Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flushing

Caricato da

sujan1980Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flushing

Caricato da

sujan1980Copyright:

Formati disponibili

FLUSHING, CLEANING AND WATER TREATMENT

HES carries out pre-commisioning and flushing to BS7593 for LPHW and chilled water systems. Cleaning of tanks and domestic services is carried out to BS 6700 (Chlorination Standard) Full documentation is provided along with documentation to assist with regular service procedures to help you comply with all the latest legal requirements.

Example of a typical Water Treatment Procedure

The following is work necessary for Pre-flush, Pre-commisioning cleaning and inhibitor dosing (including biocide in chilled systems) of LPHW and Chilled systems. Water Treatment The LPHW/CHILLED systems will be flushed with a cleansing agent, CT340. Then when all of the agent is removed a corrosion inhibitor HE H 600 will be added to the heating/chilled systems. The correct dosing levels will be attained and a report provided for your records (BSRIA Application guide 8/91).

All requirements of COSHH regulations will be complied with during the chemical cleaning and chemical treatment. An Ivorine label will be permanently fixed adjacent to the dosing area stating the chemicals and dose quantity. A completion certificate will be issued when the above has been performed.

Sterilization (Chlorination) The mains water systems including the water storage tanks will be chlorinated in accordance with BS6700. The systems will then be flushed and the sterilization chemical will be introduced up to the correct chlorine concentration. The systems are then left for the correct period of time (indicated) whilst monitoring the chlorine level at intervals to ensure that the concentration is maintained. When the chlorination is complete and the chlorine in the systems has been neutralised a sample will be taken and tested for bacteria. This sample will be sent to the Public health laboratory which is a CPA Acredited Laboratory. On completion of the procedure full certification will be given. Documentation A hard cover binder with all the procedures, chemical treatments and quantities used; on site testing procedures; control limits; material safety data sheets for all chemicals

Detailed Example of the Pre-commisioning Flushing and Cleaning Procedure

(as applied in a major works contract) General Mains Water Analysis Method Statement Preliminary Checks Flushing Cleaning and Water Treatment, Heating and Chilled Water Systems Cleaning and Sterilisation, Domestic Systems Documentation

General This applies specifically to pipework for water systems, specifically heating systems, chilled water systems and hot and cold water domestic systems, including mains water. Flushing, cleaning and water treatment should be carried out on all projects and pipework modification works, unless specifically indicated as not necessary in the particular specification. All works comply with Statutory Authority and HSE requirements and regulations. The whole of our flushing, cleaning and water treatment procedures comply fully with BSRIA Application Guides 8/91, Pre-commissioning Cleaning of Water Systems, and 2/93, Water Treatment for Building Services Systems. Liason is necessary to ensure that any special requirements, such as flushing points, by-passes, dosing pots, pockets, valves, strainers, etc, are provided to enable work to be undertaken fully and completely. Also, information regarding all materials used within the system and hence all the materials that will come into contact with all cleaning and treatment chemicals.

Mains Water Analysis An analysys of the water is supplied which can be checked with the local water supply

authority to ensure that the end analysis results are typical for the site area.

Method Statement A method statement is provided including details of works sequence, programme, chemicals and concentrations, and any temporary or portable equipment required to complete the works satisfactorily. The Mechanical Contractor may then notify manufacturers and suppliers of equipment of the proposed system cleaning and chemical treatment processes to establish if any manufacturer or supplier of equipment requires any particular cleaning and chemical treatment process due to size of waterways or materials used, or if any of the methods or chemicals proposed by the Water Treatment Specialist present potential problems or hazards to the equipment supplied.

Preliminary Checks Prior to carrying out cleaning or chemical treatment process, we ensure that all foreign matter is removed, and that certified pressure tests have been carried out in the parts of the system to be cleaned. We carry out further pressure tests on the isolated sections of the system independently. To comply with instruction we ensure that circulation has been demonstrated and approval gained on all the parts of the system, leave fully open all valves other than those used to isolate sections. We carry out balancing and certification after the flushing, cleaning and passivation operations. We may also ensure that no damage can occur to any item of plant or equipment due to cleaning and chemical processes, that chemicals used are compatible with system materials, and that all items of plant and equipment subject to damage or blockage due to cleaning and chemical treatment processes are isolated or removed. All strainers are cleaned out once during flushing and again after the flushing operation is complete. We comply with all requirements of COSHH regulations during the chemical cleaning

and chemical treatment of the system, and where required by the local Water Authority, can provide effluent tanks for storage of all waste products of cleaning and chemical treatment processes. Following local Water Authority approval we either neutralise and dispose to drain of all waste produces, or ensure authorised disposal at registered sites.

Flushing HES carries out pre-commisioning and flushing to BS7593 for LPHW and chilled water systems. The whole of our flushing, cleaning and water treatment procedures comply fully with BSRIA Application Guides 8/91, Pre-commissioning Cleaning of Water Systems, and 2/93, Water Treatment for Building Services Systems. All systems are flushed in accordance with documents specified. Flushing is undertaken, using portable equipment if necessary, to achieve a full dynamic flush.

Cleaning and Water Treatment, Heating and Chilled Water Systems Water treatment consists of two separate stages, the exact requirements being as recommended by specialist water treatment equipment and chemical manufacturers, on the basis of our water analysis. The first stage treatment follows the flushing indicated above, the system then being chemically cleaned using a sequestrant anti-foulant, or alkaline based solutions, acceptable to the NRA and local water authority, having a PH value between 5 and 10. The second stage consists of a combined corrosion inhibitor and anti-biological fouling agent being introduced.

Cleaning and Sterilisation, Domestic Systems After completion of the flushing process, the systems are sterilised in accordance with BS 6700 and Health and Safety Executive guidance notes HS(G) 70, ensuring prior to sterilisation that systems have been flushed, cleaned and drained. Temporary connections necessary to permit introduction of sterilisation chemicals and fluids should be provided, including a 22mm valved drain connection on the incoming main immediately downstream of the mains isolating valve. Once chemicals have been introduced , the systems are left standing for 24 hours and then repeatedly flushed with clean water until all traces of chlorine have been removed. Prior to handover, samples are taken to provide a certificate of conformity. After chlorination of mains and cold water systems, samples are taken to be analysed and cultured. Duplicate copies of certificates of acceptance as drinking water are provided. Sterilisation of systems includes all equipment containing stored water.

Documentation On completion of all cleaning and treatment operations, certificates and documents are issued detailing the exact works undertaken, together with details of all chemicals used, conditions in which the systems have been left, and recommendations for future system treatment. Further copies of these documents should then be incorporated into the O&M manuals.

Potrebbero piacerti anche

- Method of Statement For Cleaning Flushing and Passivation of Chilled Water PipingDocumento10 pagineMethod of Statement For Cleaning Flushing and Passivation of Chilled Water PipingMYKNessuna valutazione finora

- Flushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQDocumento3 pagineFlushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQابوزيد عبد الجوادNessuna valutazione finora

- Flushing Procedure For Chilled Water System Chemical Treatment Method Statement HQDocumento8 pagineFlushing Procedure For Chilled Water System Chemical Treatment Method Statement HQTerrence Gil Pamienta Buenaflor67% (3)

- T&C of Pressurization UnitDocumento6 pagineT&C of Pressurization UnitMohamed YousufNessuna valutazione finora

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 pagineTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNessuna valutazione finora

- MEP Testing and Commissioning ManagementDocumento6 pagineMEP Testing and Commissioning ManagementJon TyackeNessuna valutazione finora

- Chemical Flushing PDFDocumento13 pagineChemical Flushing PDFtonylyfNessuna valutazione finora

- Air Handling Unit PDFDocumento16 pagineAir Handling Unit PDFizani_idrisNessuna valutazione finora

- Maintenance ManualDocumento16 pagineMaintenance ManualAbdul HakkimNessuna valutazione finora

- Method Statement For Precommissioning & Commissioning of Extract FansDocumento3 pagineMethod Statement For Precommissioning & Commissioning of Extract Fansvin ssNessuna valutazione finora

- OMM-Kandis Residences (2019) PDFDocumento38 pagineOMM-Kandis Residences (2019) PDFjo_eli_Nessuna valutazione finora

- BTU Meter Installation GuideDocumento1 paginaBTU Meter Installation GuidePraveen SagayarajNessuna valutazione finora

- 5-Corrective Maintenance FahuDocumento2 pagine5-Corrective Maintenance FahuUmair LiaqatNessuna valutazione finora

- Method Statement For Air Balancing in HVAC SystemDocumento5 pagineMethod Statement For Air Balancing in HVAC SystemNadeem khanNessuna valutazione finora

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Documento2 pagineSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRNessuna valutazione finora

- DD Electric Driven Fire Pump SpecificationDocumento16 pagineDD Electric Driven Fire Pump SpecificationNurcahyo Djati WNessuna valutazione finora

- LUFT AHU Installation Startup MaintananceDocumento38 pagineLUFT AHU Installation Startup MaintananceUğur DarcanNessuna valutazione finora

- Temporary Site DrainageDocumento9 pagineTemporary Site DrainageGary LoNessuna valutazione finora

- Cooling Tower TNCDocumento6 pagineCooling Tower TNCAarol Hatta100% (1)

- 1.method of Statement - BMS - R0Documento2 pagine1.method of Statement - BMS - R0JaveedMdJaveedNessuna valutazione finora

- Standard Operating Instruction: Sop For Condenser Ball CleaningDocumento6 pagineStandard Operating Instruction: Sop For Condenser Ball CleaningSonratNessuna valutazione finora

- Precommision Cleaning of Piping SystemsDocumento10 paginePrecommision Cleaning of Piping SystemsElias EliasNessuna valutazione finora

- VRF & DX Split Type ACU Testing MethodologyDocumento1 paginaVRF & DX Split Type ACU Testing MethodologydamianNessuna valutazione finora

- Flushing StatementDocumento4 pagineFlushing StatementMohd Salleh Zainal100% (1)

- Domestic - MTD SilentDocumento6 pagineDomestic - MTD SilentVan Vinh NguyenNessuna valutazione finora

- Precommissioning & Commissioning Procedure For Vavs & CavsDocumento3 paginePrecommissioning & Commissioning Procedure For Vavs & Cavsvin ssNessuna valutazione finora

- Shuhail Ibis Hvac ReportDocumento61 pagineShuhail Ibis Hvac ReportNikhil TbNessuna valutazione finora

- Method Statement For Installation of Sanitary FixturesDocumento7 pagineMethod Statement For Installation of Sanitary Fixturesadeniyi abiola100% (2)

- Fans Testing & Commissioning Format-R0Documento13 pagineFans Testing & Commissioning Format-R0Hari SankarNessuna valutazione finora

- Hvac Sys Verification Checklist v2 5 PDFDocumento4 pagineHvac Sys Verification Checklist v2 5 PDFtsraj10100% (1)

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocumento4 pagine2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNessuna valutazione finora

- AHU ChecklistDocumento11 pagineAHU ChecklistRavi SharmaNessuna valutazione finora

- Chilled Water Buffer TankDocumento4 pagineChilled Water Buffer TankThiraviam Ayyappan100% (1)

- Hvac Testing Adjusting BalancingDocumento7 pagineHvac Testing Adjusting Balancingarour.mokraneNessuna valutazione finora

- Sprinkler System Design CapacityDocumento14 pagineSprinkler System Design Capacityisaacodi100% (1)

- LAWA Basic Commissioning Forms - CompleteDocumento53 pagineLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Regulationsof Internal Water Installationsand ConnectionDocumento66 pagineRegulationsof Internal Water Installationsand ConnectionHenrik Gal de OcampoNessuna valutazione finora

- 23 3400 - Hvac Fans PDFDocumento4 pagine23 3400 - Hvac Fans PDFMohamed FawzyNessuna valutazione finora

- HN-MECH-31 Progress Report PDFDocumento1 paginaHN-MECH-31 Progress Report PDFZeshan HaydarNessuna valutazione finora

- Method Statement For Testing & Commissioning of AHUDocumento4 pagineMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- HVAC Maintenance ActivitiesDocumento23 pagineHVAC Maintenance ActivitiesLungisaniNessuna valutazione finora

- External Building DrainageDocumento11 pagineExternal Building Drainagevelayuthan_s9168Nessuna valutazione finora

- Building Services Branch Testing and Commissioning ProcedureDocumento211 pagineBuilding Services Branch Testing and Commissioning ProcedurePHYRAK100% (1)

- Testing & Commissioning Procedure For Staircase Pressurisation SystemDocumento3 pagineTesting & Commissioning Procedure For Staircase Pressurisation Systemvin ssNessuna valutazione finora

- Air Handler Check ListDocumento3 pagineAir Handler Check Listmnt6176100% (1)

- SMP - Condenser, Tube Cleaning & Debris FilterDocumento3 pagineSMP - Condenser, Tube Cleaning & Debris Filtervivekpathak101100% (1)

- Testing and Commissioning Air Handling UnitsDocumento32 pagineTesting and Commissioning Air Handling UnitsWin100% (1)

- Installation of Chilled Water PumpsDocumento1 paginaInstallation of Chilled Water Pumpsmohamed farookNessuna valutazione finora

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocumento3 pagineTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong VanraNessuna valutazione finora

- Precommissioning & Commissioning Procedure For Card Access Control SystemDocumento4 paginePrecommissioning & Commissioning Procedure For Card Access Control Systemvin ssNessuna valutazione finora

- APMRG1 Series: Packaged Air ConditionersDocumento32 pagineAPMRG1 Series: Packaged Air Conditionerszaid jamaluNessuna valutazione finora

- Pre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFDocumento5 paginePre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFjajaka100% (2)

- Hvac-00 2. Hvac-01 3. Hvac-02 4. Hvac-03 5. Hvac-04 6. Hvac-05Documento1 paginaHvac-00 2. Hvac-01 3. Hvac-02 4. Hvac-03 5. Hvac-04 6. Hvac-05Haneefa ChNessuna valutazione finora

- Cooling TowersDocumento11 pagineCooling TowersSlim Kat Nkosi0% (2)

- Booster Pump CommissioningDocumento24 pagineBooster Pump CommissioningOnur Sürücü100% (4)

- Method Statement For Chlorination Domestic Water Supply and Dosing SystemDocumento6 pagineMethod Statement For Chlorination Domestic Water Supply and Dosing SystemMuhammad ZubairNessuna valutazione finora

- Flushing Procedure For Chilled Water SystemDocumento3 pagineFlushing Procedure For Chilled Water SystemJohnna CenaNessuna valutazione finora

- Water DisinfectionDocumento24 pagineWater DisinfectionJaycen RussellNessuna valutazione finora

- Health Code Chapter8Documento14 pagineHealth Code Chapter8Victor PugliesiNessuna valutazione finora

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ADa EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANessuna valutazione finora

- MEP Systems Design RequirementsDocumento1 paginaMEP Systems Design Requirementssujan1980Nessuna valutazione finora

- Method Statement For Installation of Rmu: Al Naboodah Mep L.L.CDocumento5 pagineMethod Statement For Installation of Rmu: Al Naboodah Mep L.L.Csujan198050% (2)

- Grade 2 Reading PassageDocumento1 paginaGrade 2 Reading Passagesujan1980Nessuna valutazione finora

- Chiller Efficiency ConversionDocumento3 pagineChiller Efficiency Conversionsujan1980Nessuna valutazione finora

- Reply To Comments - SampleDocumento1 paginaReply To Comments - Samplesujan1980Nessuna valutazione finora

- Snagging List: ISSUE: 02 DATE: 01.11.2012 REV.: 01 Form No.Documento3 pagineSnagging List: ISSUE: 02 DATE: 01.11.2012 REV.: 01 Form No.sujan1980Nessuna valutazione finora

- PPR Pipe Installation MethodDocumento2 paginePPR Pipe Installation Methodsujan198081% (16)

- MEP Construction Details Below Ground ServicesDocumento1 paginaMEP Construction Details Below Ground Servicessujan1980Nessuna valutazione finora

- Snagging List: ISSUE: 02 DATE: 01.11.2012 REV.: 01 FORM NO.: SPML-CAD-F-018Documento3 pagineSnagging List: ISSUE: 02 DATE: 01.11.2012 REV.: 01 FORM NO.: SPML-CAD-F-018sujan1980Nessuna valutazione finora

- Method Statement FOR Vac Air Balancing System: Rev. Date Description Prepared by Reviewed by ApprovedDocumento3 pagineMethod Statement FOR Vac Air Balancing System: Rev. Date Description Prepared by Reviewed by Approvedsujan1980Nessuna valutazione finora

- Weekly Report (11 05 2014)Documento2 pagineWeekly Report (11 05 2014)sujan1980Nessuna valutazione finora

- Comparision StatementDocumento3 pagineComparision Statementsujan1980Nessuna valutazione finora

- Method Statement For Drainage & Vent PipingDocumento6 pagineMethod Statement For Drainage & Vent Pipingsujan198050% (2)

- SmacnaDocumento58 pagineSmacnascribdquyNessuna valutazione finora

- JSA FormatDocumento3 pagineJSA Formatsujan1980Nessuna valutazione finora

- Cleaning and Flushing of The Chilled Water Piping SystemDocumento2 pagineCleaning and Flushing of The Chilled Water Piping Systemsujan198086% (14)

- FlushingDocumento5 pagineFlushingsujan1980100% (1)

- MOS - Installation of Feeder PillarDocumento3 pagineMOS - Installation of Feeder Pillarsujan1980100% (2)

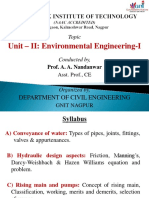

- Unit - II: Environmental Engineering-I: TopicDocumento53 pagineUnit - II: Environmental Engineering-I: Topicbharatiya technologyNessuna valutazione finora

- Operating and Maintenance Manual FOR Horizontal Immersion Heated Steam BoilersDocumento10 pagineOperating and Maintenance Manual FOR Horizontal Immersion Heated Steam BoilersSubburajMechNessuna valutazione finora

- SULZER Water MixerDocumento12 pagineSULZER Water MixerAlfonso José García LagunaNessuna valutazione finora

- Souvenir of Garrettsville CentenDocumento65 pagineSouvenir of Garrettsville CentenEric DunnNessuna valutazione finora

- Tirupur Water Supply and Sanitation Project: An Impediment To Sustainable Water Management?Documento17 pagineTirupur Water Supply and Sanitation Project: An Impediment To Sustainable Water Management?ObaidUrRehmanNessuna valutazione finora

- Irrigation Systems and ComponentsDocumento32 pagineIrrigation Systems and ComponentsKristia Jane Guno Repolidon100% (1)

- Saringan Air HujanDocumento8 pagineSaringan Air HujanDannyNessuna valutazione finora

- Records Management in Ministry of WaterDocumento52 pagineRecords Management in Ministry of WaterEdmond MulindwaNessuna valutazione finora

- Global Actiflo Ref Sorting List (June 2010) PDFDocumento16 pagineGlobal Actiflo Ref Sorting List (June 2010) PDFtkortiz24Nessuna valutazione finora

- Drawing Control: - Sasec Engineering Consultants Ramon C. JalandoniDocumento4 pagineDrawing Control: - Sasec Engineering Consultants Ramon C. Jalandoni龙琦Nessuna valutazione finora

- Assessment of Hygiene Promotion in Madagascar - 2009Documento66 pagineAssessment of Hygiene Promotion in Madagascar - 2009HayZara MadagascarNessuna valutazione finora

- 2022 EU 2 Module 2 Designing Building Water Systems Part 3Documento60 pagine2022 EU 2 Module 2 Designing Building Water Systems Part 3BryanHarold BrooNessuna valutazione finora

- 7.RA 9275 Phil - Clean Water Act Engr. Wilma UyacoDocumento62 pagine7.RA 9275 Phil - Clean Water Act Engr. Wilma UyacoDyeri FloresNessuna valutazione finora

- Landscape Irrigation DESIGN STANDARDSDocumento36 pagineLandscape Irrigation DESIGN STANDARDSEppNessuna valutazione finora

- Yelm Commercial Water Conservation BudgetDocumento8 pagineYelm Commercial Water Conservation BudgetNisqually Valley NewsNessuna valutazione finora

- Form SWA-LRDocumento8 pagineForm SWA-LRMatthew WeeNessuna valutazione finora

- MPA Chapter 6 PDFDocumento116 pagineMPA Chapter 6 PDFWidya AyuningtiyasNessuna valutazione finora

- Unit 3 Pictures About WaterDocumento5 pagineUnit 3 Pictures About WaterJulia Casanova GonzalezNessuna valutazione finora

- University of Garmian Civil Engineering Department Third Stage Water Supply and SewerageDocumento15 pagineUniversity of Garmian Civil Engineering Department Third Stage Water Supply and SewerageZhwa 18Nessuna valutazione finora

- Mirani DamDocumento2 pagineMirani DamNabi BakhshNessuna valutazione finora

- Group 1 - Introduction To PlumbingDocumento19 pagineGroup 1 - Introduction To PlumbingKade julian RentaNessuna valutazione finora

- River Hindon PDFDocumento241 pagineRiver Hindon PDFR P SinghNessuna valutazione finora

- Zone 1678330388Documento4 pagineZone 1678330388Myo Myint MaungNessuna valutazione finora

- Pharmaceutical Water System Design OperationDocumento11 paginePharmaceutical Water System Design OperationManivannan KathirvelNessuna valutazione finora

- ENG341 - Exam Study PDFDocumento18 pagineENG341 - Exam Study PDFBlake MarxsenNessuna valutazione finora

- TamorDocumento3 pagineTamorBidur GautamNessuna valutazione finora

- Marcus TableDocumento1 paginaMarcus TableMarcus AustriaNessuna valutazione finora

- Piping Identification and Valve Tagging StandardDocumento6 paginePiping Identification and Valve Tagging Standardmanox007Nessuna valutazione finora

- Dam Break Analysis of Mullaperiyar Dam Using HEC-RASDocumento8 pagineDam Break Analysis of Mullaperiyar Dam Using HEC-RASIJRASETPublicationsNessuna valutazione finora