Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Anexa 19

Caricato da

pokemon69Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Anexa 19

Caricato da

pokemon69Copyright:

Formati disponibili

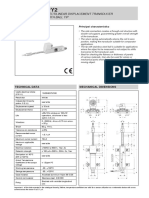

CT ( A - B - C - D)

TOROIDAL FORCE TRANSDUCER FOR

INDUSTRIAL APPLICATIONS

Main features

• Range of measurement: from 100 to 3000 kN

• Accuracy class: 0,5%

• Elastic element in stainless steel

• Corrosion resistant

• Internally generated calibration signal

• Grade of protection: IP65 (DIN 40050)

The CT series force transducers, have been specially desi-

gned for use in polymer processing in applications where it is

required to measure the reaction force produced by the extru-

sion pressure on the gearbox along the axis of the screw.

They measure a force whose value is indicative of the extru-

sion pressure over the area of the screw.

The CT series force transducers can also be used in all other

applications where it is required to measure the forces on

shafts or columns and in any application where the geometry

demands a toroidal form load cell.

TECHNICAL DATA

Accuracy 0,5%

Nominal full scale load (Ln) 100...3000 kN

Nominal output at FSO 2mV/V

MECHANICAL DIMENSIONS

Output tolerance at Ln <± 1% FSO

Load introduction

direction

Combined errors: Non linearity < ± 0,5% FSO

Histeresis, Repeatibility

Creep (after 30 min. at Ln) < ± 0,06% FSO

Zero load out of balance signal < ± 1% FSO

Calibration signal * 80%FSO ± 1%

Thermal drift in Sensitivity < ± 0,02% FSO°C

Load introduction

compensated Zero < ± 0,02% FSO°C surface

range Calibration < ± 0,02% FSO°C

Nominal input resistance 700 Ohm

Isolation resistance > 10 GOhm

Nominal supply voltage 10 V

Maximum supply voltage 15 V

Compensated temperature range -20...+50°C

Maximum temperature range -20...+60°C

Storage temperature range -30...+80°C Dimensions mm. (± 0,1)

Permitted static load 130% Ln mod. Ln (kN) A B C D E F

100 54,2 57,8

Maximum applicable load 150% Ln

CTA 200 46 52,6 59,7 80 45 15

Rupture load > 300% Ln 300 50,7 61,4

200 76,2 81,3

Maximum static lateral load 40% Ln 300 74,9 82,5

CTB 500 70 72,2 84,9 101 45 45

Maximum elastic deformation at Ln < 0,1 mm

750 72 84,7

Grade of protection (DIN40050) IP65 500 102,8 112,1

750 100,2 114,2

Electr. connections: Connector VPT02A10-6PT2 CTC 1000 94 97,9 116,5 140 60 45

1500 95,3 118,6

Elastic element material Stainless steel

1500 124,1 146,2

Case material Anodize aluminium 2000 120,1 149,6

CTD 2500 110 115,8 152,9 196 60 80

* The exact value is indicated on the instrument nameplate. 3000 111,4 156

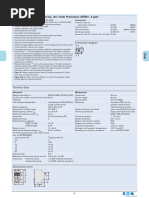

ELECTRICAL CONNECTIONS OPTIONAL ACCESSORIES

Connectors

CONNECTOR CABLE

OUTPUT OUTPUT Female cable connector

SIGNAL + Red Grade of protection IP65 CON300

SIGNAL - Black

EXCITATION + White

6-pin connector with 8m (25ft) cable C08W

EXCITATION - Green 6-pin connector with 15m (50ft) cable C15W

CALIBRATION SHUNT Blue-Orange

6-pin connector with 25m (75ft) cable C25W

6-pin connector with 30m (100ft) cable C30W

Other lengths

consult

factory

APPLICATION NOTE

CONNECTOR

VPT02A10-6PT2 For a correct use of the transducer, it is necessary to ensure

that the load is evenly distributed over the application surfaces

If the transducer is supplied complete with prewired shown in the diagram.

connection cable, the colour code is that indicated in the It is essential to centre the transducer using the circular crown

table. of diameter C and to apply the load installing the transducer

between two grinded surfaces perpendicular to the direction of

Cells connected in parallel the applied load.

Red

Yellow or Black ORDER CODE

White

Green

Yellow-Green

Force transducer CT

Red

Yellow or Black MODEL

White A

Green

B

Yellow-Green

C

Yellow-Green D

Red

Yellow or Black Mod. MEASUR. RANGE (kN)

White

Green

0-100 KN1C

CTA 0-200 KN2C

0-300 KN3C

SHUNT BOX

0-200 KN2C

In systems that use several cells, the parallel 0-300 KN3C

connection automatically sums the loads on each CTB

0-500 KN5C

individual cell. 0-750 KN7.5C

Using this method of measurement, the maximum load 0-500 KN5C

will be the sum of the loads on the individual cells and 0-750 KN7,5C

the sensitivity will be the average value of these cells. CTC

0-1000 KN1M

It is important that the user ensures that no cell is 0-1500 KN1.5M

stessed beyond its maximum rating under any load 0-1500 KN1.5M

condition. 0-2000 KN2M

CTD

0-2500 KN2.5M

0-3000 KN3M

CONVERSION TABLE

If request, it is possible to sup-

ply models with non-standard

Kg N Lb mechanical and/or electrical

features.

1 9.807 2.205

0.102 1 0.225 Ex.: CTC - KN1M

CT force transducer, model C, measurement range

0.454 4.448 1 0 - 1000 kN.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

GEFRAN spa

via Sebina, 74

25050 PROVAGLIO D’ISEO (BS) - ITALIA

ph. 0309888.1 - fax. 0309839063

Internet: http://www.gefran.com

www.gefranonline.com cod. CT - 09/04

Potrebbero piacerti anche

- Load Cell For Tension/Compression Applications: Technical DataDocumento3 pagineLoad Cell For Tension/Compression Applications: Technical DataDfunz WilphenNessuna valutazione finora

- DTS CM 0709 EngDocumento3 pagineDTS CM 0709 EngBruno HauckNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Data Sheet Potenciometro TCC regis2DTS - PA1 - 02-2019 - ENGDocumento3 pagineData Sheet Potenciometro TCC regis2DTS - PA1 - 02-2019 - ENGLuiz Gustavo Santos AlbertoNessuna valutazione finora

- DTS Pa1 01-2013 EngDocumento3 pagineDTS Pa1 01-2013 EngJose Luis Barrueta HernandezNessuna valutazione finora

- SMFT2Documento2 pagineSMFT2noureddineNessuna valutazione finora

- Rectilinear Displacement Transducer With Bearing Tip: Technical Data Mechanical DimensionsDocumento3 pagineRectilinear Displacement Transducer With Bearing Tip: Technical Data Mechanical DimensionsSathish J EceNessuna valutazione finora

- Eng Ds Xftc300 A5Documento4 pagineEng Ds Xftc300 A5Zoltán SoósNessuna valutazione finora

- Protect 8.inv: Industrial InvertersDocumento4 pagineProtect 8.inv: Industrial InvertersMossin SimonNessuna valutazione finora

- AEG Protect-8 INV ENDocumento4 pagineAEG Protect-8 INV ENibs434Nessuna valutazione finora

- Data Sheet Py2 PDFDocumento3 pagineData Sheet Py2 PDFErik HenriqueNessuna valutazione finora

- Protect 8 Inv1 A 3f enDocumento4 pagineProtect 8 Inv1 A 3f enAnonymous 1gQEvRUNessuna valutazione finora

- Ficha Técnica - OVH SWITCHGEAR-TEC-0Documento6 pagineFicha Técnica - OVH SWITCHGEAR-TEC-0Anthony Román V.Nessuna valutazione finora

- DTS Py2 06-2016 EngDocumento3 pagineDTS Py2 06-2016 EngramkrishnapasalaNessuna valutazione finora

- Dbs50e S5ek00500Documento6 pagineDbs50e S5ek00500ganiNessuna valutazione finora

- Eng Ds Xftc310 A4Documento4 pagineEng Ds Xftc310 A4Zoltán SoósNessuna valutazione finora

- Self-Supporting Linear Position Transducer With Magnetic PullingDocumento2 pagineSelf-Supporting Linear Position Transducer With Magnetic PullingGopal HegdeNessuna valutazione finora

- Catalogo Transductores Novotechnik PDFDocumento4 pagineCatalogo Transductores Novotechnik PDFGerEspNessuna valutazione finora

- TLH PDFDocumento4 pagineTLH PDFvalter mNessuna valutazione finora

- TLH PDFDocumento4 pagineTLH PDFhassanchaarNessuna valutazione finora

- Powervar Abcdef5200 22 SpecsDocumento3 paginePowervar Abcdef5200 22 SpecsCarlos BladinieresNessuna valutazione finora

- Balluf BTL0324 PDFDocumento2 pagineBalluf BTL0324 PDFEwin ApriansyahNessuna valutazione finora

- SB6 Beam Load Cell: Product Description ApprovalsDocumento3 pagineSB6 Beam Load Cell: Product Description ApprovalsPhilippe MeynardNessuna valutazione finora

- Celda Huntleigt Modelo 1263Documento3 pagineCelda Huntleigt Modelo 1263Fam. Alarcon RojasNessuna valutazione finora

- Stainless Steel Single-Point Load Cell Stainless Steel Single-Point Load CellDocumento3 pagineStainless Steel Single-Point Load Cell Stainless Steel Single-Point Load CellkorpaapNessuna valutazione finora

- HM460 Double Shear Load Cell - Eng PDFDocumento2 pagineHM460 Double Shear Load Cell - Eng PDFevet cachoNessuna valutazione finora

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocumento2 pagineRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJansirani SelvamNessuna valutazione finora

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocumento6 pagineSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNessuna valutazione finora

- Load CellDocumento3 pagineLoad Celllmriose94Nessuna valutazione finora

- Encoder Rebo Rusa Antigua Dfs60e-Bhcm01000 - 1038159Documento8 pagineEncoder Rebo Rusa Antigua Dfs60e-Bhcm01000 - 1038159colines surpackNessuna valutazione finora

- IS P627 DatasheetDocumento2 pagineIS P627 Datasheetucb51525354Nessuna valutazione finora

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocumento2 pagineRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJan MaksNessuna valutazione finora

- AccelerometerDocumento11 pagineAccelerometerAnonymous i2eRrmmNessuna valutazione finora

- CT 200 DatasheetDocumento2 pagineCT 200 Datasheetjeffv65Nessuna valutazione finora

- HV Full CatalogueDocumento17 pagineHV Full CataloguemaggamNessuna valutazione finora

- Torque Transfer Standard: Special FeaturesDocumento4 pagineTorque Transfer Standard: Special FeaturesdabafiNessuna valutazione finora

- Level Sensor Pancake PR 6251 and Mounting Kit PR 6051: The Space-Saving Solution For Simple ApplicationsDocumento8 pagineLevel Sensor Pancake PR 6251 and Mounting Kit PR 6051: The Space-Saving Solution For Simple ApplicationsDytta AchmadNessuna valutazione finora

- I30s I30iseng0000-587987Documento11 pagineI30s I30iseng0000-587987bffNessuna valutazione finora

- SA5.0 (C) A - SA170 (C) A: 500 Watt Transient Voltage SuppressorsDocumento5 pagineSA5.0 (C) A - SA170 (C) A: 500 Watt Transient Voltage SuppressorsSero StivNessuna valutazione finora

- Celula Carga Single Point pwsmc3 Datasheet PDFDocumento2 pagineCelula Carga Single Point pwsmc3 Datasheet PDFEndang MawarNessuna valutazione finora

- Pressure Transducer: Special FeaturesDocumento4 paginePressure Transducer: Special FeaturesIMP PROYECTONessuna valutazione finora

- Model 240 Model 240: Tedea-HuntleighDocumento3 pagineModel 240 Model 240: Tedea-HuntleighJuan Carlos BallinariNessuna valutazione finora

- 3 72 E EL Linear Electric Actuators 56c1af24ba529Documento10 pagine3 72 E EL Linear Electric Actuators 56c1af24ba529Puja MagfiraNessuna valutazione finora

- SP8 Pesaje Dinamico - B04504 PDFDocumento4 pagineSP8 Pesaje Dinamico - B04504 PDFFernando PastorNessuna valutazione finora

- TP03AL220S03LSW 2W 85-265VAC Input 3.3VDC OutputDocumento3 pagineTP03AL220S03LSW 2W 85-265VAC Input 3.3VDC OutputtoppowerNessuna valutazione finora

- ElectricalDocumento4 pagineElectricalwagner_guimarães_1Nessuna valutazione finora

- Eaton Afdd Catalog Tech en UsDocumento4 pagineEaton Afdd Catalog Tech en UsjenelbNessuna valutazione finora

- Technical Data Sheet 60-80-100-125-160Documento6 pagineTechnical Data Sheet 60-80-100-125-160Florin MNessuna valutazione finora

- RTS DC Servo DriveDocumento4 pagineRTS DC Servo DriveJunaid YNessuna valutazione finora

- Digi SM300 ManualDocumento3 pagineDigi SM300 ManualWilly Bracamonte TellesNessuna valutazione finora

- Inductor Automotive Power Spm5030-Hz enDocumento4 pagineInductor Automotive Power Spm5030-Hz enJulio J. Rodríguez GarcíaNessuna valutazione finora

- RLC78D Draw Wire Sensor: Product Selection GuideDocumento4 pagineRLC78D Draw Wire Sensor: Product Selection GuideTamás HarasztosiNessuna valutazione finora

- 2864 VT DS 2864-EN 614 LoresDocumento3 pagine2864 VT DS 2864-EN 614 Lorestulio enrique leon ayalaNessuna valutazione finora

- LWX Serie 001Documento4 pagineLWX Serie 001Rodica PuscauNessuna valutazione finora

- Catalog Pages Solahd Cvs Hardwired Series Transformers en Us 163818Documento2 pagineCatalog Pages Solahd Cvs Hardwired Series Transformers en Us 163818paulo-956880Nessuna valutazione finora

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Documento3 pagineTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariNessuna valutazione finora

- Gas-Filled Contactor For High-Voltage DC SwitchingDocumento8 pagineGas-Filled Contactor For High-Voltage DC SwitchingIslam Ahmad AbuhamamNessuna valutazione finora

- Datasheet 4Documento2 pagineDatasheet 4Roel GloriosoNessuna valutazione finora

- Some Practical Laboratory ExperimentsDocumento15 pagineSome Practical Laboratory ExperimentsZwinky ManlaiNessuna valutazione finora

- View Interpolation For Image Synthesis: Shenchang Eric Chen, Lance Williams Apple Computer, IncDocumento10 pagineView Interpolation For Image Synthesis: Shenchang Eric Chen, Lance Williams Apple Computer, IncPiyush JainNessuna valutazione finora

- Instruction Cadweld Grounding ConnectionsDocumento2 pagineInstruction Cadweld Grounding ConnectionsadityaprazttNessuna valutazione finora

- 171001Documento2 pagine171001vishalsanziraNessuna valutazione finora

- Seminar Report SampleDocumento22 pagineSeminar Report SampleDhruve EBNessuna valutazione finora

- How To Calculate Boiler BlowdownDocumento2 pagineHow To Calculate Boiler Blowdownagus rasidNessuna valutazione finora

- Soil Science: Classification of PedologyDocumento24 pagineSoil Science: Classification of Pedologyekush amar100% (1)

- Geology Report Group 6Documento19 pagineGeology Report Group 6Muiz Sofi100% (1)

- 27-12-14 SR - Iit-Z (Iz) Co-Spark Jee Main (2011) Ptm-16 Q'paperDocumento23 pagine27-12-14 SR - Iit-Z (Iz) Co-Spark Jee Main (2011) Ptm-16 Q'paperazeemNessuna valutazione finora

- A Handbook of Minerals, Crystals, Rocks and Ores by Pramod O. AlexanderDocumento22 pagineA Handbook of Minerals, Crystals, Rocks and Ores by Pramod O. AlexanderBee PshNessuna valutazione finora

- Physics A+ TestDocumento3 paginePhysics A+ TestMirza Umar Farooq BaigNessuna valutazione finora

- A Review of Piezoelectric Energy Harvesting Based On VibrationDocumento13 pagineA Review of Piezoelectric Energy Harvesting Based On VibrationardnetirarhsimNessuna valutazione finora

- Shrinking Core ModelDocumento10 pagineShrinking Core ModelscribdNessuna valutazione finora

- Instruction Manual PHE PDFDocumento78 pagineInstruction Manual PHE PDFzniperxNessuna valutazione finora

- WEEK 5 Dot Product and WorkDocumento10 pagineWEEK 5 Dot Product and Workmaria1345Nessuna valutazione finora

- Comportamiento y Diseño de Puentes Extradosados PDFDocumento176 pagineComportamiento y Diseño de Puentes Extradosados PDFJulio Rafael Terrones Vásquez100% (1)

- XRF Theory PDFDocumento258 pagineXRF Theory PDFXONΔΡΑΚΗΣ ΓΙΩΡΓΟΣ100% (1)

- Effect of Specimen Thickness and Stress Ratio On Fatigue Crack Growth After A Single Overload Cycle On Structural SteelDocumento8 pagineEffect of Specimen Thickness and Stress Ratio On Fatigue Crack Growth After A Single Overload Cycle On Structural SteelKamal MankariNessuna valutazione finora

- Andover Standard Bandpass FiltersDocumento15 pagineAndover Standard Bandpass FiltersAshish ChaturvediNessuna valutazione finora

- RDM-chapter 1Documento35 pagineRDM-chapter 1Mat MatttNessuna valutazione finora

- Datasheet BSS66Documento1 paginaDatasheet BSS66Diego DiazNessuna valutazione finora

- Kanako Detailed ManualDocumento74 pagineKanako Detailed ManualastikaprasiddhaNessuna valutazione finora

- Rankine Cycle Notes PDFDocumento6 pagineRankine Cycle Notes PDFmizpah mae jolito0% (1)

- Week 3 Earth Science FINALDocumento4 pagineWeek 3 Earth Science FINALMichael DelivaNessuna valutazione finora

- Multi Phase Flow in WellDocumento149 pagineMulti Phase Flow in WellOmar 'Tanzania'100% (1)

- Cauchy Riemann EquationDocumento6 pagineCauchy Riemann EquationeSinist3rNessuna valutazione finora

- Chap 4Documento18 pagineChap 4api-3702256100% (2)

- Modeling of Temperature Distributions in Canned Tomato Based Dip During Industrial PasteurizationDocumento7 pagineModeling of Temperature Distributions in Canned Tomato Based Dip During Industrial PasteurizationHugo GermaniNessuna valutazione finora

- Experimental and Theoretical Study of Pool BoilingDocumento11 pagineExperimental and Theoretical Study of Pool Boilingvaibhav pawarNessuna valutazione finora