Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lycoming O 360 O 540 Overhaul

Caricato da

hallmarckrecordsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lycoming O 360 O 540 Overhaul

Caricato da

hallmarckrecordsCopyright:

Formati disponibili

-

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

..

OVERHAUL MANUAL

LYCOMING

0-360 &0-540 Series Aircraft Engines

Approved by :-

Chief of Aircraft Engineering Division

Fede ' I Aviation Alency

Date :- . /

L ycoming

DIVISION A...:o CORPORATION

Wll UAMSPORT, PA,, U. S. A.

This Publication

F i r st Edition

Part No. e oaes -3

Price $ 6 .0 0

Printed In U. S. A,

ii

I.Y C OMDIG A l ll C H;\ FI E N C IJ\ E O VE Hli A U I.. ~ I A N U A L

WARRANTY

LYCOMING Divi sion - A VCO Cor poration warrants each new e ngi ne to be free

from defe<:ts in material and workmansttip, when prope r ly Installed and used under

normal conditions , for ninety days after the shipment of each engine from the plant or

one hundered hours of operation, whichever eve nttakespla<:e soone r . This warranty

Is Umlted to replacing or repairing at iis shops any part or parts which have been

returned to LYCOMING Divi s ion - AVCO Cor por ation, with t r ansportation charges

prepaid and which, in its opinion, are defective, and LYCOMING shall have no

responsibility lor any consequential da mages. Thi s war ranty is expressly in Ueu of

a ll other warranties and representations, expressed or implied, and a ll other

obligations or liabilities on too pa rt of LYCOMING Division - AVCO Corporation.

Tttis warranty does not cove r any labor char ges for replacement of parts,

adj ustments, repairs or any other work done on LYCOMING e ngines.

This warranty shall not apply to any engine which shall have been repaired

or altered outside of our factory In any way so as In our judgment to affect Us

operation, or which has been s ubj ect to misus e, negllgence or accident, or which

shall have h<len ope rated at a speed exceeding t he ma nufacture r 's rated s peed.

This warrant y s hall not apply to any engine which s hall have h<len operated

With any ot her t han fuel, oil and other lubricants conforming to speclflcations of

LYCOMING Division - AVCO Corporat ion.

LYCOMING Division - A VCO Cor poration, r eserves the r ight at a ny time to

revise, modify or change the construction of LYCOMING engines Wit hout incurring

any obligation to incor porate s uch al terations to engines previous ly sold.

LYCOMING Division - AVCO Corporation, makes no warranty with res pect

to ignition apparatus, carburetors, generators, starters, voltage regulators or

other t rade accessories, Inasmuch as they are usually warranted specially by thei r

respective manufacture rs, and all s uch ltems are sold ''as is. n

,

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L YCOMIJ\G AliiCRAFT E ~ C I N E OVE R H A U L MANUAL

SPECIAL WARRANTY

FOR

Premium Packaged Engines and Service Par ts

LYCOMING Division - AVCO Corporation warrants each ne w pr e mium pack-

aged LYCOMING engine and/or service p<l.rt to be free fr om defects ln mat erial a nd

workmanshi p when pr ope r ly installed and used under normal conditions for 100

hours of operation or 90 days subsequent to r emova l of the engine or part from the

original premium packaging, whichever event takes place sooner, provided that

(I) such p<l.Ckag:ing bas remained sealed and undamaged at all limes, (2) the e ngine

and/or part has been stored at a ll times in a weather protected dry area under

normal humidity conditions, (3) the humidity indicators inslalled within the vapor

barrier have not shown an unsafe condition at any time, and (4) s uch storage of

each engine and/or part in such premium p<l.Cl<aglng has not exte nded beyond six

months from the date of shipment from LYCOMING'S plant in Williamsport,

Pennsylvania.

This warranty is limited to r eplacing ot' repairing at its s hops any part or parts

which have been returned to LYCOMING Division - AVCO Corporation, with trans-

portation charges prepaid and which, in its opinion, are defective, and LYCOMING

shall have no responsibility for any consequential damages. This warranty ls

expressly in lieu of all other warranties and representations, expr essed or implied,

and all other obligations or llabllltles on the part of LYCOMING Division - AVCO

Corporation.

This warranty does not cover any labor charges for replacement of parts,

adjustments, repairs or any other work done on LYCOMING engines.

This warranty shall not applY to any engine or part which shall have been

repaired or altered outside of our factory in any way so as, ln our judgment, to

aifect its operation, or wblch has been subject to misuse, negligence or accident,

or which shall have been operated at a speed exceeding the manufacturer' s rated

speed.

This warranty shall not apply to any engine which shall have been operated

with any other than fuel, oil and other lubricant.s conforming to specifications of

LYCOMING Division - AVCO Corporation.

LYCOMING Division - AVCO Corporation, reserves the right at any time to

revise, modify or change the construction of LYCOMING engines or parts without

Incurring any obligation to incorporate such alterations t o engines preViously

sold.

LYCOMING Division - AVCO Corporation, makes no warranty with respect

to ignition apparatus, carburetors, generators, starters, voltage regulators or other

trade accessories, inasmuch as they are usually warranted s pecially by t.heir

respective manufacturers and all such items are sold

0

as is."

* - The term ((premium packaged" shall mean packaging in accordance with

LYCOMlNG Standard packaging specifications for export shipment.

iii

LYCOMING :\ JRCRAJo' T J:::'i(: I NE OVERHAUL MANU AL

I

I

I

I

TABLE OF CONTENTS

SECTION PAGE

I

I Introduction l

u Gener al 3

I

Lubrication system Diagrams 6-7

In General Overhaul Procedures 9

I

rv Ignition System 15

Ignition Wiring D103rams 17

v Accessor y Housing 21

I

VI Cylinders , Pis tons, a.nd Valve Train 27

V1I Crankcase, Crank.shalt and Reciprocating Parts 43 I

vm Oil Sump 55

IX Test Procedure 59 I

General SpecUlcatlons 59

Preparation lor Stora&e 61

X Table ol Limits 65 I

XJ Over haul Tools '73

I

I

I

I

I

I

,

I

IV

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

'I

I

I

LYC OM I N G AI RC R ,\ FT E N GI NE OVERHA U L ~ I A N V A L

Figure 1. Left Side Vie w, 0 - 360-A

,

Figure 2. Rear View, 0 - 360- A

v

LYCOM ( NC ,lf. RCR AF T E ~ G l ~ E OVE RHA UL MANl:: AL

Figure 3. Left Side View, 0 - 540- A

'

Figure 4. Three-quarter Rear VIew, 0 - 540- A

Vi

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

l. Y C 0 M I N C A I R C R A F T E N C I K E 0 V E R ll A U L A :>! V A L

l

----------------------------------------Introduction

SECTION I

INTRODUCTION

1- 1. This manual contains the necessary Information

for the complete maj or overhaul of the Lycoming

0 -360-A Series, 0-360-C Ser ies and 0 - 540- A Series

Aircraft Engines.

1- 2. The main portion or the text Is divided Into sec-

tions correapon<ting to the basic engine components;

that ts, cylinders, sump, acceasory housing, Ignition

system, etc. Each of these secUoos wlll deal in com-

plete detail with all phases of the overhaul procedure

(Disassembly, Cleaning, Inspection, Repair and Re-

placement, and Reassembly), thus constituting a com-

plete manual In ltsell with reepect to the component

being discussed. Additional sections are Included

covering such subjects as Test Procedure, Prepara-

tion for Storage, General Overhaul Procedures, and

other ilems of a non-spoclfic nature.

1-3. The fools used for overhauling this engine (ell-

eluding the ordinary mecbrutlc's tools found in most

overhaul shops) are Usted in Section XI. When re-

questing Information concerning one of these tools,

refer to tho toot by number and name, and not merely

by name. Inspection gages are Incl uded in the toot

lists.

1-4. It should be noted that when overhauling an en-

gine, It may be necessary to order standard or over-

size parts. A Parts Catalos, with the engine parts

2

3

,

Figure 1- t. Cylinder Numbering Diagram, 0 - 360

listed numerically and alphalleUcaUy, may be obtained

by writing 1o the Service Department, LycomtngDivl-

sion-AVCO Corporation, Williamsport , Pennsylvania.

If for any reason parts are returned to the factory,

the folloWing Information should accompany them;

engine serial number and model, number of hours

service, the reason for the parts being returned,

and any other facts concerning the parts.

1- 5. Service Bulletins are also issued from time to

time whenever the engine is modified or the overhaul

procedure is revised. When received, these bulletins

should be Inserted In the rear of this manual.

1-6. In this manual, the term "front" of the ongtne

shall r efe r to the propeller end of the engine. The

term " r ear " of the engine shall refe r to the anti-

propeller or accessory housing end or the engine. The

terms "right" and " left" shall apply when lhe engine

is viewed by an observer standing at the rear of the

engine, that is, facing the accessory housing. The oil

sump is considered the lower section of the e ngine.

Wben refer ence is made to Individual cylinders and

pistons, the section nearest the crankshaft will be re-

fer red to as the lower section and the section most

remote from the crankshaft (nearest the rocker box

cover) will be referred to as the upper section. Tho

right front cylinder is No. 1 and the cylinders on the

right s ide are designated by odd number (1liJid 3 on

_...Jr - -_ _)

2

)

,-J

I

4

l

r 6

I I

l L__ J- I[J ' > (

Figure 1- 2. Cylinder Numbering Diagram, 0-540

1

Section I

L YC O M ING AIRCRAFT ENG INE O V E R HA U L Mi\.NU A L

- --------- - ------ - --------- - - - --- - - - -------

0 - 360 e ngines; 1, 3, and 5 on 0 - 540 engines). The

left front cylinder is No. 2 and the cyllnders on the

left s ide are de signated by even numbers (2 and 4 on

0 - 360 engines; 2, 4, and 6 on 0 - 540 e ngines). (See

figures 1- 1 and 1- 2.) Tbe direction of rotation of the

crankshaft, looking at the prOpeller end of the engine,

,

2

is counter- clockwise.ln this manual, any reference to

the direction of rotation of the crankshaft shall apply

only when the engine is viewed from the propeller end.

All reference s to direction of rotation of accessory

drives apply only when facing the drives or the dr ive

mounUng pads.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

LYCOMING AI R C RAF T El\GIJ\E OVERHA UL

Se<:tion 2

------ --- - --------------- - - - ---------- GtMrol O.seription

SECTION lJ

GENERAL DESCRIPT ION

2- 1. Tile Lycoming 0-360 se.r ies is a four cyllnder

engine and the 0-540 is a six cyltnder engine. Bolli

model s are air cooled, hor izontally opposed, direct

drive models incorporating a wet sump. Tho 0 - 360

engines have a total displacement or 361 cubic Inches

a nd 0 - 540-ll Ct'lginesllave a dis placement of 541,5 cubic

Inches. Table ll-1 provides lnlor mation on the Individual

features Incorporated in t he various engine models.

2- 2. CYUNDERS. Instead of being directly opposite

each other, the cylinders are staggered, tllus pormlt-

llng a separate throw on the crankshaft for each con-

necUng r od. The cylinders are of conventional air -

cooled construction, with tile two major parts, barrel

and head, screwed and shrunk togetller. The heads

are made from an aluminum alloy casting with a fully

mac hined combustion chamber. The barrels are ma-

chined from chrome nickel molybdenum steel forg-

ings with deep Integral cooling fins; the interior walls

of the barrel are ground and honed to a specilied fin-

ish. The standard engine Is equipped with unplated

barrels and chrome faced piston r ings; chr ome plated

barrels (which require t.he use of plaln rings) are

available as optional equipment.

TAIL! 11 - 1

INDIVIOUAL CHARACTIRISTICS OF VARIOUS HGIN MODU

Number of Propeller lcounter -

Pr opeller

Carburetor Magnetos Mounts Cylinders Operation weights

Governor

Studs

#

!.

:<> !. .{;

(;S .s- .. .. li'

9 ,.. "' <;; # .y _.,., " i i;> d' !.

.,

0 0

..: ., ' ' ' ' ' .d'

l> ,. ;..

'

l / i'

r;{

,! ;,0 . ., 'ti 0"

'<.0

4; .&-&

-::!, .... S'.E S'.:::- .s',f; &

G "'

0 -360-AlA

X X X X

y

0 -360-AIB X X X X X

0-360-AIC X X X X X

0-360-AIO X X X X X

0-360-A2A X X X X X

0-360- A2D X X X X X

0 -360-CIA X X X X X

0 - 360- C!C X X X X X

0-360-C2A X X X X X

0-360-C2B X X X X X

0-360.C2C X X X X X

0-360-C2D X X X X X

0-540-AIA X X X X X X X

0-540-AI.A! X X X X X X X

0 - 540-AI B! X

X X X X X X

0-540-AIC5 X X X X X X X

0-540-AIDS X X X X X X X

0-540-A2B X X

,

X X X X X

0-540-A20 X X X X X X X

3

Se-ction 2

L YC O\fi .'IC A I RC HAF T EN G I N E OVE RII AL'L

Oetcription ------ ----------------------- ----- ------

WARNING

Do not under any circumstances a ssemble

chrome plated piston r ings in a chrome plated

cylinder barrel. Chrome plat ed cylinder s are

identified by an orange band a r ound t he base

of the cylinder ba rrel.

2- 3. Rocker shall beari ng s upports are cas t integr a l -

ly with the heads along with housings to form t he

r oc ker boxes lor both the exhaust and Int ake valve

rocke rs.

2-4. VALVE OPERATING MECHANISM. The valve

operating mechanism Is located on the upper side of

the engine, t hereby facl lltating proper lubrication and

accessibility. The camshall Is parallel to and above

t he crankshalt, a nd In aluminum bear ings.

Hardened and ground cam lobes actuate lhe valves by

means of mushroom type hydraulic tappets which

automatically keep the valve c learance at zero, there-

by eliminating the necessity of any valve c learance

adjustment mechanism. The val ve spr i ngs be ar against

both lower and upper spring seats and are retained

on lhe valve stems by means of tapered split keys .

The valve rockers ar e s upported on lull floating

steel pins.

2- 5. HYDRAULIC VALVE TAPPETS. When t he engine

valve is closed, lhe face of lhe cam follower is on

t he base circle or back of lhe cam. The light plunger

spring lilts lhe hydraulic plunger so that Its outer

end contacts the pus h rod, exe rting a light pressure

against it, thus eliminating any clearance i n the valve

linkage. As the plunger moves outwar d, the ball

check valve moves off its seat. (See figure 2-1. )

Oil from the supply chamber, which i s directly

connect ed wilh the engine lubrication system, llowsln

and fills the pressure chamber. As t he camshalt

rotates, the cam pushes the cam followe r and the

hydraulic lifter cylinder outwar d. Thi s action forces

t he ball check valve onto Its seat; t hus, the body of

6 5 4 II

7

oil trapped i n the pressure chamber acts as a cus hion.

During lhe inte rval when the engine valve is off its

seat, a predete rmined leakage occur s between pl unger

and cylinder bore which compensates for any expansion

or contraction occurring in tbe valve train. lmmedi -

ately alter the engine valve closes, the amount of oil

r equired to fi ll t he pressure chamber !lows in from

t he supply chamber, thereby pr eparing for another

cycle of operation.

2-6. CRANKSHAFT. The cranks halt is made from a

chrome nickel molybdenum steel forging. AU beari ng

journal surfaces are nitrided and centrUugal sludge

r emovers are provided in lhe form of oil tubes at each

crankpi n journal. These tubes are removed during

ove rhaul and replaced with new ones; this enables

t hor ough cleaning of the internal oil passages in the

crankshalt.

NOTE

Cr ankshafts on engines equipped for const ant

speed oper ation are not inter changable wi th

crankshalts on engines equlpped forllxed pilch

oper ation unless the plug installed In lhe r ear

of the hollow front section of the crankshaltls

remove d. In addition, two s pecial (short) pro-

peller flange bushings are used on constant -

speed Installations t o accommodate a controll-

able pitch propeller. (See figure 7- 9 and applic-

able Parts Lists.)

2- 7. CRANKCASE. The crankcase assembly consi sts

of two r einforced aluminum alloy castings divided

vertica lly at t he centerline of the e ngine and fastened

togelher by means of a series of studs and nuts . The

mating surfaces of the crankcase are joined without

lhe use of a gasket, and the ma in bearing bor es ar e

machined for the use of preci sion type main bearing

inserts. Machined mounting pads a r e Incorporated

Into the crankcase for attaching the accessor y hous

ing, cylinders, and oil sump.

3 8

12

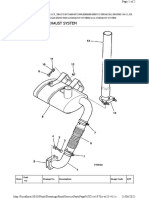

1. Tappet body 5. Push rod socket 9. 011 s upply chamber

2. Cylinder

3. Plunger

4. Plunger spring

6. Push r od shr oud lube

7. Push rod

8. Ba ll cheCk valve

10. Oil hole

11. Oil pre s sure chamber

12. Camshalt

Figure 2- 1. Diagram of Hydraulic Tappet

4

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

LYC OMll\ G 1\ l i\ C RAJiT ENGI NE OVE RIIAI:L MA!\UAL

Sectio" 2

- ---- - --- - - ---- - - - - ------- - --- --- - - ----- Description

2-8. SUMP. The engines covered in this manual are

of the wet sump type. The oil sump Incorporates a

carburetor mounting pad, the Intake riser, and the In-

take pipe connections. The fuel-air mixture, as It

passes through the riser, is vaporized by the heated

oil in the sump that surrounds t he riser. Drilled pas-

sages are provided in the sump for conveying oil to

tbe oil pump.

2-9. CONNECTING ROOO. The connecting rods are

made In tbe form of "H" sections from alloy steel

forgings. They have replaceable bearing Inserts In

the crankshaft ends and split type bronze bushings In

the piston ends. The bearing caps on the crankshaft

ends of the rods are retatned by means of two bolts

through each cap, secured by slotted nuts and cotter

pins.

2-10. PISTONS. The full ski r t type piston Is machined

from an aluminum alloy forging and is provided with

grooves for three rings; two compression rings and

an eJ<pander type oil regulating ring. The piston pin

is of the l ull floating type with an aluminum plug lo-

cated at each end to prevent the pin fr om touching the

cylinder wall.

2-11. ACCESSORY HOUSING. The accessory housing

Is machined from an aluminum alloy casting and is

fastened to the rear of the crankcase assembly and

the !OJ? rear of the sump by hex head bolts. A gear

train (see figures 2-2 and 2- 3) mounted inside the

housing, transmits power from the crankshaft to the

camshaft, oil pump, magnetos, tachometer drive, and

accessories. The gears, which are of the conventional

spur type, are precision ground and hardened to

insure long life and satisfactory operating qualities.

Mounting pads are provided on the rear olthe housing

for the oil pressure screen chamber, magnetos, and

accessories.

2-12. COOIJNG SYSTEM. The air pressure cooling

system Is actuated by the forward speed of the air-

plane. Baffles are provided to build up apre98ure be-

tween the cowling and the cylinders, thus forcing the

cool air thr ough the cylinder fins. Tbe air Is then

exhausted through augmenter tubes or gills located at

the rear of the engine cowling.

2- 13. LUBRICATION SYSTEM. (See figures 2- 4 and

2- 5.) Lubrication is of the lull pressure wet sump

type. The main bearings, connecting rod be arings,

camshaft bearings, valve t appets, and push rods are

lubricated by positive pressure. The pistons, piston

pins, cams, cylinder walls, valve rockers, valve

stems, and other parts are lubr icated by means of

oil collectors and sl'ray.

2-14. The oil pump, which Is located in the accessory

housing, draws oilthrougb a drilled passage which is

connected to a similar drilled passage In the rear of

the sump. The oil from the pump then enters a drilled

passage In the accessory housing which leeds the oil

to a threaded connection on the rear lace of the acces-

sory housing, where a flexible line leads the oil to tlie

external full flow oil cooler. (See figure 5- l.) Pres-

sure oil from the cooler returns to a second threaded

connection on the accessory housing, from which

point a drilled passage conducts the oil to the oil

press\U'e screen which is contained in a cast cham-

Figure 2-2. Gear Train Diagram, 0-360

'V!L """'"

SW.FT<f.R-NI nn

-'"*.OJJ',.

A\ 10 .30 1

,.H"(JP.U.U(: Pt.-WP

Tlo'NG "\\la(S,ljl \\'lUI

11.1QI'.'Jt<>' tl S 1.T T,:

Figure 2- 3. Gear T r ain Diagram, 0-540

her mounted on tbe accessory hous;ng. In the event

that cold oil or an obstruction should restrict the flow

of oil to the cooler, an oil cooler by- pass valve is

provided to pass the pressure oil directly from the

oil pump to the oil pressure scr een chamber. The oil

pressure screen Is provided as a means to filter any

solid particles from the oil. Alter being filtered in

the pressure screen chambe r, the oil is led through a

drilled passage to the oil pressure r elief valve, lo-

cated in the uppet right side of the crankcase in front

of the accessory housing.

2-15. The oil pressur e r elief valve regulates the en-

gine oil pressW"e by allowing excessive oil to return

to the snmp, while the balance of the pr essure oil is

5

Section 2

L YCOMI K C Ali\ C I\ AFT E N C l i\ E OV E RH AU L

Gencrol Description - - - ----------- - --- - --- - - - - ---- - - --- - - - ---

to the mai.n oil gallery in the right half of the

crankcase. During its trave l through the main gallery,

tbe oil i s by means of separate drilled pas-

sages to the main bearings of the crankshaft. The

drilled passages to the bearings are located In such a

manner as to for m an Inertia type lUter. Thus, only

tbe cleanest oil will be fed to the bearings. Angular

holes are through the main bearings to the rod

journals where sludge removal tubes are located.

Here the centrifugal force of the crankshaft removes

any sludge or heavy matter that may be present In tbe

oil. passages f rom t he rear main bearings s up-

ply oil to the crankshaft Idler gear shafts. Oil from

the malo oil gallery also flows to the cam and valve

gear passages, and is then t hrough branch

passages to the hydrauli c tappets and camshaft bear-

ings. Oil enters the tappets t.brough indexing hol es

and travels out through the hollow push rods to the

valve mechanism, lubricating the valve rocker bear-

ings and valve stems . Residual oil from the bearings,

accessory drives, and rocker boxes is returned by

gravity to the sump, from where it is again circulated

through the engine.

2- 16. Pressure bUild up wltbln the crankcase Is held

to a minimum by means of a cenlrifugal type breather

(see figure 5-1) mounted on the upper section of the

accessory housing.

ASH OIL TO PIS'fONS

PIHS,.CAS.E

2- 17. INDUCTION SYSTEM. Carburetion Is provided

by either a Marvel-Schebler model MA-4-5carburetor

or a BendiX PS- 5BD pressure carburetor. Particularly

good distribution of the fuel-ai r mJJd.ure to each cyl -

Inder Is obtained by the center zone Induction system,

which is integral with the sump and is submerged In

oil, insuring a more uniform vaporization of fuel and

aiding In cooling t he oil in the sump. From the riser

the Cuel-alr miJd.ure is distr ibuted to each cylinder by

separate steel intake pipes.

2-18. IGNITION SYSTEM. Dual ignition is furnished

by two Scintilla SN magnetos, which are

respectively on the upper right and left s ides of the

accessory drive housing. The shielded ignition wiring

Is s o arranged that the leftmagnetoflres the top plugs

In the left- hand cylinders and the bottom plugs in the

r ight- hand cylinders, while the r ight magneto fires the

bottom plugs or the left- hand cylinders and the top

plugs of the right- hand cylinders . (See figures 4- 2 and

4-3 .) This ar rangement i nsures consistent drop off

when switching from both magnetos to either the right

or left magneto.

2-19. ACCESSORY DRIVES. The following accessory

drives are as s tandard equipment: starter,

generator , and tachometer. Vacuum pump drives, fuel

pump dr ive s, and propeller governor drives are avail-

able as optional equipment.

'tAPPETS

LEfl&.ANK

GAM SHAFT

SEARING t.IQ,l

CAMSHAFT

GA.IIHKSHAfl i O ER GEAA:S

6

NO.I Irll oli H N0.2. MAI N

8EAR!r.i BEARI NG

(

I

I PUSH ROO SOCI<.ETS

t-PROP. GOVERNOR OIL

I

:C>---.C).o---()1APPETS VACUUM P\IMP

RIGHT BANI( ORIV

I PUSH ROOS PUMP() p

I SPLASH 01\.10 ROCI(lR AO<:II.Eft ARM y

1

. R,.S,Y4Lv .. , /

l oRAI NOI J osuwP . L PRESSURE SCI\EEN 1,./

l fHRU OIL DRAI N f USES

GRAVITY OIL 'THAU

SHROUD TUBES

PRES SUitt

OIL

OI L RELI('

VALVE

DRAIN OI L 10 SUMP

OIL PUMP

SUCTI ON SCREEN

011, SUMP

OIL COOLER

8 '14ASS VAL\It

... . ...... = ..

:

............ ....

Figure 2- 4. Lubrication Diagram, 0 - 360

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

AIR C IIA l'T EN G I:-I E OVERHAUL MANI: I\.1, Section 1

-------------------------------------- -------- - Gene,o.l De-sc:riptlon

011. fO

P$TtNS, I'ISlON MNJ>,

CAM$ , (1t'C. - - -'---ft-- -1-

CAANIWIN - j j---f- -(j

SUC'TlOH SCAtN

.........

011. COOLER

SUIW' 011.

DAAIH 0t. TO IOUMP

CPTIONAl. 11-IERMOSr.t.nc tW-MS5

'JI'il \IE fM'rd.M!I..E

Figur e 2-S. Lubrication Diagram, 0 - 540

7

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L Y C 0 M I N C A t Jl C H A t' T E N G I N E 0 V E R H A G L ~ ~ A l\ U :\ L Se<tlon 3

------- - - - ----- - - ----------- - - - ------Generol 0 ..-e rhoul Procedures

SECTION III

GE N E RAL OVERHAUL P R OCEDURES

3- 1. As mentioned in Section I, this manual will de-

scribe in separate chapters the complete overhaul of

each i ndividual section of the engine, thus dividing t he

manual, for all practical purposes, into a series of

individual overhaul handbooks dealing in turn with t he

ignition system, accessory housing, cylinders, crank-

case and cranksh.alt, and sump. Since tbere are vari -

ous prescribed overhaul practices and instructions of

a non- specific nature which apply equally to all basic

engine components, these general i nstructions wlll be

grouped together and described in Section ill herein,

thus eliminating repetition.

DISASSEMBLY

3-2. Inasmuch as visual inspection immediately fol-

lows disassembly, all Indi vidual parts should be laid

out in an orderly manner on a. workbench as they are

removed from the engine. No cleaning operations

shoul d be performed until this initial visual inspec-

tion has been completed. All loose studs, cracked

cooling fins, loose or damaged fittings, and the like,

should be carefully tagged to prevcnttheir being over-

looked during Inspection.

3- 3. PREPARATION FOR OVERHAUL. By means of

the engine lifting strap and a suitable chain hoist,

remove the engine from the airframe. While the engine

is supported in the atr by the chain holst, bolt the

engine mounting ring (1, figure I-ll to the englne

mounts. The engi ne should then be lowe red into position

on the overhaul stand and dolly (2 and 3, figure 11-1)

or other suitable rotary overhaul stand.

NOTE

If engine is equipped with dynafocal mounts,

first attach dynafO<>al mount mounting ring

adapter s (4, figure 11-ll to the engine and

then fasten mounting ring to adapters.

CLEANING

3-4. With certain limitations as described under Dis-

assembly and Inspection headings of this section, it

is Imperative to clean all engine parts thoroughly to

facilitate inspection. Two processes are involved in

cleaning engine parts; degreaslng and removal of dirt

and sludge (soft carbon), and the removal of bard car-

bon deposits by decarbonizing, brushing or scraping,

and grit-blasting.

3-5. DECREASING. Degreaslng is accomplished by

immersing or spraying the part inasolutionot'carbon

tetrachloride, white furnace oil (38-40 specitic grav-

i ty), or a suitable commercial solvent such as Varsol

or Perm-A-Cblor. Operators are warned agains t the

use of solvents wi th which they are unfamitiar, since

there are products on U>e market which are injurious

to aluminum and magnesium. Extreme care must. be

exercised 11 any water-mi xed degreasing solutions

containing caustic compounds or soap are used. Such

compounds, in addition to being potentially dangerous

to aluminum and magnesium, may become impreg-

nated in the pores of the metal and cause oil foaming

when the engine is returned to service. Wben using

water-mlx.ed solutions, therefore, it is imperative

that the parts be completely and thoroughly rinsed in

clear bolllng water after degreasing. Regardless or

the method and type of solution used, coat and spray

ail parts with lubricating oil immediately after clean-

ing in order to prevent corrosion.

3-6. REMOVAL OF HARD CARBON. While the de-

greasing soluUon will remove dirt, grease, and soft

carbon, deposits of hard carbon will almost invariably

remain on many interior surfaces. To facilitate re-

moval, these deposits must first be loosened by Im-

mersion in a tank containing a decarbonizing solution

(usually heated). A great variety of commercial de -

carbonizing agents are available, including such

products as Gunk, Penetrol, Carbrax, Super .. Chemaco,

Gerlach No. 70 and many others. Decarbonizers, like

the degreasing solutions previously mentioned, fail

generally into two categories, water-soluble and

hydro- carbons, and the same caution concerning tbe

use of water-soluble degreasers Is applicable to

water- soluble decarbonizers.

CAUTION

Extreme caution should be exercised when usw

ing a decarbonizing solution on magnesium

castings. It is recommended that the use of

heated solutions be avoided unless the opera-

tor ill thoroughly famlUar with the particular

solution being used. In addition, the operator

is strongly advised against Immersing steel

and magnesium parts In the same decarboniz-

Ing tank, because this practice often results in

damage to the magnesium parts from corro-

sion.

3-7. Decarbonizing will usually loosen most of the

hard carbon deposits remaining after degreasing; the

complete removal of all hard carbon, howe\'er, gen-

erally requires brushing, scraping, or grit-blasting.

All of these operations demand care on the part of the

mechanic to avoid damage to the machined surfaces.

In parUcular, wire brushes and metal scrapers must

never be used on any bearing or contact surface.

3- 8. When grlt- bl.aBting parts, do not use sand or any

metallic abrasives. It is recommended Instead that

9

LYCOMING A IRC RAF T ENGI:-IE OVERHA UL M,\ 1\' UAL

Genorol Octhoul Proudure--- - ------ - ------ - - - - - ----------- - -

mlldl:y abrasive organic substances ouch as rice,

baked wheat, pla.stic pelleta, or criiBhed walnut sbeUo

be used. All machined surfaces must, of course, be

pr operly and adequately masltedandall open!nga tight

ly plugged before blasting. The one exception to this,

Is the valve seats which may be left unprotected whco

blastina the cyllocler bead combustion chamber. It Ia

oflen advanllltleous to grit blast the seats, since this

will cut the glaze which tends to form (particularly on

the exhaust valve seat), thus facllltating subsequent

va lve seat reconditioning. Piston ring grooves may

be grit -blasted U necessary; extreme caution must be

used, however, to avoid the removal of o1eta.l from the

bottom and aides of the grooves. When grit-blasting

boiiBings, plug all drilled oil passages with rubber

plugs or other suitable material to prevent the en-

trance ot forei gn matter.

3-9. The decarbonizing solution wtllgeneraUy remove

most of the enamel on exterior surfaces. All remain-

Ing enamel should be removed by grlt-blastina, par-

ticul.arly lo the crevices between cylinder cooling

fins.

3- 10. At the conclusion of cleaning operattono, rinse

the part In pe(foleum solvent, dry and remove any

loose particles of carbon or other foreign matter by

air- blasting, and apply a liberal coating of preserva-

tive oil to aU surfaces.

NOTE

A recommended preservative oil Is Sinclair

Rust-0- Lene 50, or equivalent.

INSPECTION

3- 11. The loepecllon of engine parts durlna overhaul

Ia diVIded Into three categor ies; visual, magnetic, and

dimensional. The first two methods are aimed at de-

termining structural failures In tbe parte, while the

third and last method deals witb the size and shape of

each part. A " TABLE OF LIMITS" is shown In Sec-

tion X. Structural failures can be determined by sev-

eral different methods; the method employed depends

on the part 1tseU. Non-austenitic steel parts eao

readily be examined by the magnetic particle method.

Other methods such as X- ray or etching can be used.

During the Inspection of an engine, It Is a useful habit

to have on hand several sets of inspection data sheets

and, u each part Is inspected, it can be cheeked off

on the sheet with any discrepancies noted.

3-12. Visual Inspection should precede all other In-

spection procedures. Do not clean any parts prior to

visual Inspection, since i ndications or a dangerous

operallna condition may often be detected from tbe

residual depoalta of metallic particles found In some

parllcular recess In the engine.

3-13. Defects In non-ferro- magnetic part.& are best

found by careful visual inspection along with a suita-

ble etching process. If it is thought that a fracture

exists In an aluminum part, clean It wltb a fine wire

brush (to r e m o ~ e any carbon, paint or gum) very care

fully so as not to scratch the surface. Apply to the

10

pari a solution made from 1- 1/ 4 poundsolsoclium hy-

droxide and one pint of water at room temperature.

R11111e tbe part thoroughly with water after about me

minute's contact with the solution. l.mmedlately neu-

tralize the part with a solution of one pari ol nitric

acid and three parts of water he:>ted to 38' C. (100'

F.). Keep the parlin this solution until the black de-

posit is disssolved. Dry the part with compressed air.

If a crack exists, the edges will tum black after this

treatment, thus aiding In Its detection. For magnesium

paris, the pr ocess of applying a len percent solution

of acetic acid at room temperature for a maximum

time of one minute should be used, after which the

part should be rinsed with a solution of one oWtce or

hoiiBehold ammonia in one gallon of water.

3-14. BEARlNG SURFACES. All bearing surfaces

should be examined for scores, galling, aod wear.

Considerable scratching and Ught scoring of atumi-

nwn bearing surfaces in the engine will do no harm

and should not be considered cause for rejection of

the part, provided it falls lrlthln the clcaranoes set

forth In the Table of Limits. Even though the part

comes wttbln the specific clearance limits, however,

It will not be satisfactory for reassembly Into the en-

gine unless inspection shows the part to be free from

other scriOIIB defects. Ball bearings should be in-

spected visually and by feel for roughness, flat spots

on balls, flaking or plltlng or races, and for scoring

on outside of races. All journals should be checked

for galllog, scores, misalignment and. out-of-roWtd

condition. Shafts, pins, etc., should be checked for

straightness. Tbis may be done In most cases by us-

Ing vee blocks and a dial indicator.

3- 15. GEARS. All gears should be examined for evi-

dence of pitting and excessive wear. These conditions

are or partic.ular importance when they occur on the

Involute of the teeth; deep pit marks In this area are

sufficient cause to reject the gear. Bearing surfaces

ot all gears should be f ree !rom deep scratches. Bow-

ever, minor abra.slons may be dreseed out with a fine

abrasive cloth.

3-16. CORROSION ON STRESSED AREAS. Pitted sur-

laces In blgbly stressed areas resulting from cor -

rosion can cause ultimate !allure of the part. The fol-

lowing areas should be carefuUy examined lor evi

dence of such corrosion; Interior s urfaces of piston

pins, the fillets at the edges of crankshaft main and

crankpln journal surfaces, and thrust bearing races.

lf pitting exists on any or the surfaces mentioned to

the extent that it cannot be removed by polishing with

crocus cloth or other mild abrasive, tbe part must be

rejected.

3-17. SCREWED FITTiNGS. Screlfled llttings (aoy

parta such as threaded fastenings or plugs) should be

Inspected for condition of threads. Badly worn or

mutilated threads must not be tolerated; the parts

shculd be rejected. However, email defects such as

' slight nicks or burrs may be dressed out with a small

llle, fine abrasive cloth or stone. If the pari appears

to be distorted, badly galled, or mui!Jated by over-

tightening, or from the use of improper tools, it must

be replaced wltb a new one. Defective studS must be

replaced wlt b oversize studs.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L YC O MI N G AI R C RAFT E l\Cl l'i' E O VER H A U L MA :.-IUAL

------ --- ---- - - ---- - ----- ----------Generol O... erhoul Procedures

Fonn m

Sheet No. 1.

Lycoming

Engine No . .............. .... .

OI VUoi OII - A ... COI! POit .4 f JOM

Type - -- -- ---

SERVICE ENGINE OVERHAUL RECORD AND

INSPECTION FOR OPPOSED ENGINES

Carburetor No . ......... .......................... .................... .

Magneto No. Rt ........... ...... ...... Lft ........................ .

SA No . ............... : ......... .. . RS No . ........... .......... _ .. .

.. ................ ................... ....... ....................................... ........ Date ..... ............... ............................ .... ............... ........... -

Owner' s Name ................ ............. - .. ........ - .. .............. ...... Address .............. ......... ... ... ............................... ................. .

Date Rcc'd ............. . .. ............ . Tot. Eng. Time ...... ............. ........... Ti me Since Last OverhauL ................................. .

Reason For This OverhauL .................. .............................. ......................... - ..................................... ... ...... ............. - ..

Starter No . .. .................................... .. Fuel Pump No ...... ............................... Generator No ............ .................. .. ...... .

Carburetor Int. Hang . ....................... .............. ............. ...... Prop. Parts Received ......... .. ....... ................ ............... ...... .

Oil Fittings .. ................................. .... ............ ..................... Spark Plugs ........................ .... ........................................ ..

Special Equipment .............................. . _ ......... .................. _ ............. .............. ...................... ........................... ... ......... .

RJght Loft

Crankcase or

Crankcase Cylinder Assembly

Finished Surfaces

Studs

Thrust Bearlna

Main Bearinn

Remarks

Follower

Cam Follower Body

H ullc Unit

Finished surtacu

Remarks

Crank!Jhalt

Main Bearinit Jou.rnals

Rod Bearing Joumals

Oil Tubet ' "

pjnfsbcd Surfaces

S pline

Counterweights

Rollers

PI

Cams haft

cam Bea ring Journals

Finl.shed

Sercen

Pl ugs

Studs

Finished Surfacet

Rt-marks

Top Cover Plate

Finished Surfaces

Figur e 3- 1. Typical Overhaul Record and Inspection Forms

II

Section 3

L YC OM J N C A JTI C RA F T 1: '1(; I J\ I' OVER HA C L

Gc:nerol ()oferkoul Pro,edure - --- ----------- --- - --- - - - - - --- --- --

3-18. MAGNETIC INSPECTION. AU ferro- magnetic

steel parts should be inspected by the magnetic parti-

cle method. The suc cessful detection of structural

failure by magnetic Inspection demands skill and ex-

perience on the part ol operating personnel. It muat

be remembered thaJ almost any fabricated steel part

will show Indications of some kind, and it is important

thal the operator exercise good judgmentinevaluatlng

the indications. Too rigid an interpretation may r e-

sult in the rejection of a sound part, while on the other

hand, a part showing a dangerous indication may be

returned to service as a result of a too casual diag-

nosis. ln general, areas of stress concentration must

be watched c losely for fatigue cracks. These areas

i nclude such l ocations as keyways, gear teeth, splines,

roots of threads, small holes, and fillets.

3- 19. Proper judgment must also be used In deter-

mining the a mount of curr ent (amperage) applied; t oo

little current will not sufficiently magnetite the part,

while too heavy an application wUI permanently dam-

age the part by overheating and burning thin ar e as ad-

jacent to the electrodes. Agaln, skill and experience

on the part of the operator are of the utmost Import-

ance.

3- 20. COR.ROSION- :PREVENTION. Upon completion

of inspection, coat all s teel parts with preservative

oil. See t ext under "Cleaning" In this section tor

recommended mixture.

REPAIR AND REPLACEMENT

3-21. DAMAGED PARTS. Abnormal damage such as

burr s , nicks, scratches, scoring, or galling should be

removed with a fine oil stone, crocus cloth, or any

similar abrasi ve substance. Following any repair s of

t his type, the part should be carefully cleaned i n order

to be certain that all abrasive has been removed, and

then checked with Us mating part to assure that the

cl earances a.re not exc essive. Flanged surfaces that

are bent, warped, or nicked may be repaired by lap-

ping to a true s urface on a surface plate. Again the

part s hould be c leaned to be certain that all abrasive

has been r emoved. Defective threads can sometimes

he r epaired with a s uitable die or tap. Small nicks

can be r emoved sa.tlsfactorily with Swiss pattern files

or s mall, edged etones. Pipe tapped threads should

not be tapped deeper in order to clean them up, be-

cause this practice will Invariably result in an over-

s ize d t apped hol e. If scratches or galling are r e moved

from a bear ing s urface of a journal, It should be buffed

to a high fi nish. Generally It is impossible to r epair

cracks; bowever, welding operations may be per -

for med In some parts of housings, provided the area

Is not a s tressed section of the part. For eumple,

al most any area of a rocker box may be welded, but

no part or the cylinder head, except t he fins , may be

welded.

3- 22. PAINTED PARTS. Following repair o! parts

requiring us e of paint !or pr otection or appearanae

parts should be repainted according to the following

recommendations:

12

3- 23. Aluminum- alloy parts should have original ex-

terior painted surfaces rubbed s mooth to provide a

proper palnl base. See t hat surfaces to be paint ed are

thor oughly cleaned. Ca re must be taken t o a void

painting mating surfaces. Exterior alumi num parts

should be primed !lrsl with a thin coat of zinc chro-

mate primer. Each coat should be either air dried

for two hours or bal<edati77' C. (350' F.) !or one- half

hour. After the primer is dry, parts should be painted

with gray engine enamel, which should be air dried

until hardorbakedforone-halfhour al82' C. (180' F.).

Aluminum parts from which the paint haa not been re-

moved may be repainted without tho usc of a pri ming

coat, provided no bare aluminum Is exposed.

3-24. Parts requiring a black gloss finish should be

primed first with Zinc chromate pr i mer and then

painted with glossy black cylinder enamel. Each coat

should be baked for 1- l / 2 hours at 177' C (350' F). If

baking facilities are not avaJlabl e , cylinder enamel

may be alr dri ed; bowever, an Inferior fi nish will re-

sult. All paint applied in the abOve operations prefer-

ably should be sprayed; however, If It Is necessary to

use a brush, exercise care to avoid an accumulation

of paint pockets.

3- 25. Shroud tubes should be refinished Inside and out

by dippi ng in zinc chromate primer thinned to spr ay-

ing consistency. After the zinc c hromate primer is

dried, the outside or the shroud tubes should be re-

finished with glossy black enamel.

3-26. Magnesium parts should be e leaned thoroughly

with a dichromate treatment prior to painting. This

t r eat ment consists of cleaning all traces of grease and

otl from the part by us ing a neutral, non .. corroaive

degreaslng medium followed by a rinse, afle r which

the part i s i mmersed for at least 45 minute s in a hot

dichromate solulion (3/ 4 pounds of aodlumdichromate

to one gallon of water at 180 - 200' F-quantlty as r e-

quired). Then the part sbould be wa shed thor oughly

In cold running water, dipped In hot water, and dried

In an al r blast. Immediately the r ealtor , the par t

s hould be painted With a prime coat and grey engine

enamel in tbe same as that prescribed !or

aluminum parts.

3- 27. STUD REPLACEMENT. Any s tuds which are

bent, br oken, damaged, or looso mus t be r eplaced.

After a stud has been removed, the tapped stud hole

should be examined for s ize and condition of threads .

If it is necessary to retap tl\e stud hole, II will also

be necessary to use a suit able oversize st ud. Over-

size studs are furnished 0. 003, 0. 007 and 0. 012-inch

oversize. Studs tl\at bzvc been broken off flush wlth

the case must be drllled and removed with an '"Easy-

Out or other suitable s tud remover . Be careful not

to damage threads. When replacing tiluds, coat the

coarse threads of the stud with anti-seize compound.

3 28. CORROOION- PREVENTION. At the conclusion

of all repair operations and subsequent Inspection,

coat all steel parts with preservau ve oil. See text

w1do r "Cleaning" in this s ection for recommended

mixture.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L YCOM! l\G All1 C l1 :\ F T Cll\ E O V E RH AU L

Seclion i

Overhaul Procedures

REASSEMBL Y

3- 29. CORROSION- PREVENTION. Prior to assem-

bly of subassemblies, all parts should be c leaned to

remove all traces of preservative oil and accumu-

lated foreign matte r. During assembly, cover all

steel parts with a heavy coat of preserva.tive oil

(Sinclair Rust -0 - Lene 50 or equivalent). This pr e -

servative should be used on all machlned surfaces,

especially on bearing surfaces, cylinder bor es, and

piston r ings. The pr actice of using plain lubricating

oil dur i ng assembly Is not r ecommended.

3-30. TABLE OF LIMITS. The Table of Limits (Sec-

tion X) should be consulted wheneve r it is desi r ed to

determine t he backlash and end clearance of gears,

t he clearance between mati ng machined par ts , the

clear ance between movi ng parts which are In close

contact with each other, and the torque limits for var-

ious nuts, scr ews, and fastenings.

3-31. OIL SEALS AND GASKETS. Whe n building up

an engine during major ove rhaul, replace a ll oil seals

and gaskets t hr oughout t he engine. For complete r e -

,

placement sets of seals and gaskets avaJlable for these

engines, consult applicable Parts Catalog.

3- 32. ARBITRARY REPLACEMENT OF PARTS. It

is r ecommended t hat certain parts t hroughout the en-

gine be r eplaced at norma l over haul r egardless of

their apparent condition. Included among these are

the following:

All engine oil bose

All oil seals

All gaskets

All cir clips, lockplates , and ret aining r i ngs

Pi s ton rings

All exhaust valves

All bearing Inserts (main and cr ankpinsl

Magneto drive c ushions

Stressed bolts a nd fastenings

Ca mshaft gear attaching bolts

Connect ing rod bolts a nd nut s

Cr ankshalt flange bolts

Ignition cables

All laminated s hims

Crankshaft s ludge tubes

Exhaust valve keys

13

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Soctlon 4

LYCOMING AIR C R A FT E NGINE OV E 1111A UL MA:>IUAL

--------------------- - - - - - - - --- - -------Ignition Syttc"'

SECTION IV

IGNIT ION SYST EM

4- 1. There are eight different magnetos used on the

various ell8Lne models Incorporated in this overhaul

manual . The 0-360 Series engines Incorporate S4 LN

magn.etos and the Series engines Incorporate

S6LN magnetos. In each of these two groups there

are four different models. The -20 magnetos are

standard magnetos employing two-pole rotating type

mapets. The - 21 are lll<e the - 20 magnetos

but employ an Impulse eoupUng. The purpose of the

impulse coupUng Is: (I) to rotate the magnet faster

than engine crankll\8 speed, thus generating a better

spark for startil\8 (2) to automatically retard the spark

when starting the englne. When the engine ts running

the Impulse coupling acts as a drive coupUng for the

mapeto. Magnetos with the - 200 suffix Incorporate

a retard breaker and are used with a starting vibrator

to faeilltste better starting. The - 200 magnetos also

contain a noise rutcr. All - 204 magnetos are like -20

magnetos except that they, too, Incorporate noise

filters.

4- 2. Table ll-1 In Section U provides Information as

to which magnetos aro Incorporated on the various

model engines. There l.s Utile dUference between

the various model magnetos where timing and ells-

assembly and assembly to the engine are concerned.

V

4- 3. IGNITION CABLES. Remove all elbow termina ls

from the top and bottom spark plugs. Remove the

clamps wbicb secure the lower Ignition cables to each

Intake pipe and remove the clamps from both the right

and left sides of the ell81ne near the lower engine

mounting lugs. Do not remove t he clamps which

encircle the cables a.t Ibis time. Disengage aU ignltloc

cables from the engine. Place a suitable covering

over the ter minal boles In the magnetos to pr event

any for eign substance from entering therein, and un-

screw the spark plugs from each cyllnder with spark

plug wrench aocltet (1, llgure 11-2) and offset handle

(4, figure 11-2).

4- 4. MAGNETOS. Remove the magnetos, adapter and

gaskets from the engine byunscrewlngthetwo5/16- 18

plain nuts and washers I rom the studs which secure the

magnetos to tbe engine. Reach through the opeolngsln

the magneto drive pads ol 0-540 engines and remove

the drive cushions, drive cushion retainers and gears.

No further disassembly of magnetos Is needed other

than the removal of tho drive coupling from the right

magneto of the engine. Place shouldered bush-

Ing, washer and nut, wblch are magneto partsr back on

S6LN magneto shafts after removing drive coupling;

t his Is to prevent threads from being damaged.

REPA IR AND R E P LACEMENT

4-5. IGNITION CABLES. Unless the lgnltloc cable

assembly Is obviously to new condition and Ia knOwn

to have been installed recently, It La recommended

Lbat the Ignition cables be replaced at normal over-

haul. Note, however, that the following parts may be

re- used at the cllscretton of Inspection personnel;

ouUet plate, 4 or 6-wire grommet, coupllng out,

and the grommets and clips o.ttachlng the Ignition

cables to the engine.

4- 6. MAGNETCS. For Information concerning the In-

spection and overhaul of Scintilla magnetos, refer

to manufacturer 's applicable publications.

R E ASSE.MBL Y

NOTE

The following Instructions lor reassembly axe

for engines Incorporating -20or - 204 magnetos

on the r ight side and - 21 or -200 magnetos on

the left . When assembling 0 - 540-AIB5 or

0 -540 AIC5 engines which have two S6LN 21

mapetos, one oc each side, almply use In-

structions given for left magneto, to assemble

and lnstsU both right and left magnetos.

4- 7. MAGNETCS (0- 360 Engines). Install a Woodruff

key in the keyway of the magneto shaft and assemble the

magneto gear In place on the shaft. Place a spacer over

the shaft and scre w on a castellated nut. The magneto

gear may be held in a vise while tbe nut Ia being

tightened. Secure nut with a cotter pin.

4-8. MAGNETCS Engines). Assemble tbe mag-

neto drive coupling on tapered shaft ol S6LN-20

(right) magneto. De certain the Woodruff lr.ey Ia In

the slot of the mapeto shaft. Assemble magneto drive

bushing on the magneto shaft and again be certo.ln a

Woodruff key is Ln the slot in the shall. Assemble

the magneto - sber and nut on the shaft. T!ghlon t he

nut to 15 to 25 loot pounds torque a.nd secure with

cotter pin. Assemble t wo mag1>eto drive cushions and

a drive cushion retainer over the bushing on each

magneto.

4- 9. MAGNETO DRIVE (0- 540 Engines). Install the

magneto gears by reaching through the openings In

t he magneto drive pads and inserting the gears Into

t he bearings. lt will be noted that each of the gears

has a t iming mark etched on one of Its gear teeth

and the crankshaft idler gears each have mark8

15

Section -4 L Y C 0 M ll\ G A 1 1\ C 1\ A I' T E N G I ;>; 0 V E R H A U L ~ ~ A l\ U A L

lgnilioft Sydcm- ----- - - ----- - ----- - - ----- - - - - - - -------

7

5

I

3 1, b

~ _ , . 15

2 'fo-1

I ~ 0

"

14

1. Spark plug sleeve

2. Spark plug collar

COMPLETE IGNITION CABLE ASSY.

6. Spark plug union nul I I. 8-Wire grommet

3. Spark plug elbow

1. Ignition cable 12. Slotted contact washer

8. CoupUng nut 13. Ignition cable sleeve

4. Ferrllie 9. Contour vhsber 14. Cable plate and grommet

5. Sleeve I 0. Ignition cable outlet plate 15. Spark plug

Figure 4- 1. Ignition Cable Assembly, Exploded

etched on two adjacent teeth. The marked tooth of the

magneto gear must mesh wit h the s pace between the

marked teeth ofltte crankshaft idler gear.

4- 10. MAGNETO TIMING.

4-11. When the engine bllildup bas progressed to lhe

pcl nt where all major subassemblies are assembled

and In place on the engine, the magnetos sbollid be

Installed and timed. The following paragraphs des-

cr ibe the recommended procedure.

4- 12. Tum the crankshaft appcslte to Its normal

direction of rotation until it is approximately 35

degrees BTC on lhe compr ession stroke of number one

cyUnder. Clamp the lgllltlon timing pointer (2, !lgure

11-2) on the 25 degrees mark on the starter rtng gear.

Rotate the c rankshaft In Its normal direction of rota-

tion until the pointer and lhe crankcase parting fla.nge

are aligned. ln this position bot h valves on number

one cyllnder should be closed. If the exhaust valve or

number one cylinder Is open, lhe engine Is on the

exhaust stroke o1 number one cylinder and the

c rankshaft must be turned one complete revolution

befor e It Is In proper pcsltlon to install the magnetoe.

Leave the crankshaft in this position until right

magneto le Installed in place on lhe engine.

4- 13. Rotate lhe drive coupling (SSLN magnetos) or

magneto gear (S4LN magnetos) on the r i ght magneto

until the chamfered tooth on the distributor gear to-

s ide the magneto aUgn.s with the white pcinter as seen

through the window in the magneto cover. Without

a llowing gear to turn !rom this position, assemble tho

magneto and gasket; on 0-540 engines also asscm6lo

adapter and second gasket. Secure magneto In place with

washers and nuts; tighten lhe nuts only finger tight.

16

4- 14. Fasten ground wire on electric timing light to

any unpainted metallic portion ortbe engine, and one o1

the pcsltlve wir es of the timing Ught to a suitabl e

terminal connected to the ground terminal connection

ol the right magneto. Turn engine c r ankshaft several

degrees from BTC In direction opposite to that o1

normal rotation.

4- 15. Turn on the switch ol the timing light. Tbe light

should be lit. Turn the crankshaft very slowly in

direction of norm2.! rotation until the Ignition timing

pointer aligns with lhe mark on the c amshaft gear, at

which point the light shollid dlm (or go out on battery-

operated models). lf It does not , turn lhe magneto in

Its mounting flange slots and repeat the procedure

until the light dims at 25 degrees bel ore dead center.

Tighten the two mounting nuts and replace magneto

Inspection plug.

4- 16. Install the lrnpllise coupling rna.gnotoadapter and

gasket on the l eft magneto mounting pad of the acces-

sory housing.

CAUTION

Thelmpulsecoupling magneto(-21) or the 200

magneto can be used only on the left side o1

the engine (as viewed !rom rear) when used

In conjunction wllh -20 or -204 magnetos.

4- 17. Remove inspection plug, depress pawl on lm-

. puJ.se coupling sba.ft and turn lmpuloe coupling on left

magneto until the white beveled tooth (or middle tooth,

If timing gear has tbree beveled teeth) aUgns with the

timing pcinter. Without allowing the magneto gear to

turn from this position, assemble the left magneto

to the accessory housing and secure with washers and

nuts. Tighten nuts only finger tight.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

AIRC RAF T E:\C I:'< E OVERllAUL MANCAL

Soctlon 4

- - - --------------- --------- - - - - - --- ---- Syutm

Figure 4-2. Ignition Wiring Diagram, 0 - 360

NOTE

I! retard breaker (- 200) magneto Is used on

left side of engine, the chamfered tooth marked

with red dye must align wllh the white timing

mark on the distributor block before magneto

Is Installed on engine.

4-18. Connect the other positive wire of the timing

light to a suitable termln3l connected to the ground

t erminal connection 01 the left magneto and time the

magneto ln the same manner as described for the

right magneto.

NOTE

The crankshaft shOuld not be rotated more than

10 degrees In direction opposite normal rota-

tion; because the pawl on the Impulse coupling

WIU engage wlthtbe stop pin and late timing wiU

be Indicated throuch the Impulse coupling

mec hanism. I! tills abould happen, rotate en-

gine In normal direction until sharp click Is

heard; thls w!U Indicate that the Impulse

coupling has passed through !Iring position.

Turn crankshaft In direction opposite nor-

mal rotation to approximately 35 degrees BTC

and proceed with timing check.

4-19. After both magnetos bave been timed, leave tbe

timing light wires connected and re-check magneto

timing as previously described to make sure that both

magnetos are set to fire together. If timing Is cor-

rect, both timing lights will dim simultaneously when

the timing pointer aligns With the centerline of the

crankcase. It the breaker points open too early,

loosen the mounting nuts and rotate the magneto

clockWise. If the breaker pointe open too late, rotate

the magneto count or-clockwlee. Remove Umlng light

Figure 4- 3. Ignition Wiring Diagram, 0-540

and Ignition timing pointer, and r eplace timing In-

spection plug in magneto.

4-20. After the magnetos have been properl,y timed,

clean the breaker points to remove any trace of oil

or dirt. Replace breaker cover and lock the retaining

screws together with lockwire.

4- 21. IGNITION CABLE ASSEMBLY AND JN.

STALLATION.

4-22. ASSEMBLY OF IGNITION HARNESS (AUTO-

LITE OR PACKARD). To assembletbelgnltloncables,

first cut the Individual cables to the lengths shown In

TABLES IV -I, IV - IT, or IV -lll. Assemble each harneas

(right and left) using a epeclal crlmpinQ tool and wire

stripper (Aircraft-Marine Products, Inc., Harrisburg,

Pa., Part No's . . 59249 and 47665 or equivalent). The

procedure for assembl,y of the harness Is u follows:

4-23. See figure 4- 4. M.ake a mark 1- 1/ 4 Inches back

from the magneto end of the cable, and using the nlldclle

cutter (marked "shield") provided on the cutting tool,

proceed to cut through the outer cover and the Wire

braJdJng, being careful not to cut the inside cable. The

cutting can be facilitated by using a pendulum motion

with the cutter. Remove the cut material by sUdlng

It off the end ol tbe cable. Make a mark 1-3/ 4 Inches

from tbe end of the Turn the cutting head over

and using the uppermost cutter, cut through the outer

shielding and remove by sliding olf cable. Make a

mark, 1/ 4 inch from the end 01 the cable; and using

the lower cutter provided on the cutting tool, strip

the cable to the Wire, leaVIng the wlro strands

exposed.

4-24. Prepar e the spark plug ends of the cables in the

same manner as described in the preceding paragraph;

except that the first cut is taken three Inches from the

17

Section 4

LYCOMING AI R C RA F T OVERHA UL MAl\UAL

Ignition Syste"" - - - - - - --- - - - - --- - - --- - - - ------ --- --- ---

end of the cable and the second cut Is 3-1/2 Inches

from the cable end. See figure 4-4.

4-25. Slide a coupling nut (8, figure 4- 1) and sleeve

(5, figure 4-1) (tapered end >ward cable end) over the

magneto end of the cable. Select the prOper ferrule

(4, figure 4- 1) to provide minimum clearance when

assembled, nnd sUp It up under the braiding that is

exposed. Slide the sleeve (5, llgure 4- 1) Into there-

cess provided In the ferrule. Open the crimping tool

jaws to their maximum by opening the lever provided

on the tool and insert the assembled ferrule and

sleeve Into t he bole provided In the jaws. Apply a

llrm pressure on the handles of the tool to crimp the

ferrule In order to make a firm tight grip on the

cable.

4-26. Refer to the Ignition .vlrlng diagram (figure 4- 2

or 4- 3) and arrange the cable lin the proper sequence.

Install a contour washer (9, figure 4-1) over the end

of each cable; then slide the magneto ends of tbe six

cables Into the holes In the lgnltlon outlet plate (10,

figur e 4- l l, making sur e that the number one cable

enters the marked hole In the plate and that the re-

maining cables follow in their proper order. Slioo

the 6-wlre (or 4-wire) grommet (11, figure 4- 1)

onto the cable ends protruding from the outlet plate.

Insert the bared ends at tbe cable strands through

the hole in the center of the slotted contact washer,

(12, figure 4-1). Divide thcstrandsandbendthem over

the face, through the slots and under the rim of tbe

washer.

TABLE IV- I

LINGTH OF INDIVIDUAL AUTOLIT

OR PACKARD CAl lES

10 -360 AIRCRAFT ENGINES)

Cylinder No. and

Plug Location

1 Bottom

3 Bottom

2Top

4 Top

I Top

3 Top

2 Bottom

4 Bottom

Magneto

No.

Lett 1

Left 2

Left 3

Left 4

Right 1

Right 2

Right 3

Right 4

Cable Length

(Inches)

47

41

29.25

21.75

30.50

24.50

44. 50

39.50

REMOVE OuttR COVERING

TO LENGTH SHOWN ----..__ SEE TASl.E I!Z-1

REMOVE WlRE BJWOING "---. i.7&

TO LENGTH 1.2'

&ARE MR ro nu

DIMENSION

4-27. Slide the cable plates (14, figure 4- 1) onto their

respective cables; on an 0 - 540 harness a single

grommet plate is Installed over each of the three top

leads or each harness and on the 0-360 harnesses a

dual grommet plate Is Installed over the two top leads

of eacb harness.

TAILE IV - II

LENGTH OF INDIVIDUAL AUTOLITE

OR PACKARD CABLES

<0-$40 AIRCRAFT ENGINES I

Cylinder No. and Magneto Cable Length

(Inches) Plug Location No.

1 Bottom Left I 53.5

4 Top Left 2 32.5

5 Bottom Left 3 41

2 Top Left 4 41

3 Bott om Left 5 47.5

6Top Left 6 27.5

I Top Right I 42.5

4 Bottom Right 2 47.5

5 Top Right 3 32

2 Bottom Right 4 53.5

3 Top Right 5 35

6 Bottom Right 6 43

A.ll 0 - 540 engines except those Installed In aircraft

manufactured by Piper Aircraft Corporation.

TABLE IV - Ill

lENGTH OF INDIVIDUAL AUTOLITE

OR PACKARD CABLES

10 -$40 ENGINES INSTALLED IN PIPU AIRCRAFTI

Cylinder No. and

Plug Location

1 Bottom

4 Top

5 Bottom

2 Top

3 Bottom

6 Top

I Top

4 Bottom

5 Top

2 Botlom

3 Top

6 Bottom

Magneto

No.

Left 1

Le!t 2

LeftS

Left 4

Left 5

Lefl6

Right 1

Right 2

Right 3

Right 4

Right 5

Right 6

Cable Length

(Inches)

53.5

34.5

41

42

47.5

30.5

42.5

47.5

36

53.5

40

43

OUTER COVERING

TOWGTHSHOWN

RMOVE WIRE BRAIDING

TO LENGTH SHOWN

F+- :;z:r+ $-+ 0 ---

125 -r I 3.00 _ _ _ _j _ -i

SUP COUPI.IHG NUTS <MA CAll

,. IIEFORE ASSEMkY OF FEAALl.E ANO SU:EVE

Figure 4-4. Preparation of Autollte Cables for Assembly

18

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

A I RCIIAI'T ENC JNE OVERHAt:L M., I\V AL Section 4

------------------------ - - ------------- t9nition SY'tcm

4 28. Slide an Ignition cable sleeve (13, !lgur,e 4- 1)

each bottom spark plug lead, then slide a spark

Pill& union nut (6, flgure 4- I) over the spark plug end

of each lead. Install a sleeve and ferrule (5 and 4,

figure 4-1) on each lead In tbe same manner as

described In paragraph 4-24. Install a. spark plug

elbow (3, figure 4-1) and secure In place with the

spark plug union nut. Strip the cable back 1/ 4 Inch

from the end, slide the spark plug collar (2, llgure

4- 1), then the spark plug sleeve (1, figure 4-1) over

the cable and secure the sleeve by dividing the con-

ductor strands into two groups and bending each

group back over the end of the sleeve; repeat Cor all

cables.

4-29. INSTALLATION OF AUTOLITE OR PACKARD

HARNESSES. (See !!gure 4-1. ) Secure each harness to

Its respective magneto by screwing the outlet pi;Lte

(10) t o the pJ;Lte mounting flange on the magneto. In-

stall cable clips at sides and on rear of acceeaory

housing to secure bottom ignition leads to engine. (See

tostallatlon drawings at end o1 Section IX for tocUon

or cUps.) Attach each bottom lead to Its adjacent Intake

pipe with an oUset clamp and screw the elbow Into

the spark plug. All upper leads run directly from the

magnetos to the plugs without Intermediate clamps.

Refer to the Ignition wiring diagrams (figures 4- 2

and 4 -3) for correct terminal connections when ln-

stalUng all leads.

4-30. ASSEMBLY OF BREEZE AND CO-OP HAR-

NESSES (0- 360 ONLY). Make certain the cable at the

magneto ends ol the ignition harness lead Sis trimmed

1.31 - 1.37 Inches from the lace ot the ferrule. The

spark plug end of the leads must be trimmed 1.12 -

1. 18 Inches from tbe ferrule face. Trim the Insu-

lation from both ends of each cable, cutt1ng the

losuJ;LtJon back .32 inch. Assemble each harness rlgl\t

and left as follows:

4- 31. Refer to the ignition wiring diagram (figure 4- 2)

and arrange tbe lead assemblies in the proper sequence.

Insert the magneto ends of the lead assemblies into

the outlet plate making sure that the No. I cable enters

the marked bole In the plate a.nd that the remaining

cables follow In the proper Order. Slide the terminal

block onto the cable ends protruding !rom the outlet

plate. Insert the bared ends of the cable strands of

each lead through the hole In the center of a slotted

cable fastening washer. Divide the strands Into two

groups o1 three and lour, and bend them over the

face, through the slots under the rim of the washer.

Complete the assembly of the magneto end of the

harness by screwing the bushing outs Into the outlet

plate using the magneto bushing wrench (3, Ugure

11- 2).

4- 32. Slide a rubber couar and terminal over the

end of each ca.ble and secure tbe terminal by bending

the exposed conductor stra.nds back over the end of

the terminal.

4-33. INSTALLATION OF BREE.i:E AND CO-OP

HARNESS (0- 360 ONLY). Secure each harness to Its

respective magneto by screWing the outlet plate to the

pWe moW>ting llange on the Install cable

clips at sides and on rear ol accessory housing to

secure bottom Ignition leads to engine. (See installa-

tion draWings at endofSecttoniX!or location of clips .)

Attach each bottom lead to its adjacent Intake pipe

with an orrset clamp a.nd screw the elbow into the

spark plug. All upper leads run directly from 1be

magnetos to 1be plugs without Inter mediate clips.

Refer to Ignition wiring diagram (figure 4-2) !or

correct terminal connections when Installing all

leads.

19

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

'I

I

I

LY C OMli\C AIRCRAF T ENG I NE O VE R ii AUL MANU AL

Section S

- - - ------ - ---- ---- ------- --- - ----- - --- AC<etsory Housi ng

S ECTION V

ACCESSOR Y HOUSING

5- 1. It is assumed that all accessories , such as fuel

pump, vacuum pump, etc., with which the engine is

equipped, WiU have been removed from the accessory

housing before the di sassembly of the housing, a s

descr i bed In the folloWing paragraphs, Is begun.

For overhaul procedures covering the various acces-

sories themselves, consult the applicable manufac-

turer' s handbook.

DISASSEMBLY

5-2. INITIAL DISASSEMBLY.

5- 3. OIL PRESSURE SCREEN HOUSING. (See fig-

ure 5- 1.) Remove thls unit ! rom the engine by un-

screwing t he four 1/4- lnch hex head bolts which se -

cure t he housing to the r ear of the accessor y housing.

5-4. REMOVAL FROM ENGINE. The accessory hous -

ing is removed from engine by unscrewing tbe twe lve

1. Oil Cooler by-pass valve