezNessuna valutazione finora

- Flowmaster v7.0 Easy GuideDocumento109 pagineFlowmaster v7.0 Easy Guidepinenamu100% (1)

- CMETERDocumento16 pagineCMETERHgfdfgh KjhgjhkgNessuna valutazione finora

- ETM TroubleshootingDocumento11 pagineETM TroubleshootingHumberto ClaudinoNessuna valutazione finora

- Star MazdaDocumento40 pagineStar MazdastvnscottNessuna valutazione finora

- Gas Control - Case Study: TopicDocumento5 pagineGas Control - Case Study: TopicMohit GuptaNessuna valutazione finora

- Objectives:: Experiment 7 Open & Closed Loop SystemsDocumento5 pagineObjectives:: Experiment 7 Open & Closed Loop SystemsHennesey LouriceNessuna valutazione finora

- Efi 3Documento2 pagineEfi 3ภูเก็ต เป็นเกาะNessuna valutazione finora

- Chapter 1 EepwDocumento11 pagineChapter 1 EepwPandimadevi SelvakumarNessuna valutazione finora

- Q & A of InstrumentsDocumento86 pagineQ & A of InstrumentsAbdelrahman Mohamed Elshafei100% (1)

- Electrical Basic KnowledgeDocumento10 pagineElectrical Basic Knowledgetushar shindeNessuna valutazione finora

- Application - Mech Engg - 1 - Automotive Applications PPT - Case Study 2 FinalDocumento88 pagineApplication - Mech Engg - 1 - Automotive Applications PPT - Case Study 2 Finalrohinigulhane604Nessuna valutazione finora

- Unidad Electronica para Compresor Velocidad Variable NLVDocumento2 pagineUnidad Electronica para Compresor Velocidad Variable NLVAdán Castro Gallegos100% (1)

- DTrends Feb 2011Documento14 pagineDTrends Feb 2011Rui AllenNessuna valutazione finora

- The Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkDocumento6 pagineThe Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkPrashant Sangulagi100% (1)

- Unit 5Documento38 pagineUnit 5rohanrec92Nessuna valutazione finora

- Review - Three Phase Fault Analysis With Auto Reset For Temporary Fault and Trip For Permanent FaultDocumento4 pagineReview - Three Phase Fault Analysis With Auto Reset For Temporary Fault and Trip For Permanent FaultMukeshNessuna valutazione finora

- Ac Heater System AutoDocumento18 pagineAc Heater System AutoToua YajNessuna valutazione finora

- Feedback Exam ReviewerDocumento5 pagineFeedback Exam ReviewerShania LoveresNessuna valutazione finora

- ATPL Inst 8.3 PDFDocumento4 pagineATPL Inst 8.3 PDFKoustubh VadalkarNessuna valutazione finora

- BTEC Unit 82 HND AerospaceDocumento14 pagineBTEC Unit 82 HND AerospaceCraig JonesNessuna valutazione finora

- Monitoring Equipment Performance With Thermal ImagingDocumento4 pagineMonitoring Equipment Performance With Thermal ImagingRachit SharmaNessuna valutazione finora

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDa EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNessuna valutazione finora

- Parking Brake System: SectionDocumento8 pagineParking Brake System: Sectiontipo3331Nessuna valutazione finora

- Tomcotechtips: Egr Valve Position SensorsDocumento4 pagineTomcotechtips: Egr Valve Position Sensorstipo3331Nessuna valutazione finora

- Tomcotechtips: Air Charge Temperature SensorsDocumento4 pagineTomcotechtips: Air Charge Temperature Sensorstipo3331Nessuna valutazione finora

- Tomcotechtips: Cam and Crank Position SensorsDocumento4 pagineTomcotechtips: Cam and Crank Position Sensorstipo3331Nessuna valutazione finora

- ttt1 PDFDocumento4 paginettt1 PDFtipo3331100% (1)

- Obd1 Toyota Codigos de ECUDocumento42 pagineObd1 Toyota Codigos de ECUDaniel GarciaNessuna valutazione finora

- HME ENG GDS Vehicle SW ManagementDocumento71 pagineHME ENG GDS Vehicle SW ManagementhoangnhuphuocNessuna valutazione finora

- Buick OBD-I Codes Applicable To 93-95 LT1 Equipped CarsDocumento2 pagineBuick OBD-I Codes Applicable To 93-95 LT1 Equipped CarsAndres GaldamesNessuna valutazione finora

- ETM Flow Chart 99 01 New FinalDocumento1 paginaETM Flow Chart 99 01 New FinalHumberto ClaudinoNessuna valutazione finora

- System Component TestsDocumento64 pagineSystem Component Testsdani748Nessuna valutazione finora

- Autel DiagDocumento5 pagineAutel DiagscootdocNessuna valutazione finora

- Final Edition of Automotive QBDocumento15 pagineFinal Edition of Automotive QByoussef faroukNessuna valutazione finora

- Scan Tool Test ProceduresDocumento42 pagineScan Tool Test Proceduresrazaq athabNessuna valutazione finora

- Efi Engine SensorsDocumento2 pagineEfi Engine SensorsraheelNessuna valutazione finora

- Subaru WRX Performance Design GuideDocumento202 pagineSubaru WRX Performance Design Guidegigabyte3235840Nessuna valutazione finora

- Ford Mazda EM MT OHDocumento118 pagineFord Mazda EM MT OHianpramana91Nessuna valutazione finora

- Shema 1Documento2 pagineShema 1anon-78857Nessuna valutazione finora