Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Colloidal Silver Generator

Caricato da

Jdoe3399Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Colloidal Silver Generator

Caricato da

Jdoe3399Copyright:

Formati disponibili

The first thing people need to know is that there are at least FOUR different products on the market

being called COLLOIDAL SILVER. The first type of product is the classic, original kind, usually called "electro-colloidal silver." This product is made either by the "electro-arc" method in deionized water, or by the "low voltage electrolysis" method in distilled water. This product is usually found in concentrations between 35 ppm (parts per million), but sometimes as high as 100 ppm. Properly made, this product consists of microscopic particles of pure, elemental silver suspended in water, with no other elements present. Each particle of silver carries a POSITIVE electrical charge. Colloidal silver made this way appears either transparent-clear or transparent-light yellow. The second is called "mild silver protein." This product chemically binds microscopic particles of silver to a protein molecule. It is usually found in concentrations between 20-40 ppm. Its appearance may be transparent-clear or amber. The third are "silver salts." These products can be made either chemically or electro-chemically and usually create a form of silver that DISSOLVES in the water. Concentrations range between 50-500 ppm. Its appearance is transparent-clear. The silver particles do carry a POSITIVE electrical charge, but almost invariably, these products contain other elements or compounds other than silver. The fourth is sometimes referred to as "powdered silver." This product was developed by the Russians and is made when a pure silver wire is rapidly disintegrated by an high voltage electrical discharge, similar to an old photographic flash bulb. The microscopic silver dust is collected and either dissolved in water or added to salves and creams for topical use. Concentrations range from 100-500 ppm. All of these products work, to one degree or another, as a broad spectrum germicide because they all contain microscopic particles of SILVER. That said, it is important to understand a number of things: 1) all of these products are not "colloidal suspensions" of silver, 2) these products DO NOT all behave the same in the body or in laboratory tests, 3) effectiveness and dosage varies from product to product, 4) quality varies from product to product and from batch to batch with the same product, and 5) they are NOT all uniformly safe and non-toxic. There are no industry standards that manufacturers voluntarily follow to assure quality control and there is no governmental regulation of the industry. On the other hand, there are millions and millions of satisfied colloidal silver users who would like to have continued, free access to the product, and a growing number of manufacturers entering the market with a wide variety of new products. The critical factors that make a "good" colloidal silver product are particle size, purity, concentration, and cost. The only way to authoritatively determine the first three is by laboratory analysis. The best way to determine particle size is by electron microscope photograph. The best way to determine purity is by mass spectroscopy or by x-ray defraction analysis. The best way to determine concentration is by chemical analysis of total dissolved solids. The cost of the product should be calculated in reference to the total quantity of silver present, such as: $5.00/oz of 100 ppm is equal to 25/oz of 5 ppm (the first has 20 times more silver by volume and costs 20 times more by volume.) Making Your Own The simplest way to control these factors is to make the colloidal silver for yourself. By doing this, you will not know exactly what is there unless you do laboratory testing, but you will have a pretty good idea. (See our TDS Meter) Without laboratory testing of commercial products, you don't know much more, because the quality control batch to batch is loose with most brands. Also, by making it yourself, you will end up with real "colloidal" silver, which is the product referred to in most of the literature. If you are already making your own colloidal silver, please pay special attention to this section because much of the information you now have may be incorrect. The simplest way to make real colloidal silver at home is by the "low voltage electrolysis" method. A few batteries may be connected to some silver electrodes and placed in a glass of water. This process will cause small particles of silver to be sintered off the electrodes and enter the water. This deceptively simple method is very easy to do WRONG, and most people who are making colloidal silver at home are making an inferior product.

It's In The Water When you do this yourself, it is very important to control the purity of the water, because the purity of the water is one of the factors that controls how small the particles of silver will be. Only high quality DISTILLED water should be used. (See our TDS Meter) You cannot use purified or filtered water because it still has too many dissolved minerals in it. You cannot use deionized water because it doesn't conduct electricity well enough to start the reaction. Distilled water is just perfect to start the reaction slowly and let it proceed properly. Another variable that influences particle size is the water temperature. The warmer the water, the faster the reaction will take place, and the smaller the particles will be. Please Pass The Salt Regardless of what anyone has said to the contrary, silver chloride will ALWAYS form if any amount of salt is present. Never add anything to the water that will make the water conduct electricity better. Never add salt, sea salt, or Celtic sea salt to the distilled water because the salt puts chloride ions in the water that react with the silver to form silver chloride. Another serious problem arises when making colloidal silver with salt in the water. The presence of salt increases the electrical conductivity of the water and this dramatically speeds up the reaction. As the reaction speeds up under these circumstances, it produces larger particles. The product produced is invariably cloudy-white in appearance. Actual electron microscope photographs of this material show silver particles in the range of .05 to .15 microns. These particles are TOO LARGE to form a colloidal suspension, and the proof is that the material will settle to the bottom of the container in a very short period of time. Therefore, this home brewed "colloidal silver" product may be dangerous to consume internally for TWO reasons: the presence of silver chloride and the production of large particles. The Best Is Yet To Come The very best voltage for the reaction is 30 volts, because the electrodes run the cleanest at this voltage. If you have a small power supply, set it for 30 volts. If you are running on batteries, it is best to start at 36 volts (three 12 volt batteries or four 9 volt batteries) and let the batteries drain down from there. Holding the silver electrodes at a uniform distance away from each other yields a better product. When 30 volts is applied across silver electrodes held uniformly apart in distilled water, a totally different event happens. First, the reaction proceeds very slowly. Often, for the first 15 minutes nothing seems to be happening. Then finally, a faint yellow mist will begin to form. Within a few minutes, the reaction will speed up, but the particles produced will be a golden-yellow as viewed with a flashlight. Using this method, 8 ounces of distilled water at room temperature can be made into a 3-5 ppm colloidal silver preparation in 20-25 minutes. Made this way, colloidal silver can cost under 10/oz to make. Electron microscope photographs of this product show a silver particle size in the range .001 to .004 microns. During manufacturing, the particle cloud is a golden-yellow. These particles will hang in the water at the level they are produced, and for the most part, will not fall to the bottom of the glass. This is what a "colloidal" preparation of silver looks like. After the particles disperse, the water will look clear again, but may turn a light yellow if the concentration is high enough and after the particles have become evenly dispersed. "The Yellow Color" There has been a fair amount of controversy in the public literature concerning the appearance of the "yellow" color. A lot of well meaning people have told me that "yellow is bad", "silver isn't yellow", "yellow is sulfur contamination", "yellow is iron contamination", and lots of other things. I finally found what I believe to be the answer to this question in a book titled Practical Colloid Chemistry, published in London in 1926. In the section on the "Colours of Colloidal Metals", subsection on the "Polychromism of silver solutions" on page 69, I found the following statements: "The continuous change in colour from yellow to blue corresponds to a change in the absorption maximum of the shorter to longer wave-lengths with a decreasing degree of dispersion. This is a general phenomenon in colloid chemistry illustrating the relation between colour and degree of dispersion." This section goes on to describe the colors that show up in a wide variety of colloidal metal solutions. Interestingly, they ALL have a yellow phase. For true "electro-colloidal" silver, the particle size range that can appear yellow is .01 to .001 microns (10 to 100 angstroms) because that is the size of silver particle that best absorbs the indigo light, leaving only its

inverse color, yellow, to be observed. The final transparent-yellow appearance only shows up after the particles have become evenly dispersed. The Brown Glass Bottle Once you have gone to the trouble of making colloidal silver particles as small as .001 microns, it is important to protect them. The particles stay away from each other in suspension because they each have a positive electrical charge (+) and these "like charges" repel each other. Anything that can strip this charge off the particles will degrade the quality of the colloidal silver by a process called re-coagulation, where the particles clump together again to form larger aggregates. Ultraviolet light from the sun and many plastics can cause this process to occur. Therefore, colloidal silver is best stored in dark, glass containers. The two kinds of glass container that are suitable for this are the dark amber and the cobalt blue. The Same Difference The biggest "secret" about the manufacture of high quality colloidal silver is that it is nearly impossible to standardize the product. Silver is apparently reactive to a number of natural forces that have yet to be identified. Even when the voltage, the water, and the water temperature are identical, different batches will proceed at different rates on different days. The speed of the reaction can vary by over 100% depending on the day. On "normal" days, the reaction is proceeding well by 15 minutes, with a visible cloud of particles. On "slow days" it may take 30 minutes before any visible production of yellow particles begins. Because of this variation, it is always wise to observe the reaction with a B flashlight so you can see how quickly the reaction is happening. Once the yellow cloud starts forming, time the batch for 5 more minutes. This is the best way to standardize your home brewed colloidal silver. Colloidal or Ionic? Another big controversy surrounds the question of whether this method produces "colloidal" silver or "ionic" silver. Most people have been told that colloidal silver is "good" and ionic silver is "bad." Once again, the truth might be unpopular. The word "colloidal" refers to a condition where, in this case, a solid particle is SUSPENDED in a liquid (silver in water). The solid particles are too large to be considered DISSOLVED, but are too small to be filtered out. This colloidal condition is most easily detected by what is called the "Tyndall effect", where a narrow beam of light is shined through the liquid to produce a cone shaped dispersion of the light. The particles so illuminated also exhibit a random, zig-zag activity called "Brownian motion" when observed under a microscope. When something is completely dissolved, both the Brownian and Tyndall effects disappear. The word "ionic" refers to a condition where a particle has an electric charge. In the case of "electro-colloidal" silver, this electric charge is ALWAYS positive. Silver will not form a negatively charged ion. So, the truth is that electro-colloidal silver is BOTH colloidal and ionic. It is considered colloidal because of the particle SIZE and it is considered ionic because of the particle CHARGE. In fact, most of the biological studies suggest it is colloidal silver's ionic characteristics that make it such a good germicide. It is also interesting to note that the old chemistry books make no distinction between the colloidal and ionic states of the electro-colloidal metals. Purity of Silver The quality of your finished product depends entirely on the purity of the water you start with and the purity of the silver you start with. Most home brew systems use 99.9% pure silver. According to Academy Metals, a company in Albuquerque, New Mexico, that produces commercial silver, the total allowable impurities in 99.9% (.999 fine) silver is 1000 ppm or 1 part in 1000. These impurities and their maximums are 1) Copper, 800 ppm, 2) Lead, 250 ppm, 3) Iron, 200 ppm, and 4) Bismuth, 10 ppm. This product is readily available in wire form and costs about $3.00 above the market (spot) price of silver. When this product is used to make electrocolloidal silver at a concentration of 5 ppm, the total impurities from the silver drop to 4 ppb (parts per billion) copper, 1.25 ppb lead, 1 ppb iron, .05 ppb bismuth. With all allowable impurities at these low levels, there is a reasonable argument for not being concerned. Still, sometimes small things make a big difference. 99.99% silver (.9999 fine) has total allowable impurities of 100 ppm of the same metals in the same ratios, and costs (in wire form) between $50-$90 per ounce above the spot price of silver. 99.999% silver (.99999 fine) has total allowable impurities of 10 ppm, and in wire form costs about $250 above the spot price. 99.9999% silver, in wire form, costs more than gold and is very difficult to find commercially.

In one sample of 10 ppm colloidal silver we sent out for total analysis (made with 99.9% silver electrodes), the primary impurities found were: 1) Sodium, 470 ppb, 2) Calcium, 260 ppb, 3) Manganese, 70 ppb, 4) Potassium, 50 ppb, and 5) Magnesium, 24 ppb. Since none of these impurities could have come from the silver, it suggests that the purity of the water should be of greater concern to the person making their own colloidal silver, than spending extra money on purer silver. Concentration The concentration of silver in the water is usually measured in parts per million, or ppm. While this is the standard convention, ppm is a "ratio" and not an indicator of quantity. When a laboratory tests colloidal silver for concentration, they report the findings in milligrams per liter (mg/L). Milligrams per liter is an actual measurement of weight per volume, and therefore is a real quantity measurement. In the metric system, one liter of water weighs 1000 grams, and one milligram is one thousandth (1/1000) of a gram, so 1 mg/L is the same as 1 ppm, as long as we are talking about water. Silver weighs a little more than water, but the equivalence is very close, and the terms are often used interchangeably. With this in mind, we can calculate that one teaspoon of 5 ppm colloidal silver has about 25 mcg (micrograms) of silver in it. Dosage In 1940, R. A. Kehoe reported that under normal circumstances, the average daily intake of fruits and vegetables would provide between 50-100 mcg of silver as a trace element. Since that time, the commercial farm soils of this country have become extremely deficient in trace minerals. Although I do not have authoritative figures for silver, according to the Earth Summit Report, issued in 1992, the levels of soil based minerals in North America have dropped over 85% in the last 100 years. Assuming that our ancestor's diet used to contain trace silver, and that our diet probably has greatly reduced levels, there is a reasonable argument for supplementing with colloidal silver. Two teaspoons of 5 ppm colloidal silver provides about 50 mcg of silver and could be considered a "nutritional" amount, if taken on a daily basis. Any amount above four teaspoons a day or 100 mcg should be considered a "therapeutic" amount. That said, it should not be assumed that electro-colloidal silver is equivalent to or has the same metabolic effect as receiving trace silver from dietary plant sources. But since there are very few plant sources of trace silver available today, colloidal silver is probably the best substitute. If you want to experiment with taking colloidal silver for an extended period of time, stay within the amounts considered to be nutritional. If you want to experiment with larger doses, do so with caution, and only for a day or two at a time. Safety and Toxicity Silver can act as a heavy metal poison in the body. It can also act as a trace mineral nutrient. The difference is in the particle size, NOT the concentration. Colloidal silver with a particle size of .001 microns has particles 100 times smaller than a preparation of silver with a particle size of .1 microns. The smaller the particle, the less likely it will behave as a toxin. Typically, the worst toxic reaction from metallic silver, cited in the medical literature, is a condition called Argyria. Argyria is primarily a cosmetic condition characterized by a permanent, bluish discoloration of the skin. Argyria causes no physical discomfort, and does not have any other known side effects. Your skin just looks bluish-gray. In fact, the term "blue bloods," in reference to the royal families of Europe, probably refers to a mild, argyrial condition caused by the constant eating of food from silver place settings. It is interesting to note, however, that there has never been a case of Argyria reported from the use of electro-colloidal silver, free of salts or other impurities. Argyria, while not being a deadly condition, certainly is undesirable. It is usually caused by the massive intake of silver salts, such as silver nitrate, silver sulfate, and silver chloride. To determine just how toxic these substances are, I contacted the Agency for Toxic Substances and Disease Registry through their on-line information service at (http://atsdr1.atsdr.cdc.gov:8080/ToxProfiles). All of these silver salts are talked about as toxins, but the only consequence of even high exposure in humans that is listed is Argyria. EPA issues a "control code" for each toxic substance it tracks that can cause human illness. Silver nitrate and silver sulfate have control codes, but silver chloride does not. I received essentially the same information when I spoke with Dr. Eidson at the Department of Epidemiology in Santa Fe, New Mexico. Apparently, the government thinks silver and silver compounds are toxins that essentially have no significant toxic effects other than the ability to discolor your skin.

Looking just a little deeper into the situation, I pulled out Lectures on Homeopathic Materia Medica by J.T. Kent. In the section on the use of metallic silver as a homeopathic remedy, there are 7 pages of indications (symptoms) that include actions on the nerves and cartilage, as well as increased tendency toward emotional outbursts and mental excitability. In fact, the list of symptoms is rather extensive. So, exposure to silver may not kill you or cause organic disease, but that may not mean there is no toxicity. Apparently, silver has the ability to act as a subtle irritant as well as lodge in certain tissues. This suggests that taking colloidal silver every day may not be a good idea for people who already have these symptoms. Effectiveness In a study done, in part, by the Institute of Microbiology in Rome, Italy, and published in Applied and Environmental Microbiology, in December, 1992, various forms of silver were tested for their ability to kill micro-organisms. Pure electro-colloidal silver out performed silver nitrate, silver chloride, and silver sulfadiazine as a broad spectrum germicide. For all classes of bacteria, fungus, and mold samples tested, pure electro-colloidal silver worked better, and at much lower concentrations. They concluded that any additives reduced the effectiveness of the pure silver ion; the silver salts being as much as 100 times less effective. Electro-colloidal silver's effectiveness as a broad-spectrum germicide is directly related to the number and size of the particles. The same volume of space taken up by one silver particle .1 microns in size, will hold about 10,000 silver particles .001 microns in size. This reduction in particle size not only allows for a greater distribution of the silver, but it also greatly increases the total surface area of silver available for interacting with the environment. These, plus the stability of the electrical charge, are the most important factors when considering the effectiveness of colloidal silver. The Regulators While silver has been shown to be a very effective germicide, killing gram-negative bacteria, gram-positive bacteria, yeasts, molds, and viruses in laboratory experiments, this does not mean that it will invariably cure disease conditions in the body caused by these organisms. Colloidal silver is a fantastic adjunct to the home, but it is by no means a "cure-all". The biggest obstacle to using colloidal silver as a "home remedy" is the lack of information in the public domain on how to use it effectively in any given situation. The FDA has tested colloidal silver extensively and found that different micro-organisms succumb to its action at a wide variety of concentrations and exposure times. If any of this information entered the public domain, the FDA would consider their own research "unsubstantiated medical claims" and reason enough to classify colloidal silver as a "new drug." The "new drug" classification would be "required" because "new use protocols" had been developed that did not exist before 1938. Here is an example of the problem. It is now estimated that one in four women will develop breast cancer in their lifetime. I have spoken to two women who claim to have cured themselves of breast cancer with colloidal silver. They were both diagnosed by biopsy. After the diagnosis, they took 2 teaspoons of colloidal silver a day until their surgery. One took a home-made product, the other took a silver protein product. In both cases, the biopsy of the removed breast tissue and lymph nodes was cancer free. The question is, will colloidal silver work this well for all cases of breast cancer? Probably not, but in the current legal and political environment, we may never know. No pharmaceutical company can control or monopolize ownership of colloidal silver, so none of them will ever fund the testing, which currently costs over $10 Million and takes 10 years. FDA says if you claim that colloidal silver cures breast cancer, that would classify it as a new drug, and the public cannot be given access to new drugs without proper testing. Using the FDA model, it could cost the public $1-billion to "prove" to the FDA what the FDA already knows about colloidal silver. Politics has definitely entered this picture. FDA does not want to be exposed as an enforcer for the drug companies, or be seen as an agency clearly not acting in the public's best interest. While these ideas are not new to some of us, it would be a startling revelation if a large portion of the population began thinking this way. FDA would certainly like to avoid this "public relations" embarrassment. The fact is, FDA has never spent our tax dollars discovering something important, and then published their findings for the benefit of the public at-large; especially when it involved something that was powerful, safe, and inexpensive for the public to make for themselves. Obviously, empowering the population to be self-reliant and frugal in relation to their own healthcare is not the FDA's responsibility.

Colloidal silver clearly has some extraordinary capabilities and hundreds of legitimate uses. But without standardization, quality control, and extensive medical testing, the public will never know how best to use colloidal silver in a given situation. FDA may yet try to restrict public access to colloidal silver, claiming it is unsafe, even though they know how "safe and effective" it CAN BE when used properly. In the absence of the release of this authoritative testing data, the public is left just experimenting and groping for the answers. A big fight over the public's access to colloidal silver may be looming because the cost of healthcare in this country is out of control, and the public is looking for inexpensive solutions that work. In that sense, colloidal silver could be "just what the doctor ordered." Digestive Interactions Colloidal silver is apparently able to kill nearly all micro-organisms, including the "friendly flora" your digestive system needs for proper function. I have spoken with hundreds of people who have taken colloidal silver on a daily basis and have noticed no digestive upset, even after prolonged use. I have also spoken to two individuals who reported digestive upset after taking colloidal silver one time. So, in my experience, the die-off of friendly flora is possible, but rare. There are a number of strategies that can reduce the probability of digestive interactions. The simplest one is to swish the colloidal silver around in your mouth for 30 seconds before swallowing. This promotes an absorption of the colloidal silver into the body away from the intestinal tract. Another strategy is to take smaller doses, multiple times per day, or with meals. Either way, if you do experience a die-off of friendly flora, they can be re-populated by taking any of the acidophilus products on the market. Septic Tanks Septic tanks are like your home's intestinal tract. They only work when populated with friendly flora. If you live in a rural area with your house on a septic system and you are making your own colloidal silver, make sure you don't throw a lot of it down the sink or your septic system may stop working properly. This problem can be handled by using a product like RID-X periodically, which is a good idea anyway. Conclusions Colloidal silver is an extraordinary product. It can enhance your health and the health of your family in hundreds of ways. Everyone should learn how to make high quality colloidal silver, and have that capability in their home, in case the regulators restrict its availability at some point in the future. This could be the best "health insurance" policy you ever implemented! If you buy one of the colloidal silver makers on the market, make sure it can make the "yellow" particles. When you make it yourself, make sure you are making the "yellow" particles. If you have any doubts about the quality of the product you are making or buying, you can send samples to any of the following laboratories for definitive testing. For particle size testing with electron microscope, contact: EMS Laboratories, 117 West Bellevue Drive, Pasadena, CA 91105 (818) 568-4065 Price will be under $200 per sample. For concentration test (mg/L) of total dissolved solids, contact: Associated Laboratories, 806 North Batavia, Orange, CA 92668 (714) 771-6900 Call for prices. For elemental analysis, including "Tyndall effect" and "precipitation" test, contact: Kimball Laboratories, 600 East 11800 South, Draper, UT 84020 (801) 571-3695 Call for prices. These companies are busy professionals who have no idea I am listing them in this article. Please don't waste their time unless you plan to submit samples for testing with payment. References: Agency for Toxic Substances and Disease Registry, on-line information service: (http://atsdr1.atsdr.cdc.gov:8080/ToxProfiles) Kehoe, R. A. et al, 1940. J. Nutr. 19:579. Kent, J.T. Lectures on Homeopathic Materia Medica, Jain Publishing Co. New Delhi, India, reprint 1982. Michaelis, L. The Effects of Ions in Colloidal Systems , Williams & Williams Co. Baltimore, MD, 1925. Ostwald, W. Practical Colloid Chemistry, Methuen & Co. Ltd. London, UK, 1926. Simonetti, N. et al, Electrochemical Ag+ for Preservative Use. Applied and Environmental Microbiology. American Society for Microbiology: Washington,1992, Vol. 58, No. 12, pp 38343836.

The Association for Advanced Colloid Research, 232 NE Lincoln St. Ste."G", Hillsboro, OR 97124, private conversations. Borderland Sciences Research Foundation, PO Box 220, Bayside, CA 95442 Special thanks to Michael Theroux for valuable research and private consultation Supplies Need to Build the Generator

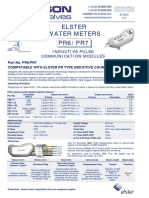

Four nine volt alkaline batteries are needed to achieve the desired 30 volts of electricity. Although four batteries in series total 36 volts, the drain on the batteries quickly starts to bring the total voltage down. See the advanced basic generator pages for modifications to control the current/voltage output. Also note that three batteries can be used, but for our tutorial, we suggest four.

Two nine-volt battery-to-clamp adapters and two metal clamps.

One glass production vessel ( 6 - 12 ounces )

Two fine silver rods ( 9 cm rods shown, minimum 14 gauge ) or two strips of 18 gauge fine silver wire. Any silver used must be at least 99.9 percent pure. See our products page for sources. One gallon of distilled water ( Walgreens and Arrowhead are two recommended brands )

A roll of pure white paper towels One pure nylon scrub pad ( the green Scotch Brite pads ) A glass or FDA grade plastic container to store the colloidal silver in ( UV protected glass is recommended ) General Assembly - Preparing the Batteries in Series

Clip off the unused lead: For convenience, cut off the unused battery lead on each clamp attachment.

Attach the battery pairs: Take two nine-volt batteries and snap the positive pole of one to the negative pole of the other ( there is only one way this attachment will work ). Repeat the process for the second set of batteries. The end result is two sets of two batteries attached to each other.

Attach the two battery sets together: ( Do not perform this step until you are actually prepared to make your colloidal silver. Take the two battery sets and snap them together. The end result is four batteries attached together, which actually completes a circuit. Note: To avoid a potential hazard created by alkaline batteries wired in series, any concerned user may wire in a 24 volt light bulb in series. We have, however, never heard of a problem with the batteries exploding. This design should never include the batteries being encased without current control.

The basic generator is now complete. The only remaining step is to prepare the glass and rods for use. Three Principles to Mastering Colloidal Silver Production 1. Purity: The quality of any colloidal silver is foremost determined by 1) the purity of the silver used, 2) the purity of the initial water supply, and 3) the cleanliness of both the silver rods and the glass container used for production. Even variables such as air quality and light concentration can influence colloidal silver production. 2. Current Control: The entire colloidal silver generation process is geared toward strict regulation of the flow of silver ( both ions and particles ) into the distilled water base. The more command one successfully wields toward this end, the higher the end quality will be. Variable conditions include everything covered in the purity principle, plus: a) The voltage applied, b) the amount of current, c) the size and the shape of the silver electrodes, d) the amount of water used, e) the water temperature, f) the size and shape of the container, g) the spacing between the silver rods, h) the motion ( if any ) of the water in the container, and even i) the Earth's electromagnetic field and j) the shape of the silver electrodes. 3. Timing: Understanding and properly measuring the duration of each batch of colloidal silver is of paramount importance both to the particle size of the silver ions and the concentration of the batch itself, and thus critical to the end quality of the product. All variables of the timing are dependent upon the variables of the first two principles. Timing influences particle sizing and particle dispersion ( otherwise known as proper hydration of the silver ). Each of these three principles relies upon the other. Mastery of these simple principles equates to the mastery of colloidal silver production. Every advanced colloidal silver generator IS advanced due to the fact that it addresses one or more of these principles more successfully than the basic generator is able to. Some

"advanced generators" defy the above principles, and the end result is always a lower quality product. These production flaws can only be detected by expensive analysis of the end colloidal silver, including both Atomic Adsorption Spectronomy ( AAS ) and Transmission Electron Microscopy ( TEM ). Three Principles to Mastering Colloidal Silver Production 1. Purity: The quality of any colloidal silver is foremost determined by 1) the purity of the silver used, 2) the purity of the initial water supply, and 3) the cleanliness of both the silver rods and the glass container used for production. Even variables such as air quality and light concentration can influence colloidal silver production. 2. Current Control: The entire colloidal silver generation process is geared toward strict regulation of the flow of silver ( both ions and particles ) into the distilled water base. The more command one successfully wields toward this end, the higher the end quality will be. Variable conditions include everything covered in the purity principle, plus: a) The voltage applied, b) the amount of current, c) the size and the shape of the silver electrodes, d) the amount of water used, e) the water temperature, f) the size and shape of the container, g) the spacing between the silver rods, h) the motion ( if any ) of the water in the container, and even i) the Earth's electromagnetic field and j) the shape of the silver electrodes. 3. Timing: Understanding and properly measuring the duration of each batch of colloidal silver is of paramount importance both to the particle size of the silver ions and the concentration of the batch itself, and thus critical to the end quality of the product. All variables of the timing are dependent upon the variables of the first two principles. Timing influences particle sizing and particle dispersion ( otherwise known as proper hydration of the silver ). Each of these three principles relies upon the other. Mastery of these simple principles equates to the mastery of colloidal silver production. Every advanced colloidal silver generator IS advanced due to the fact that it addresses one or more of these principles more successfully than the basic generator is able to. Some "advanced generators" defy the above principles, and the end result is always a lower quality product. These production flaws can only be detected by expensive analysis of the end colloidal silver, including both Atomic Adsorption Spectronomy ( AAS ) and Transmission Electron Microscopy ( TEM ). The Basics: Demystifying Colloidal Silver What is Colloidal Silver? Simply stated, colloidal silver is water containing both microscopic particles of elemental silver and silver ions. The most common electrolysis processes used to create colloidal silver sinter metallic silver from a silver rod or wire, and deposit ions ( Ag+ ) and particles ( particles with no charge and clusteres of charged particles, Ag- ) into the water. What separates electrically isolated colloidal silver from other types of silver products is the fact that the state of silver is either in isolated ionic form or pure particle form ( not bonded with other elements ), and the size of any silver particles is incredibly small compared to other methods of silver production. In other words, the silver ions and particles are isolated by water molecules only. Whether the benefit of colloidal silver is due solely to the silver, the size of the silver particles, the ionic charge or particle charge, or a combination of all three, is a matter of debate. Please keep in mind that the term "colloidal silver" should be considered a generic term and not a scientific one, as colloidal technically means particles in suspension, not dissolved solids. How is quality gauged? The therapeutic quality of colloidal silver is determined by 1) the product purity 2) the size of the silver particles, 3) the concentration and/or ratio of ionic silver to particle silver, 4) and both the dispersion of silver in the water and the surface area that active silver area covers ( which is related to the size of the silver particles ). One of the greatest motivating factors for manufacturing one's own colloidal silver is to ensure product purity. By using inferior silver or thoughtless bonding agents ( even

accidentally ), it is just as easy to toxify the body as it is to heal it. For instance, Silver Nitrate is a known toxic substance, and silver chloride has questionable benefit in the body. While it is true that even the poorest quality colloidal silver available for purchase is unlikely to contain enough contaminants to do the body serious harm, it is equally true that ANY contaminants cause the formation of larger silver particles and silver compounds. This may significantly decrease the benefit possible compared to a properly made colloidal silver. Using the production methods on these pages will ensure both a safe and effective colloidal silver. However, it should be noted that home brewing colloidal silver can only be taken so far without a sterile lab environment and incredibly sophisticated controls. That said, just because a colloidal silver is "lab made" does not mean that the producers are making it properly! The size of silver particles is important for three reasons: The smaller the particle size, the more likely the colloidal silver will be adsorbed in a useable form by the body. A high quality colloidal silver should have particles small enough to be adsorbed sublingually and through lung tissues. Small particles of silver cover a greater surface area, increasing the potential contact with microbes. Ionic silver is a whole field unto itself. A high quality colloidal silver has ionic silver that does not readily agglomerate. By properly making colloidal silver with the basic generator, particle sizes between . 001 - .04 microns may be uniformly achieved ( with concentration strength between 3 - 5 parts per million ) - a decent colloidal silver. The concentration strength is the amount of actual silver contained within the water by volume, and is measured in ppm ( parts per million ). Five parts per million is generally accepted as a safe and effective general purpose strength. However, a 5ppm solution is not universally regarded as effective. Generally speaking, one may achieve a suitable quality 50 ppm solution using a more advanced generator. The basic generator, with practice and extreme care, can safely generate a batch ( estimated ) of about 10 - 12 ppm, although there will be a quality difference as compared to a batch of 3-5 PPM. With all of these variables, and without lab equipment, can one be certain to achieve a quality colloidal silver with a basic generator? Yes. The primary purpose of this tutorial is to introduce colloidal silver to the interested novice. The following instructions will provide both the method of achieving a safe and effective colloidal silver solution and a method of testing it. After experimentation, and with continued interest, one should explore a more advanced generator. Preparing the Materials 1. Use the nylon scrub pad and dry scrub the inside of the glass container used in the generator. 2. Rinse the container thoroughly. Use a clean paper towel to dry the container. Rinse a second time with a small amount of distilled water. 3. Always scrub the silver wire or rods with a nylon scrub pad before use. To save silver, use light pressure and agitate quickly. The smoothness of the electrodes will help to ensure a uniform draw of ions from the silver rod. 4. Wipe off the rods with a clean paper towel soaked with a small amount of distilled water. 5. Make sure one's hands are clean. 6. Assemble the colloidal silver generator as previously described ( attaching the two battery sets together, remember to never leave the generator assembled when not in use ). 7. Add approximately eight ounces of distilled water to the glass container. Preparation is complete. Clamp the silver rods to the battery setup. Any clean, nonreactive substance may be used to help position the rods above the container. See the following picture for an example.

NOTES: Nylon is used for two reasons: 1) It is a non-reactive substance and any accidental contamination will not interfere with the reaction. 2) It is a nontoxic substance.

Position the battery setup so that both attached rods may be easily inserted in the water. For optimum performance, the spacing between rods should be between 1.5 and 2.0 inches. The rods should be positioned as close to the center of the container as possible to prevent increased conductivity generated along the rim of the container. Position the rods parallel to each other. This encourages uniform conductivity between both rods, and therefore a uniform draw of silver. The positive and negative leads/rods should never touch each other. Once the rods are positioned correctly, note the time. As the batch progresses through the first 10 to 15 minutes, very little change should be apparent. As the fifteen minute mark approaches, pay particular attention to the reaction. Anywhere between 15 and 30 minutes, one should notice a thin yellow cloud or a yellow "wisp" drifting between the electrodes. This indicates that the saturation of silver ions between both rods is reaching a point of ideal saturation. Mark the time. Allow the reaction to continue for five minutes. Then, very carefully, remove the "negative" rod from the water. Wait about two minutes. Gently remove the positive rod from the colloidal silver. Dissasemble the batteries. Increasing the time will increase the concentration of the end colloidal silver. However, be aware that one risks degrading the product. One can use a Hanna PWT meter to measure the ionic content of silver ( as well as the initial quality of the distilled water ). A laser pen in a dark room can be used to gauge the amount of particulate silver in the end product. One may notice the remaining yellow wisps slowly dissipating. As time progresses, the colloidal silver will retain its "water" clear color. No visible particles should be present. Increasing the production time will eventually result in a colloidal silver with a yellow hue. Although with this method, every single batch will have a variable PPM reading, if the above instructions are followed, the end product silver concentration will be 3 to 5 parts per million. The sizing will be between .001 and .04 microns in diameter. At this point, it is very advantageous to acquire a simple laser light pen. It is a wise practice to both check the quality of the distilled water before a batch, AND to test the colloidal silver once the solution has "matured" a few hours. See the next section for further information and notes on the process itself.

Using a laser pen to detect particle density in a ~ 5 ppm CS solution

Using a laser pen to detect particle density in a ~ 50 ppm ( low quality ) CS solution A Closer Look at the Generation Process When both silver electrodes are placed in the distilled water, an electrolysis reaction begins. Electrolysis is the production of chemical changes by passing an electrical current through an electrolyte. In our case, the electrolyte is the distilled water. One will notice that at first, no visible reaction is apparent. This is due to the fact that distilled water, a VERY low semiconductor of current, allows very little travel of electrons between both silver rods. It is the travel of electrons that sinters off the silver into the distilled water. The less the conductivity between the the electrodes, the slower the reaction. From the moment an actual circuit is completed ( by placing both rods in the water ), electrons DO, however, begin to travel from the negative pole to the positive pole, passing through the distilled water. Through the process, the metallic silver atoms gain an electron, and thus ionic silver ( Ag + ) is created. As the process continues, increased conductivity also caused charged particles to form in the water ( Ag - ). Since distilled water heavily restricts this travel, the amount of current traveling through the solution is very low. This is ideal. It keeps the reaction at a bare minimum, which in turn produces the smallest possible particles of silver, and a "theoretical" ideal ionic silver. The greater the current traveling through the water, the faster the reaction takes place. Any increase in the speed of the reaction results in the production of LARGER particles of silver. Keeping the current well below 40 milliamps ( ideally between 5 20 ) helps to prevent agglomeration. As the minutes pass, one will notice a slight discoloration on both rods. This is a good indication that the reaction is proceeding as desired. On the negative terminal ( the cathode ), neutral silver ( silver with no electrical charge ) begins to plate the silver rod. As the reaction continues, one will notice small bubbles forming and rising off of the silver rod. This is H2, a simple and harmless hydrogen gas. On the positive

terminal, as the reaction continues, one will begin to notice the buildup of "sludge", as it is often called. This is actually silver oxide ( dark brown ). While this silver oxide is relatively harmless, it is undesirable to have silver oxide or silver flakes in the end product ( for internal use colloidal silver ). To avoid this, pay close attention to the purity principle listed on a previous page. Avoid overrunning or "over burning" the batch. Leave the "positive" electrode in the solution for a few minutes after the removal of the "negative" terminal to allow the sludge to oxidize a bit. By doing this, when the sludge covered rod is gently removed, the sludge will stay adhered to the rod and not drop off into the solution. By the discoloration of the rods, it is evident that a reaction is indeed occurring. Colloidal silver is actually being produced from the first moment, although the concentration is not great enough to been seen by the naked eye. As time passes, the reaction begins to speed up. The silver ions, being dissolved, increase the conductivity of the water. In turn, more current travels between the two poles. This, of course, increases the amount of silver ions being siphoned ( or sintered ) from the silver rod. There is a very definite point in this process where the speed of the reaction causes LARGE nonionic particles of silver ( sometimes referred to as sparklies ) to be deposited into the end solution. That is why both purity and timing are important elements in producing a quality colloidal silver solution, especially with the basic generator. At this point, it is interesting to note the reason behind the idea of using a 30 volt power source. Experienced practitioners in this colloidal silver generation method have discovered that the the silver electrodes burn cleanest using 30 volts of electricity. There are numerous ways to refine the colloidal silver generation process, and these will be dealt with in other sections of the website.The timing indicator to watch out for is the first sign of golden "wisps" in the solution. This indicates that there is an EQUAL dispersion of electro-colloidal silver particles, usually sized between .001 and .01 microns, in the area in which this yellow color is visible. Silver particles adsorb indigo light between this size range and therefore reflect yellow. Extensive testing conducted through electron microscope photography ( through trial and error batch testing ) has shown that once the first sign of yellow wisps appear, a 3-5 ppm solution is created if the reaction is then stopped five minutes from the initial observation. This is dependent on using about eight ounces of room temperature distilled water, and careful observation of the purity principle and all of the suggestions mentioned on the previous pages.The longer the batch runs after this "rule of thumb" point, the greater the risk of producing large particle of silver. Once the electrodes have been removed, cover the top of the container, and allow the batch to sit for a few hours, preferably in a dark storage area. Test the batch, if possible, with a laser light pen in the dark. A light "tyndall" effect will be observed. Search the solution for bright shining "sparklies" floating in the water. With practice, one can easily produce a sparklie free colloidal silver batch. If large, bright particles ARE observed, avoid filtering if at all possible. Instead, use a needless syringe or other similar process to transfer the colloidal silver from one container to another. If proper care is taken, the new container will not contain the large particles. One may use any leftover colloidal silver in the original container for topical applications with no risk. For those interested in reaching toward perfection: Careful study of an average ( as apposed to superior ) batch with a laser pen reveals the following: 1) Possible very tiny flakes of silver floating on top of the solution. Siphon off the top portion. 2) Theoretical larger particles that settle toward the bottom third of the solution. Use the bottom portion of each batch for non-internal uses.3) Possible small particles of silver free floating in the water ( "sparklies" ). Slowly extract the desireable solution with a needleless syringe. Retest batch. Countless people have used far less stringent guidelines, drinking the colloidal silver on a daily basis for years with no adverse effects. These guidelines are provided to

give the interested novice a strong knowledge base to start from. It is a wise practice to store colloidal silver in a UV protected glass container. However, most practitioners agree that a high quality solution will be fine in any glass container. Many people store their colloidal silver in plastic and report no problems. Periodically, check a stored batch of colloidal silver for "fallout" on the sides and the bottom of the container. In fact, it is interesting to store a "good" batch in a see through glass container, and observe any changes occurring over time. This will give one a strong indication on the quality of the colloidal silver being produced. After setting "overnight" the completed batch should either maintain it's clear color, or have a slightly yellow tone. However, please keep in mind that if needed, the colloidal silver can be used immediately after production.

How to make your own Silver Colloid Generator. While it has been discovered that 30 volts is the ideal for Silver Colloid production, 27 volts is very effective and happens to be the convenient result of wiring three 9-volt batteries together. Therefore, you'll need three 9-volt transistor radio batteries, three battery snap-on lead connectors, 2 insulated alligator clips, 1 "grain-of-wheat" 24 volt 40 mA sub miniature incandescent bulb, a foot of 3/32" heat-shrink insulation tubing, a foot of 2-conductor stranded insulated wire for clip-leads, a small box to put it all in, and 10" of pure silver wire (.999 fine). This should cost under $30.00 for everything. Assuming some skill with a soldering iron, you should spend about thirty minutes constructing the generator. Solder your three snap-on battery clips in series (red to black) to provide 27 volts. Connect a 24V incandescent lamp in series with either positive or negative output lead. Solder the red insulated alligator clip to the positive (anode) and the black insulated clip to the negative (cathode) 2-conductor lead wires. Insulation is shrunk over soldered connections using a heat gun or hair dryer. Cut your 10" of silver wire in half. Bend top ends of your two 5" silver electrode wires so they can clip over the top rim of a plastic or glass cup (not metal). About 4" of each wire should be submerged.

WARNING! Use ONLY pure silver (.999 fine) electrodes. #14 gauge is the preferred thickness. Pure silver is sometimes available at electroplating supply companies. Or, inquire at a jewelry store specializing in silver about who their wholesale supplier is. Do not use sterling silver (.9275) since sterling contains copper and nickel. NICKEL CAN BE TOXIC. (With this in mind, you may want to have a chemical analysis (assay) of your purchased silver in addition to the written word of your supplier.) If the Silver Colloid is to be ingested or injected, be sure to use distilled water. Tap water is fine for other uses, such as for a topical spray or for plants. Also, before beginning to make your Colloidal Silver you will need to make a saline solution for enhancing conductivity. ************************************************** NOTE: Two points of interest since this file was posted; 1) DO NOT USE SALT - just use distilled water 2) An ingot of silver cut in half works better than wire ************************************************** Saline solution can be made by mixing six ounces of distilled water with one tea-spoon of sea salt in a separate container. Do not use common table salt as table salt has chemical additives. After stirring the salt solution, pour some of the water into an eye dropper bottle. Now you're ready to make Colloidal Silver. Pour eight ounces of water into your glass. Add 1 or 2 drops of saline solution (3 drops at the most; if you use too much salt, you'll be making silver chloride instead!) to distilled water and stir with a plastic/non-conductive utensil. Insert silver electrode wires. Placement of wires is not critical, but they must not be touching each other or the process will stop. (You cannot shock yourself in this process so do not be concerned.) Attach alligator clips to the ends of the silver electrode wires coming over the outside rim of the glass and you will see a grey mist inside the glass start to peel away from the positive polarity wire while bubbles of hydrogen rise from the other. Laboratory tests show that this method creates a silver colloid of approximately 1 ppm per minute of activation time. Since you are only taking microscopic particles from the silver wire, your silver wire may very well last for years.

The brightness of the light bulb is related to the conductivity of the water. It is not necessarily a problem if the bulb is very dim or even remains dark as long as the process itself is occurring. (If the bulb is dark you can always consider adding one more drop of saline solution next time.) Do not add saline solution after process has begun. Of course, when batteries are old, the light will also become dimmer, signaling it's time for a change. Touch the two alligator clips together to test the brightness of the bulb as a battery check. A fresh set of three alkaline batteries should make several hundred thousand batches of concentrated Silver Colloid. Also, put a few drops of Silver Colloid in the saline solution to prevent fungus growth. When finished, detach alligator clips. Clean silver electrode wire after each use to remove dark oxide on the anode. Use a small piece of 1/4" thick nylon kitchen scouring pad to polish dried silver, then wipe with paper napkin to make ready for next use. Store your Colloidal Silver in dark, non-conductive (and if plastic, non-reactive) containers, like empty hydrogen peroxide bottles. Keep away from light as even room light will degrade colloids rapidly by turning solution grey or black just as exposure to light darkens the silver in camera film. Stir thoroughly or shake each time before using. Keep cool, but do not refrigerate. In using your own home-made silver colloid generator it will become apparent that you now have the power to safely protect yourself, your family, your pets and plants, your community, and (through the dissemination of this information), our nation, from over 650 pathogens, viruses, microbes, fungi and parasites. Upon creating your first batch of Colloidal Silver, you will find it tastes the same as untreated water. And it won't sting, even in a baby's eyes. Congratulations and bon appetit! c1995 Mark Metcalf, a.k.a. Mark Nine All rights reserved. References Introduction To Making Your Own Silver at Home This article will describe a way to make colloidal silver at home. After the first batch of colloidal silver is made, the second and future batches should make one gallon of high quality 6 PPM to 8 PPM (Parts Per Million) colloidal silver in one and a half hours. The fist batch will take about three hours, since it will not have the benefit of "seeding" the gallon with previously "cooked" colloidal silver (this "seeding" is necessary to create better electrical current in the distilled water). Once the first batch is made, future batches can be "seeded," so it will take less time to make these batches.

All of the statistics in this article are based on a 400 mA (400 milliamp) power pack. Should someone use a 800 mA power pack, the necessary times will likely be shorter. The Power Supply There are several important aspects of this method, but the key is a 12 volt D.C. power supply. Here are its specifications: Input (standard outlet in the U.S.): 120 volts AC 60 Hz 20 Watts Output: 12 Volts DC 400 mA (milliAmps) The output can actually be anywhere between 400 mA and 800 mA. To write this article, the 400 mA was used. As a physical discription, these are power packs that consist of a small black box, with the plug sticking directly out of the box. In other words, the black box plugs directly into the wall. It has two long wires sticking out the box. What is on the other end of the wires is not relevant because you will cut the ends off and strip the two wires (obviously while the power pack is unplugged). Such power packs should be available at Radio Shack or any electronics store. They can be bought in bulk over the Internet at very inexpensive prices. The Silver Wires The silver wires should be 12 or 14 gauge (AWG) pure silver wire (14 guage is highly preferred), between 99.95% and 99.999% pure silver. You should NOT use sterling silver, as it contains high levels of nickel, which is toxic. Make sure you buy pure silver wire. There are several vendors of silver wire, but the silver wire you buy should be purchased by the foot, and you should buy several feet of it, since you will need 2 wires at least 12 inches long and you will use the wires up every several months, depending on how often you make the colloidal silver. AT ALL TIMES, EXCEPT DURING THE COOKING OF THE COLLOIDAL SILVER, THE SILVER WIRES SHOULD BE PROTECTED FROM ANY LIGHT. THEY SHOULD BE WRAPPED AND STORED SO THEY ARE NEVER EXPOSED TO LIGHT. SILVER WILL CHEMICALLY REACT TO LIGHT. Here are a couple of vendors: http://www.ccsilver.com/silver/fines.html http://www.silveredgehealth.com/ The Glass Jars You will need a 1 gallon wide-mouth glass jar. It is critical this jar is made of pure glass, and not plastic!! Plastic can create a static charge. The easiest way to obtain such a jar, if you cannot find one, is to buy a 1 gallon glass jar of pickles. At Wal-Mart, for example, the ones with the food stores in them, you can buy pickles in bulk in 1 gallon glass jars. Wal-Mart also has a section with many glass jars in it. At grocery stores the large jars will be in the bulk food section or in the pickle section. You will also need a plastic funnel which has a very wide bottom and a large funnel with has a narrow bottom. The wide-bottom funnels can be found at Wal-Mart in the canning section, or at any grocery store that has a canning section. These funnels are not critical, but they come in very handy when pouring the water from jar to jar. You should also have some amber jars for storing the finished colloidal silver. Even if you are able to buy the amber jars, in quart or half-gallon size, you still need to store the jars in a dark place. Here is one vendor of quart-sized (i.e. 950 cc) amber jars (product: 4011-05): http://www.sks-bottle.com/340c/fin2b.html Construction of the Unit You will need two alligator clips, which can be small, but yet large enough to hold a 12 or 14 guage silver wire in place (these would be medium sized alligator clips at Radio Shack). Usually, these clips come in packs of 10 or so alligator clips. With the power pack unit unplugged, during construction, cut-off whatever is at the end of the wire on the original power pack. Separate the two wires for several inches. Strip each wire and

solder an alligator clip at the end of each wire. Use one red alligator clip and one black alligator clip for the two wires. It doesn't matter which color goes on which wire. You may want to use one 100 ohm resistor. There are pros and cons associated with putting a 100 ohm resistor on one of the wires. The good news is that it will protect the power pack should to two silver wires touch each other by accident. The bad news is that putting a 100 ohm resistor on one of the wires will DOUBLE the length of time it takes to cook the colloidal silver. Most people will not use a resistor. They will plug the power pack into a power strip, with the power strip turned off. They will then set up their silver wires in place. With the silver wires in place they will turn the power strip power on. Likewise, when they have to remove the silver wires for cleaning, they will turn off the power pack before they touch the silver wires. It is your choice. If you do choose to use a resistor, it needs to be put on one of the wires (it doesn't matter which one) between the power supply and the alligator clip. It doesn't matter in what direction the resister is pointed. If you are going to use an LED, to display a current (which really isn't necessary), put it on the other wire, meaning do not put it on the same wire the resistor in on. Other Comments You will definitely want to buy a small, battery powered, hand-held laser, to see how dense the colloidal silver is becoming. These can also be purchased at Radio Shack or any office supply store. After the colloidal silver has been "cooking" for 20 or 30 minutes, if you shine the laser through the glass jar, and look at the laser beam perpendicular to the beam, you can see the progress of the colloidal silver. In other words, your line of sight is perpendicular to the laser beam, which is pointed through the water. You will probably want a long WOODEN spoon to stir the colloidal silver from time to time. However, stirring the colloidal silver will actually slow down the cooking slightly. You will need a WOODEN board to hold the wires in place on top of the glass jar. Certainly do not use metal or it will short-circuit the silver wires. For example, use a small cutting board, with two 1/8" holes drilled in the middle, 1 to 1 1/4 inches apart. Put one alligator clip on the end of each 12 inch silver wire to keep the wire from falling into the water. The other end of the silver wire is pushed through the hole in the wood and goes into the water. Thus, the wooden board in placed on top of the wide mouth jar and holds the silver wires in place. The alligator clip is positioned so that the silver wire goes down to about 1 inch from the bottom of the jar. The Type of Water to Use The ONLY type of water you should use is distilled water, which has been distilled by water distillation (not reverse osmosis). There are NO exceptions. All other types of water have too many impurities. While water impurities help speed up the cooking of the colloidal silver, the minerals in the water can bind to the silver particles and may eventually create a health condition known as argyria. Argyria is a condition where the skin turns grey or blue-grey because of taking high doses of impure colloidal silver over time. It is very difficult to reverse the condition, so it should be avoided. DO NOT ADD SALT OR ANYTHING ELSE TO THE WATER - PERIOD. While salt will allow current to flow, it may create silver chloride, which can cause argyria over time. Do NOT add ANYTHING to the water if it will create a silver compound, such as silver chloride. Do NOT add preservatives, minerals, EDTA, proteins, gelatin, coloring, honey, etc. You may use tap water ONLY if you are going to use the colloidal silver for EXTERNAL purposes. It is 10 times easier to use tap water than distilled water because it allows electrical currents to flow much, much better than distilled water. However, such colloidal silver should only be used for external purposes. No matter what kind of water you use, if the water turns black, throw the water away, it has too many impurities in it. Heating the Water The water will always be put into the one gallon jar in two parts. For the first part, one-half quart (e.g. one-half liter) of distilled water is put into the one gallon jar. This is either distilled water or distilled water from a batch of colloidal silver (this will be explained below). Either way the water

is at room temperature. The main reason for putting this water in first is to keep the glass jug from breaking when you pour the boiling water into it. The second part of putting liquids into the jar, is when you put pure distilled water, which was heated to a low boil, into the jar to finish filling the one-gallon jar up with water. In other words, first put 1/2 quart of distilled water or colloidal silver water, at room temperature, then put in low boiling distilled water to fill the rest of the jar. Always heat the distilled water in a STAINLESS STEEL POT WHICH IS UNCOATED! NEVER use an aluminum pot or a stainless steel pot which is copper coated or has any other coating. Heat until it comes to a low boil. Then pour the hot water into the jar that already has the room temperature water in it. This is when you use the wide-mouth funnel, though you may use it at other times as well. Instructions For Cooking the FIRST Batch of Colloidal Silver The instructions for cooking your first batch of colloidal silver is different than at other times. This is because your first batch does not have the luxury of having previously cooked colloidal silver put into the jar to help enhance the electrical current between the two silver wires. Pure distilled water, which is the only kind of water you have for the first batch, conducts electricity very, very poorly. The good news is that as the colloidal silver is made, the current will start to flow better and better. Nevertheless, the first batch will take about three hours to make. Plug the power supply into a power strip which has an on/off switch, so you can turn the power on and off with a switch. Turn the power off so you don't damage the power supply while you are getting set up. Place the alligator clips onto the silver wires, one black on the top of one wire and one red alligator clip on top of the other wire. Do not let the silver wires touch, just in case you forgot and left the power on. Put the silver wires through the wood and into the water and make sure the two wires are not touching each other or the side or bottom of the glass jar. Lower the silver wires to about 1 inch from the bottom of the glass jar. Mark the time and turn the power on. EVERY 4 or 5 minutes you need to: 1) Turn off the power, 2) Remove the silver wires from the jar, 3) Wipe the two silver wires with a paper towel AND a non-metallic pot scrubbing pad (e.g. 1/4" thick nylon Scotchbright pad), 4) Put the silver wires back into the water, and 5) Turn the power back on. All of this is necessary to prevent a black crud from building up on the silver wires and floating to the bottom of the jar. This cooking should last about three hours (which includes the frequent stops to clean the silver wires). The water should NOT turn milky or black, but it may turn light yellow, if looked at from above. (These numbers are based on a 400 mA power pack.) Light yellow is good, but not necessary. The real test is the laser light. After the first half hour or so, you should start shining the laser through the water from time to time, looking at it with a line of sight which is perpendicular to the laser beam. You will start to see the beam, over time, get brighter and thicker. The thicker and brighter the beam, as it appears in the water, the higher the PPM of the colloidal silver. By the time you are finished the beam should look solid red (or whatever color laser you have), with crisp edges at the top and bottom of the light. This is your sign the colloidal silver is ready. After three hours of cooking and cleaning, you should be able to see what this type of laser light looks like. When you are done cooking the colloidal silver, put the water into the quart jars. Put aside one of the amber jars to "seed" the next batch of colloidal silver. You will use one-half of this quart jar to "seed" the next batch. Every subsequent batch needs to be "seeded" from one of the prior batches. The Second, Third, etc. Batches There are only two differences between the second, third, etc. batches and the first.

The first difference is that the half-quart of distilled water, at room temperature, that was put into the jar will be replaced by a half-quart of colloidal silver previously cooked. This is important to help the electrical current flow and shorten the time it takes to make a batch. The second difference is that the second, third, etc. batches should only take about an hour and a half. Other Comments It is important to rotate the silver wires. In other words, do not always put the same silver wire on the red alligator clip and the other one on the black alligator clip. How you make sure you rotate them is up to you, but the silver wires will last a lot longer if they are rotated at least once per cooking, though they may be rotated during a cooking (after they are cleaned, for example). Store the silver wires in a dark envelope or other dark place. Store the colloidal silver in a cool place, but do NOT refrigerate the colloidal silver. Store the amber jars in a dark place. If you buy a pickle jar, it is impossible to remove the pickle smell from the plastic liner in the lid. You may want to just remove the lid and never use it again. Or you could put wax paper between the lid and jar. NEVER REFRIGERATE THE COLLOIDAL SILVER. How Much To Drink This is up to the individual. If the colloidal silver is being used for prevention, 3 ounces of 6 to 8 PPM colloidal silver per day is all an adult would likely need. If there is a common cold, pandemic flu, or other type of flu, going around, then it would be best to double the daily dose for prevention. If the colloidal silver is being used for treatment purposes, it might be best to take 8 to 12 ounces of colloidal silver a day, for as much as 2 or 3 weeks at a time. If you are going to take the colloidal silver for several weeks at a time, make triple sure it is pure silver that is being used, and not silver chloride or some other silver compound. See the Bob Beck Protocol article for more information: Bob Beck Protocol [see: Colloidal Silver section] Friendly Bacteria in the Digestive Tract Yes, colloidal silver may kill friendly bacteria in the digestive tract. Many uses take probiotics, lactobacillus acidophilus, lactobacillus bulgaricus, yogurt, etc. to replace friendly intestinal flora. An Alternate Method If You Cannot Obtain a Power Pack If you are not able to obtain the power pack, you can substitute three 9-volt radio batteries. Hook them in series (hook the three battery leads negative to positive, leaving a positive lead at one end and a negative lead at the other end open) so they output 27 volts. The three 9-volt batteries replace the power pack until you can get a power pack. When using the three batteries, it is better to use a 16 ounce glass jar (i.e. 450 grams). As above, in the first batch you should use distilled water, thus it may take a signficant amount of time to make the first batch. Using the technique above, put 10% or so of this first batch in a glass storage container. Then, put this 10% in the second batch so it will not take as long to make the second batch. And so on. Many thanks to Mr. Denzel "Denny" Moyer and Mr. Troy Mullins, who each contributed to this article.

Colloidal Silver Use

Wednesday, April 02nd, 2008 2:43pm Colloidal Silver Use has been defined in the last 103 years by physicians treating every known bacterial caused disease from acne to yeast infection until the debut of penicillin. Antibiotics took the lead in fighting disease and colloidal silver use was made an across the counter product no longer requiring a prescription for colloidal silver use. Silver is an unusual element in health science. First and foremost it is important to understand that claims made as to specific benefits resulting from the use of Colloidal Silver Use are not the claims of this author but the statements of many physicians, books printed accounts and internet testimonials from the last 103 years. Information conveyed from history beyond the 103 years is

based on ancient records and research from Biblical times until recently. Therefore we cannot imply that everyone will experience similar beneficial results. Many studies seem to reflect that Colloidal Silver use remedy has been proven to be useful against many different infections and is toxic in concentrations of 3 - 5 ppm (parts per million) against all species of fungi, bacteria, protozoa, parasites and certain viruses, in the laboratory, in a petri dish. Doing a little math is in store now. If you start with 3-5 ppm and add this colloidal silver use to 5 liters of fluid such as the amount of blood in a human, you will not have the same results in killing bacteria and virus YOU WILL NEED MORE PPM of COLLOIDAL SILVER use. Colloidal silver use does not kill or inhibit all forms of bacteria, virus or fungi. Actually, this is good news for us. If colloidal silver use killed all organisms then it would also kill essential healthy flora, necessary to maintain life, both human and animal. Today various applications of colloidal silver use include oral, topical, by injection, as a nasal, ear or eye drops, vaginal and even on other sensitive tissues. Silver has been applied directly to cuts, scrapes, eczema, acne and open sores. A few drops of colloidal silver use on a Band-Aid and worn over abrasions, open sores and even warts. It has been successfully used in the treatment of these conditions. The colloidal silver use depends on the body weight of an individual and ones metabolism and general health. The least amount of colloidal silver use regarding PPM effectively would be topical use where the colloidal silver use would not be diluted. There are surveys results from many people who have reported the prevention or a reduction of several illnesses during changing seasons or the rapid recovery of current illnesses. It is like having another immune system. After taking an individually determined dosage, people have gone through a cleansing of bodily toxins prior to full recovery from illnesses. Documentation reports neither adverse side effects nor any harm to the person taking colloidal silver use according to the manufacturers suggested use or physicians prescription. colloidal silver use Technorati Tags: colloidal silver use Colloidal Silver Use | Comments (0) Colloidal Silver Use vs. Which Colloidal Silver to Use Wednesday, February 03rd, 2010 7:57pm Colloidal silver use would be a lot easier to explain if one knew which colloidal silver to use Your frustration is shared! You want to know the best colloidal silver to use, colloidal silver use, what colloidal silver is used for and the more you surf the net the harder it seems to be able to get reliable colloidal silver information. First lets address the straight forward answer, if we tell you colloidal silver should be used for _______ or you should take 3_______ of colloidal silver ____ times a day, the vitamin police would shut our site down and force us out of business for diagnosing and prescribing . SOoo, lets see if we can address your questions without a sales pitch of this one is better than the other please sharpen up on reading between the lines. Which colloidal silver is the best to use? There are reports that colloidal silver use topically can be a low ppm with good results. There are reports that higher ppm colloidal silver is needed when it is (diluted with 5 liters of blood) ingested. We have received reports that high voltage low ppm colloidal silver is better than mild protein high ppm colloidal silver one is not necessarily better than the other. The colloidal silver use depends upon the application. We can only say that colloidal silver is a supplement. We sell both kinds. We sell the most of the 1100 PPM colloidal silver, this formula is 112 years old, the most studied, most used and has the most testimonies for its use. The commercially produced Advanced colloidal silver process, (high voltage), is about 20 years old. Can I use Colloidal silver in my eyes? Hospitals have used a silver solution to put in newborn infants eyes at birth to prevent venereal disease from mother to child for decades. There are many reports of the advanced colloidal silver used in eyes. However, we have even more reports of individuals using 1100 PPM for eye support. Which Colloidal Silver PPM should I take? This is purely consumers choice. We offer 20 PPM, 30 PPM, 500 PPM and 1100 PPM colloidal silver. For 112 years the 1100 PPM formula has been the flagship for all colloidal silver sales. Which is better ionic or non-ionic colloidal silver? The clear decision is in on this topic. Only the ionic, large particle, clear HOMEMADE colloidal silver using a 9 volt battery CAN be detrimental to