Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5.3 Volume Solids and Spread Rate

Caricato da

م.ذكى فضل ذكىCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5.3 Volume Solids and Spread Rate

Caricato da

م.ذكى فضل ذكىCopyright:

Formati disponibili

Volume Solids and Spreading Rate

What Is Volume Solids?

All paints are made up of resin, pigments, additives (such as stabilisers, antifoams and thickeners) and solvent. After the paint is applied, the solvent evaporates, leaving only the dry SOLIDS in the form of a continuous coating.

5.3

The solids can be expressed as a volume percentage of the entire volume of the can of paint. For example, if solvent takes up half the paint volume, then one can say that the paint is 50% solids. One can therefore expect that if a wet coat of paint is applied to a wet film thickness of 100 microns, the dry paint film will be 50 microns in thickness. % Volume Solids = Dry Film Thickness x 100 Wet Film Thickness

So, for a product that, when applied, had a measured wet film film thickness of 100 microns, microns and after the solvent had evaporated, left a dry film of 50 microns, microns the volume solids would be: % Volume Solids = 50 x 100 = 100 50%

We rarely need to calculate volume solids, though, as it is quoted on the product data sheet. The volume solids value can help you calculate theoretical spreading rates, the wet film thickness to deliver the required dry film thickness and corrected wet and dry film thicknesses when thinned by a known amount of solvent.

Relationship Between Spreading Rate And Volume Solids

If you have the volume solids value, and know what dry film thickness you require, then you can calculate what the wet film thickness needs to be using some simple mathematical formulae: Wet Film Thickness Spreading Rate (m2/litre) = = Dry Film Thickness x 100 % Volume Solids % Volume Solids x 10 DFT Required

Example

A section of steel needs to be coated in 125 microns (DFT) of Duremax GPE, which is 71% solids. solids What is the wet film thickness required? Wet Film Thickness = 125 microns x 100 71 = 176 microns

To achieve this wet film thickness, what should the spreading rate be (in square metres per litre)? Spreading Rate (m2/litre) = % Volume Solids x 10 DFT Required = 71 x 10 125 = 5.7 m2/litre

Volume Solids and Spreading Rate

Page 1 of 4

2 November, 2006

Volume Solids and Spreading Rate

5.3

Effect Of Thinner On Volume Solids And Wet Film Thickness

We often need to thin a product down to apply it more easily in certain conditions. If we know the volume solids of a product and the dry film thickness required, and add a precisely known amount of thinner, the wet film thickness and the spreading rate required can be calculated thus: Corrected % Volume Solids = % Volume Solids x 100 (100 + % Thinner added) Dry film thickness x (100 + % Thinner added) % Volume solids

Corrected Wet Film Thickness =

Example:

If we are to apply Duremax GPE, GPE with a Volume Solids of 71%, 71% to a dry film thickness of 125 microns after adding 5% thinner: thinner Corrected % Volume Solids Wet Film Thickness Spreading Rate (m2/litre) = = = % Volume Solids x 100 (100 + % Thinner added) Dry film thickness x 100 Corrected % Volume Solids Corrected % Volume Solids x 10 DFT Required = = = 71 x 100 100 + 5 125 x 100 67.6 67.6 x 10 125 = = = 67.6 % 185 microns 5.4 m2/litre

Converting From Theoretical To Practical Spreading Rate

Theoretical spreading rates are based on the volume solids of each product and offer a factual starting point from which to estimate practical spreading rates. The amount necessary to reduce theoretical rate to arrive at practical rate is best determined by experience with similar jobs, since it depends on:

1. 2. 3. 4. 5. 6.

Type of object being painted. Material needed to fill in the surface depressions caused by pitting and by abrasive blasting. Excessive film thickness over the required minimum. Material losses due to: wastage in pots, hoses, brush, rollers, overspray, wind losses, etc. Skill and experience of spray painter and painters. Porosity of surfaces.

Practical spreading rates may be estimated using the following rule of thumb:

Application by brush or roller Application by airless spray Application by conventional spray 10 15% reduction in theoretical spreading rate 10 15% reduction in theoretical spreading rate 40 50% reduction in theoretical spreading rate

Estimation of Paint Required

Volume of paint (litres) = 10 x Area (sqm) x Dry film thickness % Volume Solids x (100 % Wastage)

Page 2 of 4 2 November, 2006

Volume Solids and Spreading Rate

Volume Solids and Spreading Rate

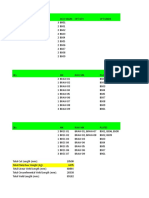

Wet Film Thickness (microns)

Volume Solids (%)

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

5.3

Specified Dry Film Thickness (microns) 20

200 133 100 80 66 57 50 44 40 36 30 -

25

250 166 125 100 83 71 62 55 50 45 41 38 35 -

30

300 200 150 120 100 85 75 66 60 54 50 46 42 40 37 -

35

350 233 175 140 117 100 87 77 70 63 58 53 50 46 43 41 38 -

40

400 266 200 160 133 114 100 88 80 72 66 61 57 53 50 47 44 42 40

50

333 250 200 166 142 125 111 100 90 83 76 71 66 62 58 55 52 50

60

300 240 200 171 150 133 120 109 100 100 85 80 75 70 66 63 60

75

300 250 214 187 166 150 136 125 115 107 100 93 88 83 78 75

90

300 257 225 200 180 163 150 138 128 120 112 105 100 94 90

100

285 250 222 200 181 166 153 142 133 125 117 111 105 100

125

357 312 277 250 227 208 192 178 166 156 147 138 131 125

200

500 444 400 363 333 307 285 266 250 235 222 210 200

250

555 500 454 416 384 357 333 312 294 277 263 250

300

545 500 461 428 400 375 352 333 315 300

350

538 500 466 437 411 388 368 350

500

666 625 588 555 526 500

1000

1111 1052 1000

Theoretical Spreading Rate (m2/L)

Dry Film Thickness (micron)

20 25 30 50 75 100 125 150 175 200 250 300 400 500

Volume Solids (%) 20

10.0 8.0 6.7 4.0 2.7 2.0 1.6 1.3 1.1 1.0 0.8 0.7 0.5 0.4

25

12.5 10.0 8.3 5.0 3.3 2.5 2.0 1.7 1.4 1.3 1.0 0.8 0.6 0.5

30

15.0 12.0 10.0 6.0 4.0 3.0 2.4 2.0 1.7 1.5 1.2 1.0 0.8 0.6

35

17.5 14.0 11.7 7.0 4.7 3.5 2.8 2.3 2.0 1.8 1.4 1.2 0.9 0.7

40

20.0 16.0 13.3 8.0 5.3 4.0 3.2 2.7 2.3 2.0 1.6 1.3 1.0 0.8

45

22.5 18.0 15.0 9.0 6.0 4.5 3.6 3.0 2.6 2.3 1.8 1.5 1.1 0.9

50

25.0 20.0 16.7 10.0 6.7 5.0 4.0 3.3 2.9 2.5 2.0 1.7 1.3 1.0

55

27.5 22.0 18.3 11.0 7.3 5.5 4.4 3.7 3.1 2.8 2.2 1.8 1.4 1.1

60

30.0 24.0 20.0 12.0 8.0 6.0 4.8 4.0 3.4 3.0 2.4 2.0 1.5 1.2

65

32.5 26.0 21.7 13.0 8.7 6.5 5.2 4.3 3.7 3.3 2.6 2.2 1.6 1.3

70

35.0 28.0 23.3 14.0 9.3 7.0 5.6 4.7 4.0 3.5 2.8 2.3 1.8 1.4

75

37.5 30.0 25.0 15.0 10.0 7.5 6.0 5.0 4.3 3.8 3.0 2.5 1.9 1.5

80

40.0 32.0 26.7 16.0 10.7 8.0 6.4 5.3 4.6 4.0 3.2 2.7 2.0 1.6

85

42.5 34.0 28.3 17.0 11.3 8.5 6.8 5.7 4.9 4.3 3.4 2.8 2.1 1.7

90

45.0 36.0 30.0 18.0 12.0 9.0 7.2 6.0 5.1 4.5 3.6 3.0 2.3 1.8

95

47.5 38.0 31.7 19.0 12.7 9.5 7.6 6.3 5.4 4.8 3.8 3.2 2.4 1.9

100

50.0 40.0 33.3 20.0 13.3 10.0 8.0 6.7 5.7 5.0 4.0 3.3 2.5 2.0

Volume Solids and Spreading Rate

Page 3 of 4

2 November, 2006

Volume Solids and Spreading Rate

Corrected Volume Solids After Thinning (%)

Original Volume Solid (%)

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

5.3

Percentage Thinner Added (%) 5

14 19 24 29 33 38 43 48 52 57 62 67 71 76 81 86 90 95

10

13.6 18 23 27 32 36 41 45 50 55 59 64 68 73 77 82 86 91

15

13 17 22 26 30 35 39 43 48 52 56 61 65 70 74 78 83 87

20

12.5 16.7 21 25 29 33 37 42 46 50 54 58 62 67 71 75 79 83

25

12. 16 20 24 28 32 36 40 44 48 52 56 60 64 68 72 76 80

33

11 15 19 23 26 30 34 38 41 45 49 53 56 60 64 68 71 75

50

10 13 17 20 23 27 30 33 37 40 43 47 50 53 57 60 63 67

For more information, please contact the Dulux Protective Coatings Technical Consultant in your state, or refer Dulux Protective Coatings Product Manual CD.

Volume Solids and Spreading Rate

Page 4 of 4

2 November, 2006

Potrebbero piacerti anche

- Coverage Spreading Rate and Paint Consumption Calculations 01nov2022Documento4 pagineCoverage Spreading Rate and Paint Consumption Calculations 01nov2022Tirumala PrasadNessuna valutazione finora

- Paint Calc-UaeDocumento16 paginePaint Calc-UaeKawser Hossain100% (2)

- Presentation Industrial PaintDocumento46 paginePresentation Industrial Paintpriya jadhavNessuna valutazione finora

- Explaining Product Data Sheet InformationDocumento0 pagineExplaining Product Data Sheet InformationeraswastaNessuna valutazione finora

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocumento4 pagineASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNessuna valutazione finora

- Paint Technology Diploma Course AssignmentDocumento11 paginePaint Technology Diploma Course AssignmentAnonymous UdYX3bNessuna valutazione finora

- Critical Review of Concrete Scaling CausesDocumento41 pagineCritical Review of Concrete Scaling CausessatpalNessuna valutazione finora

- Steel Surface Defects Diagnosis and CureDocumento19 pagineSteel Surface Defects Diagnosis and Cureahmerkhateeb100% (1)

- 521 Mio Coatings-What Are TheyDocumento3 pagine521 Mio Coatings-What Are TheypardissNessuna valutazione finora

- Paint CalculationDocumento16 paginePaint CalculationthandeshNessuna valutazione finora

- Dry Film Thickness Measurements How Many Are EnoughDocumento11 pagineDry Film Thickness Measurements How Many Are EnoughSds Mani SNessuna valutazione finora

- Paint TerminologyDocumento9 paginePaint TerminologyKAMAL BEHLNessuna valutazione finora

- Shin CombinedDocumento29 pagineShin CombinedAce Ace100% (1)

- Paint CalculationDocumento5 paginePaint CalculationEdy AlamNessuna valutazione finora

- Profit in The Paint Shop Series (1 of 4) - Anticipate The BlendDocumento5 pagineProfit in The Paint Shop Series (1 of 4) - Anticipate The BlendTillPaintNessuna valutazione finora

- AstmDocumento4 pagineAstmmohamed abd eldayemNessuna valutazione finora

- Asian Paints Tractor EmulsionDocumento2 pagineAsian Paints Tractor EmulsionAsian PaintsNessuna valutazione finora

- Laboratory Studies on Small Scale Production of Three Grades of Emulsion PaintsDocumento13 pagineLaboratory Studies on Small Scale Production of Three Grades of Emulsion Paintsmohamed sabryNessuna valutazione finora

- Amine Blush+Bloom Explained - Dow BulletinDocumento5 pagineAmine Blush+Bloom Explained - Dow BulletinPhilip La Trobe100% (2)

- Electrostatic SprayerDocumento13 pagineElectrostatic SprayerMuhammad AzrinNessuna valutazione finora

- Paint Component AustraliaDocumento146 paginePaint Component AustraliaAnonymous HargxqRNessuna valutazione finora

- PG Program in Paint & Coating Technology-April-2013Documento10 paginePG Program in Paint & Coating Technology-April-2013Uday Kumar GantiNessuna valutazione finora

- Marine Paint Guide Coverage EstimatesDocumento6 pagineMarine Paint Guide Coverage EstimatesTanmay GorNessuna valutazione finora

- FBE Testleri - DeFelskoDocumento54 pagineFBE Testleri - DeFelskoÖzgür TuştaşNessuna valutazione finora

- How Thermal Cutting Affects Galvanized CoatingsDocumento5 pagineHow Thermal Cutting Affects Galvanized Coatingsnarmatha100% (1)

- Priming Process Training PPT 14.08.14Documento49 paginePriming Process Training PPT 14.08.14sunil srivastavaNessuna valutazione finora

- Pull-Off Adhesion Testing ExplainedDocumento5 paginePull-Off Adhesion Testing Explainedzavisa2Nessuna valutazione finora

- Paint ApplicationDocumento4 paginePaint ApplicationSteven FlynnNessuna valutazione finora

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocumento2 pagineAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Pamphlet On Quality Assurance For Cement PlasteringDocumento4 paginePamphlet On Quality Assurance For Cement PlasteringD V BHASKARNessuna valutazione finora

- SSPC Pa1 PDFDocumento14 pagineSSPC Pa1 PDFAnonymous zia5og7psNessuna valutazione finora

- GAMESA Handbook Hempel 024 en Rev5 June2016Documento47 pagineGAMESA Handbook Hempel 024 en Rev5 June2016asim alok swain100% (2)

- Common Problems in Exterior PaintingDocumento14 pagineCommon Problems in Exterior Paintingharish420Nessuna valutazione finora

- What Is Paint? Composition of Paint Binder Pigment Extenders Solvents Application of PaintDocumento13 pagineWhat Is Paint? Composition of Paint Binder Pigment Extenders Solvents Application of PaintmhnmndrkNessuna valutazione finora

- TMS: Thermal Metal Spray Coatings: Corrosion Engineering DivisionDocumento7 pagineTMS: Thermal Metal Spray Coatings: Corrosion Engineering DivisionCorrosion Factory100% (1)

- Dr. Fixit HydroShield PUD Plus - Updated TdsDocumento4 pagineDr. Fixit HydroShield PUD Plus - Updated TdsAbraham George100% (2)

- C Tape Datasheet PDFDocumento2 pagineC Tape Datasheet PDFIftikhar Ahmed KhalidNessuna valutazione finora

- 5 Things Surface Prep 1Documento40 pagine5 Things Surface Prep 1Jesus De la RosaNessuna valutazione finora

- Paint Over Galvanized Steel Duplex SystemsDocumento12 paginePaint Over Galvanized Steel Duplex Systemselectrosysro8560Nessuna valutazione finora

- Jota Armour Brochure 2007Documento6 pagineJota Armour Brochure 2007yudiar2008Nessuna valutazione finora

- Dimetcote 9 PDS AIDocumento3 pagineDimetcote 9 PDS AIAmer Y KNessuna valutazione finora

- Steps to PVDF Coating on AluminumDocumento4 pagineSteps to PVDF Coating on AluminumnarmathaNessuna valutazione finora

- Samudayik BhawanDocumento13 pagineSamudayik BhawanManish PatelNessuna valutazione finora

- Iso12944 Technical PaperDocumento10 pagineIso12944 Technical PaperGuillermo Arnulfo Villa Garay100% (1)

- Water Repellent Cement Paint ProjectDocumento9 pagineWater Repellent Cement Paint ProjectSwaroop MnNessuna valutazione finora

- ASTM D 714 - 87 r00Documento6 pagineASTM D 714 - 87 r00Abi PutraNessuna valutazione finora

- The Wagner TipsDocumento12 pagineThe Wagner Tipsihrodri100% (1)

- IMO Ballast Tank Coating RegulationsDocumento12 pagineIMO Ballast Tank Coating RegulationsislimaNessuna valutazione finora

- Luwax AF TypesDocumento10 pagineLuwax AF TypesSunil GaikwadNessuna valutazione finora

- Interthane 990 Test Data PDFDocumento2 pagineInterthane 990 Test Data PDFImam Situmeang100% (2)

- Handy Calculations - Volume Solids and Spreading RateDocumento4 pagineHandy Calculations - Volume Solids and Spreading Ratevengadesh100% (1)

- Coverage Spreading Rate and Paint Consumption Calculations 13jul2023Documento4 pagineCoverage Spreading Rate and Paint Consumption Calculations 13jul2023Mohamed AtefNessuna valutazione finora

- Coverage/ Spreading RateDocumento2 pagineCoverage/ Spreading RateSaleh EttehadiNessuna valutazione finora

- Microsoft Word - 13 Calculations FINAL 13-09Documento12 pagineMicrosoft Word - 13 Calculations FINAL 13-09Djou KetataNessuna valutazione finora

- TechTalk - Sealants and CoatingsDocumento4 pagineTechTalk - Sealants and CoatingsPutra Panca WardhanaNessuna valutazione finora

- Coating BlanketsDocumento17 pagineCoating BlanketsJavier Martinez CañalNessuna valutazione finora

- A Flock PrintingDocumento34 pagineA Flock Printingaqsa imranNessuna valutazione finora

- Elastogran cellularPOLYURETHANEelastomerDocumento6 pagineElastogran cellularPOLYURETHANEelastomerAngelo NutiNessuna valutazione finora

- Mesh Tablas EquivalenciasDocumento19 pagineMesh Tablas EquivalenciasLocer2011100% (1)

- Mechanical Analysis of Soil ExplainedDocumento7 pagineMechanical Analysis of Soil ExplainedPlatón J. Colque Vargas100% (2)

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocumento8 pagineLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNessuna valutazione finora

- GRP Installation GuideDocumento13 pagineGRP Installation GuidepparreraNessuna valutazione finora

- Visual Inspection Test ReportDocumento2 pagineVisual Inspection Test Reportم.ذكى فضل ذكىNessuna valutazione finora

- Heat Treating The SteelDocumento12 pagineHeat Treating The Steelyasir_anjumNessuna valutazione finora

- PR-1002 - Operations Excavation ProcedureDocumento19 paginePR-1002 - Operations Excavation Procedureم.ذكى فضل ذكىNessuna valutazione finora

- Chapter 5 98Documento34 pagineChapter 5 98masturaabdulrahimNessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationmail_younes659283% (29)

- Supported Cone Roof (CS) Add.4Documento21 pagineSupported Cone Roof (CS) Add.4skhurramq100% (2)

- API 650-Water SS Tank-060914Documento84 pagineAPI 650-Water SS Tank-060914Hamou MelloulNessuna valutazione finora

- API 650 Design TanksDocumento51 pagineAPI 650 Design Tanksم.ذكى فضل ذكى100% (2)

- Steel Construction and Bridges Allowable Stress DesignDocumento263 pagineSteel Construction and Bridges Allowable Stress DesignSaharAkthamNessuna valutazione finora

- IS Code 803Documento98 pagineIS Code 803prnpa234Nessuna valutazione finora

- Sloshing Wave 2 PDFDocumento5 pagineSloshing Wave 2 PDFم.ذكى فضل ذكىNessuna valutazione finora

- Structural SteelDocumento6 pagineStructural SteelYusuf SaputraNessuna valutazione finora

- API 650 Design TanksDocumento34 pagineAPI 650 Design TanksSyedZainAli100% (13)

- Tank API 650 SI 0001Documento23 pagineTank API 650 SI 0001م.ذكى فضل ذكىNessuna valutazione finora

- Pad Eye Design Lifting Lug StandartDocumento7 paginePad Eye Design Lifting Lug Standartstalin_83Nessuna valutazione finora

- GRP Installation GuideDocumento13 pagineGRP Installation GuidepparreraNessuna valutazione finora

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocumento28 pagineIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiNessuna valutazione finora

- Lifting Lug CalculationDocumento8 pagineLifting Lug CalculationLathesh JanarthananNessuna valutazione finora

- Is 4049 2 1996Documento14 pagineIs 4049 2 1996م.ذكى فضل ذكىNessuna valutazione finora

- TANK Design DetailingDocumento17 pagineTANK Design DetailingTiffany Vabiola100% (8)

- Autocad NotesDocumento53 pagineAutocad Notesadnan100% (7)

- F45 CDD 01Documento54 pagineF45 CDD 01paimpillyNessuna valutazione finora

- Ziolko J Supernak E Borek P Jedrzejewski M T Kowalski D Tank Construction of 75000 m3 Capacity With A Double Shell and Double ButtomDocumento9 pagineZiolko J Supernak E Borek P Jedrzejewski M T Kowalski D Tank Construction of 75000 m3 Capacity With A Double Shell and Double Buttomم.ذكى فضل ذكىNessuna valutazione finora

- Supplier ITP Inspection PlanDocumento4 pagineSupplier ITP Inspection PlanHassan SajidNessuna valutazione finora

- Types TanksDocumento17 pagineTypes TanksCarlos Augusto FerreiraNessuna valutazione finora

- BTE Dome Brochure Jun 10Documento2 pagineBTE Dome Brochure Jun 10م.ذكى فضل ذكىNessuna valutazione finora

- Ldo Storage Tank Calculation 170Documento6 pagineLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Supported Cone Roof CS Add 4 PDFDocumento13 pagineSupported Cone Roof CS Add 4 PDFم.ذكى فضل ذكىNessuna valutazione finora

- Squeezing Ground ConditionDocumento16 pagineSqueezing Ground ConditionMourad HosniNessuna valutazione finora

- Liquid ring vacuum pumps and compressors operating modesDocumento5 pagineLiquid ring vacuum pumps and compressors operating modesSandi AslanNessuna valutazione finora

- Solar Super CapacitorDocumento276 pagineSolar Super CapacitorGilberto Alves RodriguesNessuna valutazione finora

- Junctions ExplainedDocumento4 pagineJunctions ExplainedJulio SaldanhaNessuna valutazione finora

- Comparatii Si Echivalente Branduri Sarma TubularaDocumento4 pagineComparatii Si Echivalente Branduri Sarma TubularaAnonymous LpKY4pNessuna valutazione finora

- 3rd International Conference On The Advancement of Materials and Nanotechnology 2013 - ICAMN III 2013Documento5 pagine3rd International Conference On The Advancement of Materials and Nanotechnology 2013 - ICAMN III 2013Khairol Anuar MohammedNessuna valutazione finora

- p22MNVMB MN Gtaw+Smaw (Pipe)Documento2 paginep22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Nessuna valutazione finora

- Unit 10 Packet 3 AnswersDocumento4 pagineUnit 10 Packet 3 AnswersBrandon BaxterNessuna valutazione finora

- Molecular ModelingDocumento22 pagineMolecular ModelingHely PatelNessuna valutazione finora

- Bamboo Reinforced ConcreteDocumento14 pagineBamboo Reinforced ConcreteharisankarNessuna valutazione finora

- Twyman Lothian PpaerDocumento8 pagineTwyman Lothian PpaerchristianNessuna valutazione finora

- Stoichiometry Basics NotesDocumento5 pagineStoichiometry Basics NoteswardaNessuna valutazione finora

- Bradford Method Protein Assay GuideDocumento3 pagineBradford Method Protein Assay GuideDoreliaNessuna valutazione finora

- Difference Between Sewing Method and Alternative Method4Documento40 pagineDifference Between Sewing Method and Alternative Method4sabberNessuna valutazione finora

- Rr322105-High Speed AerodynamicsDocumento8 pagineRr322105-High Speed AerodynamicsSRINIVASA RAO GANTANessuna valutazione finora

- PRODUCT INFORMATIONDocumento2 paginePRODUCT INFORMATIONAdriana GonçalvesNessuna valutazione finora

- Is 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersDocumento26 pagineIs 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersShivakumara ArehalliNessuna valutazione finora

- Chemistry Aqa A Level AlkenesDocumento21 pagineChemistry Aqa A Level AlkenesAttec OinotnaNessuna valutazione finora

- C78IA009EN A ViscoQC Yield PointDocumento2 pagineC78IA009EN A ViscoQC Yield Pointjomoro29Nessuna valutazione finora

- Glass Manufacturing ProcessDocumento2 pagineGlass Manufacturing ProcessNur Aulia S100% (2)

- Atomic Structure and Chemical Bonding Chapter 2 QuestionsDocumento19 pagineAtomic Structure and Chemical Bonding Chapter 2 QuestionsAhmed ZiadNessuna valutazione finora

- Stainless Steel Molecular Etching PDFDocumento6 pagineStainless Steel Molecular Etching PDFp.designNessuna valutazione finora

- DNS Question PapersDocumento5 pagineDNS Question PapersAkansha Khurana100% (3)

- Non Chip FormingDocumento33 pagineNon Chip FormingNur AmirahNessuna valutazione finora

- Toluene: Safety Data SheetDocumento10 pagineToluene: Safety Data SheetLiaHerlianaNessuna valutazione finora

- Depolymerization of Tire and Natural Rubber Using Supercritical FluidsflaDocumento8 pagineDepolymerization of Tire and Natural Rubber Using Supercritical FluidsflaAli DueNessuna valutazione finora

- Assignment 1 CarboxylicDocumento8 pagineAssignment 1 CarboxylicYu HuiNessuna valutazione finora

- SET Syllabus Chemical Sciences: Inorganic ChemistryDocumento3 pagineSET Syllabus Chemical Sciences: Inorganic Chemistryराहुल शर्माNessuna valutazione finora

- Technical Specification For Level GaugesDocumento6 pagineTechnical Specification For Level Gaugesat35100% (1)

- ASTM E291 - 09 - Standard Test Methods Forchemical Analysis of Caustic Soda and Caustic Potash (Sodium Hydroxide and Potassium Hydroxide) 1Documento15 pagineASTM E291 - 09 - Standard Test Methods Forchemical Analysis of Caustic Soda and Caustic Potash (Sodium Hydroxide and Potassium Hydroxide) 1Boby WongNessuna valutazione finora