Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Earthing IEEE80 Final

Caricato da

Abdulyunus AmirTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Earthing IEEE80 Final

Caricato da

Abdulyunus AmirCopyright:

Formati disponibili

DESIGN PROCEDURE BLOCK DIAGRAM

FIELD DATA

A,

CONDUCTOR SIZE

ts,d,Io

TOUCH & STEP

CRITERIA

Etouch70, Estep70

INITIAL DESIGN

D,n,LT,h

GRID RESISTANCE

Rg,LT

GRID CURRENT

IG

GPR < Etouch

MESH & STEP

VOLTAGES

Em,Es,Km,Ks,Ki,Kii

Es<Estep

Em<Etouch

DETAIL

DESIGN

MODIFY DESIGN

D,n,LT,LR

YES

YES

YES

NO

NO

NO

EARTHING CALCULATION

A GENERAL DESIGN DATA

1 Soil Resistivity, : 80 Ohm-M

2 Gravel Resistivity, : 2500 Ohm-M

3 Symmetrical Short Circuit Current, Iefs : 25000 A

4 Duration of Earth Fault Current, ts : 1 Sec

5 Maximum Allowable Conductor Temp. : 700 C

6 Design Ambient Temperature : 40 C

7 Thickness of Crushed Gravel, : 0.102 mtr.

8 Depth of Earth Grid, h : 0.5 mtr.

9 Reference depth of the Grid, h o 1 mtr.

10 Frequency 60 Hz

STANDARDS USED

IEEE Gude for Safety in AC Substation

Grounding IEEE - 80 2000

B SIZE OF EARTHING CONDUCTOR :

Eqn.: 40 Page : 43

IEEE Std. 80 - 2000

Where

Material Proposed

= Resistivity of Conductor Material 0.00381 Ohm - M

= Thermal co-efficient of resistivity at reference temperature Tr in 1/C 1.78

Tm = Max. allowable temperature in C 700 C

Ta = Ambient temperature in C 40 C

Ko = 1/o0 or 1/or - Tr in C 242

|

|

.

|

\

|

+

+

|

|

.

|

\

|

=

a

m

r r c

T K

T K

t

TCAP

I

Amm

0

0

4

2

ln

10

o

r

r

o

s

hs

EARTHING CALCULATION

Iefs = rms current in Ka 25 KA

t c = Duration of Current in s 1 Sec.

TCAP = thermal capacity per unit volume from Table 1 3.42 J/(cmC)

Amm = Conductor cross section in mm 101.37 mm

= 200.10 kcmil

Amm = 101.37 mm

THE SIZE OF CONDUCTOR SELECTED = 11.4 mm

Diameter of the Grid Conductor ,d = 0.01136 mtr.

Rounded of = 0.01 mtr.

Eqn. 21, Page 21, IEEE 80 2000

Eqn. 27, Page 23, IEEE 80 2000

= Reflection factor between different material resistivities

= Resistivity of the earth beneath the surface material in O.m

= Surface material resistivity in O.m

= Thickness of the surface material in m

= Surface layer derating factor

= -0.94

= 0.70

Eqn. 30, Page 27, IEEE 80 2000

Where

= Step Voltage for body weight of 70 kg

= 1814.15 Volts

TOUCH & STEP CRITERIA

kcmil

A

s

s

K

+

=

K

K

09 . 0 2

1 09 . 0

+

|

|

.

|

\

|

=

hs

C

s

s

s

C

hs

s

C

70 step

E

70 step

E

s

s s step

t

C E

157 . 0

) 6 1000 (

70

+ =

EARTHING CALCULATION

Eqn. 33, Page 27, IEEE 80 2000

Where

= Touch Voltage for body weight of 70 kg

= 571.29 Volts

C INITIAL DESIGN ASSUMPTIONS

Length Breadth

Preliminary Layout of Grid = 213.36 91.44

n = Number of parallel conductors = 43

D = Conductor Spacing = 5 m

h = Depth of grid burial = 0.8 m

Lp = Length of the conductor across perimeter = 609.6 m

Nr = No. of Ground Rods = 50

Lr = Length of Ground Rods = 12 m

LR = Total length of Ground Rods = 600 m

LT1 = Total length of buried condcutor = 8109 m

LT = Total length of buried conductors & rods = 8709 m

Lx = Maximum length of conductor in X-Axis = 213

Ly = Maximum length of conductor in Y-Axis = 91

D GRID RESISTANCE

Where

A = Area of the Grid = 19509.6384 m

= Grid Resistance

= 0.26 O

70 step

E

70 touch

E

70 touch

E

L Na L

T

= 2

(

|

.

|

\

|

+

+ + =

A h A L

R

T

g

/ 20 1

1

1

20

1 1

g

R

g

R

s

s s touch

t

C E

157 . 0

) 5 . 1 1000 (

70

+ =

EARTHING CALCULATION

E MAXIMUM GRID CURRENT

Where

= Maximum grid current in A 25000 A

X/R= 10

Ta= 0.0265258

= Decrement factor for the entire duration of fault, given in s 1.0131761

= 25329.40268 A

F GROUND POTENTIAL RISE

= 6639.6 V

The safety to personnel is specified by IEEE 80, which requires to limit the development of

electrical potential to dangerous value during earth fault current.

The regulation stipulates the following parameters to be within the permissible limit

a) Step Voltage (Foot to Foot Contact)

b) Touch Voltage(Hand to Foot Contact)

A Mesh Voltage

Eqn. 80, Page 91,

IEEE 80, 2000

= Corrective factor for current irregu-

larity

Where

CALCULATION FOR ACTUAL DERIVED STEP & MESH VOLTAGE

VERIFICATION FOR HUMAN SAFETY

R

Ly x

r

C

i m G

L

l L

L

L

K K I

Design Emesh

(

(

|

|

.

|

\

|

+

+ +

=

2 2

22 . 1 55 . 1

) (

Ki

g

I

g f G

I D I =

f

D

G

I

g G

R I GPR =

GPR

n K

i

148 . 0 644 . 0 + =

d c b a

n n n n n =

P

T

a

L

L

n

=

2

EARTHING CALCULATION

= 26.6

= 1 for square grids = 1

= 1 for square and rectangular grids = 1

= 1 for square, rectangular and L-shaped grids = 1

= 26.60

= 4.58

= Spacing factor for Mesh Voltage Eqn. 68 Page 113 IEEE 80

Eqn. 81, Page 93

IEEE 80, 2000

Where

= Corrective wieghting factor that adjusts the effect of inner conductors on the corner mesh

= 0.81

= 1.00 With Rods

= Corrective weighting factor that empasising the grid depth

=

Where

= Reference depth of grid = 1

= Depth of the ground grid conductor = 0.5

= 1.22

= 0.50

= 511.43 Volts

Km

( )

( )

(

H

+

(

+

+

H

=

1 2

8

ln

4 8

2

16

ln

2

1

2 2

n Kh

Kii

d

h

Dd

h D

hd

D

Km

Kii

Kh

|

.

|

\

|

+

ho

h

1

ho

h

Kh

Km

) (Design Emesh

n

ii

n

K

2

) 2 (

1

=

Kii

P

T

a

L

L

n

=

2

a

n

b

n

c

n

d

n

n

Ki

Kii

EARTHING CALCULATION

Calculated Mesh Voltage is Lower than the Tolerable Touch Voltage.HENCE SAFE

B Step Voltage

Voltage developed for step as per the earthing system proposed during full Earth fault current

Eqn. 92, Page 94

IEEE 80, 2000

Where

= Spacing factor for Step voltage

Eqn. 94, Page 94, IEEE 80, 2000

= 0.440

= 4.5812736

= 619.78 Volts

= 620 Volts

Calculated Step Voltage is Lower than the Tolerable Step Voltage.HENCE SAFE

( ) | |

| |

R C

G

L L

I Ki Ks

Design Estep

+

=

85 . 0 75 . 0

) (

Ks

(

(

|

|

.

|

\

|

+

+

+

H

=

D h D h

Ks

n 2

5 . 0 1 1

2

1 1

Ks

Ki

) (Design Estep

) (Design Estep

n K

i

148 . 0 644 . 0 + =

EARTHING CALCULATION

EARTHING CALCULATION

EARTHING CALCULATION

EARTHING CALCULATION

EARTHING CALCULATION

EARTHING CALCULATION

EARTHING CALCULATION

SUMMARY

A EARTH GRID CONDUCTOR

Type of Conductor

Size of Conductor 200 MCM

Length of Conductor 8109 mtr

Depth of Conductor 0.5 m below GL

B GROUND RODS

Total Length of Ground Rods 600 mtr

Length of Individual Ground Rods 12 mtr

No. of Ground Rods 50 No.

C HUMAN SAFETY

Mesh Voltage

511

620

Volt

1814

571.29

GPR Volt 6639.6

Permissible Value

Volt

Copper, commercial hard - drawn

Step Voltage

UNIT Designed Value

Description

Material

Conductivity

(%)

or factor

at 20C

K 0 at

(0C)

Fusing

Temperature

Tm (C)

1

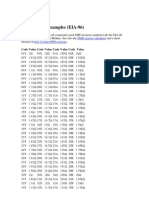

Copper annealed

soft - drawn 1 100 1 0.00393 1 234 1 1083 1

2

Copper, commercial

hard - drawn

2 97 2 0.00381 2 242 2 1084 2

3

Copper-clad steel

wire 3 40 3 0.00378 3 245 3 1084 3

4

Copper-clad steel

wire 4 30 4 0.00378 4 245 4 700 4

5

Copper-clad steel

rod 5 20 5 0.00378 5 245 5 1084 5

6

Aluminium EC

Grade 6 61 6 0.00403 6 228 6 657 6

7

Aluminium 5005

alloy 7 53.5 7 0.00353 7 263 7 652 7

8

Aluminium 6201

alloy 8 52.5 8 0.00347 8 268 8 654 8

9

Aluminium-clad steel

wire 9 20.3 9 0.0036 9 258 9 657 9

10

Steel, 1020

10 10.8 10 0.0016 10 605 10 1510 10

11

Stainless - clad steel

rod 11 9.8 11 0.0016 11 605 11 1400 11

12

Zinc-coated steel

rod 12 8.6 12 0.0032 12 293 12 419 12

13 Stanless steel, 304 13 2.4 13 0.0013 13 749 13 1400 13

TABLE 1 - MATERIAL CONSTANTS

s

s s touch

t

C E

157 . 0

) 5 . 1 1000 (

70

+ =

s

s s step

t

C E

157 . 0

) 6 1000 (

70

+ =

r

20C(O.

cm)

TCAP

Thermal

Capacity

[J/(cm.C]

1.72 1 3.42

1.78 2 3.42

4.4 3 3.85

5.86 4 3.85

8.62 5 3.85

2.86 6 2.56

3.22 7 2.6

3.28 8 2.6

8.48 9 3.58

15.9 10 3.28

17.5 11 4.44

20.1 12 3.93

72 13 4.03

TABLE 1 - MATERIAL CONSTANTS

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Top 100 Engineering Interview QuestionsDocumento11 pagineTop 100 Engineering Interview QuestionsAbdulyunus AmirNessuna valutazione finora

- SMD Resistor ExamplesDocumento5 pagineSMD Resistor Examplesmarcbuss100% (1)

- ThaiREC Checklist-Barge Inspection Questionnaire GasDocumento18 pagineThaiREC Checklist-Barge Inspection Questionnaire Gasเปีย วันชัย สวนทอง100% (1)

- What Are The Reason A 33kV Bus PT Fuse Is Blowing Out FrequentlyDocumento10 pagineWhat Are The Reason A 33kV Bus PT Fuse Is Blowing Out FrequentlyAbdulyunus Amir100% (1)

- State of Patriot MissilesDocumento13 pagineState of Patriot MissilesTaira Mai100% (1)

- LeaderDocumento34 pagineLeaderAbdulyunus AmirNessuna valutazione finora

- Haldimann - Structural Use of Glass BookDocumento221 pagineHaldimann - Structural Use of Glass BookKenny Tournoy100% (6)

- Wood Magazine Issue #189Documento96 pagineWood Magazine Issue #189bangbang63100% (1)

- DP1100Documento3 pagineDP1100tunradotNessuna valutazione finora

- A Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisDocumento7 pagineA Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisSalma SherbazNessuna valutazione finora

- Material Test Report: ISO EN 10204 2004-3.1Documento4 pagineMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNessuna valutazione finora

- CSG CMT CalculationsDocumento5 pagineCSG CMT Calculationsfrancisryan4519Nessuna valutazione finora

- CVP AnalysisDocumento41 pagineCVP AnalysisAbdulyunus Amir100% (1)

- Activity Based CostingDocumento51 pagineActivity Based CostingAbdulyunus AmirNessuna valutazione finora

- Combustor InsulationDocumento4 pagineCombustor InsulationAbdulyunus AmirNessuna valutazione finora

- Dynamics On Industrial RelationsDocumento24 pagineDynamics On Industrial RelationsAbdulyunus AmirNessuna valutazione finora

- What Does Regenerative Air Pre-Heater Means, Why They Named SoDocumento10 pagineWhat Does Regenerative Air Pre-Heater Means, Why They Named SoAbdulyunus AmirNessuna valutazione finora

- Annex I UAT Name Plate 081210Documento1 paginaAnnex I UAT Name Plate 081210Abdulyunus AmirNessuna valutazione finora

- Voltage Management A Hidden Energy Efficiency ResourceDocumento3 pagineVoltage Management A Hidden Energy Efficiency ResourceAbdulyunus AmirNessuna valutazione finora

- What Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Documento3 pagineWhat Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Abdulyunus AmirNessuna valutazione finora

- Voltage and Current UnbalanceDocumento2 pagineVoltage and Current UnbalanceAbdulyunus AmirNessuna valutazione finora

- Utility ICS Current Practices Survey 2013Documento13 pagineUtility ICS Current Practices Survey 2013Abdulyunus AmirNessuna valutazione finora

- Three Phenomenons in The Iron of AC MachinesDocumento4 pagineThree Phenomenons in The Iron of AC MachinesAbdulyunus AmirNessuna valutazione finora

- 4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignDocumento10 pagine4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignSamawat AhsanNessuna valutazione finora

- Business Dynamics in The 21st CenturyDocumento270 pagineBusiness Dynamics in The 21st CenturyskilmagNessuna valutazione finora

- TDS Tixatrol STDocumento2 pagineTDS Tixatrol STJose E BatistaNessuna valutazione finora

- DP Chipset 15045 DriversDocumento592 pagineDP Chipset 15045 DriversRajesh1146Nessuna valutazione finora

- RIL AGM Presentation SlidesDocumento44 pagineRIL AGM Presentation SlidesDeshGujaratNessuna valutazione finora

- Retrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsDocumento2 pagineRetrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsMichael GorobaoNessuna valutazione finora

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDocumento38 pagineSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakNessuna valutazione finora

- Wheels & BrakesDocumento14 pagineWheels & BrakesJoshua Saldana VélezNessuna valutazione finora

- Computer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)Documento118 pagineComputer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)iamy2ramsNessuna valutazione finora

- Water Technology 2015 2016 1Documento86 pagineWater Technology 2015 2016 1Srinivas AkHilNessuna valutazione finora

- 11i APC Imp GuideDocumento108 pagine11i APC Imp GuidePrashanth ReddyNessuna valutazione finora

- Recommendation Handling of Norit GL 50Documento9 pagineRecommendation Handling of Norit GL 50Mátyás DalnokiNessuna valutazione finora

- Flabeg Solar enDocumento11 pagineFlabeg Solar enZeec NoorNessuna valutazione finora

- Gulfco Fleet Premium: Heavy Duty Gas Engine Oil For Mobile ApplicationDocumento1 paginaGulfco Fleet Premium: Heavy Duty Gas Engine Oil For Mobile ApplicationAlisson Marcela ContrerasNessuna valutazione finora

- Msi ms-7222 Rev 3.0 SCH PDFDocumento30 pagineMsi ms-7222 Rev 3.0 SCH PDFRodney RibeiroNessuna valutazione finora

- Sample Electrical LayoutDocumento1 paginaSample Electrical LayoutBentesais Bente UnoNessuna valutazione finora

- 2015 VGP Checklist - Rev0Documento9 pagine2015 VGP Checklist - Rev0Takis RappasNessuna valutazione finora

- Precision r5500 Service Manual en UsDocumento104 paginePrecision r5500 Service Manual en UsJonDyson32Nessuna valutazione finora

- ThanksDocumento17 pagineThankssselvanjhcNessuna valutazione finora

- Parts Catalog: Paper Feed Unit Type 3800C (G568)Documento23 pagineParts Catalog: Paper Feed Unit Type 3800C (G568)poldisagtNessuna valutazione finora

- Home Automation Control System Using DTMFDocumento25 pagineHome Automation Control System Using DTMFengaydiNessuna valutazione finora