Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Strainer Sizing

Caricato da

aliscribd46Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Strainer Sizing

Caricato da

aliscribd46Copyright:

Formati disponibili

STRAINERS

SIZING

SCREEN OPENINGS FOR STRAINERS

100 Mesh - 30% O.A. 0.006 Openings 80 Mesh - 36% O.A. 0.008 Openings 60 Mesh - 38% O.A. 0.010 Openings 40 Mesh - 41% O.A. 0.016 Openings 30 Mesh - 45% O.A. 0.022 Openings 20 Mesh - 49% O.A. 0.035 Openings 0.027 Dia. - 23% O.A.

FACTORS

TO CONSIDER

1 Purpose

If the strainer is being used for protection rather than direct filtration, standard screens will suffice in most applications.

2 Service

With services that require extremely sturdy screens, such as high pressure/ temperature applications or services with high viscosities, perforated screens without mesh liners are recommended. If mesh is required to obtain a certain level of filtration, then a trapped perf/mesh/perf combination is recommended.

3 Filtration Level

When choosing a perf. or a mesh/perf. combination, attention should be given to ensure overstraining does not occur. As a general rule, the specified level of filtration should be no smaller than half the size of the particle to be removed. If too fine a filtration is specified, the pressure drop through the strainer will increase very rapidly, possibly causing damage to the screen.

0.033 Dia. - 28% O.A.

3/64 Dia. - 36% O.A.

1/16 Dia. - 37% O.A.

Notes:

1. Screen openings other than those shown above are readily available. Various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2 Dia. are in inventory. 2. Screens are available in a wide range of materials. Various screen materials in carbon steel, stainless steel (304, 316), alloy 20, monel 400, hastelloy C and titanium grade 2 are in inventory. 3. Custom manufactured screens are available upon request. Please consult factory.

3/32 Dia. - 39% O.A.

1/8 Dia. - 40% O.A.

5/32 Dia. - 58% O.A.

3/16 Dia. - 50% O.A.

1/4 Dia. - 40% O.A.

SCREEN CORRECTION FACTOR CHART

For Non-Standard and Mesh Lined Screens

*Multiply values obtained from Pressure Drop Charts by the appropriate values shown below

CHART #1

Size Range SCREEN OPENINGS Perforated Plate Mesh lined standard screens % Screen Material Open Area % Screen Material Open Area 50% 40% 30% 20% 50% 40% 30% 0.55 0.7 1 1.15 1.05 1.05 1.2 0.8 1 1.4 2.15 1.05 1.05 1.2

60% 1/4 - 1-1/2 0.45 2 - 48 0.65 Notes: 1. See Screen Openings for % Open Areas of inventoried perforated plate. 2. Standard screens for sizes 1/4 to 1-1/2 is approximately a 30% open area screen media. 3. Standard screens for sizes 2 and larger is approximately a 40% open area screen media. Example: Strainer Size: Model: Filtration: Flow rate: Service:

6 150BFSBW1 100 Mesh lined 1/8 Perf. 700 GPM Water

A) The Pressure Drop Chart for Fabricated Basket Strainers indicates a drop of 0.9 psid with standard screen. B) The Screen Openings Chart indicates the % Open area of 100 mesh is 30% C) Using Chart 1 we read the correction factor to be 1.2 for 100 mesh lined 1/8 perf. D) Total pressure drop equals 0.9 x 1.2 = 1.08 psid clean.

VISCOSITY AND DENSITY CORRECTION FACTOR CHART

CHART #2

Size Range Component factor (CF) 0.25

CHART #3

Viscosity Body Loss Screen Loss Factor Cp Factor Perf alone 20 mesh 30, 40, mesh 60 to 300 Mesh (BF) (PF) lined (MF) lined (MF) lined (MF) 10 1 1.15 1.3 1.4 1.5 25 1.2 1.25 2 2.2 2.5 100 1.6 1.4 3 4 6.5 200 2.2 1.5 4.5 7 11.5 500 4.4 1.6 10 15 25 1000 8 1.7 15 30 50 2000 15.2 1.9 30 60 100

1/4 - 1-1/2

2 - 48

0.35

How to Use: 1) Determine the pressure drop (P1) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used, apply factors in Chart #1 to determine corrected pressure drop (P2). 3) Multiply P1 or P2 (if used) by the specific gravity of the fluid actually flowing through the strainer to get P3. 4) Using Chart #2 multiply P3 by the appropriate Component Factor (CF) to get P4. 5) Let P5 = P3 - P4. 6) Multiply P4 by the appropriate Body Loss Factor (BF) in Chart #3 to get P6. 7) Multiply P5 by the appropriate Screen Loss factor (PF or MF) in Chart #3 to get P7. 8) Total pressure drop P8 = P6 + P7. Example: Strainer Size: 6 Model: 150BFSBW1 Filtration: 100 Mesh lined 1/8 perf. Flow rate: 700 GPM Specific Gravity:1 Viscosity: 100 cP A) As shown in the above example, the corrected pressure drop (P2) = 1.08 psid B) Since S.G. = 1, P3 = P2 = 1.08 psid C) Using Chart #2 P4 = 0.35 x P3 = 0.38 psid D) P5 = 1.08 - 0.38 = 0.7 psid E) Using Chart #3 P6 = 0.38 x 1.6 = 0.61 psid F) Again using Chart #3 P7 = 0.7 x 6.5 = 4.55 psid G) Total pressure drop P8 = 0.61 + 4.55 = 5.16 psid clean

CORRECTION FACTORS FOR CLOGGED SCREENS

* Multiply values obtained from Pressure Drop Charts by the appropriate values shown below

CHART #4

% Clogged 10% 20% 30% 40% 50% 60% 70% 80% 90% 2.3 1.1 3.45 1.75 6 1.15 1.75 3.6 13.5 1.25 1.8 2.95 6.25 24 1.15 1.4 1.8 2.5 3.7 6.4 14 55 10:1 8:1 Ratio of Free Screen Area to Pipe Area 6:1 4:1 3:1 2:1 1:1 3.15 3.9 5 6.65 9.45 14.5 26 58

Notes: A) See Effective Area Charts for the ratio of free area to pipe area for Strainers equipped with standard screens. B) For screens other than standard, use the following formula to calculate the ratio free area to pipe area:

R = Ag x OA 100Ap

where; R Ag OA Ap = = = = Ratio free area to pipe area Gross screen area, sq. in. (See Effective Area Charts) Open area of screen media, % (See Screen Openings Chart, i.e. 1/8 perf. = 40%) Nominal area of pipe fitting, sq. in. (See Effective Area Charts)

Example #1 Strainer Size: 12 Model: 150TFSBW1 Filtration: 1/8 Perf. Flow rate: 2000 GPM Service: Water % Clogged: 20%

A) The Pressure Drop Chart indicates a drop of 0.75 psid with standard screen. B) The Effective Area Chart indicates a ratio of free area to pipe area for a 12 series T strainer is equal to 1.2:1 (1:1 approx.). C) Using Chart #4 we read the correction factor to be 3.9 at 20% clogged. D) Total pressure drop equals 0.75 x 3.9 = 2.9 psid when 20% clogged.

Example #2 Strainer Size: 12 Model: 150TFSBW1 Filtration: 5/32 Perf. Flow rate: 2000 GPM Service: Water % Clogged: 50%

A) B) C) D) E)

The Pressure Drop Chart indicates a drop of 0.75 psid with standard screen. The Screen Openings Chart indicates the % Open area (OA) of 5/32 Perf. is 58%. Using Chart #1 we read the correction factor to be 0.65 for 5/32 Perf. Total clean pressure drop equals 0.75 x 0.65 = 0.49 psid. Since a non-standard screen is being used, we must calculate the Ratio free area to pipe area. F) The Effective Area Chart indicated Ag = 330 in2, Ap = 113 in2. G) The ratio free area to pipe area is calculated as 1.7:1. (2:1 approx.) H) Using Chart #4 we read the correction factor to be 2.5 at 50% clogged. I) Total pressure drop equals 0.49 x 2.5 = 1.2 psid when 50% clogged.

Y-STRAINER PRESSURE DROP-LIQUIDS

FIGURE 1

FIGURE 2

Notes: (1) Pressure drop curves are based on water flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings.

Y-STRAINER PRESSURE DROP - SATURATED STEAM

(Sizes 1/4 to 1 1/2)

FIGURE 3

Notes: (1) Pressure drop curves are based on saturated steam flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings. (2) Chart can be used for air and gas by using the following formula: where; Qs = Equivalent Steam Flow, lbs./hr. Qg = Air or gas flow, SCFM. t = Temperature, F. s.g. = Specific gravity (s.g. = 1 for air.) DP = Pressure Drop, psid P2 = Outlet Pressure

Qs = 0.138Qg (460+t) s.g.

DP <1.0 P2

FOR NON-CRITICAL FLOW

}

A) B) C) D) E)

Example: Service: Pressure: Steam Flow: Size:

Saturated Steam Flow 160 psig 1000 Lbs/hr 1-1/2

Locate steam flow Follow horizontal line to required pressure. Follow vertical line downward to required strainer size. Follow horizontal line to read pressure drop. Pressure drop equals 0.8 psid.

Y-STRAINER PRESSURE DROP - SATURATED STEAM

(Sizes 2 to 16)

FIGURE 4

Notes: (1) Pressure drop curves are based on saturated steam flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings. (2) Chart can be used for air and gas by using the following formula: where; Qs = Equivalent Steam Flow, lbs./hr. Qg = Air or gas flow, SCFM. t = Temperature, F. s.g. = Specific gravity (s.g. = 1 for air.) DP = Pressure Drop, psid P2 = Outlet Pressure

Qs = 0.138Qg (460+t) s.g.

DP <1.0 P2

FOR NON-CRITICAL FLOW

}

A) B) C) D) E)

Example: Service: Pressure: Steam Flow: Size:

Saturated Steam Flow 120 psig 20,000 Lbs/hr 5

Locate steam flow Follow horizontal line to required pressure. Follow vertical line downward to required strainer size. Follow horizontal line to read pressure drop. Pressure drop equals 1.8 psid.

BASKET STRAINER PRESSURE DROP-LIQUIDS

FIGURE 5

FIGURE 6

STYLE 2 FLANGED BASKET STRAINER PRESSURE DROP - LIQUIDS (SIZES 2" - 24")

10

PRESSURE DROP (PSID)

10

0.1 10 100 1000 10000

FLOW RATE (GPM)

Notes: (1) Pressure drop curves are based on water flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings. (2) For Style 1 basket strainers, multiply value obtained in figure 2 by 1.15 to obtain clean pressure drop.

24

12 14 16 18 20

TEMPORARY STRAINER PRESSURE DROP - LIQUIDS

FIGURE 7

FIGURE 8

Notes: (1) Pressure drop curves are based on water flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings.

FABRICATED Y & TEE STRAINER PRESSURE DROP - LIQUIDS

FIGURE 9

FIGURE 10

Notes: (1) Pressure drop curves are based on water flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings.

FABRICATED BASKET & DUPLEX STRAINER PRESSURE DROP - LIQUIDS

FIGURE 11

FIGURE 12

Notes: (1) Pressure drop curves are based on water flow with standard screens. See Screen Correction Factor Chart for correction factors to be used with other fluids and/or screen openings.

Y-STRAINER SCREEN BURST PRESSURE

FIGURE 13

Notes: (1) The above chart is for use with perforated plate and based on the formula:

P=

St R - 0.4t

SOURCE: ASME Section VIII, Div. 1, Appendix 1.

P S t R

= = = =

Burst pressure, psid Reduced allowable stress, psi Thickness of perforated plate, in. Outside radius of screen, in.

(2) The above chart is based on a screen material of stainless steel and is valid for operating temperatures up to 100F The chart may be used for higher temperatures however it will result in a safety factor reduction. (At 100F the charts safety factor is approximately four (4), at 1000F the chart safety factor is reduced to approximately two (2). It is the responsibility of the user to determine an acceptable safety factor. (3) The chart may be used for carbon steel at an approximate 25% reduction in safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example: Strainer Size: 8 Screen Thickness: 20 Gauge Screen Perforations: 0.125 (40% O.A.)

A) B) C) D) E)

Locate screen diameter (assume a 8 diameter screen) Follow vertical line to gauge thickness. Follow horizontal line to required perforation open area. Follow vertical line downward to read burst pressure. Burst pressure equals 60 psid approx.

BASKET & DUPLEX STRAINER BASKET BURST PRESSURE

FIGURE 14

60% 50% 40% 30% 20%

11 16 20 26 32 G

TOM BOT SOLID

AU

AU

AU

AU

AU

10

20

30

40 0

25

50

75

100

STRAINER SIZE (In.)

BURST PRESSURE (PSID)

Notes: 1) The above chart is to be used for strainers manufactured from perforated plate and is based on the formula:

t =d

0.3P S

SOURCE: ASME Section VIII, Div. 1., UG-34.

t d P S

= = = =

Thickness of perforated plate, in. Basket Diameter, in. Burst Pressure, psi Reduced allowable stress, psi

2) Baskets with perforated bottoms are supplied as standard. 3) The above chart is based on standard dimensions. Higher burst pressure ratings are available. Please contact factory. 4) The above chart is based on a screen material of stainless steel. No safety factor is incorporated. It is the responsibility of the user to determine an acceptable safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example #1 Strainer Size: 10 Basket Type: Perforated screen with 11 gauge solid flat bottom Screen Material Open Area: 20% - 60%

A) B) C) D) E)

Locate Strainer size. Follow vertical line to solid thickness. Follow horizontal line to solid bottom curve. Follow vertical line downward to read burst pressure. Burst pressure equals 15 psid.

Example: #2 Strainer Size: 4 Basket Type: 11 gauge perforated screen with 11 gauge perforated flat bottom. Screen Material Open Area: 40%

A) B) C) D) E)

Locate Strainer size. Follow vertical line to gauge thickness. Follow horizontal line to 40% Open Area curve. Follow vertical line downward to read burst pressure. Burst pressure equals 25 psid.

SERIES TB STRAINER BURST PRESSURE

FIGURE 15

60% 50% 40% 30% 20%

11 G A

16 20 26 32

G A

G E

10 12 14 16 18 20

40 0

25

50

75

100

STRAINER SIZE (In.)

BURST PRESSURE (PSID)

Notes: (1) The above chart is to be used for strainers manufactured from perforated plate and is based on the formula:

t =d

0.3P S

SOURCE: ASME Section VIII, Div. 1., UG-34.

t d P S

= = = =

Thickness of perforated plate, in. Dimension B (See page 4), in. Burst Pressure, psi Reduced allowable stress, psi

(2) The above chart is based on standard dimensions. Higher burst pressure ratings are available. Please contact factory. (3) The above chart is based on a screen material of stainless steel. No safety factor is incorporated. It is the responsibility of the user to determine an acceptable safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example: Strainer Size: Screen Thickness: Screen Material Open Area:

14 11 gauge 20%

A) B) C) D) E)

Locate Strainer size. Follow vertical line to gauge thickness. Follow horizontal line to required perforation open area. Follow vertical line downward to read burst pressure. Burst pressure equals 15 psid.

SERIES TC STRAINER BURST PRESSURE

FIGURE 16

11

GA

16 G

20 G 26 G

32 GA

UG

AU G

GE

AU

AU

E

GE

60% 50% 40% 30% 20%

UG

10

20

30

40 0

25

50

75

100

STRAINER SIZE (In.)

BURST PRESSURE (PSID)

Notes: (1) The above chart is to be used for strainers manufactured from perforated plate and is based on the formula: P S t D = = = = = Burst Pressure, psi. Reduced allowable stress Thickness of perforated plate, in. Dimension B (See page 4), in. 15 degree

P = 2St cos D + 1.2t cos

SOURCE: ASME Section VIII, Div. 1., Appendix 1.

(2) The above chart is based on standard dimensions. Higher burst pressure ratings are available. Please contact factory. (3) The above chart is based on a screen material of stainless steel. No safety factor is incorporated. It is the responsibility of the user to determine an acceptable safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example: Strainer Size: Screen Thickness: Screen Material Open Area:

A) B) C) D) E)

20 16 gauge 40%

Locate Strainer size. Follow vertical line to gauge thickness. Follow horizontal line to required perforation open area. Follow vertical line downward to read burst pressure. Burst pressure equals 48 psid.

FABRICATED Y-STRAINER SCREEN BURST PRESSURE

FIGURE 17

11 16 20 26 32 GA GA UG GA UG GA

GA

UG E

UG E

UG

60% 50% 40% 30% 20%

6 7 8 9 10

20

30

40 0

25

50

75

100

STRAINER SIZE (In.)

BURST PRESSURE (PSID)

Notes: 1. The above chart is to be used for strainers manufactured from perforated plate and is based on the formula:

P=

St R - 0.4t

SOURCE: ASME Section VIII, Div. 1., Appendix 1.

P S t R

= = = =

Burst Pressure, psi Reduced allowable stress, psi Thickness of perforated plate, in. Outside radius of screen, in.

2. The above chart is based on standard dimensions. Higher burst pressure ratings are available. Please contact factory. 3. The above chart is based on a screen material of stainless steel. No safety factor is incorporated. It is the responsibility of the user to determine an acceptable safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example: Strainer Size: Screen Thickness: Screen Material Open Area:

20 16 gauge 40%

A) B) C) D) E)

Locate Strainer size. Follow vertical line to gauge thickness. Follow horizontal line to required perforation open area. Follow vertical line downward to read burst pressure. Burst pressure equals 48 psid.

FABRICATED T-STRAINER SCREEN BURST PRESSURE

FIGURE 18

11 16 20 26

60% 50% 40% 30% 20%

A U G E

32

10

20

30

40 0

25

50

75

100

STRAINER SIZE (In.)

BURST PRESSURE (PSID)

Notes: (1) The above chart is to be used for strainers manufactured from perforated plate and is based on the formula:

t =d

0.3P S

SOURCE: ASME Section VIII, Div. 1., UG-34.

t d P S

= = = =

Thickness of perforated plate, in. Basket Diameter, in. Burst Pressure, psi Reduced allowable stress, psi

3. The above chart is based on standard dimensions. Higher burst pressure ratings are available. Please contact factory. 4. The above chart is based on a screen material of stainless steel. No safety factor is incorporated. It is the responsibility of the user to determine an acceptable safety factor. (4) See Screen Openings Chart for % Open Areas of inventoried perforated plate.

Example: Strainer Size: Screen Thickness: Screen Material Open Area:

10 11 gauge 40%

A) B) C) D) E)

Locate Strainer size. Follow vertical line to gauge thickness. Follow horizontal line to required perforation open area. Follow vertical line downward to read burst pressure. Burst pressure equals 13 psid.

Y-STRAINER SCREEN EFFECTIVE AREA

Strainer Series 250YTI Pipe Size (In.) Nominal Std. Opening (in.) 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.045 0.045 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.045 0.045 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.045 0.032 0.032 0.032 0.032 0.032 0.045 0.045 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 Gross Area of Pipe Fitting (Sq. In.) Screen Area (Sq. In.) Ratio Free Area (Sq. In.) 1.02 1.02 1.13 1.86 2.54 3.40 5.00 8.42 16.26 21.71 1.32 1.32 1.32 2.02 2.61 3.79 5.39 9.34 12.79 17.48 0.78 2.19 2.45 4.18 5.88 8.67 0.87 1.45 2.20 2.80 4.00 5.98 0.79 1.16 2.28 3.32 4.65 9.75 1.42 1.99 3.33 6.53 6.52 10.75 10.82 15.96 20.32 39.56 58.85 71.68 133.75 202.08 266.31 474.54 578.74 Nominal Free Area Strainer to Pipe Series Area 20.79 9.24 5.78 4.20 3.23 2.77 2.83 2.68 3.31 3.07 26.38 11.99 6.59 4.59 3.31 3.08 3.05 2.25 2.60 2.47 3.99 4.95 3.12 3.40 3.32 2.76 4.44 3.28 2.80 2.29 2.26 1.90 4.03 2.63 2.90 2.70 2.63 3.11 7.25 4.51 4.24 5.32 3.69 3.42 3.45 3.25 2.88 3.15 3.00 2.54 2.66 2.57 2.35 3.44 3.17 250YF Pipe Size (In.) 2 2-1/2 3 4 5 6 8 10 12 14 1/2 3/4 1 1-1/2 2 2-1/2 3 4 6 8 10 12 1/2 3/4 1 1-1/2 2 2-1/2 3 4 6 8 10 12 2 2-1/2 3 4 6 8 10 12 2 3 4 6 8 2 3 4 6 Gross Std. Opening (in.) 0.045 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.032 0.032 0.032 0.032 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.032 0.032 0.032 0.032 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.045 0.125 0.125 0.125 0.125 0.045 0.125 0.125 0.125 Area of Pipe Fitting (Sq. In.) Ratio Screen Area (Sq. In.) Free Area (Sq. In.) 12.83 15.96 20.32 39.56 58.85 79.17 168.39 258.40 350.68 474.54 1.65 2.51 3.56 6.44 10.18 18.27 25.03 34.14 84.35 129.59 205.28 276.17 1.89 2.88 4.20 8.52 10.74 17.57 27.29 41.16 92.33 134.66 223.80 301.25 14.10 20.32 29.98 51.37 102.38 161.43 240.83 328.07 17.66 42.98 61.17 112.00 181.84 17.66 42.98 62.07 122.85 Free Area to Pipe Area 4.08 3.25 2.88 3.15 3.00 2.80 3.35 3.29 3.10 3.44 8.43 5.69 4.53 3.65 3.24 3.72 3.54 2.72 2.98 2.58 2.61 2.44 9.45 6.55 5.32 4.81 3.42 3.58 3.86 3.28 3.27 2.68 2.85 2.66 4.49 4.14 4.24 4.09 3.62 3.31 3.23 3.03 6.36 6.60 5.17 4.31 4.12 6.36 7.24 6.03 5.40 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 125YTB 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 250YTB 1/2 3/4 1 1-1/4 1-1/2 2 150Y/300Y 1/2 3/4 1 1-1/4 1-1/2 2 600Y 1/2 3/4 1 1-1/4 1-1/2 2 1500Y 1/2 3/4 1 1-1/4 1-1/2 2 125YF 2 2-1/2 3 4 5 6 8 10 12 14 16 0.05 3.64 0.11 3.64 0.20 4.05 0.44 6.63 0.79 9.06 1.23 12.14 1.77 17.87 3.14 30.07 4.91 45.16 7.07 60.30 0.05 4.71 0.11 4.71 0.20 4.71 0.44 7.22 0.79 9.33 1.23 13.53 1.77 19.25 4.14 33.34 4.91 35.52 7.07 48.55 0.20 2.80 0.44 7.81 0.79 8.76 1.23 14.91 1.77 20.98 3.14 30.96 0.20 3.11 0.44 5.17 0.79 7.85 1.23 10.01 1.77 14.28 3.14 21.35 0.20 2.82 0.44 4.15 0.79 8.14 1.23 11.85 1.77 16.59 3.14 27.10 0.20 5.08 0.44 7.11 0.79 11.90 1.23 23.32 1.77 23.28 3.14 29.85 3.14 30.07 4.91 44.33 7.07 56.45 12.57 98.91 19.63 147.11 28.27 179.19 50.27 334.38 78.54 505.21 113.10 665.77 137.89 1186.34 182.65 1446.85 3.14 35.64 4.91 44.33 7.07 56.45 12.57 98.91 19.63 147.11 28.27 197.92 50.27 420.97 78.54 645.99 113.10 876.70 137.89 1186.34 0.20 5.91 0.44 8.97 0.79 12.71 1.77 23.01 3.14 28.27 4.91 50.76 7.07 62.59 12.57 85.34 28.27 210.88 50.27 323.98 78.54 513.21 113.10 690.41 0.20 6.75 0.44 10.30 0.79 14.99 1.77 30.42 3.14 29.85 4.91 48.81 7.07 68.22 12.57 102.90 28.27 230.83 50.27 336.64 78.54 559.50 113.10 753.12 3.14 39.17 4.91 56.45 7.07 74.96 12.57 128.41 28.27 255.94 48.77 403.57 74.66 602.08 108.43 820.18 2.78 49.06 6.51 107.45 11.82 152.93 25.97 279.99 44.18 454.60 2.78 49.06 5.94 107.45 10.29 155.17 22.73 307.12

150YF

300YF

600YF

900YF

1500YF

NOTES: (1) Values shown are for strainers with standard screens. (2) Ratio free area to pipe area may be increased by changing perf. stagger or by using mesh. (3) In many cases the specified screen burst pressure limits the maximum value for the ratio free area to pipe area.

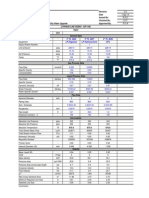

BASKET STRAINER EFFECTIVE AREA

Strainer Series 300B (Style #2) Pipe Size (In.) 1/2 3/4 1 1-1/4 1-1/2 2 125BFI (Style #1) 2 2.5 3 4 5 6 8 10 12 14 16 18 20 150BFB (Style #1) 2 2.5 3 4 5 6 2 3 4 6 8 10 12 150BFC (Style #2) 1-1/2 2 3 4 6 8 Nominal Std. Opening (in.) 0.032 0.032 0.032 0.032 0.032 0.045 0.045 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.045 0.045 0.045 0.125 0.125 0.125 0.045 0.045 0.125 0.125 0.125 0.125 0.125 0.045 0.045 0.045 0.125 0.125 0.125 Gross Area of Sch. 40 / Std. Pipe (Sq. In.) 0.30 0.53 0.86 1.50 2.04 3.36 3.36 4.79 7.39 12.73 20.01 28.89 50.03 78.85 113.10 137.89 182.65 233.71 291.04 3.36 4.79 7.39 12.73 20.01 28.89 3.36 7.39 12.73 28.89 50.03 78.85 113.10 2.04 3.36 7.39 12.73 28.89 50.03 Screen Area (Sq. In.) 14.73 23.01 23.01 47.80 47.80 58.32 29.27 45.11 78.53 106.51 139.27 176.16 300.37 446.39 654.83 885.34 1437.23 1437.23 1916.37 29.27 45.11 78.53 106.51 139.27 176.16 35.20 57.86 116.03 167.33 303.77 409.43 693.85 30.74 44.07 105.29 143.21 364.56 666.56 Ratio Free Area (Sq. In.) 4.12 6.44 6.44 13.38 13.38 21.00 10.54 16.24 28.27 42.60 55.71 70.46 120.15 178.56 261.93 354.14 574.89 574.89 766.55 10.54 16.24 28.27 42.60 55.71 70.46 12.67 20.83 46.41 66.93 121.51 163.77 277.54 11.07 15.87 37.90 57.29 145.82 266.62 Free Area to Pipe Area 13.6 12.1 7.5 8.9 6.6 6.3 3.1 3.4 3.8 3.3 2.8 2.4 2.4 2.3 2.3 2.6 3.1 2.5 2.6 3.1 3.4 3.8 3.3 2.8 2.4 3.8 2.8 3.6 2.3 2.4 2.1 2.5 5.4 4.7 5.1 4.5 5.0 5.3

NOTES: (1) Values shown are approximate. Contact factory for exact ratios. (2) Values shown are for strainers with standard screens. (3) The ratio free area to pipe area may be increased by changing perf. stagger or by using heavy wire mesh.

FABRICATED STRAINER SCREEN EFFECTIVE AREA

Strainer Type Y (Style #1) Pipe Size (In.) 2 3 4 5 6 8 10 12 14 16 18 20 24 2 2.5 3 4 5 6 8 10 12 14 16 18 20 24 2 3 4 5 6 8 10 12 14 16 18 20 24 2 3 4 5 6 8 10 12 14 16 18 20 24 Std. Opening (in.) 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.188 0.188 0.188 0.188 0.188 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.188 0.188 0.188 0.188 0.188 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.188 0.188 0.188 0.188 0.188 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.188 0.188 0.188 0.188 0.188 Nominal Area of Gross Sch. 40/Std. Pipe Screen Area (Sq. In.) (Sq. In.) 3.36 7.39 12.73 20.01 28.89 50.03 78.85 113.10 140.50 185.66 237.10 294.83 429.13 3.36 4.79 7.39 12.73 20.01 28.89 50.03 78.85 113.10 140.50 185.66 237.10 294.83 429.13 3.36 7.39 12.73 20.01 28.89 50.03 78.85 113.10 140.50 185.66 237.10 294.83 429.13 3.36 7.39 12.73 20.01 28.89 50.03 78.85 113.10 140.50 185.66 237.10 294.83 429.13 39 77 135 160 215 375 545 785 900 1210 1560 1950 2765 22 25 40 58 82 105 167 235 330 420 510 640 780 1060 215 265 265 380 560 570 910 1300 1600 1830 2290 2800 4090 215 265 265 380 560 570 910 1300 1600 1830 2290 2800 4090 Free Area (Sq. In.) 16 31 54 64 86 150 218 314 360 484 624 780 1106 9 10 16 23 33 42 67 94 132 168 204 256 312 424 86 106 106 152 224 228 364 520 640 732 916 1120 1636 86 106 106 152 224 228 364 520 640 732 916 1120 1636 Ratio Free Area to Pipe Area 4.6 4.2 4.2 3.2 3.0 3.0 2.8 2.8 2.6 2.6 2.6 2.6 2.6 2.6 2.1 2.2 1.8 1.6 1.5 1.3 1.2 1.2 1.2 1.1 1.1 1.1 1.0 25.6 14.3 8.3 7.6 7.8 4.6 4.6 4.6 4.6 3.9 3.9 3.8 3.8 25.6 14.3 8.3 7.6 7.8 4.6 4.6 4.6 4.6 3.9 3.9 3.8 3.8

T (Style #1)

B (Style #1)

DB (Style #1)

NOTES: (1) Values shown are approximate. Contact factory for exact ratios. (2) Values shown are for strainers with standard screens. (3) The ratio free area to pipe area may be increased by changing perf. stagger or by using heavy wire mesh.

Potrebbero piacerti anche

- Psychometric Success Numerical Ability - Reasoning Practice Test 1Documento7 paginePsychometric Success Numerical Ability - Reasoning Practice Test 1mita000Nessuna valutazione finora

- Control Valve Sizing - LiquidDocumento4 pagineControl Valve Sizing - Liquidbrazili2010100% (1)

- Jazz Piano Skills (Music 15) : TH TH THDocumento2 pagineJazz Piano Skills (Music 15) : TH TH THaliscribd4650% (2)

- Rock Guitar BasicsDocumento3 pagineRock Guitar Basicsaliscribd46Nessuna valutazione finora

- CPF-010 Process Line Sizing Attachment - 0Documento38 pagineCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Machine FoundationDocumento4 pagineMachine Foundationp kishorNessuna valutazione finora

- PSV SizingDocumento6 paginePSV SizingBui Khoi Nguyen100% (1)

- Blowdown of A Gas VolumeDocumento41 pagineBlowdown of A Gas VolumeJames R. Lawrence Sr.20% (5)

- Control Valve SizingDocumento3 pagineControl Valve SizingN. S. PanditNessuna valutazione finora

- PSV Reation Force - Two Phase - Assumption Close SytemDocumento4 paginePSV Reation Force - Two Phase - Assumption Close SytemNesrine MhedhbiNessuna valutazione finora

- Pressure Drop CalculationDocumento30 paginePressure Drop CalculationEbby Onyekwe100% (1)

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Documento3 pagineLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieNessuna valutazione finora

- PSV Sizing - Two Phase (Two-Points)Documento2 paginePSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradNessuna valutazione finora

- Esstd0202scjp Pip Pnfj8000Documento71 pagineEsstd0202scjp Pip Pnfj8000Engr Tahir UL HaqNessuna valutazione finora

- Line Sizing GuidelinesDocumento32 pagineLine Sizing Guidelinesyunjun12100% (2)

- C Tower SpreadsheetDocumento17 pagineC Tower SpreadsheetJulio Cisneros GrandaNessuna valutazione finora

- Liquid Line SizingDocumento12 pagineLiquid Line Sizinglolofm25Nessuna valutazione finora

- Service Standards For Elevators PDFDocumento42 pagineService Standards For Elevators PDFx79133000100% (1)

- Master Plumbing 6Documento21 pagineMaster Plumbing 6mcpayodNessuna valutazione finora

- Liquid Line SizingDocumento6 pagineLiquid Line SizingManoj KumarNessuna valutazione finora

- 08 PRV SizingDocumento117 pagine08 PRV SizingchenguofuNessuna valutazione finora

- Strainer GuideDocumento26 pagineStrainer Guidemudrijasm100% (1)

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocumento3 paginePressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- Centrifugal Pump Cal - r4Documento24 pagineCentrifugal Pump Cal - r4danNessuna valutazione finora

- Spreadsheet To Design SeparatorsDocumento21 pagineSpreadsheet To Design SeparatorsreninbabaskiNessuna valutazione finora

- Draining Time (Gravity Flow)Documento2 pagineDraining Time (Gravity Flow)Saeid Rahimi MofradNessuna valutazione finora

- K Factor TransformersDocumento6 pagineK Factor TransformersFábio BauerNessuna valutazione finora

- PSV Blocked Fire Relief Valve CasesDocumento21 paginePSV Blocked Fire Relief Valve CasesTun Naing WinNessuna valutazione finora

- Pump and Line Sizing CalcDocumento5 paginePump and Line Sizing CalcMuthuKumar ArunachalamNessuna valutazione finora

- Strainer Pre. Drop and Sizing CalcDocumento6 pagineStrainer Pre. Drop and Sizing CalcChandrakant SalunkheNessuna valutazione finora

- Line SizingDocumento18 pagineLine SizingImaniar Cahyani100% (2)

- PSV Sizing - API-520 PDFDocumento8 paginePSV Sizing - API-520 PDFAnonymous da6X60VpII100% (1)

- Line SizingDocumento18 pagineLine SizingNathaniel Thomas100% (1)

- Calculation of FlowDocumento3 pagineCalculation of FlowPhyu Mar Thein Kyaw100% (1)

- Strainer Drop PressureDocumento2 pagineStrainer Drop PressureJose Manuel Cervantes0% (1)

- BAsket Strainer Sizing HaywardDocumento1 paginaBAsket Strainer Sizing Haywardmarcoo8Nessuna valutazione finora

- Process Line SizingDocumento21 pagineProcess Line Sizingsj_scribdNessuna valutazione finora

- Line Sizing - 2PHASEDocumento11 pagineLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Data Sheet 3Documento3 pagineData Sheet 3Fitroh MalikNessuna valutazione finora

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDocumento9 paginePressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRapee PuaksungnoenNessuna valutazione finora

- Blowdown OrificeDocumento2 pagineBlowdown OrificeOmprakaash MokideNessuna valutazione finora

- Pump Sizing CalculationDocumento12 paginePump Sizing CalculationLee Min Hyuk100% (3)

- Strainer CalculationDocumento3 pagineStrainer CalculationMuhammad Hariri Shofa0% (2)

- Restriction Orifice Plate Calculator GasDocumento25 pagineRestriction Orifice Plate Calculator GaseshraghianNessuna valutazione finora

- 2 Phase Flow Pressure Drop Calc Suresh1Documento853 pagine2 Phase Flow Pressure Drop Calc Suresh1Phani Raj M100% (1)

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Documento2 pagineWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariNessuna valutazione finora

- Tank Pressure & Vacuum ReliefDocumento9 pagineTank Pressure & Vacuum Reliefkomalrana2007100% (1)

- Calculation of Height of The Siphon SystemDocumento2 pagineCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Nitrogen PurgingDocumento4 pagineNitrogen PurgingSaeid Rahimi MofradNessuna valutazione finora

- Orifice Plate Showing VenaDocumento6 pagineOrifice Plate Showing VenahugepotatoNessuna valutazione finora

- Strainer Open Area RatioDocumento1 paginaStrainer Open Area Rationeurolepsia3790100% (1)

- PSV Sizing CalculationsDocumento53 paginePSV Sizing CalculationsAMITH OK93% (28)

- Basket Strainer PDC 350NBDocumento1 paginaBasket Strainer PDC 350NBKailas Nimbalkar0% (1)

- Liquid Hold Up Change and Slug Catcher SizingDocumento2 pagineLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Strainer Screen & Mesh Selection GuideDocumento4 pagineStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Turbines Paper Ray BeebeDocumento9 pagineTurbines Paper Ray Beebealiscribd46Nessuna valutazione finora

- Guide For Vessel Sizing PDFDocumento24 pagineGuide For Vessel Sizing PDFManish542Nessuna valutazione finora

- Sizing SF 6 Inch Y-Strainer-1Documento11 pagineSizing SF 6 Inch Y-Strainer-1BIDDU GHOSHNessuna valutazione finora

- A350-1000 Airport Compatibility Brochure August 2014Documento50 pagineA350-1000 Airport Compatibility Brochure August 2014Matias Javier AlvarezNessuna valutazione finora

- Tank Vessel Overflow Line SizingDocumento4 pagineTank Vessel Overflow Line SizingSteve Wan100% (1)

- B A S Ket Strainer Pressure Drop-LiquidsDocumento4 pagineB A S Ket Strainer Pressure Drop-LiquidsguillemaraNessuna valutazione finora

- Sizing StrainerDocumento8 pagineSizing Strainerchadvillela0% (1)

- Liquid Orifice SizingDocumento4 pagineLiquid Orifice SizingrmaganNessuna valutazione finora

- Basket Type StrainerDocumento12 pagineBasket Type Strainerprateek_bhoir100% (1)

- Strainer Pressure DropDocumento26 pagineStrainer Pressure Dropmkchy1260% (5)

- A Guideline For Design Pressure - Part 1Documento4 pagineA Guideline For Design Pressure - Part 1Said Ahmed SalemNessuna valutazione finora

- Screen Openings For Y-StrainersDocumento6 pagineScreen Openings For Y-Strainersboom10Nessuna valutazione finora

- Fabrication Strainers Mesh SizingDocumento6 pagineFabrication Strainers Mesh SizingArun GuptaNessuna valutazione finora

- Sizing of StrainerDocumento20 pagineSizing of StrainerMASOMESE KIKILENessuna valutazione finora

- Pressure Drop - COLTON Strainers PDFDocumento2 paginePressure Drop - COLTON Strainers PDFcavillalobosb8167Nessuna valutazione finora

- 33 - STR990-1 - Pressure Drop Data YDocumento2 pagine33 - STR990-1 - Pressure Drop Data YblindjaxxNessuna valutazione finora

- Berklee Online: Sample One of Berklee's Interactive Online Music Courses For FreeDocumento4 pagineBerklee Online: Sample One of Berklee's Interactive Online Music Courses For Freealiscribd46Nessuna valutazione finora

- ISEP Economics Study SummaryDocumento8 pagineISEP Economics Study Summaryaliscribd46Nessuna valutazione finora

- Thermal PeakingDocumento26 pagineThermal PeakingbananosnetNessuna valutazione finora

- ISEP Economics Study SummaryDocumento8 pagineISEP Economics Study Summaryaliscribd46Nessuna valutazione finora

- WHITE PAPER - Cost of New Generating Capacity in PerspectiveDocumento12 pagineWHITE PAPER - Cost of New Generating Capacity in Perspectivealiscribd46Nessuna valutazione finora

- American Popular Piano Title ListDocumento2 pagineAmerican Popular Piano Title Listaliscribd46Nessuna valutazione finora

- Berklee Shares - Lyric Writing - Brainstorming, Object WritingDocumento5 pagineBerklee Shares - Lyric Writing - Brainstorming, Object Writingjohn_davidsson0% (1)

- Employing: Petroleum Production Heat CarriersDocumento1 paginaEmploying: Petroleum Production Heat Carriersaliscribd46Nessuna valutazione finora

- Discrete Mathematics: Introduction: Slides By: Christopher M. Bourke Instructor: Berthe Y. ChoueiryDocumento15 pagineDiscrete Mathematics: Introduction: Slides By: Christopher M. Bourke Instructor: Berthe Y. ChoueiryAnonymous PkeI8e84RsNessuna valutazione finora

- Minecraft Logic Gates 8.5X11Documento1 paginaMinecraft Logic Gates 8.5X11aliscribd46Nessuna valutazione finora

- Beethoven LV Sonata n14 Moonlight Op27 n2 2nd Mov PianoDocumento2 pagineBeethoven LV Sonata n14 Moonlight Op27 n2 2nd Mov PianoAmy119Nessuna valutazione finora

- 1.8 Minor Scales: Two Roads: Road One: The Relative RoadDocumento1 pagina1.8 Minor Scales: Two Roads: Road One: The Relative RoadElizabeth Alarcón-GaxiolaNessuna valutazione finora

- Henricus Glareanus: Type No. Byzantine/Greek Mode Name Final Ambitus TenorDocumento1 paginaHenricus Glareanus: Type No. Byzantine/Greek Mode Name Final Ambitus Tenoraliscribd46Nessuna valutazione finora

- Tritone SubDocumento1 paginaTritone Subaliscribd46Nessuna valutazione finora

- Staff PaperDocumento1 paginaStaff Paperaliscribd46Nessuna valutazione finora

- Theory 06 GR 5Documento1 paginaTheory 06 GR 5aliscribd46Nessuna valutazione finora

- Elementary School Activities With SketchpadDocumento3 pagineElementary School Activities With Sketchpadaliscribd46Nessuna valutazione finora

- 19.-Pyrolysis FurnaceDocumento5 pagine19.-Pyrolysis FurnaceWilfredo PastranaNessuna valutazione finora

- Lubrication Practices Grease VANZ 09Documento10 pagineLubrication Practices Grease VANZ 09aliscribd46Nessuna valutazione finora

- EPCOR Voluntary Action Plan 1999Documento22 pagineEPCOR Voluntary Action Plan 1999aliscribd46Nessuna valutazione finora

- File 34767 66587Documento12 pagineFile 34767 66587aliscribd46Nessuna valutazione finora

- 0142-1123 (91) 90472-b) - Bore Inspection and Life Evaluation of Vintage Steam Turbinegenerator Rotors - Jhansale, H.R. and McCann, D.R. ASTM J. Test. EvaDocumento1 pagina0142-1123 (91) 90472-b) - Bore Inspection and Life Evaluation of Vintage Steam Turbinegenerator Rotors - Jhansale, H.R. and McCann, D.R. ASTM J. Test. Evaaliscribd46Nessuna valutazione finora

- Process Heating, Power and IncinerationDocumento1 paginaProcess Heating, Power and Incinerationaliscribd46Nessuna valutazione finora

- PMP+ 2009 Course+Outlines5+Day+ KSADocumento5 paginePMP+ 2009 Course+Outlines5+Day+ KSAaliscribd46Nessuna valutazione finora

- NGQ All Archive LinksDocumento1 paginaNGQ All Archive Linksaliscribd46Nessuna valutazione finora

- 10481-BCL-AKSX-ST-REP-0001 - 1 - IFR - Civil and Structural Design BasisDocumento73 pagine10481-BCL-AKSX-ST-REP-0001 - 1 - IFR - Civil and Structural Design Basischukudi oguneNessuna valutazione finora

- TL-WA750RE V1 User Guide 19100Documento42 pagineTL-WA750RE V1 User Guide 19100Isabela BălașaNessuna valutazione finora

- Elfiq Networks Product MatrixDocumento2 pagineElfiq Networks Product MatrixElite58Nessuna valutazione finora

- Mumbai Vodafone SCFT Status 26 September 2013Documento127 pagineMumbai Vodafone SCFT Status 26 September 2013Charles WeberNessuna valutazione finora

- Board of Engineers Malaysia (BEM)Documento13 pagineBoard of Engineers Malaysia (BEM)ScalperNessuna valutazione finora

- Eng Pro 0003Documento7 pagineEng Pro 0003Mahmoud TourkeyNessuna valutazione finora

- Denon PMA 500AE Owners ManualDocumento12 pagineDenon PMA 500AE Owners ManualJora MormontNessuna valutazione finora

- Din 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsDocumento1 paginaDin 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsImanuel KurniawanNessuna valutazione finora

- Topcon Tools Quick Reference Guide PDFDocumento72 pagineTopcon Tools Quick Reference Guide PDFCharlees IvaxNessuna valutazione finora

- Proces Sg001 en PDocumento76 pagineProces Sg001 en PAnhell Salvador LozaNessuna valutazione finora

- Appendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryDocumento2 pagineAppendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryTarif Aziz MarufNessuna valutazione finora

- 740 Architecture OverviewDocumento73 pagine740 Architecture OverviewsribNessuna valutazione finora

- Kokan Mercantile Co-Operative Bank LTD.: Grievance Redressal PolicyDocumento3 pagineKokan Mercantile Co-Operative Bank LTD.: Grievance Redressal Policy077 - Ubaid dhansayNessuna valutazione finora

- DMS SapDocumento9 pagineDMS SapsathishNessuna valutazione finora

- QS Evinrude JohnsonDocumento4 pagineQS Evinrude JohnsonmohamedalibctNessuna valutazione finora

- Material Handling Control Procedure PDF FreeDocumento9 pagineMaterial Handling Control Procedure PDF FreeAli KayaNessuna valutazione finora

- Sed CMD Unix E-GDocumento6 pagineSed CMD Unix E-GKARTHIK145Nessuna valutazione finora

- Service Manual: DVP-S325/S525D/S725DDocumento31 pagineService Manual: DVP-S325/S525D/S725Dapi-3702225Nessuna valutazione finora

- Cosmoplast Upvc Drainage Pipes FittingsDocumento34 pagineCosmoplast Upvc Drainage Pipes FittingsBahar AbdulqadirNessuna valutazione finora

- New SEM Socio Economic Segmentation Tool ExplainedDocumento3 pagineNew SEM Socio Economic Segmentation Tool ExplainedanzaniNessuna valutazione finora

- Conference Paper TemplateDocumento3 pagineConference Paper TemplateDeden MSNessuna valutazione finora

- Ip-10 Cli Command LineDocumento9 pagineIp-10 Cli Command Linedipaksahoo4025100% (2)

- program Name: Departmental StoreDocumento6 pagineprogram Name: Departmental StoreAkshara ReddyNessuna valutazione finora