Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manual Surface Impedance

Caricato da

Naveen DhananjayanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manual Surface Impedance

Caricato da

Naveen DhananjayanCopyright:

Formati disponibili

icroflown Technologies B.V.

Manual free field surface impedance setup

Author: Microflown Technologies Dhr. E. Tijs info@microflown.com tijs@microflown.com T: +31 316 581 490 F: +31 316 581 491

Calibration report

PU-Probe Model A

Page 1 of 11

Microflown Technologies B.V.

Table of contents

1. Bill of materials ..................................................................................... 3 2. Setup of the system ............................................................................... 3 2.1. Hardware ....................................................................................................... 3 2.2. Schematic setup of the system.......................................................................... 5 3. Surface Impedance Program ................................................................. 6 3.1. Program start up ............................................................................................. 6 3.1.1. Sound card settings.................................................................................... 6 3.1.2. Running the program.................................................................................. 7 3.2. Measurements................................................................................................. 7 3.2.1. Settings .................................................................................................... 8 3.2.2. Measure.................................................................................................... 8 3.3. Process the measurements ............................................................................... 9 3.3.1. Load files .................................................................................................. 9 3.3.2. Screen content ........................................................................................ 10 3.3.3. Separate plots ......................................................................................... 11 3.3.4. Workspace .............................................................................................. 11

Calibration report

PU-Probe Model A

Page 2 of 11

Microflown Technologies B.V.

1. Bill of materials

Surface Impedance software Grid with elastics fastened and spherical loudspeaker mounted. Specified probe (PU mini and/or PU match) with mounting screw(s). Handle Mini tripod to mount under the handle Lemo probe cable Jack loudspeaker cable Signal conditioner & sound card amplifier Cables signal conditioner to sound card amplifier USB sound card cable to computer 2 x 110/230 Volt to 18Volt adaptor 2 x Adaptor cable

2. Setup of the system

2.1. Hardware

1. Carefully remove the protective grid from the probe. Especially the PU match probe can be fragile. Mount the probe on the grid. The probe should be orientated as indicated in Figure 1. The blue arrow indicated the measurement direction. The measurement direction should point to the loudspeaker. 2. Then tighten the screw (red arrow, Figure 1).

Figure 1. The sensitive direction is indicated with the blue arrow and should point towards the loudspeaker. Left: Mounting of the PU mini probe. Right: PU match probe

Calibration report

PU-Probe Model A

Page 3 of 11

Microflown Technologies B.V. 3. Then put the protective grid on the probe. Make sure the pillars of the grid are not in front of the sensor, see Figure 2. They can obstruct and alter the measurement

Center of the sensor

Figure 2. The pillars of the protective grid should not be in front of the sensor 4. Connect all electronics Sound card / channel 1 Sound card / channel 2 Particle velocity output Sound pressure output Loudspeaker volume BNC to loudspeaker

Signal conditioner

Sound card amplifier

Front view

Signal conditioner Sound card amplifier

Power switch amplifier Power switch signal conditioner Gain setting (set to high gain) Correction (set on) 18V power supply

USB cable to computer 18V power supply Rear view

Figure 3. Connections signal conditioner and sound card amplifier Calibration report PU-Probe Model A Page 4 of 11

Microflown Technologies B.V. 5. Connect the Lemo cable that comes from the signal conditioner to the probe. Then tighten the knob.

Tighten the knob

Plug from probe Jack cable from amplifier Connect the Lemo cable to the probe

Figure 4. Connections backside of the surface impedance setup 6. Switch on the signal conditioner and set it to corrected mode, high gain. Both for impedance calibration as for the sample measurement. Left switch down: corrected mode Right switch up: high gain

Orange led Figure 5. The signal conditioner should be set on high gain, corrected mode

2.2. Schematic setup of the system

Spherical loudspeaker Sample Probe

hs - h hs

Figure 6. Schematic layout of the setup Distance sphere-probe (hs h) : Distance from the front of the loudspeaker to the center of the probe Distance probe-sample (h) : Distance from the center of the probe to the material

Calibration report

PU-Probe Model A

Page 5 of 11

Microflown Technologies B.V.

3. Surface Impedance Program

3.1. Program start up

3.1.1. Sound card settings

7. Connect the sound card the computer 8. Please make sure the following sound card settings apply at all times (Figure 7) a. Double click the volume icon or select the sound and audio devices properties from the Control Panel b. For both the Playback and Recording the USB sound card should be selected. c. Playback > With the Speaker slider the speaker volume can be adjusted d. Playback > Mute the Line output e. Recording / Capture > Select the Line input and position the slider between the two lower stripes (the precise level is not needed) Select the USB Audio sound card Select the USB Audio sound card

Recording

Playback

Volume icon

Select the Line input

Set speaker to maximum

Mute the Line output

Figure 7. Left: Recording sound card properties. Right: Playback properties

Calibration report

PU-Probe Model A

Page 6 of 11

Microflown Technologies B.V.

3.1.2. Running the program

9. Open Matlab and select the folder where the program is located 10. Run SURFACE IMPEDANCE PROGRAM.M (right mouse button > run)

Figure 8. Matlab opening window. Run SURFACE_IMPEDANCE_PROGRAM.M

3.2. Measurements

11. Click the Measure button, see Figure 9. The 2 channel recording window will open.

Measure

Figure 9. Main window surface impedance program

Calibration report

PU-Probe Model A

Page 7 of 11

Microflown Technologies B.V.

3.2.1. Settings

12. Under Options >> Settings the measurement parameters can be changed.

Number of fft points Sample rate

Ambient temperature Select USB audio if not selected Measurement time (seconds)

Figure 10. Settings window of the 2 channel recording panel

3.2.2. Measure

Select Calibration or Measurement

Coherence

Auto spectrum: Pressure (ch1) Velocity (ch2)

Transfer function magnitude u/p

Transfer function phase u/p

Save the measurement

Figure 11. 2 channel recording measurement panel 13. Select Measurement or Calibration first. The measurement can automatically be saved to a subfolder in the Measurement or Calibration folder. This subfolder will automatically contain the date. 14. Press Start to start measuring.

Calibration report

PU-Probe Model A

Page 8 of 11

Microflown Technologies B.V.

15. Calibration. The measurements can be performed within a normal room (not anechoic). But please make sure there is not too much background noise during calibration. This will also result in a less high coherence. Make sure there are no drastic peaks in both the magnitude and the phase of the transfer function like in Figure 11. The phase flips of course from 180 to -180, but this is okay. 16. Sample measurement. The transfer function deviates from the calibration because of the material. Also the coherence is likely to drop at the frequencies where the sample is reflecting (area of high impedance so the velocity signal will be low). 17. Press Save. A window will open. The measurement can be saved to a .mat file in the specified directory. Avoid names containing an underscore (_), a comma separator (,) or a spacebar ( ). If for somewhat reason the signals do not appear properly in the 2 channel recording panel, check if the sound card is receiving the signals. In that case please re-initialize the sound card as described under 3.1.1 Sound card settings

3.3. Process the measurements

3.3.1. Load files

18. Load the calibration file

Figure 12. Load calibration / measurements 19. Load the measurement file. All windows will automatically refresh. When a different measurement is loaded it is not necessary to reload the calibration file.

Calibration report

PU-Probe Model A

Page 9 of 11

Microflown Technologies B.V.

3.3.2. Screen content

Change the axis properties of the selected graph and click Apply Fill in the distances used in the measurement

Averaging coefficient

Figure 13. Screenshot of the program with an example measurement loaded Transfer function of sound pressure (ch. 1) divided by particle velocity (ch. 2) The raw data is smoothed to filter out unwanted reflections. Please look at the data carefully to see if the smoothed line follows the raw data sufficiently. If this is not the case the number of averages can be influenced by changing the value of the averaging coefficient # average measured sample. A value of zero means the data is not smoothed. For most samples this parameter can have a value of 1 or higher. But some samples have a very drastic behavior (like the quarter lambda sample). To follow the measured data correctly the averaging coefficient should be lower. Upper left graph : The magnitude of the raw data with all reflections and the smoothed response. Both the calibration measurement as the sample measurement is displayed. Upper right graph : The phase of the raw data and the smoothed response. Calibration measurement and sample measurement.

Impedance Middle left graph

: The magnitude response of impedance divided by c (density of air and speed of sound) Middle right graph : The phase response of impedance

Calibration report

PU-Probe Model A

Page 10 of 11

Microflown Technologies B.V. Absorption / Reflection coefficient Lower left graph : The magnitude response of reflection and the absorption coefficient. Both lines can be selected or unselected with the checkmarks below the graph

Figure 14. The checkbox should be selected to display the absorption or reflection curve Lower right graph : Phase of the reflection coefficient

3.3.3. Separate plots

The curves from the main window and some additional curves can be plotted.

Figure 15. The curves can be plotted in a separate window.

3.3.4. Workspace

After loading a calibration and measurement file, automatically the following values will be exported to the workspace.

1. 2. 3. 4. 5. 6.

1. Name Measurement file 2. Name Calibration file 3. Column 1: Coherence pressurespeaker Column 2: Coherence velocity-speaker 4. Matrix with all data 5. Names of the columns of TotalMatrix 6. All measurement settings

Figure 16. Data will automatically be exported to the Matlab workspace

Calibration report

PU-Probe Model A

Page 11 of 11

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Kingmaker With Mike Rashid - 4 Weeks To Fighting ShapeDocumento6 pagineKingmaker With Mike Rashid - 4 Weeks To Fighting ShapeRayNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- 03 Big Bands (The Giants of The Swing Big Band Era)Documento103 pagine03 Big Bands (The Giants of The Swing Big Band Era)Axel JuárezNessuna valutazione finora

- 21 Defensive IdDocumento29 pagine21 Defensive IdJay Green100% (1)

- Component Locations: 966G and 972G Wheel Loader Hydraulic SystemDocumento4 pagineComponent Locations: 966G and 972G Wheel Loader Hydraulic SystemAndrei Bleoju100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Cutting Edge STARTER Final TestDocumento12 pagineCutting Edge STARTER Final TestprofaderomanaNessuna valutazione finora

- Music in The Age of Mechanical ReproductionDocumento32 pagineMusic in The Age of Mechanical Reproductionajithno1Nessuna valutazione finora

- Pipe Culvert 1000MMDocumento8 paginePipe Culvert 1000MMgtarun22gupta86% (7)

- Recreation and LeisureDocumento42 pagineRecreation and LeisureGina del Mar75% (4)

- According To PlutarchDocumento10 pagineAccording To Plutarchwillrg9Nessuna valutazione finora

- ALDI Growth Announcment FINAL 2.8Documento2 pagineALDI Growth Announcment FINAL 2.8Shengulovski IvanNessuna valutazione finora

- S.No Name of The Student Reg - No Elective ChoosenDocumento3 pagineS.No Name of The Student Reg - No Elective ChoosenHarshaNessuna valutazione finora

- ERLPhase USB Driver InstructionsDocumento9 pagineERLPhase USB Driver InstructionscacobecoNessuna valutazione finora

- AEF Unit Test 2Documento7 pagineAEF Unit Test 2Trevor AndersonNessuna valutazione finora

- Gothic V RomanticDocumento10 pagineGothic V RomanticLucia InglesNessuna valutazione finora

- Materi Bahasa Inggris Report Text SMP/MTsDocumento25 pagineMateri Bahasa Inggris Report Text SMP/MTsLuthfan0% (1)

- Jazzy PrayersDocumento3 pagineJazzy PrayersTheLivingChurchdocsNessuna valutazione finora

- 1 BROASTE TA 2013 en de 09 Furniture Locking SystemsDocumento150 pagine1 BROASTE TA 2013 en de 09 Furniture Locking SystemsMada UdreaNessuna valutazione finora

- Cisco 3900 and Cisco 2900 Series RoutersDocumento31 pagineCisco 3900 and Cisco 2900 Series RoutersCassandra ShafferNessuna valutazione finora

- CIE IGCSE FLE PAST PAPER 0500 - w03 - QP - 2Documento8 pagineCIE IGCSE FLE PAST PAPER 0500 - w03 - QP - 2mwah5iveNessuna valutazione finora

- D6801 2.4G Digital Wireless Conference System Host: FeaturesDocumento2 pagineD6801 2.4G Digital Wireless Conference System Host: FeaturesArioNessuna valutazione finora

- Complex SentencesDocumento3 pagineComplex SentencesPilar Romero CandauNessuna valutazione finora

- Sach-A2 (Có Đáp Án)Documento41 pagineSach-A2 (Có Đáp Án)Đức Luận TạNessuna valutazione finora

- Literature Part 2Documento53 pagineLiterature Part 2Neliza SalcedoNessuna valutazione finora

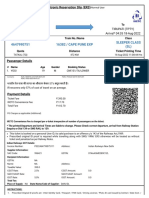

- Cape Pune Exp Sleeper Class (SL)Documento2 pagineCape Pune Exp Sleeper Class (SL)Yogiswar Goud RathipinniNessuna valutazione finora

- New Year's EveDocumento1 paginaNew Year's EveEdyta MacNessuna valutazione finora

- Neoverter III: Single-Split Inverter SeriesDocumento10 pagineNeoverter III: Single-Split Inverter SeriesdaveleyconsNessuna valutazione finora

- BDSM Library - After The Garden PartyDocumento5 pagineBDSM Library - After The Garden PartyManu ShankarNessuna valutazione finora

- Aikido VocabularyDocumento5 pagineAikido VocabularyrafiendutNessuna valutazione finora

- How To Squat Cheat SheetDocumento4 pagineHow To Squat Cheat SheetAngelNessuna valutazione finora

- Lesson A: Lifestyle Trends: DecreasedDocumento3 pagineLesson A: Lifestyle Trends: DecreasedJean Pierre Sulluchuco ValentinNessuna valutazione finora