Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme2b sb-171 DDF

Caricato da

zingalehe25464Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asme2b sb-171 DDF

Caricato da

zingalehe25464Copyright:

Formati disponibili

SPECIFICATION FOR COPPER-ALLOY PLATE AND SHEET FOR PRESSURE VESSELS, CONDENSERS, AND HEAT EXCHANGERS

SB-171

98

(Identical with ASTM Specication B 171-95 for the alloys covered except for editorial differences. Certifcation has been made mandatory.)

1.

Scope

1.1 This specication covers copper-alloy plate and sheet for pressure vessels, condensers, and heat exchangers. The following alloys are covered:

Copper Alloy UNS No.A C36500 C44300 C44400 C44500 C46400 C46500 C61300 C61400 C63000 C70600 C71500

A

Previously Used Designation Leaded Muntz Metal Admiralty, Arsenical Admiralty, Antimonial Admiralty, Phosphorized Naval Brass, Uninhibited Naval Brass, Arsenical Aluminum Bronze Aluminum Bronze D Aluminum-Nickel Bronze 9010 Copper Nickel 7030 Copper Nickel

E 8 Methods Tension Testing of Metallic Materials E 29 Recommended Practice for Indicating Which Places of Figures Are to Be Considered Signicant in Specied Limiting Values E 54 Test Methods for Chemical Analysis of Special Brasses and Bronzes E 55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition E 62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Method) E 75 Test Methods for Chemical Analysis of CopperNickel and Copper-Nickel-Zinc Alloys E 478 Methods for Chemical Analysis of Copper Alloys E 527 Practice for Numbering Metals and Alloys (UNS) 2.2 ASME Standards: SB-248 Specication for General Requirements for Wrought Copper and Copper Alloy Plate, Sheet, Strip, and Rolled Bar

New designation established in accordance with ASTM E 527, Practice for Numbering Metals and Alloys (UNS). In the new UNS system, the designations for copper alloys are simply expansions of the present standard designations by a prex C and a sufx 00.

2.

Referenced Documents 2.1 ASTM Standards:

3.

Terminology 3.1 Denitions:

2.1.1 The following documents of the issue in effect on date of material purchased form a part of this specication to the extent referenced herein: B 601 Practice for Temper Designations for Copper and Copper Alloys, Wrought and Cast

219

3.1.1 blank a piece of at product intended for subsequent fabrication by forming, bending, cupping, drawing, hot pressing, etc. 3.1.2 lengths straight pieces of the product.

SB-171

1998 SECTION II TABLE 1 CHEMICAL REQUIREMENTS

Copper Alloy Copper, incl UNS No.A Silver C36500 C44300 C44400 C44500 C46400 C46500 C61400 C63000 C70600 C71500

A B

Composition, % Tin 0.25 max 0.81.2 0.81.2 0.81.2 0.51.0 0.51.0 ... 0.20 max ... ... Nickel, Manganese, incl Cobalt max ... ... ... ... ... ... ... 4.05.5 9.011.0 29.033.0 ... ... ... ... ... ... 1.0 1.5 1.0 1.0 Lead 0.250.7 0.07 max 0.07 max 0.07 max 0.20 max 0.20 max 0.01 max ... 0.05 maxB 0.05 maxB Iron 0.15 max 0.06 max 0.06 max 0.06 max 0.10 max 0.10 max 1.53.5 2.04.0 1.01.8 0.401.0 Zinc Aluminum Chromium ... ... ... ... ... ... ... ... ... ... Other Named Elements ... 0.020.06 As 0.020.10 Sb 0.020.10 P ... 0.020.06 As 0.015 P max 0.25 Si max

B B

58.061.0 70.073.0 70.071.0 70.073.0 59.062.0 59.062.0 remainder remainder remainder remainder

remainder ... remainder ... remainder ... remainder ... remainder ... remainder ... 0.20 max 6.08.0 0.30 max 9.011.0 1.0 maxB ... 1.0 maxB ...

New designation established in accordance with Practice E 527, Practice for Numbering Metals and Alloys (UNS). When the product is for subsequent welding applications, and so specied by the purchaser, zinc shall be 0.50% max, lead 0.02% max, phosphorous 0.02% max, sulfur 0.02% max, and carbon 0.05%.

3.1.2.1 specic straight lengths that are uniform in length, as specied, and subject to established length tolerances. 3.1.3 plate a wrought at product over 0.188 in. thick and over 12 in. wide, in lengths. 3.1.4 sheet a rolled at product up to and including 0.188 in. thick and over 24 in. wide, in at lengths or coils (rolls).

5.

Materials and Manufacture

5.1 The material shall be of such quality and purity that the nished product shall have the properties and characteristics prescribed in this specication.

6.

Chemical Composition

6.1 The materials shall conform to the chemical requirements prescribed in Table 1. 4. Ordering Information 6.2 These specication limits do not preclude the presence of other elements. Limits for unnamed elements may be established by ageement between manufacturer or supplier and purchaser. 6.3 For the alloys listed in the table below either copper or zinc may be taken as the difference between the sum of all the elements analyzed and 100%. When all the elements in Table 1 are analyzed, their sum shall be as shown in the table below.

Copper Alloy UNS No. C36500 C44300 C44400 C44500 C46400 C46500 C61400 C63000 Copper Plus Named Elements, %, Min. 99.6 99.6 99.6 99.6 99.6 99.6 99.5 99.5

4.1 Orders for material under this specication shall include the following information: 4.1.1 Copper Alloy UNS No. (Section 6, Table 1). 4.1.1.1 Whether the alloy ordered will be used in applications requiring it to be welded (see Table 1, Footnotes B and C). 4.1.2 Whether plate is to be machined (see 8.3), 4.1.3 How tolerance is specied (Footnote A, Table 3), 4.1.4 Weight (total for each size), 4.1.5 Mill test report, if required (Section 17), 4.1.6 Special marking, if required (Section 18), and 4.1.7 Whether 0.2% offset yield strength is required.

220

PART B NONFERROUS MATERIAL SPECIFICATIONS TABLE 2 TENSILE REQUIREMENTS

Yield Strength at 0.2 % Offset, min, MPaB 20 15 12 15 20 18 36 28 26 28 26 34 31 28 15 15 20 18

SB-171

Copper Alloy UNS No. C36500 C44300, C44400, and C44500 C46400, C46500

Thickness in. 2 to 3.5, incl over over 3.5 to 5, incl 4 and under 3 and under over 3 to 5, incl 2 to 3, incl over over 3 to 5, incl 2 and under 2 and under

Tensile Strength min, ksiB 50 45 40 45 50 50 75 70 65 70 65 90 85 80 40 40 50 45

Yield Strength,A min, ksiB 20 15 12 15 20 18 37 30 28 30 28 36 33 30 15 15 20 18

Elongation in 2 in., min, % 35 35 35 35 35 35 30 35 35 35 35 10 10 10 30 30 30 30

C61300

C61400

over 2 to 5, incl

2 to 3.5, incl over over 3.5 to 5, incl 2 and under

2 and under

C63000

C70600 C71500

A B

over 2.5 to 5, incl over 2.5 to 5, incl

2.5 and under

2.5 and under

Yield strength shall be determined as the stress producing in elongation of 0.5% under load, that is, 0.01 in. in a gage length of 2 in. ksi p 1000 psi.

6.3.1 For the alloys listed in the following table copper may be taken as the difference between the sum of all the elements analyzed and 100%. When all the elements in Table 1 are analyzed, their sum shall be as shown in the table below.

Copper Alloy UNS No. C70600 C71500 Copper Plus Named Elements, %, Min. 99.5 99.5

9.

Dimensions and Permissible Variations 9.1 Thickness:

9.1.1 The thickness tolerances for plates of Copper Alloy UNS Nos. C36500, C44300, C44400, C44500, C46400, and C46500 shall be as prescribed in Table 2. 9.1.2 The thickness tolerances for plates of Copper Alloy UNS Nos. C61300, C61400, C63000, C70600, and C71500 shall be 25% greater than those prescribed in Table 3. 9.1.3 If plates are machined, the thickness tolerances shall apply to the machined portion only. 9.1.4 Closer thickness tolerances than those prescribed in Table 3 can be furnished by surface machining. This is a special product and is subject to agreement between the manufacturer and the purchaser. 9.1.5 Unless otherwise agreed to by the manufacturer and the purchaser, the thickness of plate to this specication shall be determined by measuring along

221

7.

Temper

7.1 The only temper applicable to this specication is described in Practice B 601, as Hot Rolled and Annealed (O25).

8.

Tensile Properties

8.1 The plates and sheet shall conform to the requirements as to tensile properties prescribed in Table 2.

SB-171 TABLE 3 THICKNESS TOLERANCES

1998 SECTION II TABLE 5 FLATNESS TOLERANCES

Flatness Tolerances (Depth of Arc) not to Exceed, in., for Diameters, Lengths, or Widths Shown Copper Alloy UNS No. C36500, C46400, and C46500 C44300, C44400, and C44500 C61300, C61400, and C63000 C70600 and C71500

A

Thickness Tolerance, Plus and Minus,A in. for Diameters or Widths Over 36 to 60 in., incl 0.012 0.027 0.030 0.035 0.040 0.045 0.055 0.062 Over 60 to 96 in., incl 0.022 0.029 0.032 0.037 0.042 0.047 0.062 0.065 Over 96 to 132 in., incl 0.028 0.031 0.035 0.040 0.045 0.050 0.065 ...

Thickness, in. Over 0.125 to 0.250, incl Over 0.250 to 0.500, incl Over 0.500 to 0.750, incl Over 0.750 to 1.000, incl Over 1.000 to 1.500, incl Over 1.500 to 1.750, incl Over 1.750 to 2.000, incl Over 2.000 to 5.000, incl

A

36 in. or Under 0.010 0.025 0.028 0.033 0.038 0.043 0.050 0.058

Over 36 Over 60 36 in. to 60 in., to 132 in., or Under incl inclA 0.050 0.050 0.060 0.060 0.055 0.065 ... 0.075 0.060 0.075 ... 0.090

Tolerance applies to any 72 in. chord.

When tolerances are specied as all plus or all minus, double the values given. B See 9.1.2 for specic alloys with a different tolerance.

9.3 FlatnessThe atness tolerances of individual plates shall not exceed those prescribed in Table 5. The tolerances shown are the total permissible variations for plates as ordered, and do not apply to the 7-in. marginal area at the edge of the plate. Inspection for atness shall be made by placing the plate on a atsurface table with the side marked Straight Side up, applying a 72-in. straightedge when the size permits, or a shorter one equal to the dimension to be inspected, and measuring the depth of arc between the straightedge and the plate. 9.4 Plate and Sheet Lot Weight for Pressure Vessels When plate or sheet of Copper Alloy UNS Nos. C70600 and C71500 are ordered for pressure vessels exclusively, the maximum lot weight restriction in Table 6 shall apply in addition to the thickness tolerance requirement of Table 3. The weight of each lot of 5 or more plates or sheets shall not exceed the nominal weight by more than the amount prescribed in Table 6. Plate and sheet of lots of less than 5 shall be governed solely by the thickness tolerances of Table 3. For purposes of calculating weights, the densities used shall be as listed in Table 7.

TABLE 4 DIAMETER, LENGTH, OR WIDTH TOLERANCES

Diameter, Length, or Width, in. 36 or under Over 36 to 60, incl Over 60 to 96, incl Over 96 to 132, incl Permissible Excess in Diameter, Length, or Width, in.

3 1 3 7 64 16 32 64

the length of the plate up to a distance of 7 in. in from the edge. 9.2 Diameters, Lengths, or Widths The diameters, lengths, or widths of plates shall be not less than those specied. The diameters, lengths, or widths of plates may exceed those specied by the amounts shown in Table 4.

NOTE 1 For the purpose of determining conformance with the dimensional requirements prescribed in this specication, any measured value outside the specied limiting values for any dimension may be cause for rejection.

10.

Workmanship, Finish, and Appearance

10.1 The material shall be free of injurious defects and have a smooth clean surface such as results from rolling operation, unless otherwise specied.

11.

Sampling

11.1 The lot size, portion size, and selection of pieces shall be as follows:

222

PART B NONFERROUS MATERIAL SPECIFICATIONS

SB-171

TABLE 6 LOT WEIGHT TOLERANCES IN PERCENTAGE OF THEORETICAL WEIGHT, ALL PLUS COPPER ALLOY UNS NOS. C70600 AND C71500 FOR USE IN PRESSURE VESSELS EXCLUSIVELY

Permissible Excess in Average Weights of Lots, Expressed in Percentage of Nominal Weights Specied Thickness in. Over Over Over Over to 38 to 34 3 to 1 4 1 to 2

2 8 3 1

48 in. and Under in Width 5.75 5.5 5 3.5

Over 48 in. to 60 in. in Width 6.5 6 5 4

Over 60 in. to 72 in. in Width 7.5 7 6.25 5

Over 72 in. to 96 in. in Width 9 8 7 6

Over 96 in. to 120 in. in Width 10 9 8 7

Over 120 in. to 132 in. in Width 11 10 9 8

TABLE 7 DENSITIES

Density lb/in.3 0.304 0.308 0.304 0.285 0.274 0.323

Copper Alloy UNS Nos. C36500 C44300, C46400, C61300, C63000 C70600, C44400, C44500 C46500 C61400 C71500

manufacturer by analyzing samples taken at the time the castings are poured or samples taken from the semi-nished product. If the manufacturer determines the chemical composition of the material during the course of manufacture, he shall not be required to sample and analyze the nished product. The number of samples taken for determination of chemical composition shall be as follows: 12.1.1.1 When samples are taken at the time the castings are poured, at least one sample shall be taken for each group of castings poured simultaneously from the same source of molten metal. 12.1.1.2 When samples are taken from the seminished product, a sample shall be taken to represent each 10,000 lb or fraction thereof, except that not more than one sample shall be required per piece. 12.2 Other Tests For other tests, a specimen shall be taken from two of the sample pieces selected in accordance with 11.1.2. The required tests shall be made on each of the specimens so selected. 12.3 Retests:

11.1.1 Lot Size10,000 lb, or less material of the same mill form, alloy, temper, and thickness, subject to inspection at one time. 11.1.2 Portion SizeSample pieces shall be selected so as to be representative of four individual pieces in each lot. If the lot consists of less than four pieces, samples shall be selected so as to be representative of each piece.

12.

Number of Tests and Retests

12.1 Chemical Analysis A sample for chemical analysis shall be taken and prepared in accordance with Practice E 55. Drillings, millings, etc., shall be taken in approximately equal weight from each of the sample pieces selected in accordance with 11.1.2 and combined into one composite sample. The minimum weight of the composite sample that is to be divided into three equal parts shall be 150 g. 12.1.1 Instead of sampling in accordance with Practice E 55, the manufacturer shall have the option of determining conformance to chemical composition as follows: Conformance shall be determined by the

223

12.3.1 If any test specimen shows defective machining or develops aws, it may be discarded and another specimen substituted. 12.3.2 If the percentage elongation of any test specimen is less than that specied, and any part of the fracture is outside the middle two thirds of the gage length or in a punched or scribed mark within the reduced section, a retest shall be allowed. 12.3.3 If one of the tests made to determine any of the mechanical properties fails to meet a specied limit, this test shall be repeated on two of the remaining pieces selected in accordance with 11.1.2 and the results

SB-171

1998 SECTION II

of both of these tests shall comply with the specied requirements. 12.3.4 If the chemical analysis fails to conform to the specied limits, analysis shall be made on a new composite sample, prepared from the pieces selected in accordance with 11.1.2. The results of this retest shall comply with the specied requirements.

nature of the facilities needed to satisfy the inspector representing the purchaser that the product is being furnished in accordance with this specication shall be included in the agreement. All tests and the inspection shall be conducted so as not to interfere unnecessarily with the operation of the works. 15.3 The manufacturer and the purchaser, by mutual agreement, may accomplish the nal inspection simultaneously.

13.

Test Methods 16. Rejection and Rehearing

13.1 The properties and chemical compositions enumerated in this specication shall, in case of disagreement, be determined in accordance with the following ASTM methods:

Test Chemical analysis Tension

A

ASTM Designation E 54, E 62, E 75, E 478 E 8A

The tension test specimen shall conform to the dimensions shown in Fig. 7 or 8 of Test Methods E 8.

16.1 Material that fails to conform to the requirements of this specication when inspected or tested by the purchaser or his agent may be rejected. Rejection should be reported to the manufacturer or supplier promptly and in writing. In case of dissatisfaction with the results of the test, the manufacturer or supplier may make claim for rehearing.

13.2 In case of disagreement, the sulfur content of the alloys covered in this specication shall be determined in accordance with the method given in the annex to Specication SB-248.

17.

Certication

14.

Signicance of Numerical Limits

17.1 The manufacturer shall furnish to the purchaser a certicate stating that each lot has been sampled, tested, and inspected in accordance with this specication and has met the requirements.

14.1 For purposes of determining compliance with the specied limits for requirements of the properties listed in the following table, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Recommended Practice E 29:

Property Chemical compositon Tensile strength Yield Strength Elongation: 5% and over Rounded Unit for Observed or Calculated Value Nearest unit in the last righthand place of gures Nearest ksi Nearest ksi Nearest 1%

18.

Mill Test Report

18.1 When specied on the purchase order, the manufacturer shall furnish to the purchaser a test report showing results of tests required by the specication.

19.

Packaging and Package Marking

19.1 The material shall be separated by size, composition, and temper, and prepared for shipment in such a manner as to ensure acceptance by common carrier for transportation and to afford protection from the normal hazards of transportation. 19.2 Each shipping unit shall be legibly marked with the purchase order number, metal or alloy designation, temper, size, shape, gross and net weight, and name of supplier. The specication number shall be shown, when specied. 19.3 Product Identication The name or trademark of the manufacturer and the manufacturers lot identication number shall be legibly stamped or stenciled on each nished plate and sheet in two places not less

224

15.

Inspection

15.1 The manufacturer shall inspect and make the tests necessary to verify that the product furnished conforms to the requirements of this specication. 15.2 If, in addition, source inspection of the material by the purchaser is agreed upon by the manufacturer and the purchaser as part of the purchase contract, the

PART B NONFERROUS MATERIAL SPECIFICATIONS

SB-171

than 12 in. from the edges. If the plate and sheet are too small to locate the markings as above, the marking may be placed near the center of the plate and sheet. In the case of butt straps, the markings may be placed 12 in. from the end. The plate number and type shall be legibly stamped on each plate and on each test specimen.

20.

Key Words

20.1 admiralty metal plate and sheet; muntz metal plate and sheet; naval brass plate and sheet; aluminum bronze plate and sheet; copper nickel plate and sheet for pressure vessels

225

Potrebbero piacerti anche

- A319Documento2 pagineA319malika_000% (1)

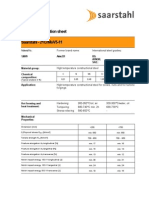

- 21 CR Mo V511Documento1 pagina21 CR Mo V511uksrajNessuna valutazione finora

- ASTM A194 A194M 2022 InglesDocumento3 pagineASTM A194 A194M 2022 InglesErickNessuna valutazione finora

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocumento4 pagineASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaNessuna valutazione finora

- Tigweldarc Alloys: Certification of TestsDocumento1 paginaTigweldarc Alloys: Certification of TestsArunNessuna valutazione finora

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocumento9 pagineFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNessuna valutazione finora

- Sfa-5 31Documento10 pagineSfa-5 31Sarvesh MishraNessuna valutazione finora

- Indian Standard: General Technical Delivery Requirements FOR Steel and Steel ProductsDocumento17 pagineIndian Standard: General Technical Delivery Requirements FOR Steel and Steel ProductsPermeshwara Nand Bhatt100% (1)

- Astm A131 2019 PDFDocumento8 pagineAstm A131 2019 PDFazam RazzaqNessuna valutazione finora

- Steel Castings, Carbon, For General ApplicationDocumento4 pagineSteel Castings, Carbon, For General ApplicationVIKAS DAHIYA100% (1)

- Sa 213Documento11 pagineSa 213gst ajahNessuna valutazione finora

- 011-Astm A 131 2008 Structural Steel For Ships PDFDocumento7 pagine011-Astm A 131 2008 Structural Steel For Ships PDFgraduateNessuna valutazione finora

- Asme Section Ii A Sa-409 Sa-409m PDFDocumento10 pagineAsme Section Ii A Sa-409 Sa-409m PDFdavid perezNessuna valutazione finora

- Astm A106 1999Documento13 pagineAstm A106 1999Rolando CastilloNessuna valutazione finora

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocumento8 pagineHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNessuna valutazione finora

- Astm A27Documento4 pagineAstm A27MAX ALBERTO JUAREZ AVALOSNessuna valutazione finora

- Astm A53Documento2 pagineAstm A53DeepakNessuna valutazione finora

- Seamless and Welded Ferritic Stainless Steel Feedwater Heater TubesDocumento7 pagineSeamless and Welded Ferritic Stainless Steel Feedwater Heater TubesMina RemonNessuna valutazione finora

- Sa 414Documento4 pagineSa 414AnilNessuna valutazione finora

- Specification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardDocumento7 pagineSpecification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardBalkishan DyavanapellyNessuna valutazione finora

- ASTM A283 Grade C: General Product DescriptionDocumento1 paginaASTM A283 Grade C: General Product DescriptionPratyas SarahNessuna valutazione finora

- Cylinder Block - Repair ProcedurDocumento34 pagineCylinder Block - Repair Procedurfebri yulianto100% (1)

- As 2331.3.9-2001 Methods of Test For Metallic and Related Coatings Corrosion and Related Property Tests - MetDocumento2 pagineAs 2331.3.9-2001 Methods of Test For Metallic and Related Coatings Corrosion and Related Property Tests - MetSAI Global - APACNessuna valutazione finora

- 7050 Aluminum Sheet SuppliersDocumento12 pagine7050 Aluminum Sheet Supplierssanghvi overseas incNessuna valutazione finora

- Bearing Steel Material Specification Sheet SAE52100Documento1 paginaBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNessuna valutazione finora

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDocumento9 pagineAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionRaj Rajesh100% (1)

- Standard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessDocumento4 pagineStandard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessarchahmedassafNessuna valutazione finora

- A276a276m 2023Documento8 pagineA276a276m 20237620383tlNessuna valutazione finora

- Astm A105Documento1 paginaAstm A105Isaac SamuelNessuna valutazione finora

- Se 1316Documento46 pagineSe 1316leonciomavarezNessuna valutazione finora

- Asme Sec II Part B 2017Documento1 paginaAsme Sec II Part B 2017Lipika Gayen0% (1)

- 04Cr18Ni10 PDFDocumento3 pagine04Cr18Ni10 PDFAvishekNessuna valutazione finora

- Ductile Iron Castings: Standard Reference Radiographs ForDocumento2 pagineDuctile Iron Castings: Standard Reference Radiographs ForJorge ToribioNessuna valutazione finora

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocumento6 pagineStainless Chromium Steel-Clad Plate: Standard Specification Forist93993Nessuna valutazione finora

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocumento4 pagineMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNessuna valutazione finora

- Asme B18.2.6 2003Documento11 pagineAsme B18.2.6 2003Jesse ChenNessuna valutazione finora

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalDocumento5 pagineAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweNessuna valutazione finora

- 1757 1988Documento4 pagine1757 1988Ramesh BNessuna valutazione finora

- EGW Welding Wire Guide for 490MPa SteelDocumento2 pagineEGW Welding Wire Guide for 490MPa SteelpratishgnairNessuna valutazione finora

- Stainless Steel Billets and Bars For ForgingDocumento4 pagineStainless Steel Billets and Bars For Forgingist93993Nessuna valutazione finora

- Api600 Valve Trim ChartDocumento2 pagineApi600 Valve Trim ChartBoankNessuna valutazione finora

- ASTM A781A781M Standard Specification For Castings, Steel and Alloy, Common Requirements, For General Industrial UseDocumento12 pagineASTM A781A781M Standard Specification For Castings, Steel and Alloy, Common Requirements, For General Industrial Usealucard375Nessuna valutazione finora

- MSE 360 Materials Laboratory I-Fall 2010 Microscopy and Microstructure AnalysisDocumento8 pagineMSE 360 Materials Laboratory I-Fall 2010 Microscopy and Microstructure AnalysisFernando ParidisoNessuna valutazione finora

- A737Documento2 pagineA737doshi78Nessuna valutazione finora

- A493 00 PDFDocumento3 pagineA493 00 PDFJohano AraújoNessuna valutazione finora

- API 2H50 Data Sheet 2012 04 02Documento2 pagineAPI 2H50 Data Sheet 2012 04 02alvaedison00Nessuna valutazione finora

- Astm A537-A537m-95-2000Documento4 pagineAstm A537-A537m-95-2000NadhiraNessuna valutazione finora

- Sa 961 PDFDocumento10 pagineSa 961 PDFaruntpeNessuna valutazione finora

- Astm A148Documento2 pagineAstm A148raghumnNessuna valutazione finora

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocumento7 pagineSpecification For Carbon Structural Steel: SA-36 /SA-36MBowo Edhi Wibowo100% (2)

- Astm A709 A709m PDFDocumento3 pagineAstm A709 A709m PDFBernathTurnipNessuna valutazione finora

- Hes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDocumento23 pagineHes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDouglas A. da SilvaNessuna valutazione finora

- इंटरनेट मानक में जानकारी का अधिकारDocumento15 pagineइंटरनेट मानक में जानकारी का अधिकारSelvaraji Muthu50% (2)

- B 92 - B 92M - 11Documento3 pagineB 92 - B 92M - 11phaindikaNessuna valutazione finora

- Astm A 143M-03Documento3 pagineAstm A 143M-03MritunjayNessuna valutazione finora

- CR StandardsDocumento6 pagineCR Standardsalpha_beta48Nessuna valutazione finora

- Asme2b sb-152Documento6 pagineAsme2b sb-152kkskasdkk12Nessuna valutazione finora

- B 134 PDFDocumento5 pagineB 134 PDFGrato Jr SingcoNessuna valutazione finora

- Ball Float Steam Trap VVVVDocumento6 pagineBall Float Steam Trap VVVVzingalehe25464Nessuna valutazione finora

- Process Recip PDFDocumento8 pagineProcess Recip PDFGanesh KumarNessuna valutazione finora

- SteamTrapApplications - 284 - 295 FFDocumento12 pagineSteamTrapApplications - 284 - 295 FFzingalehe25464Nessuna valutazione finora

- Asme V Si UnitsDocumento3 pagineAsme V Si UnitsvidhisukhadiyaNessuna valutazione finora

- Asme2b sb-171 DDFDocumento8 pagineAsme2b sb-171 DDFzingalehe25464Nessuna valutazione finora

- Resumen 4 y 5 InglesDocumento10 pagineResumen 4 y 5 InglesBilly YaniNessuna valutazione finora

- Managerial Accounting InsightsDocumento147 pagineManagerial Accounting InsightsSiddhantSinghNessuna valutazione finora

- Seminar Presentation On GeneticsDocumento60 pagineSeminar Presentation On GeneticsHardeep KaurNessuna valutazione finora

- Phone Order Form SEODocumento2 paginePhone Order Form SEOTylerNessuna valutazione finora

- Proteose Peptone for Cultivating MicroorganismsDocumento1 paginaProteose Peptone for Cultivating MicroorganismscinthiaNessuna valutazione finora

- Jayson Company Inventory ProblemDocumento6 pagineJayson Company Inventory ProblemGellie RealNessuna valutazione finora

- Praxedes Et Al 2019 PDFDocumento8 paginePraxedes Et Al 2019 PDFLhara OliveiraNessuna valutazione finora

- TDCS Montage Reference v1 0 PDF PDFDocumento10 pagineTDCS Montage Reference v1 0 PDF PDFPatricio Eduardo Barría AburtoNessuna valutazione finora

- Preboard 3 Ee 1 1Documento11 paginePreboard 3 Ee 1 1Christine Sarah LagundiNessuna valutazione finora

- Cekungan Tomori Dan SalawatiDocumento17 pagineCekungan Tomori Dan SalawatiDimas WijayaNessuna valutazione finora

- 1.super Value Titanium CardDocumento3 pagine1.super Value Titanium CardFasih AhmadNessuna valutazione finora

- Liability Is Something A Person or Company Owes, Usually A Sum of Money. ... Recorded OnDocumento5 pagineLiability Is Something A Person or Company Owes, Usually A Sum of Money. ... Recorded OnedrianclydeNessuna valutazione finora

- Module 3 EvaporationDocumento22 pagineModule 3 EvaporationPrince VinceNessuna valutazione finora

- Government of Himachal Pradesh Revenue Department: Compendium of Rules, Instructions andDocumento52 pagineGovernment of Himachal Pradesh Revenue Department: Compendium of Rules, Instructions andharish_6611Nessuna valutazione finora

- Bio (DWCL Main) - NoapplicDocumento16 pagineBio (DWCL Main) - NoapplicPRC Board100% (1)

- Metro Service Schedule InsightsDocumento16 pagineMetro Service Schedule InsightsAtul KumarNessuna valutazione finora

- FREE Shapes AssessmentDocumento10 pagineFREE Shapes AssessmentVicky ChowNessuna valutazione finora

- LS-B Series ModBus Register ListDocumento6 pagineLS-B Series ModBus Register ListEsteban MillarNessuna valutazione finora

- BEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Documento4 pagineBEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Reza Riantono SukarnoNessuna valutazione finora

- Miracle Morning For Writers PDFDocumento203 pagineMiracle Morning For Writers PDFIgnacio Bermúdez RothschildNessuna valutazione finora

- ETM-OT Electronic Temperature MonitorDocumento3 pagineETM-OT Electronic Temperature MonitorMKNessuna valutazione finora

- AMXDocumento10 pagineAMXMarco M0% (1)

- Perma (Permanent) Culture: The Prime Directive of PermacultureDocumento13 paginePerma (Permanent) Culture: The Prime Directive of Permaculturebulut83Nessuna valutazione finora

- SQL COMMANDS FOR HIGH SCHOOL DATABASEDocumento47 pagineSQL COMMANDS FOR HIGH SCHOOL DATABASESooraj Rajmohan75% (28)

- Nelson2014 Hialuronidase em HematomasDocumento3 pagineNelson2014 Hialuronidase em HematomasPaula AzevedoNessuna valutazione finora

- Pinout RS232Documento4 paginePinout RS232FranGigaNessuna valutazione finora

- Open SpaceDocumento77 pagineOpen SpaceTASNEEM HAFIZNessuna valutazione finora

- Akh Ymi DD Fy00x D Ce Rep 6101 0Documento39 pagineAkh Ymi DD Fy00x D Ce Rep 6101 0Tamrayehu KuremaNessuna valutazione finora

- CraneDocumento27 pagineCranemsk7182Nessuna valutazione finora

- Bastasa BenitezBiologyProjectCaminalculesandPhylogeneticTreeDocumento9 pagineBastasa BenitezBiologyProjectCaminalculesandPhylogeneticTreeFerdinand DagaNessuna valutazione finora