Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Neff 1978

Caricato da

Freddy Rodrigo Navarro GajardoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Neff 1978

Caricato da

Freddy Rodrigo Navarro GajardoCopyright:

Formati disponibili

886

250

J. Electrochem. Soc.: E L E C T R O C H E M I C A L S C I E N C E A N D T E C H N O L O G Y

June I978

> 200

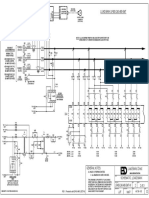

Summarizing, we have shown that the photoresponse of the conventional iron thionine system can be e n hanced with a slight modification of the solution. I n addition, an interesting pH dependence was observed. The finding presented here merits f u r t h e r exploration.

E 150

0 Ii1

I00

Acknowledgments This work was supported, i n part, by a postdoctoral e n e r g y - r e l a t e d fellowship to J. M. Mountz from the National Science F o u n d a t i o n and the College of N a t u ral Sciences, Michigan State University.

Manuscript submitted Oct. 14, 1977; revised m a n u script received Feb. 13, 1978.

50

I,O

2.0

5.O pH

I 4.0

5.0

6.0

A n y discussion of this paper will appear in a Discussion Section to be published i n the December 1978 JOURNAL. All discussions for the December 1978 Discussion Section should be submitted b y Aug. 1, 1978.

Publication costs o~ this article were assisted by Michigan State University.

REFERENCES 1. G. P o r t e r and M. D. Archer, lnterd~scip. Sci,. Rev., 1, 119 (1976). 2. E. Rabinowitch, J. Chem. Phys., 8, 551, 560 (1940). 3. A. E. Potter, Jr. and L. H. Thaller, Sol. Energy, 3, 1 (1959). 4. L. J. Miller, Tech. Ser. Rep., AD 282, 878, U.S. Dept. of Commerce Washington, D.C. (1962). 5. W. D. K. Clark and J. A. Eckert, Sol. Energy, 17, 147 (1975). 6. D. E. Hall, J. A. Eckert, N. N. Lichtin, and P. D. Wildes, This Journal, 123, 1705 (1976). 7. N. N. Lichtin, in "Photochemical Conversion and Storage of Solar Energy," J. R. Bolton, Editor, Academic Press, New York (1977). 8. J. M. Mountz and H. T. Tien, Sol. Energy, To be published. 9. R. Gomer, Electrochim. Acta, ~(}, 13 (1975).

Fig. 2. The dependence of the photogalvanie response for the solution as a function of pH.

As to w h y the m a x i m u m photopotential should occur around pH 3.4, we have no ready answer, for this p h e n o m e n o n has not been studied. However, it appears that, since the species -TH2 + is generated b y light, it is evident from Eq. [1] that the observed photopotential should depend on the stability of the entity at the electrode surface. Conceivably the acetate ion acting as a ligand can somehow either alter the redox potential of the system or increase the rate of i n t e r facial electron transfer. Additional experiments using a v a r i e t y of ligands are of obvious interest.

Electrochemical Oxidation and Reduction of Thin Films of Prussian Blue

Vernon D. Neff

Department o~ Chemistry, Kent State University, Kent, Ohio 44242

We would like to communicate some interesting prel i m i n a r y results concerning the electrochemical behavior of thin films of P r u s s i a n blue. There are actually two well-characterized forms of P r u s s i a n blue (PB) which have the formulas K F e n I F e II(CN)6 and FenI4[Fen(CN)6]~ (1). The latter compound is prepared from a solution containing a large excess of ferric ion. I n addition to PB itself, two additional, closely related compounds are of interest. These are Everitt's salt K2FenFeII(CN)6, which is colorless, and Berlin Green F e m F e m ( C N ) ~ (2). All three compo~mds have the same basic cubic crystal structure consisting of iron ions bridged b y the cyanide groups, although subtle s t r u c t u r a l modifications m a y occur, depending on the stoichiometry (3, 4). The physical and chemical properties of these compounds have been reviewed by Robin and Day (5). We have discovered a method for preparing thin adherent films of PB on various metal and semiconductor substrates. The particular e x p e r i m e n t we wish to discuss is concerned with a thin PB film on a p l a t i n u m foil electrode. The film is obtained from a solution containing equimolar a m o u n t s of ferric chloride and potassium ferricyanide. A o n e - t o - o n e complex b e t w e e n ferric ion and ferricyanide ions forms

K e y w o r d s : e l e c t r o c h e m i c a l o x i d a t i o n , e l e c t r o c h e m i c a l reduction, ]Prussian b l u e films.

in such solutions (6). The solution must be freshly prepared because the complex will slowly polymerize and e v e n t u a l l y a colloidal precipitate of insoluble Berlin green is formed (7). A fresh ~olution 0.01M i n reagent grade FeC18 9 6H20 and 0.01M i n reagent grade KsFe(CN)6 was prepared in triply distilled water. A 1 cm~ p l a t i n u m foil electrode, with p l a t i n u m lead encased i n Teflon, was cathodized for 1 hr at 1 m A in a 1M HC1 solution. The electrode was placed in the ferric ferricyanide solution and, after several m i n u t e s a b l u e film was formed on the surface. The electrode was removed from the solution and rinsed thoroughly with distilled water. A cyclic v o l t a m m o g r a m of the PB electrode in quiet 1M KC1 solution is shown i n Fig. 1. The v o l t a m m o gram was obtained with a PAR Model 173 potentiostat equipped with a Model 175 voltage programmer. The interesting feature of this v o l t a m m o g r a m is that on the anodic side of the sweep (0.6V vs. SCE) the electrode is bright blue, whereas on the cathodic side (0.0V vs. SCE) it is colorless. F u r t h e r m o r e it is possible to switch rapidly b e t w e e n the blue and colorless states with the selecting switch on the potentiostat. The electrode reaction evidently occurs i n the film itself and corresponds to the u l t i m a t e reduction of PB to the colorless "Everitt's salt."

Downloaded on 2013-08-07 to IP 200.72.179.37 address. Redistribution subject to ECS license or copyright; see ecsdl.org/site/terms_use

VoL 125, No. 6

PRUSSIAN BLUE THIN FILMS

887

the simultaneous o x i d a t i o n of chloride ion and the f o r m a t i o n of s u r f a c e oxide on t h e p l a t i n u m . The details of these electrochemical reactions are c u r r e n t l y u n d e r investigation. M a n u s c r i p t s u b m i t t e d Sept. 29 1977; r e v i s e d m a n u s c r i p t r e c e i v e d Dec. 1, 1977.

m

E E

g

D 0

A n y discussion of this p a p e r will a p p e a r in a Discussion Section to be p u b l i s h e d in t h e D e c e m b e r 1978 JOURNAL. A l l discussions for the D e c e m b e r 1978 Discussion Section should be s u b m i t t e d b y Aug. 1, 1978.

Publication costs o~ this article were assisted by Kent State University.

.5 .4 ,3 .2

( V v s SCE)

.1

POTENTIAL

Fig. 1. Single sweep voltammogram of a thin film of Prussian blue on platinum foil in 0.1M KCI solution. The scan rate is 10 mV/sec.

A second o b s e r v a t i o n is concerned w i t h t h e o x i d a tion of the PB film at m o r e anodic potentials. A t a p o t e n t i a l of a p p r o x i m a t e l y 1.0V vs. SCE the film becomes green. I n this case the film has a p p a r e n t l y b e e n oxidized to B e r l i n green. A g a i n the color can be switched r a p i d l y b e t w e e n blue and g r e e n b u t t h e film begins to d e t e r i o r a t e after s e v e r a l cycles p r e s u m a b l y because of

REFERENCES 1. D. Davidson a n d L. A. Welo, J. Phys. Chem., 3~, 1191 (1928). 2. J. F. Duncan and P. W. R. Wigley, J. Chem. Soc., 1120 (1963). 3. J. F. K e g i n and F. D. Miles, Nature (London), 137, 577 (1~36). 4. A. Ludi and H. U. Gudel, Struct. Bonding (Berlin) 14, 1 (1973). 5. M. B. Robin and P. Day, Adv. Inorg. Chem. Radiochim., 10, 247 (1967). 6. J. A_. Ibers ~nd N. Davidson, J. Am. Chem. Soc., 73, 476 (1961). 7. D. E. Knapp, Ph.D. dissertation, K e n t S t a t e U n i versity, Kent, Ohio (1966).

DISCUSSION SECTION

T h i s Discussion S e c t i o n includes discussion of p a p e r s a p p e a r i n g in t h e J o u r n a l o f T h e ELectrochemical S o c i e t y , Vol. 124, No. 7, 9, and 12, J u l y , S e p t e m b e r , a n d D e c e m b e r 1977.

I~ ~ ......

Fabricating Patterns in Tin Oxide Film by Electrochemical Reaction B. J. Baliga and S. K. Ghandhi (pp. 1059-1060, Vol. 124, No. 7)

L F. Chang:l The t e c h n i q u e of f a b r i c a t i n g p a t t e r n s of tin oxide films b y electrochemiceal reaction has also been d e v e l o p e d in our laboratory. 2 We h a v e found t h a t the o v e r - a l l etching r a t e of tin oxide film is not significantly d e p e n d e n t on the concentration of HC1 in w a t e r as shown b y Baliga e~ al.3 However, w e w o u l d like to point out an i m p o r t a n t fact concerning the selection of a critical HC1 concentration. Since the o v e r - a l l etching process consists of two consecutive steps: (i) electrochemical r e d u c t i o n of tin oxide to tin (the d a r k coloration of m e t a l tin can be dir e c t l y observed d u r i n g t h e etching and a n a l y z e d b y i n t e r r u p t i n g the etching process); and (ii) etching of tin b y HC1, it is necesary to select the e l e c t r o l y t e composition such t h a t t h e r e d u c t i o n r a t e of t i n oxide (step i) is h i g h e r t h a n the etching r a t e of tin m e t a l (step ii). This selection g u a r a n t e e s that all the detail p a t t e r n s to be etched a r e etched a w a y w i t h no electrically isolated oxide regions formed on ~he glass substrate. We h a v e found that, for achieving best etching results, the concentration of HCI in w a t e r should be a p p r o x i m a t e l y 7%. A n etched p a t t e r n w i t h resolution on the o r d e r of 20 ~m is shown in Fig. i.

I IBM T h o m a s J. W a t s o n R e s e a r c h C e n t e r , Y o r k t o w n H e i g h t s , N e w Y o r k 10598. I. F. C h a n g , W. P. H o r n b e r g e r , a n d H. H. T a u b , IBM T e c h . Disclosure Bull., 16, 3463 (1974). ~B. J. B a l i g a a n d S. K. G h a n d i , This Journal, 124, 1059 (1977).

Fig. I. Etched pattern in tin oxide film on glass substrate by electrochemical reaction technique (the ruler indicates 0.05 mm per division).

During the course of our work, w e have also discovered some p r i o r a r t in the p a t e n t l i t e r a t u r e 4,5 d e scribing g e n e r a l m e t a l oxide etching b y e l e c t r o c h e m i cal reaction.

B. J. Baliga a n d S. K. Ghandhi:6 W e a g r e e w i t h Chang t h a t b e t t e r etching can b e achieved b y ensuring

R. F. S h a w , US P a t . 3,507,759 (1970). 5 R. E. Szupillo, US P a t . 3,616,349 (1971). General Electric Corporate Research & Development, Schenect a d y , N e w Y o r k 12309.

Downloaded on 2013-08-07 to IP 200.72.179.37 address. Redistribution subject to ECS license or copyright; see ecsdl.org/site/terms_use

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- TransponderDocumento43 pagineTransponderNguyễn NhậtNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- LG Split Type Air Conditioner Complete Service ManualDocumento74 pagineLG Split Type Air Conditioner Complete Service ManualArt Del R Salonga85% (75)

- AC Power Surge ProtectorsDocumento113 pagineAC Power Surge ProtectorsGilberto MejiaNessuna valutazione finora

- FPGA Interview Questions, FPGA Interview Questions & Answers, FPGADocumento9 pagineFPGA Interview Questions, FPGA Interview Questions & Answers, FPGArajeshpandaNessuna valutazione finora

- SH 24 As 6Documento38 pagineSH 24 As 6Stefano SinigagliesiNessuna valutazione finora

- Bockris, John O'M. and Fredlein, Ronald A. - 1973 - A Workbook of ElectrochemistryDocumento179 pagineBockris, John O'M. and Fredlein, Ronald A. - 1973 - A Workbook of ElectrochemistryFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Advances in Zinc Finger Nuclease and Its ApplicationsDocumento13 pagineAdvances in Zinc Finger Nuclease and Its ApplicationsFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- MIMO Radar - Demystified - 2013-01-15 - Microwave JournalDocumento13 pagineMIMO Radar - Demystified - 2013-01-15 - Microwave JournalSudantha Jayalal PereraNessuna valutazione finora

- Cho Et Al 2011 - Rapid DeterminationDocumento4 pagineCho Et Al 2011 - Rapid DeterminationFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Bioactivities of Glycoalkaloids and Their Aglycones From Solanum SpeciesDocumento31 pagineBioactivities of Glycoalkaloids and Their Aglycones From Solanum SpeciesFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- 1984-Ahluwalia&Ellis Simple Method Determination Starch y B-Glucan Barley and MaltDocumento6 pagine1984-Ahluwalia&Ellis Simple Method Determination Starch y B-Glucan Barley and MaltFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- McCaldin 1960 - The Chemistry of NinhydrinDocumento13 pagineMcCaldin 1960 - The Chemistry of NinhydrinFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Kolb Et Al-2001-Angewandte Chemie International Edition PDFDocumento18 pagineKolb Et Al-2001-Angewandte Chemie International Edition PDFFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Characterisation of Screen-Printed Gold and Gold Nanoparticle-Modified Carbon Sensors by Electrochemical Impedance SpectrosDocumento7 pagineCharacterisation of Screen-Printed Gold and Gold Nanoparticle-Modified Carbon Sensors by Electrochemical Impedance SpectrosFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Methods in Statistical KineticsDocumento37 pagineMethods in Statistical KineticsFreddy Rodrigo Navarro GajardoNessuna valutazione finora

- Understanding Langmuir Probe Current-Voltage 1Documento4 pagineUnderstanding Langmuir Probe Current-Voltage 1Denis_LNessuna valutazione finora

- En An Ce / Co Nti Nu Ed: Silicon N-Channel Enhancement IGBTDocumento4 pagineEn An Ce / Co Nti Nu Ed: Silicon N-Channel Enhancement IGBTOsvaldo ChimbasNessuna valutazione finora

- Cylinder - CS2 PDFDocumento25 pagineCylinder - CS2 PDFFelipe Costa de MeirelesNessuna valutazione finora

- Manoj Updated CVDocumento5 pagineManoj Updated CVArun TiwariNessuna valutazione finora

- Eee 226 Microprocessor I ProposalDocumento3 pagineEee 226 Microprocessor I Proposal楊傑克Nessuna valutazione finora

- PV Curve For Voltage StabilityDocumento1 paginaPV Curve For Voltage Stabilityveeru_puppalaNessuna valutazione finora

- Lab ReportDocumento4 pagineLab ReportPearl ArcamoNessuna valutazione finora

- About MeDocumento20 pagineAbout Melovelyosmile253Nessuna valutazione finora

- Copy of ELECTRICAL BOQDocumento12 pagineCopy of ELECTRICAL BOQdesignselvaNessuna valutazione finora

- Standby Power Prime Power: Sr4B HV GeneratorsDocumento6 pagineStandby Power Prime Power: Sr4B HV GeneratorsAM76Nessuna valutazione finora

- 7 P Len Bro CCL 050Documento2 pagine7 P Len Bro CCL 050Helmi HeriyantoNessuna valutazione finora

- Non Destructive Testing of ConcreteDocumento56 pagineNon Destructive Testing of ConcreteAbbasabbasi100% (1)

- 070-0470-02 Rev EDocumento120 pagine070-0470-02 Rev ERama Tenis CopecNessuna valutazione finora

- MPMC Lesson PlanDocumento3 pagineMPMC Lesson PlanASUTOSH PATNAIKNessuna valutazione finora

- Load Bank LP400-240-480-5MTDocumento1 paginaLoad Bank LP400-240-480-5MTCarlos U. CallirgosNessuna valutazione finora

- Fluke GeneratedDocumento9 pagineFluke GeneratedAzri Ab AzizNessuna valutazione finora

- BC557 DatasheetDocumento5 pagineBC557 DatasheetArya WidyatmakaNessuna valutazione finora

- Part 2 - Type S Reversing Combination Starters To Thermal UnitsDocumento94 paginePart 2 - Type S Reversing Combination Starters To Thermal Unitsbakien-canNessuna valutazione finora

- Murata Power Supply Noise Suppression & Decoupling For Digital ICs Application ManualDocumento85 pagineMurata Power Supply Noise Suppression & Decoupling For Digital ICs Application Manualkn65238859Nessuna valutazione finora

- Ale Data PDFDocumento5 pagineAle Data PDFettorreit100% (1)

- Anachip 18CV8P 25 DatasheetDocumento11 pagineAnachip 18CV8P 25 DatasheetMarcelo PerezNessuna valutazione finora

- Challenges That Handheld DevicesDocumento11 pagineChallenges That Handheld DevicesMohamed Helmy SelimNessuna valutazione finora

- Bearing Defect Inspection Based On Machine VisionDocumento20 pagineBearing Defect Inspection Based On Machine VisionArun Kumar100% (1)