Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coating Thickness Gauge

Caricato da

carlosDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Coating Thickness Gauge

Caricato da

carlosCopyright:

Formati disponibili

COATING THICKNESS GAUGE TT210

Features:

ISO 9001

Two measuring methods: magnetic induction (F) and eddy current (N) (Refer to page AAA for details) Magnetic induction (F) method is used to measure the thickness of non-magnetic coating on ferrous metal Eddy current (N) method is used to measure the thickness of nonconducting coating on non-ferrous materials Automatic recognition of substrate Automatic selection of measuring methods 5 statistical ways: Mean values / Max. values / Min. values / testing numbers.(No.) / standard deviations (S.DeV) Upper-lower limit setting and sound alarm Data output to printer TA230 or PC by RS232 500 readings can be stored 2 measuring modes: continuous / single 2 stop ways: Manual/automatic

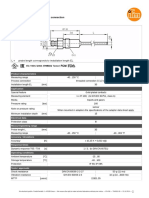

Technical Specification

Probe types Measuring methods Measuring range Display resolution One point calibration Two points calibration Min. curvature radius (mm) Measuring condition Min. testing area diameter (mm) Critical thickness of substrate (mm) Power supply Working Temperature Dimensions Weight 110mm (3%H+1) F magnetic induction 0 to 1250 0.1 (3%H+1.5) N eddy current 0 to 1250 0 to 40 (for chromeplate on copper) Standard Delivery Main unit Calibration foil set Substrate AAA 1.5V battery Waist pack for main unit Instruction manual TIME certificate Warranty card Optional Accessory Convexity 1.5 Convexity 3 Printer TA230 (see page 47) Connecting cable 7 5 1 1 2 1 1 1 1 1

Tolerance

H means the thickness of tested piece [(1~3)%H+1] [(1~3)%H+1.5]

H means the thickness of tested piece

0.5 Battery AAA 1.5V (2pcs) 0-40 50mm 100g 36

0.3

23mm

ISO 9001

COATING THICKNESS GAUGE TT211

Features:

Economical model with F probe integrated Single point measurement mode Easy calibration on zero point 3 kinds of adjustable resolution for different application High speed data collection Automatically switch off Easy conversion between mm and inch

Technical Specification

Probe types Measuring methods Measuring range Display resolution Tolerance Min. curvature radius (mm) Measuring condition Min. testing area diameter (mm) Critical thickness of substrate (mm) Power supply Working Temperature Dimensions Weight 110mm 1 (3%H+1) F magnetic induction 0 to 1250 5 (3%H+1.5) 10 (3%H+10) Standard Delivery Main unit Substrate Battery Waist pack for main unit Instruction manual TIME certificate Convexity 1.5 Warranty card 1 1 1 1 1 1 1

H means the thickness of tested piece

0.5 Battery AAA (2pcs) 0-40 50mm 100g 23mm

37

COATING THICKNESS GAUGE TT220/230

Features:

TT220: integrated probe F TT230: integrated probe N 2 measurement modes: continuous / single

ISO 9001

5 statistical ways: Mean values / Max. values / Min. values / testing numbers.(No.) / standard deviations (S.DeV) 15 measurement readings stored low battery indication Automatically switch off Real time or batch printing with TA230 printer

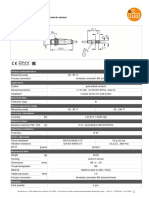

Technical Specification

TT220 Probe types Measuring methods Measuring range Display resolution One point calibration Tolerance : Two points calibration Min. curvature radius (mm) Measuring condition Min. testing area diameter (mm) Critical thickness of substrate(mm) Power supply Working Temperature Dimensions Weight 150mm 1 (0.1 F magnetic induction 0 to 1250 when thickness is less than 10 ) TT230 N eddy current Standard Delivery Main unit Charger Calibration foil set substrate Protection pocket Instruction manual TIME certificate Warranty card Optional Accessory Printer TA230 (see page 47) Connecting cable 7 5 (3%H+1.5) 1 1 1 1 1 1 1 1

(3%H+1)

H means the thickness of tested piece [(1~3)%H+1] [(1~3)%H+1.5]

H means the thickness of tested piece Convexity 1.5 Convexity 3

0.5

0.3

Rechargeable NiMH battery (2pcs) 0-40 53mm 150g 38 22mm

ISO 9001

COATING THICKNESS GAUGE TT260

Features:

Two measuring methods: magnetic induction (F) and eddy current (N) 6 types of probes are available for various applications 2 measurement modes: continuous / single 5 statistical ways: Mean values / Max. values / Min. values / testing numbers.(No.) / standard deviations (S.DeV) memory up to 495 readings Direct testing mode and block statistics mode (APPL/BATCH) Direct print out of statistical values Dataview for connecting with PC is available Low battery indication 2 switch off modes: manual and auto

Technical Specification

Measuring range Probes available Tolerance Minimum resolution Measuring condition Operation language Standards Calibration Statistics Data memory Limits Interface Working temperature power supply Dimensions Weight English DIN, ISO, ASTM,BS Zero and foil calibration Number of measurements, mean, standard deviation, maximum and minimum of 3000 readings 495 readings Adjustable with alarm RS-232 0-40 Nicd rechargeable batteries 1.25V 270mm 86mm 530g 47mm See table in the next page Standard Delivery Main unit Probe Charger Calibration foil substrate Instruction manual TIME certificate Warranty card Optional Accessory 6 optional probes PC software Dataview Calibration foils in different thickness Connecting cable 1 1 1 1 1 1 1 1

39

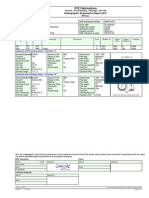

OPTIONAL PROBES AND APPLICATION GUIDE

Optional probes and technical specification

Probe model Operating principle Measuring range( Low range resolution( ) ) 0-400 F400 F1 F1/90 F10 N1 Eddy current 0-10000 10 (3%H+10) 0 to 1250 0 to 40 (for chromeplate on copper) 0.1 (3%H+1.5)

ISO 9001

CN02

Magnetic induction 0-1250 0.1 (3%H+1)

10~200 1 (3%H+1)

Accuracy

One-point calibration( ) Two-point calibration( ) Min curvature of the min area (mm) [(1~3)%H+0.7]

[(1~3)%H+1]

[(1~3)%H+10]

[(1~3)%H+1.5]

Convex 1

1.5

Flatten

10

Flatten

Measuring conditions Diameter of the min area (mm) Critical thickness of substrate (mm) 3 7 40 5 7

0.2

0.5

0.3

unlimited

Application of two measuring methods Magnetic induction (F) Coating: non-magnetic material Substrate (base): magnetic material Eddy current (N) Coating: non-conductors Substrate (base): non-magnetic metals

Any non-magnetic materials such as gold, copper, zinc, tin, lead, resin, rubber, glass and so on.

Any non-conductors such as painting, synthetic resin, rubber, glass and so on.

Any magnetic materials such iron, steel, cobalt and nickel.

Any non-magnetic metals such as brass, copper, aluminum and so on.

40

Potrebbero piacerti anche

- Ultrasonic Thickness GaugeDocumento5 pagineUltrasonic Thickness GaugecarlosNessuna valutazione finora

- 6 Medidor de Espesor de Recubrimiento TT211Documento1 pagina6 Medidor de Espesor de Recubrimiento TT211Claudio FloresNessuna valutazione finora

- Ultra Conic Thickness Gauge Tt110Documento3 pagineUltra Conic Thickness Gauge Tt110kmats7770Nessuna valutazione finora

- Triaxial Icp® Accelerometer: 339A30 Performance English SI Optional VersionsDocumento1 paginaTriaxial Icp® Accelerometer: 339A30 Performance English SI Optional VersionssarathNessuna valutazione finora

- SS 30.30x en PDFDocumento2 pagineSS 30.30x en PDFJharey Japon ReynosaNessuna valutazione finora

- Ultrasound ReportDocumento2 pagineUltrasound ReportMung Duong XuanNessuna valutazione finora

- Portable Hardness TesterDocumento9 paginePortable Hardness TestercarlosNessuna valutazione finora

- Product Characteristics: Pressure SensorsDocumento2 pagineProduct Characteristics: Pressure SensorsnvkjayanthNessuna valutazione finora

- Acceptence Criteria IMTEDocumento12 pagineAcceptence Criteria IMTEdanaka007100% (1)

- Features: Explosion ProofDocumento2 pagineFeatures: Explosion Proofhussein javanNessuna valutazione finora

- HOMMEL TESTER T500 Technical DataDocumento1 paginaHOMMEL TESTER T500 Technical DataAnonymous 8rb48tZSNessuna valutazione finora

- Digital Pressure Transmitter DTM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsDocumento4 pagineDigital Pressure Transmitter DTM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- TT3050 01 - en GBDocumento2 pagineTT3050 01 - en GBSoumyabrata PradhanNessuna valutazione finora

- Data Sheet HB03PBT7KDocumento2 pagineData Sheet HB03PBT7Kasipahi6116Nessuna valutazione finora

- Temperature Sensor With Process Connection: L Probe Length Corresponds To Installation Length ELDocumento2 pagineTemperature Sensor With Process Connection: L Probe Length Corresponds To Installation Length ELImad YahyaNessuna valutazione finora

- 11 - 819EN Rev BDocumento8 pagine11 - 819EN Rev Bvinodk335Nessuna valutazione finora

- Dtk-A Displacement Transducer: - Small and Square Shape - For Push/ Pull - Direct Reading ScaleDocumento2 pagineDtk-A Displacement Transducer: - Small and Square Shape - For Push/ Pull - Direct Reading ScalevanhaimtaNessuna valutazione finora

- Brosur EuromagDocumento4 pagineBrosur EuromagAnnisa Dipva MaryamNessuna valutazione finora

- Medidor de Espessura CTS-30CDocumento2 pagineMedidor de Espessura CTS-30CGésseca NatáliaNessuna valutazione finora

- Pressure Transmitter For Level Measurement TM/N: Features Typical ApplicationsDocumento4 paginePressure Transmitter For Level Measurement TM/N: Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- Bourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDDocumento2 pagineBourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDbehnamatgNessuna valutazione finora

- Edison Mod SonicDocumento2 pagineEdison Mod SonicEsam HamadNessuna valutazione finora

- URNDT ACCUR-1 Ultrasonic Thickness Gauge: Unirew Group Co.,LtdDocumento4 pagineURNDT ACCUR-1 Ultrasonic Thickness Gauge: Unirew Group Co.,LtdFrancisco Javier Villegas AndersonNessuna valutazione finora

- Microsoft Word - ACCUR-1 Catalogue PDFDocumento4 pagineMicrosoft Word - ACCUR-1 Catalogue PDFDarwin Zuni RosadoNessuna valutazione finora

- Pressure Transmitter ATM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsDocumento4 paginePressure Transmitter ATM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- Bimetal Thermometer With Pt100 Electrical Output Signal Model 54, Stainless Steel VersionDocumento5 pagineBimetal Thermometer With Pt100 Electrical Output Signal Model 54, Stainless Steel VersionRajendra LabadeNessuna valutazione finora

- Accelerometer, IcpDocumento2 pagineAccelerometer, IcpLuis LongoNessuna valutazione finora

- Masibus 408 - Legacy IndicatorDocumento2 pagineMasibus 408 - Legacy IndicatorPrabodh ChandimaNessuna valutazione finora

- Pressure Transmitter Intrinsically Safe: TM/ExDocumento3 paginePressure Transmitter Intrinsically Safe: TM/ExJoseph TaylorNessuna valutazione finora

- Ds Uhp Wuc 1x en Us 20710Documento10 pagineDs Uhp Wuc 1x en Us 20710behnamatgNessuna valutazione finora

- Anti-Spatter Inductive Prox: Ordering InformationDocumento9 pagineAnti-Spatter Inductive Prox: Ordering InformationBULLSPDFNessuna valutazione finora

- Datasheet Z F IMAGER 5006h PDFDocumento2 pagineDatasheet Z F IMAGER 5006h PDFRajNessuna valutazione finora

- 2 DANA-T230 Manual Book Through Coating Ultrasonic Thickness GaugeDocumento33 pagine2 DANA-T230 Manual Book Through Coating Ultrasonic Thickness Gaugecesardario90Nessuna valutazione finora

- Temperature Transmitter TS 100: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsDocumento4 pagineTemperature Transmitter TS 100: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- NG5021Documento2 pagineNG5021Fred Johonatan Lopez CoaquiraNessuna valutazione finora

- CT - PT Analyzer GDHG-106B Updated PDFDocumento2 pagineCT - PT Analyzer GDHG-106B Updated PDFLeonardo De La ViaNessuna valutazione finora

- Transmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsDocumento4 pagineTransmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- Electrical Specifications: AC TRMS Clamp With Flexible Jaws Up To 3000ADocumento1 paginaElectrical Specifications: AC TRMS Clamp With Flexible Jaws Up To 3000AZaid HadiNessuna valutazione finora

- Sony Lty (Z) 460hb01 App000Documento31 pagineSony Lty (Z) 460hb01 App000ВМалиновNessuna valutazione finora

- SI5000 Thermal Flow SwitchDocumento3 pagineSI5000 Thermal Flow Switchehab8320014413Nessuna valutazione finora

- E2j Ds e 5 1 csm456Documento7 pagineE2j Ds e 5 1 csm456Tien Dung HoNessuna valutazione finora

- Temperature Measuring Instrument (3-Channel) : Testo 735 - Highest Accuracy Thanks To System AdjustmentDocumento8 pagineTemperature Measuring Instrument (3-Channel) : Testo 735 - Highest Accuracy Thanks To System AdjustmentDefrydiba FarhandinataNessuna valutazione finora

- Pos.7 - Temperature Sensor - TT5050 ENGDocumento3 paginePos.7 - Temperature Sensor - TT5050 ENGДмитрий МазуренкоNessuna valutazione finora

- YT YS3000A Crush TesterDocumento3 pagineYT YS3000A Crush TesterEng.Abdalla QassemNessuna valutazione finora

- Torsion Testing MachineDocumento5 pagineTorsion Testing Machinegosaye desalegnNessuna valutazione finora

- SR4000 Data SheetDocumento8 pagineSR4000 Data Sheetn4arjun123Nessuna valutazione finora

- Shimaden T71 - H71 - TH71Documento4 pagineShimaden T71 - H71 - TH71Erica BeasleyNessuna valutazione finora

- Pressure Transmitter With 2 Set Points Atm/Gr: Features Typical ApplicationsDocumento4 paginePressure Transmitter With 2 Set Points Atm/Gr: Features Typical ApplicationsJoseph TaylorNessuna valutazione finora

- Memograph rsg40 Ti133ren - 0707Documento20 pagineMemograph rsg40 Ti133ren - 0707cristianmihaiNessuna valutazione finora

- TS2789 00 - en UsDocumento2 pagineTS2789 00 - en UsCemil KabakNessuna valutazione finora

- High Temperature: Industrial VRS Magnetic Speed SensorsDocumento8 pagineHigh Temperature: Industrial VRS Magnetic Speed SensorsHernan GirautNessuna valutazione finora

- 4 Inch Magnetic Flux Leakage Inspection Vehicle: RS 04 SA 01Documento1 pagina4 Inch Magnetic Flux Leakage Inspection Vehicle: RS 04 SA 01fadialkasrawiNessuna valutazione finora

- Bourdon Tube Test Pressure Gauges: EN 837-1 With NABL Traceable Calibration Certificate Solid Front Pattern (On Request)Documento2 pagineBourdon Tube Test Pressure Gauges: EN 837-1 With NABL Traceable Calibration Certificate Solid Front Pattern (On Request)kausikrNessuna valutazione finora

- BAW M18ME-UAC50B-BP03 Ordering Code: BAW0022: Cable, 3m, PUR PNP / AnalogDocumento2 pagineBAW M18ME-UAC50B-BP03 Ordering Code: BAW0022: Cable, 3m, PUR PNP / AnalogFrancisco Salas GalvanNessuna valutazione finora

- L-Dens 427F Ex Density Sensor SpecificationsDocumento6 pagineL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNessuna valutazione finora

- Micro Precision Positioning Table IKODocumento8 pagineMicro Precision Positioning Table IKOhexapodo2Nessuna valutazione finora

- Ultrasonic Thickness Gauge TT100: Technical SpecificationsDocumento1 paginaUltrasonic Thickness Gauge TT100: Technical SpecificationsSatyendra TyagiNessuna valutazione finora

- GTT200 Hirschmann Temperature TransmitterDocumento2 pagineGTT200 Hirschmann Temperature TransmitterWaskita IITNessuna valutazione finora

- Asme b31g Calculation Eml-4Documento3 pagineAsme b31g Calculation Eml-4GRANRICKY100% (4)

- Ndtspec Radiographic Nde ReportDocumento1 paginaNdtspec Radiographic Nde ReportcarlosNessuna valutazione finora

- Weld ProcedureDocumento2 pagineWeld ProcedurecarlosNessuna valutazione finora

- 1463520118Documento2 pagine1463520118carlosNessuna valutazione finora

- Zetec Ultravision EC DatasheetDocumento2 pagineZetec Ultravision EC Datasheetcarlos0% (1)

- RotoUTscan v8Documento2 pagineRotoUTscan v8carlosNessuna valutazione finora

- Winter 2018 Registration FormDocumento1 paginaWinter 2018 Registration FormcarlosNessuna valutazione finora

- VM Products Gain Test Box2Documento16 pagineVM Products Gain Test Box2carlos100% (1)

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedDocumento6 pagineSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosNessuna valutazione finora

- Aero Fab Catalog 2014Documento23 pagineAero Fab Catalog 2014carlosNessuna valutazione finora

- NDT MarketplaceDocumento1 paginaNDT MarketplacecarlosNessuna valutazione finora

- Setup Guide No 4 Weld Inspection WeldcheckDocumento7 pagineSetup Guide No 4 Weld Inspection WeldcheckcarlosNessuna valutazione finora

- OmniSX MX2 Training 4A PA Calculator OverviewDocumento10 pagineOmniSX MX2 Training 4A PA Calculator OverviewcarlosNessuna valutazione finora

- Eddyliner PX User ManualDocumento146 pagineEddyliner PX User ManualcarlosNessuna valutazione finora

- 811 2800 - PFINDER 280 - Flyer - GB - v2Documento1 pagina811 2800 - PFINDER 280 - Flyer - GB - v2carlosNessuna valutazione finora

- Tofd PCNDocumento22 pagineTofd PCNmarforall5205Nessuna valutazione finora

- Cygnus 1 Manual V617ADocumento42 pagineCygnus 1 Manual V617AMichael JordanNessuna valutazione finora

- AAR Manual of StandardsDocumento40 pagineAAR Manual of StandardsKristian Marchena100% (3)

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocumento34 pagine2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- Omniscan Setup - Basic SetupDocumento29 pagineOmniscan Setup - Basic SetupcarlosNessuna valutazione finora

- 30mm CalibrationDocumento10 pagine30mm CalibrationcarlosNessuna valutazione finora

- OmniSX MX2 Training 5A Weld and Part Wizard UseDocumento15 pagineOmniSX MX2 Training 5A Weld and Part Wizard Usecarlos100% (1)

- OmniSX MX2 Training 4C Phased Array WedgesDocumento37 pagineOmniSX MX2 Training 4C Phased Array WedgescarlosNessuna valutazione finora

- OmniSX MX2 Training 4B Phased Array ProbesDocumento49 pagineOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- HDV Accessories: Videoscope Camera Probes & AccessoriesDocumento1 paginaHDV Accessories: Videoscope Camera Probes & AccessoriescarlosNessuna valutazione finora

- 3dii BrochureDocumento6 pagine3dii BrochurecarlosNessuna valutazione finora

- 3 OmniSX GettingStarted PA Weld AnalysisDocumento16 pagine3 OmniSX GettingStarted PA Weld AnalysiscarlosNessuna valutazione finora

- 4.omniscan Setup - Min-Wheel Encoder SetupDocumento13 pagine4.omniscan Setup - Min-Wheel Encoder SetupcarlosNessuna valutazione finora

- Omniscan Setup - Basic SetupDocumento29 pagineOmniscan Setup - Basic SetupcarlosNessuna valutazione finora

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocumento34 pagine2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 1 OmniSX GettingStarted Touchscreen UseDocumento25 pagine1 OmniSX GettingStarted Touchscreen UsecarlosNessuna valutazione finora

- Cep MPDocumento1 paginaCep MPAzmat HabeebNessuna valutazione finora

- A Tutorial On Spectral Sound Processing Using Max/MSP and JitterDocumento16 pagineA Tutorial On Spectral Sound Processing Using Max/MSP and Jittertramazio0% (1)

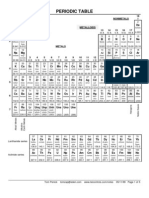

- Periodic Table and AtomsDocumento5 paginePeriodic Table and AtomsShoroff AliNessuna valutazione finora

- The Number MysteriesDocumento3 pagineThe Number Mysterieskothari080903Nessuna valutazione finora

- TE-419891-001 - 862-U-2301 - BIOCIDE DOSING PACKAGE - Rev.BDocumento12 pagineTE-419891-001 - 862-U-2301 - BIOCIDE DOSING PACKAGE - Rev.Brizwan.zamanNessuna valutazione finora

- Solution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFDocumento10 pagineSolution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFa40095824643% (14)

- Hitachi HDDs Repair Scheme Based On MRT ProDocumento21 pagineHitachi HDDs Repair Scheme Based On MRT ProvicvpNessuna valutazione finora

- Math 10 Q2 Week 5Documento3 pagineMath 10 Q2 Week 5Ken FerrolinoNessuna valutazione finora

- Bhagwat Gita in by EB KarkiDocumento97 pagineBhagwat Gita in by EB KarkiYogaguru Mohan100% (1)

- Balancing of Reciprocating MassesDocumento74 pagineBalancing of Reciprocating MassesBharaniSai100% (1)

- N5X Tuning SpreadsheetDocumento79 pagineN5X Tuning SpreadsheetWhyAnN20Nessuna valutazione finora

- MD Manu en Megaflex WebDocumento58 pagineMD Manu en Megaflex WebPhu, Le HuuNessuna valutazione finora

- Geomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruDocumento11 pagineGeomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruVayolait BardNessuna valutazione finora

- Watchgas AirWatch MK1.0 Vs MK1.2Documento9 pagineWatchgas AirWatch MK1.0 Vs MK1.2elliotmoralesNessuna valutazione finora

- Type 85 Di Box DatasheetDocumento2 pagineType 85 Di Box DatasheetmegadeNessuna valutazione finora

- T 096Documento3 pagineT 096abelNessuna valutazione finora

- Solenoid ValveDocumento76 pagineSolenoid ValveazlanNessuna valutazione finora

- MOVIDRIVE-B Lab7Documento6 pagineMOVIDRIVE-B Lab7GrungeokêNessuna valutazione finora

- WEEK 1, Grade 10Documento2 pagineWEEK 1, Grade 10Sheela BatterywalaNessuna valutazione finora

- (Complete) Electrolysis of Copper SulphateDocumento4 pagine(Complete) Electrolysis of Copper SulphateNoooooNessuna valutazione finora

- Sentinel Visualizer 6 User GuideDocumento227 pagineSentinel Visualizer 6 User GuideTaniaNessuna valutazione finora

- Genbio 1 NotesDocumento1 paginaGenbio 1 NoteselishaNessuna valutazione finora

- Chapter 6 AssignmentDocumento6 pagineChapter 6 AssignmentRohit RajeevNessuna valutazione finora

- Optimization of Decarbonization On Steel IndustryDocumento28 pagineOptimization of Decarbonization On Steel Industrymsantosu000Nessuna valutazione finora

- Systems - of - EquationsDocumento39 pagineSystems - of - EquationsAnonymous 5aPb088W100% (1)

- Data and Specifications: HMR Regulated MotorsDocumento21 pagineData and Specifications: HMR Regulated MotorsBeniamin KowollNessuna valutazione finora

- List of GHS Hazard Statement & PictogramsDocumento33 pagineList of GHS Hazard Statement & PictogramsKhairul BarsriNessuna valutazione finora

- Formula Sheet: Basic Trigonometric IdentitiesDocumento4 pagineFormula Sheet: Basic Trigonometric Identitieschetan temkarNessuna valutazione finora

- 3x Exemplar 2017 en PDFDocumento4 pagine3x Exemplar 2017 en PDFgudzalovNessuna valutazione finora

- Food Preparation, Terms and DefinitiosDocumento2 pagineFood Preparation, Terms and DefinitiosLacsi, Erica Joy V.Nessuna valutazione finora