Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Final Lifting Plan Sample

Caricato da

Htin Lin AungDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Final Lifting Plan Sample

Caricato da

Htin Lin AungCopyright:

Formati disponibili

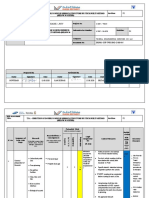

Lifting Plan

Lifting Plan No:Project: - IWWTP @ Banyan Project

Date: - -- July 2012 Contractor: - Tricaftan Environmental Technology Pte Ltd Lifting supervisor - Name:- Mongou Main Contractor - Hitachi Plant Technologies, Ltd Main contractor Engineer - Name:-Ms Amy Thoo 1. Specialist Lifting Contractor:Name: - Tricaftan Mobile Crane, Lorry Crane or Crawler Crane (What crane identify) Mobile Crane What Type:- Mobile Crane (50 Tons)

2. Time: - 9:00 Am to 5:00 pm

From: - --.07.2012 to --.07.2012

Brief Description Of Lifting Operation: - Hoisting up the ---nos: of Chemical containers to on top of the ASR/CR concrete Tank (Please Descript what activity will going to do)

3. Name of appointed Person from Contractor:- Mongou (Lifting Supervisor) Experience and qualification-Above 4 years, Lifting Supervisor Name Of Lifting Supervisor:-Mongou LOA submitted to HPT? Please clarify hereYes

4. Name of singers/signalers qualification and experience:Rigger and Signalman

Page 1

Lifting Plan

a. ---------- (Signal) b. Fazlul (Rigger)

LOA submitted to HPT? Please clarify hereYes

5. List means of identification (i.e. what clothing or color helmet etc will identify them from other site workers. Vest- Red color with RIGGER or SIGNALMAN sign at the back. Safety helmet- Red color.

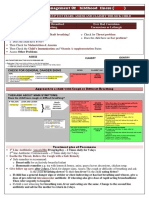

6. Description of Loads:a. Weight- Max weight of load shall be 80% of SWL. b. Characteristics- Miscellaneous types of materials, equipment c. Method of lifting- Using web belt sling and shackle. d. Center of gravity- Align with crane hook. e. Lifting point or method of sling- To be determined by lifting supervisor.

7. Lifting Equipment or appliance to be used:a. Make / Model: - KATO NK500E-III

b. Maximum capacity-

7.5 t x 9.5 m, 40m Boom

c. Counter Weight- 50T hook (500kg) d. Main Boom Length- 40m e. Fly Jib extension- 15m (2section) f. Outrigger load- 39 tonne (front: approx. 15t, rear:approx. 24t)

Page 2

Lifting Plan

g. Maximum Radius- 11.5 m h. Safe Working Load- boom 40m, 1.25 tons

8. Lifting Accessories to be used and SWLa. b. LG H624 B.S.P. shackle SWL c. LG H625 B.S.P. shackle SWL d. LG H626 B.S.P. shackle SWL e. LG H620 W.B. Sling f. LG H621 W.B. Sling g. LG H623 W.B. Sling h. Lifting gears from ? SWL SWL SWL AsiaGroup Leasing Pte Ltd Refer to PTW

9. Proximity Hazards:a. Overhead Power Lines- None b. Underground Tunnels- None c. Airports- None d. Other Strictures- None e. Underground Services- None f. Other Carnages None g. Others (specify)-NA

10.

Ground conditions & Appropriate Controls:-

Ground area is level and compacted Hardcore, concrete slab

Page 3

Lifting Plan

Steel plate supports to be used for the outrigger base Outrigger is fully extended Width of access area is adequate to allow passenger of crane including full extended outriggers.

11.

Are Temp Workers involved in the lift.

Described- 4 workers for support the lifting team

12.

What demarcation will be used:-

a. Is the area an exclusion zone- Yes. b. What barriers and signage- Temporary barriers Yellow and black flag or orange plastic net and warring signages. (Temporary barriers Yellow and black flag), (Danger, Keep Out Signage)

13.

Control of load (tag lines etc)

Use of Tag line.

14.

Crane Rigging requirement (ground condition)-

Stable and level ground, compacted hardcore, concrete slab Steel plate for outrigger base.

15.

Access/Egress (Lifting Equipment-vehicles etc.)

16. Wind speed( what is maximum wind speed for safe lifting, how is it recorded)- 20mph

Page 4

Lifting Plan

17. Is lifting Open or blind? Describe of method of signaling/dogging-(Specify the number of signalers to be used.) One signalman is to be used. Communication is by hand signals, Visual contact between operator and signalman is maintained. Whatever visibility is not possible. Communication between operator and signalman shall be by radio.

18.

Communication? (What means)

Communication between operator and signalman by hand signals and by radio.

19. Have appropriate BLL and crane operator checklist been completed.Yes.

20.

Crane Operator Appointed Person (Contractor) Review & Date.

See guidance note in section 5 below

Signature-

Print NameDate21. Approved by BLL crane Coordinator.

Signature-

Print NamePage 5

Lifting Plan

DateThe lifting plan is to be used no matter the type of lift; standard lifts may need to be reviewed weekly (not weekly. Every lifting operation must submit LP) to ensure nothing has changed. Should the lifting operation come under scrutiny the lifting plan is evidence of addressing all aspect pertaining to the planning of the operation. If lifts are to be repetitive (standard) type then the one lifting plan can be put in place and remain as long as no significant changes have taken place. However as stated preciously it must be reviewed weekly by contractors appointed person.

Note: - For all the Lifting operation must prepare lifting plan to submit HPT before commencement. And attach together Lifting permit.

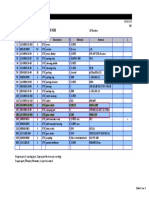

Crane Parking area-1

Page 6

Lifting Plan

Crane Parking area2

Page 7

Potrebbero piacerti anche

- Appendix G Crane Safety Attachment A Pre Lift PlanDocumento2 pagineAppendix G Crane Safety Attachment A Pre Lift PlanSyed Waqhas0% (1)

- PMF 015 HSE 151 v1 Lifting PlanDocumento8 paginePMF 015 HSE 151 v1 Lifting Plansikandar1234Nessuna valutazione finora

- 4A dm253461 Project Premobilization Safety Meeting Checklist PDFDocumento19 pagine4A dm253461 Project Premobilization Safety Meeting Checklist PDFRheNessuna valutazione finora

- Towed Scraper Checklist V0810.1 PDFDocumento1 paginaTowed Scraper Checklist V0810.1 PDFcherifNessuna valutazione finora

- Method Statement For Assembly of 200 Ton Crawler CraneDocumento7 pagineMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaNessuna valutazione finora

- Frequency Converter English ManualDocumento33 pagineFrequency Converter English Manualproduccion multipack100% (2)

- Activity - Alien DNA - CompleteDocumento36 pagineActivity - Alien DNA - CompleteJennifer ShawkiNessuna valutazione finora

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocumento8 pagineMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNessuna valutazione finora

- Lift Plan FormDocumento1 paginaLift Plan Formخالد نسیمNessuna valutazione finora

- 27k Crane Lifting PermitDocumento1 pagina27k Crane Lifting Permitsafety86Nessuna valutazione finora

- 44AB1701-Peacock Project Lifting Plan: Size CapacityDocumento2 pagine44AB1701-Peacock Project Lifting Plan: Size CapacityGokul pNessuna valutazione finora

- Gas Turbine and Generator UnloadingDocumento9 pagineGas Turbine and Generator Unloadingamritrj444Nessuna valutazione finora

- SAIC & SATR - InstrumentationDocumento7 pagineSAIC & SATR - InstrumentationAdel KlkNessuna valutazione finora

- Pe12 3067 Doc q900 Project Hse Plan r0Documento16 paginePe12 3067 Doc q900 Project Hse Plan r0morgojoyoNessuna valutazione finora

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDocumento12 pagineField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNessuna valutazione finora

- Pre Crane Lift ChecklistDocumento1 paginaPre Crane Lift Checklistg665013Nessuna valutazione finora

- Confined Space Rescue Plan: Description of The WorkDocumento2 pagineConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Documento255 pagineD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Lift Plan-Wilco Extenral StairsDocumento25 pagineLift Plan-Wilco Extenral StairsEdgar ChecaNessuna valutazione finora

- Mobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On ChecksDocumento1 paginaMobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On Checksfaisal nadeemNessuna valutazione finora

- Tra-Derrick Module Assembly Below 30 MetersDocumento37 pagineTra-Derrick Module Assembly Below 30 MetersBenasher IbrahimNessuna valutazione finora

- Drum LiftingDocumento6 pagineDrum LiftingnarayananaliveNessuna valutazione finora

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Documento5 pagineHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdNessuna valutazione finora

- Lifting Plan For Off-Loading of Tanks at Mazari YardDocumento9 pagineLifting Plan For Off-Loading of Tanks at Mazari Yardmeshahan100% (1)

- QP Lifting ProcedureDocumento24 pagineQP Lifting ProcedureEr Faiyaz Ahmed100% (1)

- Standard Operating Procedure For HSDDocumento3 pagineStandard Operating Procedure For HSDisjglfdskNessuna valutazione finora

- Inspection and Test Plan: Page 1+0 of 7Documento7 pagineInspection and Test Plan: Page 1+0 of 7Jamal Mohamed Rahamathullah100% (1)

- Indra: Inspection and Test Plan For Lifting Device (Trolley Beams, A-Frame and Jib Crane /davit Type)Documento9 pagineIndra: Inspection and Test Plan For Lifting Device (Trolley Beams, A-Frame and Jib Crane /davit Type)med chabaneNessuna valutazione finora

- Truck Load-Out ChecklistDocumento3 pagineTruck Load-Out ChecklistIsaac Anthony100% (2)

- Safety Inspection Report: KLL (I)Documento1 paginaSafety Inspection Report: KLL (I)Ega NugrahaNessuna valutazione finora

- 009-2021 - R1 - Techno-Commercial Proposal-MAKDocumento28 pagine009-2021 - R1 - Techno-Commercial Proposal-MAKpavanNessuna valutazione finora

- Wall Jib Crane With I-Beam JibDocumento6 pagineWall Jib Crane With I-Beam JibTheodoros AtheridisNessuna valutazione finora

- Guard House Monkey Ladder 01Documento5 pagineGuard House Monkey Ladder 01razi khanNessuna valutazione finora

- Crane Hoist and Rigging SafetyDocumento36 pagineCrane Hoist and Rigging SafetySalim Mohd RazNessuna valutazione finora

- Onshore Critical Lift Plan FormDocumento2 pagineOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- Crane Loading ProcedureDocumento6 pagineCrane Loading ProcedureBala MNessuna valutazione finora

- Overhead Crane Practical EvaluationDocumento3 pagineOverhead Crane Practical EvaluationSyarizal ZainuddinNessuna valutazione finora

- RSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01Documento1 paginaRSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01sani priadi100% (1)

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocumento31 paginePR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionAdnanNessuna valutazione finora

- Form Inspection Premob - Quarterly (1) - 2Documento26 pagineForm Inspection Premob - Quarterly (1) - 2Ryan Rhamdhani100% (1)

- SAMPLE - P4A-Daily Progress Report 210427 KZP 988Documento3 pagineSAMPLE - P4A-Daily Progress Report 210427 KZP 988MEMONessuna valutazione finora

- MEIL Rigging Plan For Unloading LoaderDocumento4 pagineMEIL Rigging Plan For Unloading LoaderGyanendra Narayan NayakNessuna valutazione finora

- HIRA For Steam Drum ErectionDocumento18 pagineHIRA For Steam Drum ErectionNagendra Kumar SinghNessuna valutazione finora

- Method Statement For GTG - BlankDocumento10 pagineMethod Statement For GTG - BlankNaning KusumaNessuna valutazione finora

- Scaffold Inspection Report-Master ListDocumento2 pagineScaffold Inspection Report-Master ListMobin Thomas AbrahamNessuna valutazione finora

- Lifting - SAMPLE-Method of StatmentDocumento1 paginaLifting - SAMPLE-Method of Statmentsudeesh kumarNessuna valutazione finora

- Safe Work Method For Hydro TestDocumento1 paginaSafe Work Method For Hydro TestEswar RaoNessuna valutazione finora

- Curriculum Vitae: INDIA: +91-8344756618Documento4 pagineCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNessuna valutazione finora

- Inspection Report For An Electrical InstallationDocumento4 pagineInspection Report For An Electrical InstallationazlanNessuna valutazione finora

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocumento1 paginaSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNessuna valutazione finora

- Installation Method StatementDocumento6 pagineInstallation Method StatementgururajNessuna valutazione finora

- 3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Documento16 pagine3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Pradeep Kumar MaraptlaNessuna valutazione finora

- Vessel Final BoxDocumento14 pagineVessel Final Boxmanoj thakkarNessuna valutazione finora

- PR139390 - RFP Technical Questionnaire - 20191222Documento5 paginePR139390 - RFP Technical Questionnaire - 20191222sudeesh kumar100% (1)

- MS-ASU-052 MS For Perlite On-Site Expansion and Filling R1Documento11 pagineMS-ASU-052 MS For Perlite On-Site Expansion and Filling R1LamineNessuna valutazione finora

- EOT Crane PermitDocumento1 paginaEOT Crane PermitHimanshu KumarNessuna valutazione finora

- Foam InductorDocumento6 pagineFoam InductorDipanjan Chakrabarti100% (1)

- JSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesDocumento5 pagineJSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesslmLSU100% (3)

- EOHSMS-02-C22 LOA Lifting SupervisorDocumento3 pagineEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocumento18 pagine4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNessuna valutazione finora

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocumento7 pagineLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- Lifting Plan No:-01 Project Al Kheesa Project DN 071Documento4 pagineLifting Plan No:-01 Project Al Kheesa Project DN 071loveson709Nessuna valutazione finora

- Floating Production TechnologyDocumento19 pagineFloating Production TechnologyHtin Lin AungNessuna valutazione finora

- V07a Mooring 1206Documento48 pagineV07a Mooring 1206Htin Lin Aung100% (1)

- V05b - Intro To Deck-Based Process Plant - 1206Documento20 pagineV05b - Intro To Deck-Based Process Plant - 1206Htin Lin AungNessuna valutazione finora

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocumento7 pagineLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- 2D-04: Basic Drawing Commands (Rectangle, Circle, Polygon)Documento9 pagine2D-04: Basic Drawing Commands (Rectangle, Circle, Polygon)Htin Lin AungNessuna valutazione finora

- Safe Work Procedure For Hot WorksDocumento1 paginaSafe Work Procedure For Hot WorksHtin Lin AungNessuna valutazione finora

- Safe Work Procedures For Confined SpaceDocumento3 pagineSafe Work Procedures For Confined SpaceHtin Lin Aung100% (2)

- Ra For OfficeDocumento12 pagineRa For OfficeHtin Lin AungNessuna valutazione finora

- An Overview of Confined Space RescueDocumento50 pagineAn Overview of Confined Space RescueHtin Lin Aung100% (5)

- AutoCAD Release HistoryDocumento2 pagineAutoCAD Release HistoryHtin Lin AungNessuna valutazione finora

- Code of Practice On WSH Risk Management 2011Documento30 pagineCode of Practice On WSH Risk Management 2011Htin Lin AungNessuna valutazione finora

- Cho Gsas - Harvard 0084L 11462Documento503 pagineCho Gsas - Harvard 0084L 11462Claudemiro costaNessuna valutazione finora

- XYZprint User Manual en V1 1003Documento25 pagineXYZprint User Manual en V1 1003reza rizaldiNessuna valutazione finora

- IMCI UpdatedDocumento5 pagineIMCI UpdatedMalak RagehNessuna valutazione finora

- Astm D974-97Documento7 pagineAstm D974-97QcHeNessuna valutazione finora

- Battery Installation ProcedureDocumento5 pagineBattery Installation ProceduresantoshkumarNessuna valutazione finora

- Ceu Guidance Problematic Bleeding Hormonal ContraceptionDocumento28 pagineCeu Guidance Problematic Bleeding Hormonal Contraceptionmarina_shawkyNessuna valutazione finora

- Etl 213-1208.10 enDocumento1 paginaEtl 213-1208.10 enhossamNessuna valutazione finora

- North Central Mindanao College: Maranding, Lala, Lanao Del NorteDocumento8 pagineNorth Central Mindanao College: Maranding, Lala, Lanao Del NorteAnalyn FielNessuna valutazione finora

- PositioningDocumento2 paginePositioningKishan AndureNessuna valutazione finora

- Video Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabDocumento1 paginaVideo Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabBusur DataNessuna valutazione finora

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocumento60 paginePart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65Nessuna valutazione finora

- DLL - Mapeh 6 - Q2 - W8Documento6 pagineDLL - Mapeh 6 - Q2 - W8Joe Marie FloresNessuna valutazione finora

- Problem-Based Learning ReportDocumento24 pagineProblem-Based Learning Reporterdayu86Nessuna valutazione finora

- Case Study (Co2 Flooding)Documento10 pagineCase Study (Co2 Flooding)Jessica KingNessuna valutazione finora

- Neuropsychological Performance in Neurofibromatosis Type 1: Original ArticleDocumento5 pagineNeuropsychological Performance in Neurofibromatosis Type 1: Original ArticleRaquel DuarteNessuna valutazione finora

- Theory of Earth's Magnetism and It's Relation ToDocumento15 pagineTheory of Earth's Magnetism and It's Relation ToMaster Irvin100% (1)

- Habitat Preference of Great Argus Pheasant ArgusiaDocumento11 pagineHabitat Preference of Great Argus Pheasant ArgusiaFaradlina MuftiNessuna valutazione finora

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDocumento65 pagineIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaNessuna valutazione finora

- 1.1 Introduction To KennametalDocumento40 pagine1.1 Introduction To KennametalVig PankajNessuna valutazione finora

- O Solitude! If I Must With Thee Dwell by John Keats: SonnetDocumento6 pagineO Solitude! If I Must With Thee Dwell by John Keats: SonnetshettyNessuna valutazione finora

- Boyle's Law 2023Documento6 pagineBoyle's Law 2023Justin HuynhNessuna valutazione finora

- JMO 2023 (7, 8) Question PaperDocumento2 pagineJMO 2023 (7, 8) Question PaperSuryanshu BhardwajNessuna valutazione finora

- Practical - 2: Preparation of The FixativeDocumento14 paginePractical - 2: Preparation of The FixativeIseth ISethNessuna valutazione finora

- BMS of Dubai International AirportDocumento4 pagineBMS of Dubai International AirportJomari Carl Rafal MansuetoNessuna valutazione finora

- Hydraulics Course FileDocumento81 pagineHydraulics Course FileSwarna LathaNessuna valutazione finora

- DoomsdayDocumento29 pagineDoomsdayAsmita RoyNessuna valutazione finora

- Section Thru A-A at S-1: Footing ScheduleDocumento1 paginaSection Thru A-A at S-1: Footing ScheduleJan GarciaNessuna valutazione finora

- 1943 Dentures Consent FormDocumento2 pagine1943 Dentures Consent FormJitender ReddyNessuna valutazione finora