Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Industry Practices Piping

Caricato da

raobabar21Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Industry Practices Piping

Caricato da

raobabar21Copyright:

Formati disponibili

June 2000

Process Industry Practices Piping

PIP PN01NM0B01 Piping Material Specification 1NM0B01 Class 150, Alloy 400 (UNS N04400), 0.000" C.A. Process

PURPOSE AND USE OF PROCESS INDUSTRY PRACTICES In an effort to minimize the cost of process industry facilities, this Practice has been prepared from the technical requirements in the existing standards of major industrial users, contractors, or standards organizations. By harmonizing these technical requirements into a single set of Practices, administrative, application, and engineering costs to both the purchaser and the manufacturer should be reduced. While this Practice is expected to incorporate the majority of requirements of most users, individual applications may involve requirements that will be appended to and take precedence over this Practice. Determinations concerning fitness for purpose and particular matters or application of the Practice to particular project or engineering situations should not be made solely on information contained in these materials. The use of trade names from time to time should not be viewed as an expression of preference but rather recognized as normal usage in the trade. Other brands having the same specifications are equally correct and may be substituted for those named. All Practices or guidelines are intended to be consistent with applicable laws and regulations including OSHA requirements. To the extent these Practices or guidelines should conflict with OSHA or other applicable laws or regulations, such laws or regulations must be followed. Consult an appropriate professional before applying or acting on any material contained in or suggested by the Practice.

This Practice is subject to revision at any time by the responsible Function Team and will be reviewed every 5 years. This Practice will be revised, reaffirmed, or withdrawn. Information on whether this Practice has been revised may be found at http://www.pipdocs.org.

Process Industry Practices (PIP), Construction Industry Institute, The University of Texas at Austin, 3208 Red River Street, Suite 300, Austin, Texas 78705. PIP member companies and subscribers may copy this Practice for their internal use.

Not printed with State funds

June 2000

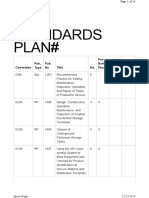

PIP PN01NM0B01 Piping Material Specification Line Class 1NM0B01

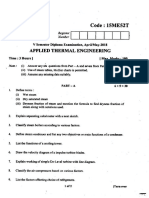

SERVICE: RATING CLASS: TEMPERATURE LIMIT: NOMINAL CORROSION ALLOWANCE: PRESSURE - TEMPERATURE RATINGS TEMP F -20 to 100 200 300 TEMP C -29 to 38 93 149 Full flange ratings per ASME B16.5, Table 2-3.4. psig 230 200 190 kPag 1586 1379 1310 ITEM PIPE NOTES 01, 21 NPS

Process 150, ASME B16.5a-1998 -20F to 750F (Note 09) 0.000 in.

MATERIAL: DESIGN CODE: STRESS RELIEF: EXAMINATION:

Alloy 400 (N04400) ASME B31.3-1999 None Required Per ASME B31.3

400 204 185 1276 SCH/RAT 40S 10S 10S 40S 40S 40S

500 260 170 1172 ENDS

600 316 140 965 DESCRIPTION

700 371 110 758

750 399 95 655

1/2 - 3/4 1-8 10 - 24 NIPPLES Branch Swage (Conc) Swage (Ecc) FITTINGS 02 Reducer (CONC) Reducer (CONC) Reducer (ECC) Reducer (ECC) BW Pipet 81 90 LR ELL 90 LR ELL 45 LR ELL 45 LR ELL Tee Tee Cap Stub End LJ Stub End LJ 22 VALVES Gate Globe Swing Check Dual PLT Check Ball Ball Ball Ball Ball Ball Plug 1/2 - 24 1/2 - 12 1/2 24 3 - 24 1/2 - 6 1/2 - 6 8 - 10 8 - 10 12 - 24 12 - 24 1-4 1/2 - 1-1/2 1/2 - 1-1/2 1/2 - 1-1/2 1/2 - 8 10 - 24 1/2 - 8 10 - 24 1/2 - 20 1/2 - 8 10 - 24 1/2 - 8 10 - 24 1/2 - 8 10 - 24 1/2 - 24 1/2 - 8 10 - 24

Alloy 400, SMLS, ASTM B165-N04400, annealed (Ej=1.00) Alloy 400, SMLS, ASTM B165-N04400, annealed (Ej=1.00) Alloy 400, EFW, ASTM B725-N04400, annealed, Cat. 2 (Ej=0.80) Alloy 400, SMLS, ASTM B165-N04400, annealed (Ej=1.00) Alloy 400, ASTM B366-WPNC-S, annealed, MSS SP-95 Alloy 400, ASTM B366-WPNC-S, annealed, MSS SP-95 Weld Weld Weld Weld Weld Weld Weld Weld Weld Weld Weld Weld Weld Weld Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 Alloy 400, ASTM B564-N04400, annealed Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-S, annealed, ASME B16.9 Alloy 400, ASTM B366-WPNC-W, annealed, ASME B16.9 short pattern Alloy 400 body w/ Alloy 400 trim, HF ST Alloy 400 body w/ Alloy 400 trim, HF ST Alloy 400 body w/ Alloy 400 trim, HF ST Alloy 400 body w/ Alloy 400 disc, HF ST Alloy 400 body w/ Alloy 400 trim, RTFE ST Alloy 400 body w/ Alloy 400 trim, RTFE ST, FP Alloy 400 body w/ Alloy 400 trim, RTFE ST, GO Alloy 400 body w/ Alloy 400 trim, RTFE ST, GO, FP Alloy 400 body w/ Alloy 400 trim, RTFE ST, GO Alloy 400 body w/ Alloy 400 trim, RTFE ST, GO, FP Alloy 400 body w/ Alloy 400 plug GA01NM500 GL01NM500 CS01NM500 CD01NM700 BA01NM500 BA01NM501 BA01NM502 BA01NM503 BA01NM504 BA01NM505 PL01NM502

62 07, 26, 63 09 08, 09 09 08, 09 09 08, 09

Class 150 Class 150 Class 150 Class 150 Class 150 Class 150 Class 150 Class 150 Class 150 Class 150 Class 150

RF RF RF RF RF RF RF RF RF RF

Process Industry Practices

Page 1 of 3

PIP PN01NM0B01 Piping Material Specification Line CLASS 1NM0B01

June 2000

ITEM FLANGES Blind Blind

NOTES 02

NPS 1/2 - 3/4 1 - 24 1/2 - 3/4 1 - 24 1/2 - 24 1/2 - 24 1/2 - 24 1/2 - 24 2 - 24 1/2 - 24 1/2 - 24

SCH/RAT Class 150 Class 150 Class 300 Class 300 Class 150 Class 300 Class 150 Class 300 Class 300 Class 150 Class 300

ENDS RF RF RF RF

DESCRIPTION Alloy 400, ASTM B564-N04400, annealed ASME B16.5 CS, ASTM A105 w/ 1/8" Alloy 400 plate, welded, serrated to 125 to 250 Ra finish, ASTM B675-N04400, annealed, ASME B16.5 Alloy 400, ASTM B564-N04400, annealed ASME B16.5 CS, ASTM A105 w/ 1/8" Alloy 400 plate, welded, serrated to 125 to 250 Ra finish, ASTM B675-N04400, annealed, ASME B16.5 CS, ASTM A105, ASME B16.5 CS, ASTM A105, ASME B16.5 Alloy 400, ASTM B564-N04400, annealed, ASME B16.5 Alloy 400, ASTM B564-N04400, annealed, ASME B16.5 Alloy 400, ASTM B564-N04400, annealed, ASME B16.36, SW taps Spiral wound Alloy 400 w/ flexible graphite filler, ASME B16.20 Spiral wound Alloy 400 w/ flexible graphite filler, ASME B16.20 ASTM A193, B7 stud w/ 2 heavy hex nuts ASTM A194, 2H

Blind 12 Blind 12 Lap Joint Lap Joint Weld Neck Weld Neck Pair WN Orifice GASKETS 22 12, 22 22 12, 22

RF RF RF

BOLTING Stud Bolts 90 BRANCH CONNECTION Legend and Chart

24 20 18 16 14 12 BRANCH SIZE 10 8 6 4 3 2 1-1/2 1 3/4 1/2 T K K K K K P P P P P P W W W W 24 T K K K K K P P P P P W W W W 20 T K K K K P P P P P W W W W 18 T P P P P P P P P W W W W 16 T P P P P P P P W W W W 14 T P P P P P P W W W W 12 T B B B B P W W W W 10 T B B B P W W W W 8 T B B P W W W W 6 T B P W W W W 4 T P W W W W 3 T E E E E 2 T E E E 1-1/2 T E E 1

T E 3/4 T 1/2

HEADER SIZE

B E K P T W

Branch Weld Reducing Tee Full Encirclement Reinforcement (Length equals twice branch pipe OD.) Branch Weld w/ Reinforcing Pad (Pad thickness equals run pipe thickness. Pad width equals 1/2 branch OD.) Tee Buttweld Pipet (Note 81)

NOTES: 01 02 07 08 09 12 21 22 26 62 63 81

Where pipe schedule is shown under SCH/RAT, it is adequate for the full flange rating. Where Calc is shown, the pressure limit may be lower than flange rating. All buttwelded component thicknesses shall match pipe thickness. These valves have no flanges, but are installed between line flanges with extra length bolts. Full port valves shall be used when indicated on P&ID. Pressure and temperature rating may be limited by certain components permitted by this specification. Refer to manufacturers recommended pressure-temperature restrictions. To be used only to match Class 300 rated flange connections at control valves and special equipment. Sch 40S pipe and pipe nipples shall be used for threaded connections for sizes NPS 1 - 2. Use stub ends with lap joint backup flanges for temperature up to 500F (260C). For higher temperatures, use weld neck flanges. To be used only when indicated on the P&ID. Install in horizontal position with cover up or in vertical position with upward flow. Install in horizontal position with hinge pin vertical or in vertical position with upward flow. Integrally reinforced branch connections are permitted outside the sizes shown in the branch connection tables.

Page 2 of 3

Process Industry Practices

June 2000

PIP PN01NM0B01 Piping Material Specification Line Class 1NM0B01

REFERENCES: Process Industry Practices (PIP) PIP PNF0200 - Vents, Drains, and Instrument Connection Details PIP PNSMV053 - Nickel and Nickel Alloy Gate Valve Descriptions PIP PNSMV054 - Nickel and Nickel Alloy Globe Valve Descriptions PIP PNSMV055 - Nickel and Nickel Alloy Check Valve Descriptions PIP PNSMV056 - Nickel and Nickel Alloy Ball Valve Descriptions PIP PNSMV058 - Nickel and Nickel Alloy Plug Valve Descriptions

Process Industry Practices

Page 3 of 3

Potrebbero piacerti anche

- 01NU0B01Documento4 pagine01NU0B01raobabar21Nessuna valutazione finora

- 01PV0C01Documento4 pagine01PV0C01raobabar21Nessuna valutazione finora

- Process Industry Practices PipingDocumento5 pagineProcess Industry Practices Pipingabdo samadNessuna valutazione finora

- Process Industry Practices PipingDocumento5 pagineProcess Industry Practices Pipingabdo samadNessuna valutazione finora

- Process Industry Practices PipingDocumento5 pagineProcess Industry Practices Pipingabdo samadNessuna valutazione finora

- 01SD1B01Documento5 pagine01SD1B01Jhonny RinconesNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- PIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)Documento5 paginePIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)César SantanaNessuna valutazione finora

- Gagemaker ProductsDocumento50 pagineGagemaker ProductsMelquiades Hernández GonzálezNessuna valutazione finora

- 12PD0H01Documento4 pagine12PD0H01Jhonny RinconesNessuna valutazione finora

- Double U BOP: TC1001 © 2002 Cooper Cameron, Cameron DivisionDocumento4 pagineDouble U BOP: TC1001 © 2002 Cooper Cameron, Cameron DivisiontamoorwazireNessuna valutazione finora

- Senior Engineer Oil Gas in Houston TX Resume Morris NarunskyDocumento4 pagineSenior Engineer Oil Gas in Houston TX Resume Morris NarunskyMorrisNarunsky2Nessuna valutazione finora

- Day 6 Welding Process, Electrode - FCAW, GTAW & SAWDocumento65 pagineDay 6 Welding Process, Electrode - FCAW, GTAW & SAWRohit Kamble100% (1)

- 4 Presentation Tenaris Premium Connection Design Sucker RodDocumento24 pagine4 Presentation Tenaris Premium Connection Design Sucker RodzhiqianxuNessuna valutazione finora

- Piping Spec C ClassDocumento1 paginaPiping Spec C Classnestor ferrel floresNessuna valutazione finora

- Pneumatic Actuated Ball Valve PE4320Documento2 paginePneumatic Actuated Ball Valve PE4320Fa ChNessuna valutazione finora

- TECH-ISH-0020A - Pen-O-Trator PDFDocumento2 pagineTECH-ISH-0020A - Pen-O-Trator PDFEdwin VelascoNessuna valutazione finora

- Thread Types and UsesDocumento1 paginaThread Types and UsesJDPNetoNessuna valutazione finora

- Pipe Fabrication Institute ES-37 Copyright GuidelinesDocumento3 paginePipe Fabrication Institute ES-37 Copyright GuidelinesДенис ПекшуевNessuna valutazione finora

- 2017 03436 01 002 - Bom 320Documento8 pagine2017 03436 01 002 - Bom 320sundyaNessuna valutazione finora

- QT-900 data sheet specificationsDocumento2 pagineQT-900 data sheet specificationsjoseperozo45Nessuna valutazione finora

- JFE CasingDocumento40 pagineJFE CasingezrawongNessuna valutazione finora

- Seamless Casing and Tubing Nipponsteel Ver PDFDocumento18 pagineSeamless Casing and Tubing Nipponsteel Ver PDFMehdi SoltaniNessuna valutazione finora

- Hose&Braid Catalog FlexicraftDocumento24 pagineHose&Braid Catalog Flexicraftkutts76Nessuna valutazione finora

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocumento15 paginePiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNessuna valutazione finora

- Jacketed Ball Valves LeafletDocumento2 pagineJacketed Ball Valves LeafletSherif EltoukhiNessuna valutazione finora

- BSPT Thread Sizes and DimensionsDocumento3 pagineBSPT Thread Sizes and DimensionsOrlando Rebelo100% (1)

- Co-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIDocumento2 pagineCo-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIHmd MokhtariNessuna valutazione finora

- 8 P 80Documento2 pagine8 P 80lionelNessuna valutazione finora

- Flange ChartDocumento4 pagineFlange ChartEddie SantillánNessuna valutazione finora

- Phu Tung YokeDocumento19 paginePhu Tung YokeAnh TranNessuna valutazione finora

- JC Catalogue Gate Valves BBDocumento24 pagineJC Catalogue Gate Valves BBMahdi DalyNessuna valutazione finora

- KL UHP Catalog 2011-02 PDFDocumento30 pagineKL UHP Catalog 2011-02 PDFaconibet9040Nessuna valutazione finora

- Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsDocumento2 pagineTable 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsMiguelRagasNessuna valutazione finora

- Tables of Piping Standards - PittsburghDocumento166 pagineTables of Piping Standards - PittsburghzhangamecNessuna valutazione finora

- Sferova API6 Ball Valve CatalogueDocumento27 pagineSferova API6 Ball Valve CatalogueWong JowoNessuna valutazione finora

- Technical Specification For Supply of Valves Table - 1: Manuf'S OfferDocumento11 pagineTechnical Specification For Supply of Valves Table - 1: Manuf'S OfferRadhakrishnan SreerekhaNessuna valutazione finora

- Innogaz Product Brochure for Electrofusion FittingsDocumento32 pagineInnogaz Product Brochure for Electrofusion Fittingsvishnu300022Nessuna valutazione finora

- API - Introduction - StandardsDocumento29 pagineAPI - Introduction - Standardsrafael0j0moreno0r100% (1)

- 03-Piping Drafting & DesignDocumento43 pagine03-Piping Drafting & DesignshaNessuna valutazione finora

- Asme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesDocumento69 pagineAsme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesnitinNessuna valutazione finora

- Maverick Valves CatalogueDocumento84 pagineMaverick Valves Cataloguer4mms3sNessuna valutazione finora

- SD Slip ManualDocumento9 pagineSD Slip ManualGregory StewartNessuna valutazione finora

- Standards Scope PDFDocumento6 pagineStandards Scope PDFaravindhcamNessuna valutazione finora

- 1st Assignment For Piping EngineeringDocumento6 pagine1st Assignment For Piping EngineeringAthulNessuna valutazione finora

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Documento21 pagineTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNessuna valutazione finora

- Norma Awwa C-207Documento14 pagineNorma Awwa C-207Clau QuilodranNessuna valutazione finora

- Grove g4n Gate Valve BrochureDocumento24 pagineGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- STP CatalogueDocumento37 pagineSTP CataloguemmkattaNessuna valutazione finora

- HDPE Pipe Specification GuideDocumento8 pagineHDPE Pipe Specification Guidenilesh_erusNessuna valutazione finora

- PNSMV046Documento8 paginePNSMV046Mehrdad HosseinzadehNessuna valutazione finora

- k10 GeothermalDocumento1 paginak10 GeothermalshegateNessuna valutazione finora

- API Standards ListDocumento14 pagineAPI Standards ListMirzaNessuna valutazione finora

- Articoli API 610 9 EditDocumento26 pagineArticoli API 610 9 EditmariasofiarossiNessuna valutazione finora

- Polyken Utility Tape 900 910 908 911 920Documento2 paginePolyken Utility Tape 900 910 908 911 920Tracy EvansNessuna valutazione finora

- Engineering All in OneDocumento245 pagineEngineering All in OneozchrisNessuna valutazione finora

- Demco DM DTDocumento30 pagineDemco DM DTGregory StewartNessuna valutazione finora

- 01SD1B02Documento5 pagine01SD1B02raobabar21Nessuna valutazione finora

- 01CS1B01Documento4 pagine01CS1B01Muhammad Farukh ManzoorNessuna valutazione finora

- 01NC0B02Documento4 pagine01NC0B02raobabar21Nessuna valutazione finora

- Refractory Solution FDocumento5 pagineRefractory Solution Fraobabar21Nessuna valutazione finora

- World Steel in Figures 2018Documento10 pagineWorld Steel in Figures 2018zubair ahmadNessuna valutazione finora

- China Coreless IntermediateDocumento21 pagineChina Coreless Intermediateraobabar21Nessuna valutazione finora

- Bangla Steel Mill RollDocumento29 pagineBangla Steel Mill Rollraobabar21Nessuna valutazione finora

- Pavingexpert - Formwork and ShutteringDocumento6 paginePavingexpert - Formwork and Shutteringraobabar21Nessuna valutazione finora

- SSPDocumento16 pagineSSPRaghunath Veeramani100% (1)

- Safety MagnalenzDocumento29 pagineSafety MagnalenzBruno ThiemeNessuna valutazione finora

- Gear FailuresDocumento12 pagineGear FailuresAnshuman RoyNessuna valutazione finora

- Shear Model - PDF MODIFIEDDocumento1 paginaShear Model - PDF MODIFIEDraobabar21Nessuna valutazione finora

- Financial AnalysisDocumento16 pagineFinancial Analysisraobabar21Nessuna valutazione finora

- Rolling Operation & SequenceDocumento20 pagineRolling Operation & Sequenceraobabar21Nessuna valutazione finora

- Geart Failure LubricationDocumento17 pagineGeart Failure Lubricationraobabar21Nessuna valutazione finora

- 04-04-2007Documento7 pagine04-04-2007raobabar21Nessuna valutazione finora

- MX-Muddassar HassanDocumento152 pagineMX-Muddassar Hassanraobabar21Nessuna valutazione finora

- 100 Keyboard ShortcutsDocumento4 pagine100 Keyboard ShortcutsrahmanagasNessuna valutazione finora

- 4536062Documento1 pagina4536062raobabar21Nessuna valutazione finora

- Ielts Information For Candidates English UkDocumento8 pagineIelts Information For Candidates English UkMeatNessuna valutazione finora

- M3 9turbineoperationbackpressureeffectsDocumento23 pagineM3 9turbineoperationbackpressureeffectsraobabar21Nessuna valutazione finora

- 42CrMo4 steel specifications and propertiesDocumento2 pagine42CrMo4 steel specifications and propertiesShubham GuptaNessuna valutazione finora

- Connections FL-01Documento2 pagineConnections FL-01saulomonNessuna valutazione finora

- Compressed Air Controls GuideDocumento8 pagineCompressed Air Controls Guideraobabar21Nessuna valutazione finora

- MmhelpDocumento4 pagineMmhelpraobabar21Nessuna valutazione finora

- Compressor ChecklistDocumento5 pagineCompressor ChecklistJuanPabloAlvarezNessuna valutazione finora

- Power Transmission Vbelt ReferenceDocumento1 paginaPower Transmission Vbelt Referenceraobabar21Nessuna valutazione finora

- Steam Turbine BasicsDocumento22 pagineSteam Turbine BasicsSumit ChaurasiaNessuna valutazione finora

- Erosion Prediction For Steam TurbinesDocumento1 paginaErosion Prediction For Steam Turbinesraobabar21Nessuna valutazione finora

- Section 10 Useful Information: Strength Information For Hexagon NutsDocumento1 paginaSection 10 Useful Information: Strength Information For Hexagon Nutsraobabar21Nessuna valutazione finora

- Inspector's Calc's QuizDocumento3 pagineInspector's Calc's QuizSakthi PanneerSelvam TanjaiNessuna valutazione finora

- 4536062Documento1 pagina4536062raobabar21Nessuna valutazione finora

- API 572 Study GuideDocumento22 pagineAPI 572 Study GuidedarestaniNessuna valutazione finora

- List of Drawings with IFR DetailsDocumento14 pagineList of Drawings with IFR DetailsDilshad AhemadNessuna valutazione finora

- Selection guide for coiled tubing and casing cuttersDocumento5 pagineSelection guide for coiled tubing and casing cuttersSusin LimNessuna valutazione finora

- 04 3 Sec IV PMS General Notes To PMSDocumento46 pagine04 3 Sec IV PMS General Notes To PMSKailas NimbalkarNessuna valutazione finora

- Gas Turbine HistoryDocumento6 pagineGas Turbine Historyzhd_shah100% (1)

- Bleed Air System Schematic: Boeing 737Documento8 pagineBleed Air System Schematic: Boeing 737Estevam Gomes de AzevedoNessuna valutazione finora

- Backview Valve-Block: Track Tensioning 50bar (Test Point P4)Documento1 paginaBackview Valve-Block: Track Tensioning 50bar (Test Point P4)AplesNessuna valutazione finora

- FERTIGATIONDocumento96 pagineFERTIGATIONNohaAbdulWarthNessuna valutazione finora

- Jet Pumps: Convertible - Shallow WellDocumento24 pagineJet Pumps: Convertible - Shallow WellArnold DelinaNessuna valutazione finora

- Esp Calculation StudioDocumento8 pagineEsp Calculation StudioMohsin ShaikhNessuna valutazione finora

- Gate Valves: Flexible Wedge PN 40-160 DN 50-600Documento2 pagineGate Valves: Flexible Wedge PN 40-160 DN 50-600Radoo NephilaNessuna valutazione finora

- Handout CHE F343Documento3 pagineHandout CHE F343Aryan ShuklaNessuna valutazione finora

- Feedwater Heaters: Cost Effective & Environmentally Friendly SolutionsDocumento5 pagineFeedwater Heaters: Cost Effective & Environmentally Friendly SolutionsrahulNessuna valutazione finora

- Heatexchanger 141216095212 ConversionDocumento23 pagineHeatexchanger 141216095212 Conversionraj2417705Nessuna valutazione finora

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Documento6 pagine1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNessuna valutazione finora

- Model VQ Vane Pump CartridgesDocumento7 pagineModel VQ Vane Pump CartridgesglobalindosparepartsNessuna valutazione finora

- Construction of Simple CarburetorDocumento2 pagineConstruction of Simple Carburetorraja30gNessuna valutazione finora

- Quotation: NG Chua TradingDocumento2 pagineQuotation: NG Chua TradingAlvin AbilleNessuna valutazione finora

- Pipeline Pigging: o o o o o oDocumento7 paginePipeline Pigging: o o o o o oAnonymous 70lCzDJv100% (1)

- Centrifugal Fan, Blowers and CompressorsDocumento41 pagineCentrifugal Fan, Blowers and CompressorsAjejejeNessuna valutazione finora

- Input To NC-3658.3 Flange Evaluation MethodDocumento7 pagineInput To NC-3658.3 Flange Evaluation MethodVishal KandNessuna valutazione finora

- HospynebDocumento2 pagineHospynebee113051Nessuna valutazione finora

- Theory Gas ChokesDocumento4 pagineTheory Gas ChokesYilmer Palacios RodríguezNessuna valutazione finora

- Catalogo Colheitadeira Case Compressor de Ar 2388Documento2 pagineCatalogo Colheitadeira Case Compressor de Ar 2388Thiago RomeroNessuna valutazione finora

- Gas Turbine Drain Pit Line GuideDocumento2 pagineGas Turbine Drain Pit Line Guidesaeed ahmedNessuna valutazione finora

- Ab 036227 001 PDFDocumento1 paginaAb 036227 001 PDF8256Nessuna valutazione finora

- A.T.E QP April May 2018Documento2 pagineA.T.E QP April May 2018Sumanth Vn100% (1)

- Pumps Turbine Submersible PumpDocumento11 paginePumps Turbine Submersible Pumpahsanul haqueNessuna valutazione finora

- Sga - SGB: Valves Safety DevicesDocumento10 pagineSga - SGB: Valves Safety DevicesErsin SucuNessuna valutazione finora

- Pumps Pumping Systems GeneralDocumento349 paginePumps Pumping Systems GeneralGokula Krishnan CNessuna valutazione finora

- Absorption Chiller Technical SpecificationsDocumento10 pagineAbsorption Chiller Technical SpecificationsMuhammed HusseinNessuna valutazione finora