Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hardness Equation For Ormosils

Caricato da

Teoria-MDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hardness Equation For Ormosils

Caricato da

Teoria-MCopyright:

Formati disponibili

Journal of Sol-Gel Science and Technology 19, 627630, 2000 c 2000 Kluwer Academic Publishers. Manufactured in The Netherlands.

Hardness Equation for Ormosils

AKIO MAKISHIMA Department of Materials Science, Faculty of Engineering, University of Tokyo, Hongo, 113-8656 Japan

makisima@glass.mm.t.u-tokyo.ac.jp

J.D. MACKENZIE Department of Materials Science and Engineering, University of California, Los Angeles, CA, 90024 USA

Abstract. Hardness of ormosils coating on various kinds of substrates is important, and by considering recent progresses in understanding the hardness of ionic crystals or covalent crystals, new hardness equations for calculating the hardness of glasses or ormosils from chemical compositions were derived. When we applied an indenter to the surface of glass or sol-gel coatings, the surface of indenter is a declined one to the at surface of glass or coating, thus the applied force should be analyzed by using the shear modulus, S , and Youngs modulus, E . This is now well accepted for the analysis of hardness of ionic or covalent bonding inorganic materials. For example, by considering the binding energy and plastic deformation, Gilman showed that Hv of NaCl crystal can be calculated by an equation including elastic stiffness which indicated a good agreement between calculated and observed value. For covalent crystals he reported that the strength of chemical bonds could be correlated with the glide (shear) activation energy for covalent crystals quantitatively. These explanations are basically applied to the hardness of silicate glasses and ormosils. By considering both shear modulus and Youngs modulus we have derived equations for calculating the hardness of glasses or ormosils from chemical composition, which includes packing density of atoms and bond energy per unit volume has been taken account. The agreements between calculated and observed hardness values for ormosils were comparatively good. Keywords: hardness equation, ormosils, sol-gel coating, shear modulus, silicate glass

1.

Introduction

Organically modied silicates (ormosils) are synthesized by chemically incorporating organic polymers and into inorganic networks and can be prepared by the reaction of tetraethoxysilane (TEOS) and polydimethylsilane (PDMS) in sol-gel method. Hardness of ormosils coating on various kinds of substrates is important. Especially this organic and inorganic hybrid coatings on the plastics attracts much attention, and increasing the values of scratch hardness or hardness of the coating is technologically interesting from the standpoint of practical use of plastics. In this paper the authors report the deriving new hardness equations for calculating the hardness of glasses

To

whom all correspondence should be addressed.

and ormosils from chemical compositions by considering recent progresses in understanding the hardness of ionic crystals or covalent crystals. A bulk modulus, K , is dened for three dimensional and hydrostatically applied forces which is compression or tension and this modulus is commonly used for thermodynamically discussion or mechanical properties in uids. A Youngs modulus, E , is dened for one dimensionally applied forces which is compression or tension to the sample. Hardness, H , is dened by the P / A, forces, P , per area, A. Area A is commonly determined by the measuring by the size of indentation after unloading. However more strictly speaking the hardness, H , must be determined underloading. When we applied an indenter to the surface of glass, the surface of indenter is a declined one to the at

628

Makishima and Mackenzie

surface of glass, thus the applied force should be analyzed by using the shear modulus, S , and Youngs modulus, E . This is now well accepted for the analysis of hardness of Ionic or covalent bonding inorganic materials. For example, for NaCl crystal, by considering the binding energy and plastic deformation, J.J. Gilman [1, 2] derived an equation and reported that Hv of NaCl crystal can be calculated by the following equation: Hv(calcu) = 1.2 103 C44 (1)

is related with shear modulus, S , and also the breaking strength of the chemical bonds. The compaction or densication, Rd, is a overlapping of elastic and shear stress because the applied pressure is not entirely hydrostatics and produces an interlocking of networks and breaking some bonds as reported by Mackenzie [4]. Thus the Eq. (2) can be written as R (( E )( S )( SE)1/2 )1/3 (3)

where, C44 is elastic stiffness (=shear modulus). For very pure single NaCl the Hv(calcu) is 17 kg/mm2 and the Hv(obs) is 16.7 kg/mm2 . These results showed a good agreement between calculated and observed values. For covalent crystals Gilman [3] reported that the difference between the energy of LUMO (the lowest unoccupied molecular orbital) and HOMO (the highest occupied molecular orbital) determines the strength of chemical bonds, and it can be correlated with the glide (shear) activation energy for covalent crystals quantitatively. These explanations are basically applied to the understanding of hardness of oxide silicate glasses, and the interpretation of hardness of glass should be consistent with the explanation of hardness for ionic or covalent materials. Same situation can be considered for oxide glasses, for example, SiO2 glass of which chemical bondings are mixtures of ionic and covalent bondings. Si O bond is 51% ionic and 49% covalent according to Pauling. In other words, chemical bonds of high bonding strength mainly contribute for hardness and it is important for understanding of hardness based on the effects of shear modulus, S , on the solid materials. 2. Deviation of Hardness Equations of Glasses and Ormosils

where is a relative bond strength comparative to Si O bond as described by Yamane and Mackenzie [5]. Thus the Eq. (3) becomes R ( SE)1/2 Since E = 2(1 + ) S (5) (4)

where, is Poissons ratio, and the Eq. (4) becomes as follows: R (2(1 + ))1/2 S (6)

If we suppose as hardness, H , is related to the resistance, H = R (7)

where is a material constant. Then hardness, H , of materials will become as H = (2(1 + ))1/2 S (8)

If we suppose that Re, Rf and Rd are resistance to compression, shear and compaction or densication for glass underloading of indentater, respectively, the resistance for the deformation, R , would be overlapping of these resistances. Thus, R = (Re Rf Rd)1/3 (2)

The Eq. (8) is similar to the J.J. Gilmans equation [2] for NaCl crystal as Eq. (1). If we apply the Eq. (8) to the Vickers Hardness of glass, Hv, Hv = {2(1 + )}1/2 S (9)

For SiO2 glass, using the observed values for S : 314 Kbar, : 0.162 by Spinner [6], and Hv is 650 Kg/mm2 by Neely [7], and is one, Eq. (9) will become as Hv = 1.36{2(1 + )}1/2 S (10)

Re is elastic compression and related with Youngs modulus, E , and Rf, is a ow caused by shear stress and

Hardness Equation for Ormosils

629

Since the Poissons ratio of glass is related with the packing density of atoms [8], Vt, which the authors derived before [8, 9]. = 0.5 1/7.2 Vt Equation (10) will become as, Hv = 1.36 2 1.5 1 7.2 Vt

1/2

sonogel is used as a reference to obtain C and the value is 0.387 as reported by Iwamoto and Mackenzie [10] Therefore the hardness equation for ormosilis is as follow Hv = 1.99 10.8 Vt 1

1/2

(11) Vt3/2 G (18)

(12) 3. 3.1. Calculation and Discussion Silicate Glasses

This equation means that if the packing density of atoms, Vt, becomes bigger, the hardness will becomes bigger by the square root of the packing density of atoms. The shear modulus of the glassy materials, S , directly relates to the packing density of atoms and the bonding energy per unite volume, G , as the authors [8, 9] reported before and is described as below: S = 7.2 Vt2 G /(10.8 Vt 1) Combining Eq. (12) and (13) we can get, Hv = 5.16 10.8 Vt 1

1/2

By supposing three-dimensional hydrostatic pressures during the densication process the hardness equation of glass was derived by Yamane and Mackenzie [5], and they adopted a bulk modulus, K (Kg/mm2 ), for expressing the Rd. Their hardness equation (YMHv) is as follows: YMHv = 0.19( SK )1/2 (19)

(13)

Vt3/2 G

As K = 2(1 + ) S /3(1 2), the YMHv becomes as (14) YMHv = 0.19{2(1 + )/3(1 2)}1/2 S By combining Eqs. (10), (11) and (20) Hv = 0.67 YMHv/Vt1/2 (21) (20)

These equations clearly show that the hardness of the glassy materials becomes bigger by increasing the packing density and bonding energy per unit volume . For multicomponent glasses of packing density of atoms of Vt and Gi is the dissociation energy per unit volume of i th composition, Eq. (14) will become as follows, Hv = 5.16 10.8 Vt 1

1/2

Vt3/2 Gi

(15)

Since gel or ormosils have hydroxyl and alkoxyl dangling bonds and pores, E and Hv for the ormosils are expressed as: E = 8.36 C Vt G 10.8 Vt 1

1/2

(16)

Hv = 5.16 C

Vt3/2 G

(17)

= 1 0.5 X ( X is mole fraction of dimethylsilixane [Si(CH3 )2 O ] In ormosils), and G = 14.4(1 0.5 X ) in Kcal/cm3 , where C is a constant, and silica

Because of the supposition of application of threedimensional hydrostatic pressure to glass during indentation, the YMHv equation may overestimate the effects of packing density of atoms on the densication process. By applying the Eq. (15) for many glasses we obtained calculated hardness values and were compared with measured values and it shows a comparatively good agreement, [11]. The measured values are taken from ref. [5, 12] and the reported hardness values in the literatures are scattered and the accuracy would be within 10%. For example 16.7Na2 O16.7CaO-66.7SiO2 soda lime glass (in mole%) the observed Hv value is 532 kg/mm2 and for nearly same composition, 16Na2 O-20CaO-64SiO2 , reported to be 490 kg/mm2 [12], and other value, 603 kg/mm2 is shown for 17Na2 O-15CaO-68SiO2 glass.

630

Makishima and Mackenzie

Table 1. Comparison of calculated hardness with measured value [10]. Mole fraction of DMS in ormosils 0.0DMS 0.079DMS 0.128DMS 0.195DMS 0.237DMS 0.275DMS 0.329DMS Packing density (Vt) 0.415 0.375 0.343 0.324 0.295 0.279 0.264 Hardness measured (kg/mm2 ) 186 160 140 110 88 83 76 Hardness calculated (kg/mm2 ) 193 168 159 129 110 107 104

new hardness equation for calculating the hardness of glasses and ormosils from chemical compositions were derived. The applied force of indentation should be analyzed by using the shear modulus, S , and Youngs modulus, E . The hardness equation includes packing density of atoms of glass and bond energy per unit volume has been taken account. The obtained calculated hardness values were compared with measured values, and the results showed a comparatively good agreement for ormosils. Acknowledgments The authors express their thanks to Professor J.J. Gilman of UCLA for stimulating discussion. A part of this work has been done at UCLA while A.M. is a NSG visiting professor to UCLA in 1998. References

1. J.J. Gilman, in The Science of Hardness Testing and its Research Applications, American Society for Metals, edited by J.H. Westbrook and H. Conrad (Chapman & Hall Ltd., 1973), p. 51. 2. J.J. Gilman, J. Applied Physics 44, 982 (1973). 3. J.J. Gilman, Materials Science and Engineering A209, 74 (1996). 4. J.D. Mackenzie, J. American Ceramic Society 46, 461 (1963). 5. M. Yamane and J.D. Mackenzie, J. Non-Crystalline Solids 15, 153 (1974). 6. S. Spinner, J. American Ceramic Society 37, 229 (1954). 7. J.E. Neely and J.D. Mackenzie, J. Materials Science 3, 603 (1968). 8. A. Makishima and J.D. Mackenzie, J. Non-Crystalline Solids 12, 35 (1973). 9. A. Makishima and J.D. Mackenzie, J. Non-Crystalline Solids 17 147 (1975). 10. T. Iwamoto and J.D. Mackenzie, J. Sol-Gel Sci. and Tech. 4, 141 (1995). 11. A. Makishima and J.D. Mackenzie, in Proceedings of the 5th ESG Conference (1999), B2-9. 12. O.V. Mazurin, Handbook of Glass Data, Part A, C (Elsevier, 1983, 1987). 13. J.D. Mackenzie, Qixin Huang, and T. Iwamoto, J. Sol-Gel Sci. and Tech. 7, 151 (1996).

DMS: dimethylsilixane [Si(CH3 )2 O ].

3.2.

Ormosils

As the present hardness equations are well applied for glasses, the Eq. (18) are tested for calculation of hardness of ormosils. The calculated values by Eq. (18) and observed hardness values by Iwamoto and Mackenzie for ormosils [10] were shown in Table 1 and agreements are comparatively good. Some calculated values have some discrepancies with observed values at higher dimethylsilixane content and the calculated values are higher than the observed hardness. The packing density of atoms in ormosils which were used for the calculation of hardness are shown. The value for silica glass is 0.51 and the values for ormosils are comparatively low especially at higher dimethylsilixane content [13] partly because the ormosils contain meso or micro pores. Further studies would be necessary to elucidate the shear stress distributions in the pores of the hybrid porous materials during the indentation. 4. Conclusion

By considering recent progresses in understanding the hardness of ionic crystals or covalent crystals,

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Omoclinic Orbits and Chaotic Behavior in Lassical EchanicsDocumento21 pagineOmoclinic Orbits and Chaotic Behavior in Lassical EchanicsDAVID ROSAS VARANessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Arm Usb OcdDocumento1 paginaArm Usb OcdGray FoxNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Dragon Jo Nakashima PDFDocumento5 pagineDragon Jo Nakashima PDFTeoria-M100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Indg 175Documento6 pagineIndg 175Teoria-MNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Assembly Arm 7Documento75 pagineAssembly Arm 7Thanh NguyenNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- ARMv8 ArchitectureDocumento26 pagineARMv8 Architecturebidyadhar100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Answer Key s2 08.2 FinalDocumento1 paginaAnswer Key s2 08.2 FinalTeoria-MNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Classical Mechanics - Solutions To Problems in Goldstein's (2000)Documento18 pagineClassical Mechanics - Solutions To Problems in Goldstein's (2000)boazspNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Use of Electrical Impedance Tomography With The Inverse Problem of EEG and MEGDocumento4 pagineThe Use of Electrical Impedance Tomography With The Inverse Problem of EEG and MEGTeoria-MNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Brief Review of Solid State PhysicsDocumento27 pagineBrief Review of Solid State PhysicschchcplayerNessuna valutazione finora

- Artifical Radioactivity Produced by Neutron Bombardment: Nobel Lecture, December 12, 1938Documento8 pagineArtifical Radioactivity Produced by Neutron Bombardment: Nobel Lecture, December 12, 1938Teoria-MNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Lie Groups Notes SumaryDocumento2 pagineLie Groups Notes SumaryTeoria-MNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Group Theory SumaryDocumento3 pagineGroup Theory SumaryTeoria-MNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Group TheoryDocumento57 pagineGroup TheoryTeoria-MNessuna valutazione finora

- John Nash's Ph.D. ThesisDocumento32 pagineJohn Nash's Ph.D. Thesisannabatayo100% (7)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Cap02 - Apostol T. M. - Mathematical AnalysisDocumento15 pagineCap02 - Apostol T. M. - Mathematical AnalysisTeoria-MNessuna valutazione finora

- Cap03 - Apostol T. M. - Mathematical AnalysisDocumento23 pagineCap03 - Apostol T. M. - Mathematical AnalysisTeoria-MNessuna valutazione finora

- Functional PDFDocumento36 pagineFunctional PDFDaniel AlejandroNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Logic 1Documento28 pagineLogic 1polaris25Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Control and Interfacing of BLDC Motor With Labview Using MyrioDocumento5 pagineControl and Interfacing of BLDC Motor With Labview Using Myriovasu_koneti5124Nessuna valutazione finora

- 2.basic Electrical Engineering PDFDocumento152 pagine2.basic Electrical Engineering PDFkandavel71Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

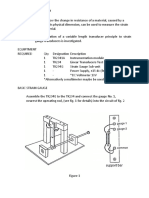

- Strain GuageDocumento6 pagineStrain GuageChristian EspanolNessuna valutazione finora

- Mathematics For Economics (ECON 104)Documento46 pagineMathematics For Economics (ECON 104)Experimental BeXNessuna valutazione finora

- Display Unit TechnologyDocumento51 pagineDisplay Unit TechnologyNavin GillmanNessuna valutazione finora

- Class Test Question Paper Kinematics of Machinery - 21-22 - FinalDocumento3 pagineClass Test Question Paper Kinematics of Machinery - 21-22 - FinalRavi PatilNessuna valutazione finora

- Design Guide UPSDocumento18 pagineDesign Guide UPSVictor BitarNessuna valutazione finora

- Electromagnetic Fields: Lecture 3: The Electric FieldDocumento24 pagineElectromagnetic Fields: Lecture 3: The Electric FieldNazar AzizNessuna valutazione finora

- Chemistry Question Bank For JEE Advance Part 1Documento55 pagineChemistry Question Bank For JEE Advance Part 1gfffdssseNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Final Test: Grade: 3 Time: 30 Minutes Your Name: .. ScoreDocumento8 pagineFinal Test: Grade: 3 Time: 30 Minutes Your Name: .. ScoreThu NguyenNessuna valutazione finora

- Formula Sheet 1Documento4 pagineFormula Sheet 1Abhimanyu DwivediNessuna valutazione finora

- StiffenerDocumento12 pagineStiffenergholiNessuna valutazione finora

- 1980-Simplified Cracked Section AnalysisDocumento6 pagine1980-Simplified Cracked Section AnalysisChan Dara Koem100% (1)

- Comparative Study of Performance of CDS, CdSeDocumento7 pagineComparative Study of Performance of CDS, CdSeAli AhmedNessuna valutazione finora

- Astm E0169 16Documento6 pagineAstm E0169 16archanaNessuna valutazione finora

- Microplan - Katalog 2009 ENDocumento18 pagineMicroplan - Katalog 2009 END.T.Nessuna valutazione finora

- Helmreich Cut Up Sonic TransductionDocumento9 pagineHelmreich Cut Up Sonic TransductiongrundumNessuna valutazione finora

- Acara 4 GranulometriDocumento63 pagineAcara 4 GranulometriHana Riwu KahoNessuna valutazione finora

- Observation Lesson in Physics DLP Activity 2 Now You Go Now Yu WontDocumento2 pagineObservation Lesson in Physics DLP Activity 2 Now You Go Now Yu WontEmma Santua50% (2)

- Unit - 13 - InstructionRevA May 1 2019Documento4 pagineUnit - 13 - InstructionRevA May 1 2019Dhruv SahniNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MathsDocumento2 pagineMathsAditya Singh PatelNessuna valutazione finora

- B SafeunitDocumento4 pagineB SafeunitSabariyantoNessuna valutazione finora

- Evaluating Risks of Construction-Induced Building Damage For Large Underground Construction ProjectsDocumento28 pagineEvaluating Risks of Construction-Induced Building Damage For Large Underground Construction ProjectsGiuseppe SquillaciotiNessuna valutazione finora

- ALLMENDINGER (1999) Introduction To Structural GeologyDocumento290 pagineALLMENDINGER (1999) Introduction To Structural GeologyeliasNessuna valutazione finora

- Test SyllabusDocumento4 pagineTest SyllabusAjinkya Aniruddha DangeNessuna valutazione finora

- Electrical Power Plans For Building ConstructionDocumento16 pagineElectrical Power Plans For Building ConstructionKitz DerechoNessuna valutazione finora

- Maxima and MinimaDocumento4 pagineMaxima and MinimaAnudeex ShettyNessuna valutazione finora

- Shop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Documento129 pagineShop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Ernest NavarroNessuna valutazione finora

- Chapter 3: Kinematics (Average Speed and Velocity) : ObjectivesDocumento4 pagineChapter 3: Kinematics (Average Speed and Velocity) : ObjectivesRuby CocalNessuna valutazione finora

- Colin MaclaurinDocumento6 pagineColin MaclaurinChristian David PecsonNessuna valutazione finora

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDa EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincValutazione: 3.5 su 5 stelle3.5/5 (137)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDa EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNessuna valutazione finora

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDa EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeValutazione: 5 su 5 stelle5/5 (4)