Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lean Manufacturing

Caricato da

ltcmenishadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lean Manufacturing

Caricato da

ltcmenishadCopyright:

Formati disponibili

Lean Manufacturing, 5S and Six Sigma

Page 1 of 8

Were big fans of lean manufacturing practices, 5S and Six Sigma based on the results weve seen in metal casting plants as well as in other manufacturing companies. If you are not embracing and implementing these concepts, chances are your company is not moving forward. If you are not continually improving you are moving backwards relative to your competitors.

LEAN MANUFACTURING

Lean manufacturing is the implementation of the concept that anything that does not create value in the product is to be eliminated. It is the concept of more value for less work. As trained industrial engineers, it seems pretty basic to us. Its simplicity is what makes it work. While the Japanese are rightfully given credit for re-vitalizing the concept of lean, its roots really go back to Frederick Winslow Taylor of Bethlehem Steel in the 1880s and 1890s. Then it was called Scientific Management. The Taylor approach starts with a clean slate it designs the process to, as much as possible, only include steps that create value in the product. It is well suited for new plants, new products or new processes. The Japanese approach addresses existing plants, products and processes. It is focused on eliminating waste (anything that is not adding value). As waste is reduced, quality improves, production times are reduced and cost is minimized. Various methodologies are used as tools to achieve this including Value Stream Mapping, 5S, Kanban (pull systems) and error-proofing. Our view is that starting with Taylors approach lets you establish the perfect world as a base line. Using the Japanese approach then helps you work toward the perfect world. Lets use a casting example. A typical process might be to

cast, clean, finish, re-clean, machine and ship. Why do we clean, finish and machine? We know these processes often cant be eliminated but why not try? If the casting can be produced as-cast either by achieving best practice methods or changing casting methods (investment casting and lost foam often achieve as-cast parts), machining can be eliminated or minimized. If you dont put the stock on you dont have to take it off. Why is finishing (or at least why is so much) required? We know a state-of-the-art OEM producing iron castings in green sand that require almost no finishing. Are you grinding/trimming parting lines? Then your patterns or molds may need attention. Are you grinding rough casting surfaces? Then your sand is not right or your die casting practices need improvement. Grinding gates? Can they be relocated to areas where they can be left untouched and minimized using knife gating? Are you welding? If you are not joining parts in welding all you are doing is fixing mistakes. Why do you clean before finishing? Good sand and shake-out practices should produce castings that are clean enough for finishing. Just clean one time after finishing. Whats your scrap level? If youre not under 3% total scrap, no matter what casting method you use, you are not achieving best practice. Thats without welding and other salvage operations by the way. There are metal casters achieving these levels every day. How do they do it? They share a lot of common traits. First, they understand what best practice is for the process they are using. That includes melting, molding, sand preparation, finishing or what-ever process they are using. They know the best practice way to do everything. You would be surprised at how many metal casters we visit who dont know what can be done. Next, they are fanatic about doing it the right way. That means equipment

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 2 of 8

is well maintained, systems are defined, documented and implemented the same way every time and everyone is well trained and does their job right. After that they focus on problem jobs ones that require re-design, special gating, handling or other steps to insure they are scrap free. Finally, they document all scrap and attack issues. There are other lean practices to implement. If production flows perfectly, there is no inventory waiting to be worked on. Metal casters have helped minimize work-in-process by installing conveyor lines to keep castings moving right through to finished goods storage. This eliminated putting the castings in totes and the added handling. One low to medium volume gray/ductile iron jobbing foundry (casting weights under 50 pounds) we know now ships 30% of its production the same day and believes they can achieve 70% same day shipment. These standards arent just for the high volume or dedicated metal casting companies any more. Autonomation or smart automation is a part of lean manufacturing as well. Autonomation refers to automating the process so humans can focus on what humans do best. The objective here is to design the machine so it knows when it is working abnormally and alerts a human. The human no longer has to monitor normal production but can focus on abnormal or fault conditions. Removing routine and repetitive activity reduces the chance for error. Lean manufacturing is focused on doing the right tasks, at the right place, at the right time, in the right quantity to achieve perfect work flow while eliminating waste (scrap) and with the ability and flexibility to change. Implementing lean manufacturing often requires a cultural change in all levels of the

organization. Once management is committed, a program needs to be started that begins with small successes and grows to include the entire organization. The Toyota Production System (TPS) focuses on muri and muda. Muri focuses on the preparation and planning of the process, or what work can be eliminated in the design process. Muda are those waste steps and processes that add cost. Muri is used in new product design and muda is used to improve existing operations. TPS identifies 7 key muda*. They are: Transportation (moving products that is not actually required to perform the processing) Inventory (all components, work-inprocess and finished stock not being processed) Motion (people or equipment moving or walking more than is required to perform the processing) Waiting (waiting for the next production step) Overproduction (production ahead of demand) Over Processing (due to poor tool or product design creating activity) Defects (the effort involved in inspecting for and fixing/scrapping defects)

*From Lean Thinking, Womack, James P. and Jones, Daniel T., Free Press, 2003, p. 352

What are the steps to developing a lean culture? 1. Senior management needs to agree on a lean vision.

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 3 of 8

2. Identify the project leader and set objectives for the leader. 3. Communicate the plan and vision to the workforce 4. Solicit volunteers to form the Lean Implementation Team. Five to seven people with varied backgrounds seems to work best. 5. Appoint the Lean Manufacturing Implementation Team 6. Train the team in various lean tools. 5S is often a good starting point. 7. Select a pilot project for implementation. 8. Implement the pilot. Evaluate the results, review and learn from mistakes made. 9. Roll out the next project(s). 10. Train supervisors how to teach and train their employees. 11. Continue adding and training in additional lean manufacturing tools.

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 4 of 8

FIVE S

Companies frequently select 5S as a method to start their lean manufacturing program. Five S is a manageable process that is relatively easy for people to understand and get their arms around. Five S is a reference to five Japanese words that have been transliterated and translated into English. The technique is often characterized, incorrectly, as a standardized cleanup. It is more than that. Five S is a method to organize and manage the workspace and work flow with the intent of improving efficiency by eliminating waste, improving work flow and reducing process inefficiencies. The 5Ss are: Sort (Seiri), Straighten (Seiton), Sweep (Seiso), Standardize (Seiketsu) and Sustain (Shitsuke). Sort This means going through the work area and making sure only essential items are present. This is eliminating tools, materials, fixtures or any other items not used in the process. Everything else is stored or, preferably, discarded. Straighten - Straighten focuses on setting the workplace in order to focus on efficiency. This is more than just arranging the tools and equipment where they will be used and in the sequence they will be used. It is straightening the work path for materials, tools and the work process. Of all the steps this is the one that typically produces the greatest cost reductions. Straightening the work process can include changes in dies or tooling that reduces finishing labor, for example. It may include interaction with the customer to implement design changes that result in cost reduction or

quality improvement. It is also the step that bears the most repeat visits to implement continual improvement. Sweep This is just what it says: keeping the workplace clean as well as neat. At the end of the shift, the work area is cleaned and everything is restored to its proper place. In straighten, the workplace is clearly marked where things go and gives confidence in the ability to find what is needed when it is needed. The key point here is that cleanliness is a regular part of the daily work effort, not an effort initiated when the workplace gets too messy. Standardize Standardizing the work practices means operating in a consistent and standardized fashion. Everyone knows their role and exactly what his or her responsibilities are. Actions are taken the same way the right way every time. Sustain This means more than just maintaining what has been established. Five S becomes a way of life and a new way to operate. It is important that management does not allow a gradual decline back to the old ways of operating. Sustain also means that when an issue arises a suggested improvement, a new tool becomes available, or a new output requirement the process is reviewed for improvement.

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 5 of 8

At times a sixth S for Safety is added. Five S purists argue that implementation of the 5S protocols will result in safety. Implementation of the 5S program usually starts with a manageable project. These tend to be in limited work areas or warehouse locations. Once implemented, the results are publicized and the concept is expanded to other areas. The strength of 5S is the ease of understanding and implementing the concept.

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 6 of 8

SIX SIGMA

Six Sigma is a quality improvement technique developed by Motorola in 1986 to improve manufacturing processes and eliminate defects. Motorola still owns the service and trade marks for the name Six Sigma. Six Sigma refers to 3.4 defects per million opportunities. For reference, Five Sigma is 230 DPMO and Four Sigma is 6,210 DPMO. Three Sigma is 66,800 DPMO or 93.32% good opportunities per million. Most people recognize Six Sigma by the Green Belts and Black Belts. In an organization fully committed to Six Sigma there are also Champions (responsible for implementation across the organization) and Master Black Belts (in-house coaches for Black and Green Belts). Black Belts are typically dedicated full time to the process and Green Belts take Six Sigma implementation along with other responsibilities. The weakness, in our view, is that practitioners become so enamored with the process that they over analyze and fail to act. Six Sigma has two key methods DMAIC (used in existing processes) and DMADV (used in new products/processes). Heres what those acronyms mean. DMAIC Define high level project goals and the current process. Measure key aspects of the current process and collect relevant data. Analyze the data to establish cause and effect relationships. Determine the nature of the relationships and attempt to insure all factors have been considered.

Improve the process based upon the results of the data analysis. Control the process to insure that any deviations from the process are corrected before they result in defects. DMADV Define the design goals that consider both customer demands and enterprise strategy/capabilities Measure and identify the characteristics critical to quality, product capabilities, production process capabilities and risks. Analyze to develop and design alternatives. This is a product improvement strategy. Design details in a manner to optimize the design. Verify the design details. Verify the design, set up pilot runs, implement the production process and turn it over to the process owners. While many metal casters would scoff at Six Sigma thats .00034% scrap a number of metal casters are achieving that level of shipped quality. If you are producing safety critical parts for passenger vehicles, Six Sigma isnt good enough. For example, if you are making 4 million steering knuckles a year Six Sigma would mean 12 vehicle failures per year. Or if you are making vanes for aircraft engines, Six Sigma just wont do it. Since most metal casters are working to improve their processes, lets work through the DMAIC process. When we started in metal casting over 30 years ago, the old timers (now us) said metal casting was an art, not a science. As engineers right out of college we knew better. Metal casting is a science with a whole lot of variables that interact in ways we may not fully understand. Were going to use

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 7 of 8

scrap reduction in a green sand foundry to explain the Six Sigma process. Also, were going to focus on green sand for our example since it is probably the greatest cause of scrap and one of the most complex ingredients in any of the casting processes. Define high level project goals and the current process This is pretty straight forward and not too hard to get right. A goal may be to lower scrap from 6% to 3%. Defining the sand selection and conditioning process is a relatively easy documentation procedure. Measure key aspects of the current process and collect relevant data. A little tougher but not all that hard. Many green sand foundries measure green strength, sand grain distribution, methylene blue (active clay levels) and moisture. All are very quantifiable and lend themselves to the standard SPC charts. We do know a few foundries that still use the molders hand, however, for sand quality. Wait! Theres more. To be of value later on, we need to track the scrap and the reason for the scrap. Remember the goal is to reduce scrap not produce molding sand within all its parameters on the SPC charts. Analyze the data to establish cause and effect relationships. Determine the nature of the relationships and attempt to insure all factors have been considered. This is the tough one and where people tend to get bogged down. On the cause side there are moisture, grain size distribution, active clay levels, levels of fines and other additives (cereals and sea coal, etc.). On the effect side are a lot of defects surface finish, sand holes, veining, etc. Some of the defects may be caused by something other than the sand

creating even more Sigma practitioners and develop a regression analysis mix.

complexity. Dedicated Six would collect tons of data complex multiple linear to develop the ideal sand

A common mistake at this point is to assume your ingredients are correct, just not in the right proportions. The first step is to understand what best practice sand preparation is and what it can do for you. Sand is not sand is not sand. Foundries on the East Coast frequently use sea sand. This sand contains calcium that has an impact on the casting process. Some East Coast foundries buy Lake Sand from the Midwest because it tends to be purer. Clay is not clay is not clay. There are Southern Bentonites and Western Bentonites and now, some clays coming from Greece seem very attractive. Selection of the tool to analyze the process and defect causes is a major reason for Six Sigma failures. A better tool selection here would have been axiomatic analysis. Axiomatic analysis places the parameters (moisture, sand type, bond types/levels, etc.) in a matrix and makes well thought out, controlled changes and analyzes the results. Its a sophisticated trial and error method. Improve the process based upon the results of the data analysis. This is where the value comes in. By making the changes indicated, costs are reduced and quality is improves. If you dont get to this point, everything else is wasted. Control the process to insure that any deviations from the process are corrected before they result in defects.

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Lean Manufacturing, 5S and Six Sigma

Page 8 of 8

Once youve determined an improved way to formulate and prepare the sand, now you have to make sure everyone sticks to it. Generally, that part is not too hard. You set the parameters, record the results and hold people accountable. Now heres the tougher part. A number of years ago Ford and Honda developed a common engine with Ford producing them in a plant in California and Honda at an identical plant in Japan. After they were in production for a while, there was a noticeable difference in the warranty claims between the engines produced in the U.S. and those in Japan. The U.S. engines had higher warranty claims, although still within reasonable levels. Engineers carefully analyzed the U.S. and Japanese manufacturing processes (the processes were identical, remember). In the U.S. operators were very careful to stay within the SPC guidelines for each process. They met all the quality requirements. In Japan, the operators tried to stay as close to the mid-point of the parameters as they possibly could. A whole difference in attitude to quality. Doing it good enough or doing it the best you can. Whats the attitude at your company? Doing it good enough or the best you can?

2009 The Folk Group, Doylestown, PA, 18901. 1.215.340.9072 www.folkgroup.com

Potrebbero piacerti anche

- AI and Chatbot Mastery: A Guide for Young Dentists Opening Their Own Practices: All About DentistryDa EverandAI and Chatbot Mastery: A Guide for Young Dentists Opening Their Own Practices: All About DentistryNessuna valutazione finora

- On Deck PDFDocumento1 paginaOn Deck PDFTre HuntNessuna valutazione finora

- Energy in Depth - The Gas RootsDocumento20 pagineEnergy in Depth - The Gas RootsJames "Chip" NorthrupNessuna valutazione finora

- TikTok SlidesDocumento17 pagineTikTok SlidesCelebiNessuna valutazione finora

- 2020 CED HighlightsDocumento16 pagine2020 CED HighlightsCTV CalgaryNessuna valutazione finora

- The Unicorn List - FortuneDocumento13 pagineThe Unicorn List - FortuneDeen SanwoolaNessuna valutazione finora

- The Message and The MessengersDocumento71 pagineThe Message and The MessengersDory HippaufNessuna valutazione finora

- Yelp TestimonyDocumento4 pagineYelp TestimonyLuther LoweNessuna valutazione finora

- AZ Poll Workers Gave Woman A Sharpie To Vote and Then Threw Out Her Ballot, Lawsuit ClaimsDocumento8 pagineAZ Poll Workers Gave Woman A Sharpie To Vote and Then Threw Out Her Ballot, Lawsuit ClaimsPJ Media100% (1)

- Koch and Export Import Bank ReportDocumento19 pagineKoch and Export Import Bank ReportM Mali100% (1)

- Coronavirus Reporter v. AppleDocumento21 pagineCoronavirus Reporter v. AppleMikey CampbellNessuna valutazione finora

- WEF Innovation in Payments and Fintech China India ENG 2020Documento14 pagineWEF Innovation in Payments and Fintech China India ENG 2020Jugal AsherNessuna valutazione finora

- Rivian HB 460 Georgia Coalition LetterDocumento3 pagineRivian HB 460 Georgia Coalition LetterMaria MeranoNessuna valutazione finora

- Owners Mag 9-2011Documento60 pagineOwners Mag 9-2011casey1936Nessuna valutazione finora

- FTX Crypto Services LTD of Limassol, Cyprus Petition For Bankruptcy, 23 Pages, Nov. 11th, 2022Documento23 pagineFTX Crypto Services LTD of Limassol, Cyprus Petition For Bankruptcy, 23 Pages, Nov. 11th, 2022Harry the Greek100% (2)

- Bill Gates SummaryDocumento10 pagineBill Gates SummaryArslanNessuna valutazione finora

- TRA IoT Regulatory Procedure UAEDocumento8 pagineTRA IoT Regulatory Procedure UAEAKNessuna valutazione finora

- Federal Funding Fallout: How Tennessee Public Schools Are Spending Billions in Relief FundsDocumento17 pagineFederal Funding Fallout: How Tennessee Public Schools Are Spending Billions in Relief FundsAnonymous GF8PPILW5Nessuna valutazione finora

- PTJ Letter BitcoinDocumento10 paginePTJ Letter BitcoinZerohedge100% (3)

- Act. 4 Cpe 107Documento2 pagineAct. 4 Cpe 107Francis Mae DayatanNessuna valutazione finora

- Name: Section: Roll No: Submission:: Hamza Dar B-Bscs 053 16 - April-2019Documento15 pagineName: Section: Roll No: Submission:: Hamza Dar B-Bscs 053 16 - April-2019ihtisham khanNessuna valutazione finora

- What The Social Dilemma Gets WrongDocumento1 paginaWhat The Social Dilemma Gets WrongElena BaranovNessuna valutazione finora

- Unige 132046 Attachment02Documento57 pagineUnige 132046 Attachment02tranduongtinhNessuna valutazione finora

- Social Networks and PrivacyDocumento4 pagineSocial Networks and PrivacyDavid WietstrukNessuna valutazione finora

- Facebook Media Brief: Privacy & Disinformation ConcernsDocumento9 pagineFacebook Media Brief: Privacy & Disinformation ConcernsAranhav SinghNessuna valutazione finora

- FakeDocumento43 pagineFakePrawn RajaNessuna valutazione finora

- Zuckerberg Responses To Commerce Committee QFRs1Documento229 pagineZuckerberg Responses To Commerce Committee QFRs1TechCrunch100% (2)

- Facebook Privacy - There Is No Privacy - CASE STUDYDocumento4 pagineFacebook Privacy - There Is No Privacy - CASE STUDYDimas IndrawijayaNessuna valutazione finora

- Presentation By: Samriddha Chakraborty Subhadip Paul Rimpa Mondal Taukeed Ul Haque Provat RoyDocumento14 paginePresentation By: Samriddha Chakraborty Subhadip Paul Rimpa Mondal Taukeed Ul Haque Provat RoySamriddha ChakrabortyNessuna valutazione finora

- Facebook Case StudyDocumento4 pagineFacebook Case StudyKAJAL GURBAXANINessuna valutazione finora

- Q4 2018 Earnings Call TranscriptDocumento28 pagineQ4 2018 Earnings Call TranscriptcliffwangNessuna valutazione finora

- Q318 Earnings Call TranscriptDocumento26 pagineQ318 Earnings Call TranscriptcliffwangNessuna valutazione finora

- Index: Sr. No. Topic Name Page NoDocumento8 pagineIndex: Sr. No. Topic Name Page NoNitisha ManjrekarNessuna valutazione finora

- Kelompok 9 Tugas 2 SimDocumento8 pagineKelompok 9 Tugas 2 SimYuli MaharaNessuna valutazione finora

- How Facebook Is Using Big Data: The Good, The Bad, and The UglyDocumento8 pagineHow Facebook Is Using Big Data: The Good, The Bad, and The UglyLadines ClarisseNessuna valutazione finora

- Facebook Privacy:: There Is No PrivacyDocumento5 pagineFacebook Privacy:: There Is No PrivacyKlaudine SantosNessuna valutazione finora

- Group 2 Case BookDocumento4 pagineGroup 2 Case BookShivam PandeyNessuna valutazione finora

- Week - 1 - DQ1 - Controversies Associated Social Network ServicesDocumento4 pagineWeek - 1 - DQ1 - Controversies Associated Social Network ServicesBuddhikaNessuna valutazione finora

- Activity #7 - TIRONES, Athina Melinette I.Documento2 pagineActivity #7 - TIRONES, Athina Melinette I.Athina TironesNessuna valutazione finora

- Benefit Is A Two-Way StreetDocumento1 paginaBenefit Is A Two-Way StreetNiki CheongNessuna valutazione finora

- Social Media Security: Leveraging Social Networking While Mitigating RiskDa EverandSocial Media Security: Leveraging Social Networking While Mitigating RiskValutazione: 5 su 5 stelle5/5 (1)

- Mark Zuckerberg Decoded: Take A Deep Dive Into The Mind Of The Business Magnate And Internet Entrepreneur (Extended Edition)Da EverandMark Zuckerberg Decoded: Take A Deep Dive Into The Mind Of The Business Magnate And Internet Entrepreneur (Extended Edition)Nessuna valutazione finora

- Privacy’s Blueprint: The Battle to Control the Design of New TechnologiesDa EverandPrivacy’s Blueprint: The Battle to Control the Design of New TechnologiesValutazione: 4.5 su 5 stelle4.5/5 (2)

- FAKE NEWS The Impact of Distorted Information on the WorldDa EverandFAKE NEWS The Impact of Distorted Information on the WorldNessuna valutazione finora

- Social Media: How To Use Social Media Marketing To Grow Your BusinessDa EverandSocial Media: How To Use Social Media Marketing To Grow Your BusinessNessuna valutazione finora

- Instagram Marketing: A Picture Perfect Way to Strike It Rich!Da EverandInstagram Marketing: A Picture Perfect Way to Strike It Rich!Valutazione: 5 su 5 stelle5/5 (1)

- Social Technologies: Creating Value Through ConnectionsDa EverandSocial Technologies: Creating Value Through ConnectionsNessuna valutazione finora

- Churches Closed... Until Further Notice: Doing COVID Life RemotelyDa EverandChurches Closed... Until Further Notice: Doing COVID Life RemotelyNessuna valutazione finora

- Social Media Marketing Algorithms Step By Step Workbook Secrets To Make Money Online For Beginners, Passive Income, Advertising and Become An Influencer Using Instagram, Facebook & YoutubeDa EverandSocial Media Marketing Algorithms Step By Step Workbook Secrets To Make Money Online For Beginners, Passive Income, Advertising and Become An Influencer Using Instagram, Facebook & YoutubeNessuna valutazione finora

- How to Find a Job on LinkedIn, Facebook, Twitter and Google+ 2/EDa EverandHow to Find a Job on LinkedIn, Facebook, Twitter and Google+ 2/ENessuna valutazione finora

- The Essential Social Media Marketing Handbook: A New Roadmap for Maximizing Your Brand, Influence, and CredibilityDa EverandThe Essential Social Media Marketing Handbook: A New Roadmap for Maximizing Your Brand, Influence, and CredibilityValutazione: 4 su 5 stelle4/5 (2)

- Legal Guide to Social Media: Rights and Risks for Businesses and EntrepreneursDa EverandLegal Guide to Social Media: Rights and Risks for Businesses and EntrepreneursNessuna valutazione finora

- Our Data, Ourselves: A Personal Guide to Digital PrivacyDa EverandOur Data, Ourselves: A Personal Guide to Digital PrivacyNessuna valutazione finora

- Retail Zipline Series A DeckDocumento19 pagineRetail Zipline Series A DeckJordan Crook100% (1)

- Guild Series A Pitch DeckDocumento10 pagineGuild Series A Pitch DeckJordan Crook100% (1)

- Heartbeat Health Pitch DeckDocumento24 pagineHeartbeat Health Pitch DeckJordan CrookNessuna valutazione finora

- Justworks Series B DeckDocumento7 pagineJustworks Series B DeckJordan Crook100% (1)

- Steady Series A DeckDocumento20 pagineSteady Series A DeckJordan CrookNessuna valutazione finora

- Vise Seed Pitch Deck PresentationDocumento11 pagineVise Seed Pitch Deck PresentationJordan CrookNessuna valutazione finora

- Coda InvestorDocumento8 pagineCoda InvestorJordan Crook0% (1)

- What Does This Mean For YouDocumento7 pagineWhat Does This Mean For YouJordan CrookNessuna valutazione finora

- Poshmark Series A DeckDocumento16 paginePoshmark Series A DeckJordan CrookNessuna valutazione finora

- Norton's Complaint For Proposed Class Action Lawsuit Against NianticDocumento24 pagineNorton's Complaint For Proposed Class Action Lawsuit Against NianticJordan CrookNessuna valutazione finora

- Shippo Series A DeckDocumento22 pagineShippo Series A DeckJordan Crook100% (3)

- Juul vs. CounterfeitsDocumento20 pagineJuul vs. CounterfeitsJordan Crook100% (2)

- Guideline Series B DeckDocumento19 pagineGuideline Series B DeckJordan CrookNessuna valutazione finora

- Shippo Series A DeckDocumento22 pagineShippo Series A DeckJordan Crook100% (3)

- Civil Cover SheetDocumento2 pagineCivil Cover SheetJordan CrookNessuna valutazione finora

- 1 1 PDFDocumento17 pagine1 1 PDFJordan CrookNessuna valutazione finora

- Backhaut V Apple IncDocumento19 pagineBackhaut V Apple IncJordan CrookNessuna valutazione finora

- WARF v. AppleDocumento7 pagineWARF v. AppleMikey Campbell100% (1)

- Moore Et Al v. Apple IncDocumento17 pagineMoore Et Al v. Apple IncJordan CrookNessuna valutazione finora

- Civil Cover Sheet: I. (A) Plaintiffs DefendantsDocumento1 paginaCivil Cover Sheet: I. (A) Plaintiffs DefendantsJordan CrookNessuna valutazione finora

- Reggie Brown Snapchat Filing October 23 2014 - Business InsiderDocumento38 pagineReggie Brown Snapchat Filing October 23 2014 - Business InsiderashontellNessuna valutazione finora

- MatchBox Deck (02/16/12)Documento10 pagineMatchBox Deck (02/16/12)Jordan CrookNessuna valutazione finora

- Aereo Boston RulingDocumento20 pagineAereo Boston Rulingjeff_roberts881100% (1)

- Apple Imessage Motion To DismissDocumento31 pagineApple Imessage Motion To DismissnicholasdeleoncircaNessuna valutazione finora

- Snapchat Files Restraining OrderDocumento29 pagineSnapchat Files Restraining OrderJordan CrookNessuna valutazione finora

- AMERICAN BROADCASTING COS., INC., ET AL. v. AEREO, INC., FKA BAMBOOM LABS, INC.Documento35 pagineAMERICAN BROADCASTING COS., INC., ET AL. v. AEREO, INC., FKA BAMBOOM LABS, INC.Brian RiesNessuna valutazione finora

- Ciri-Ciri Dan Kepentingan Komponen Pedagogi KontemporariDocumento2 pagineCiri-Ciri Dan Kepentingan Komponen Pedagogi KontemporariAzfieza LailiNessuna valutazione finora

- Worksheet - MIL - Part 2Documento4 pagineWorksheet - MIL - Part 2MeriamNessuna valutazione finora

- MTB 1 Lesson 1Documento17 pagineMTB 1 Lesson 1Oscar Hogan BaldomeroNessuna valutazione finora

- Applying Filling Gap On The Listening Instructions For Junior High School StudentsDocumento3 pagineApplying Filling Gap On The Listening Instructions For Junior High School StudentsPrincess AuroraNessuna valutazione finora

- Resume For PortfolioDocumento1 paginaResume For Portfolioapi-548459235Nessuna valutazione finora

- Instructional Lesson Plan #3 - Wangari Maathai Reading Language Arts Grade: 05 Unit Title: Earth - A Fine BalanceDocumento14 pagineInstructional Lesson Plan #3 - Wangari Maathai Reading Language Arts Grade: 05 Unit Title: Earth - A Fine BalanceSilvia MontesNessuna valutazione finora

- Guidelines UMBC PortfolioDocumento5 pagineGuidelines UMBC PortfolioNaaman Ty BrownNessuna valutazione finora

- GRADE 7-10 (Junior High School) : Homeroom Guidance Learner'S Development AssessmentDocumento2 pagineGRADE 7-10 (Junior High School) : Homeroom Guidance Learner'S Development AssessmentLeigh Cobaper100% (1)

- Hobo UK SEO Beginners Guide v3Documento239 pagineHobo UK SEO Beginners Guide v3JosepNessuna valutazione finora

- Narrative ReportDocumento4 pagineNarrative Reporthaniegrace sandroNessuna valutazione finora

- Class 7 Vedic MathsDocumento4 pagineClass 7 Vedic Mathssamridh gupta100% (1)

- NEBA BRANDON PE-WPS OfficeDocumento2 pagineNEBA BRANDON PE-WPS OfficeNeba Brandon.Nessuna valutazione finora

- Patent Application Publication: (19) United StatesDocumento82 paginePatent Application Publication: (19) United StatesGek CagatanNessuna valutazione finora

- Untitled DocumentDocumento2 pagineUntitled DocumentyelyzavetapNessuna valutazione finora

- Fossil - MSL Brief - New Blood Awards 2021Documento2 pagineFossil - MSL Brief - New Blood Awards 2021Fatmanur BenliNessuna valutazione finora

- Answering Extended Response Questions in The ExaminationDocumento2 pagineAnswering Extended Response Questions in The Examinationapi-308082215Nessuna valutazione finora

- 21st Century Literature From The Philippines and The World PDF FreeDocumento7 pagine21st Century Literature From The Philippines and The World PDF FreeESTEPHANIE TUMAGANNessuna valutazione finora

- Lesson Plan and Observation: Alverno CollegeDocumento5 pagineLesson Plan and Observation: Alverno Collegeapi-252924047Nessuna valutazione finora

- Basic Concept of Discourse AnalysisDocumento3 pagineBasic Concept of Discourse AnalysisShabirin AlmaharNessuna valutazione finora

- The Family Is The Primary Agent of Socialization: Name:Carias, Raniel C. Section: 11-Humss B Perfomance Task 3Documento2 pagineThe Family Is The Primary Agent of Socialization: Name:Carias, Raniel C. Section: 11-Humss B Perfomance Task 3Ronalyn C. CariasNessuna valutazione finora

- Clinical Teaching 1Documento12 pagineClinical Teaching 1Anand BhawnaNessuna valutazione finora

- PRACTICA CLASE 2 - Maria Elena Cruz NuñezDocumento8 paginePRACTICA CLASE 2 - Maria Elena Cruz NuñezElena CruzNessuna valutazione finora

- Feedback ExampleDocumento1 paginaFeedback Exampleapi-518408081Nessuna valutazione finora

- Poem Lesson PlanDocumento3 paginePoem Lesson Planマリアン 可愛いNessuna valutazione finora

- Error AnalysisDocumento7 pagineError AnalysisAbby OjalesNessuna valutazione finora

- DLBBAAIWB01 E Session2Documento21 pagineDLBBAAIWB01 E Session2PanduNessuna valutazione finora

- Kekamamakoaaka Ilihou K. K. Caceres: 91-225 Pilipili Ula Pl. Kapolei, HI 96707Documento2 pagineKekamamakoaaka Ilihou K. K. Caceres: 91-225 Pilipili Ula Pl. Kapolei, HI 96707api-267367564Nessuna valutazione finora

- Year 1 Unit Planner II 2019-2020Documento6 pagineYear 1 Unit Planner II 2019-2020Andrea Hernandez-VilaNessuna valutazione finora

- MICD DeploymentDocumento47 pagineMICD DeploymentCristhian HaroNessuna valutazione finora

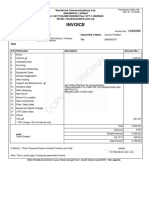

- Invoice: Worldlink Communications Ltd. Jawalakhel, Lalitpur Tel: 4217100,9801523050 Fax: 977-1-5529403Documento1 paginaInvoice: Worldlink Communications Ltd. Jawalakhel, Lalitpur Tel: 4217100,9801523050 Fax: 977-1-5529403Gaurav PradhanNessuna valutazione finora