Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-W-2043 Rev 0

Caricato da

philipyapDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-W-2043 Rev 0

Caricato da

philipyapCopyright:

Formati disponibili

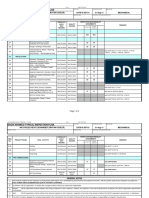

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

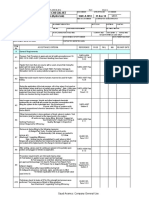

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Hardness Testing Procedure

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2043

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

The procedure shall contain the elements listed below as minimum: NOTES (The originator and reviewer shall compare the conformity of the written procedure with the requirements specified in the "Reference" column of this checklist). A1 The Procedure is identifiable and traceable to the Project's updated list Project Document of quality documents. Control Procedure The procedure addressed the method of identifying materials, parts and components, including partially fabricated assemblies, either by using tags, stamps, color coding, stencils or labels. The equipment to be used for hardness testing is specified as portable Brinell hardness tester, (NACE RP0472, Para. 3.4). NOTE: CSD shall approve the use of other hardness testers. The procedure addressed the step by step method in performing the hardness test, using portable Brinell hardness tester, as described in NACE RP0472, Appendix A. (Refer to Attachment 1 for the guidelines). The procedure specifies the maximum hardness for P1 material as follows: a) 225 BHN for non-sour service and b) 200 BHN for sour service. The procedure stated the method of evaluating the results of the hardness test performed. Sch. Q, Attachment IV, Para. 3.2 SAES-W-012, Para. 13.2

A2

A3

A4

SAES-W-012, Para. 13.2

A5

SAES-W-012, Para. 13.1

A6

SAES-W-012, Para. 13.3 & 13.4

REMARKS:

REFERENCE DOCUMENTS: 1. SAES-W-012, Welding Requirements for Pipelines, 31 December, 2002 2. NACE RP0472-2000, Methods and Controls to Prevent In-Service Cracking of Carbon Steel Welds ATTACHMENTS: 1. Attachment 2 - Guidelines fo Portable Brinell Hardness Testing of Welds (NACE RP0472, Appendix A)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Y = YES Work Verified N = NO F = FAILED

Page 1 of 3

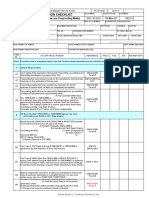

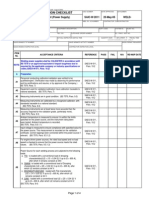

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Hardness Testing Procedure

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2043

25-May-05

WELD-

Attachment 1

(NACE RP0472, Appendix A)

Page 2 of 3

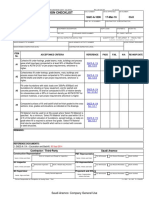

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Hardness Testing Procedure

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2043

25-May-05

WELD-

Page 3 of 3

Potrebbero piacerti anche

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocumento1 paginaSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNessuna valutazione finora

- SAIC-L-2136 Rev 0Documento3 pagineSAIC-L-2136 Rev 0philipyapNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocumento3 pagineSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNessuna valutazione finora

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocumento2 pagineSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNessuna valutazione finora

- Saic A 1017Documento1 paginaSaic A 1017jerinNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Documento10 pagineSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento13 pagineSaudi Aramco Inspection ChecklistAli AhmedNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Documento5 pagineSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNessuna valutazione finora

- Saic MPT 2004 Rev 0Documento6 pagineSaic MPT 2004 Rev 0philipyapNessuna valutazione finora

- SAIC L 2031 (Comments)Documento2 pagineSAIC L 2031 (Comments)Anton Thomas PunzalanNessuna valutazione finora

- Saic A 1002Documento2 pagineSaic A 1002Sajid ShaikhNessuna valutazione finora

- Saic RT 2007Documento9 pagineSaic RT 2007munnaNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocumento4 pagineSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNessuna valutazione finora

- 175 012300Documento2 pagine175 012300Abu Anas M.SalaheldinNessuna valutazione finora

- Ir 175-010000Documento2 pagineIr 175-010000Abu Anas M.SalaheldinNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocumento5 pagineSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNessuna valutazione finora

- SAIC-X-3104 Rev 3Documento4 pagineSAIC-X-3104 Rev 3Imran khanNessuna valutazione finora

- 175 011100Documento2 pagine175 011100Abu Anas M.SalaheldinNessuna valutazione finora

- SAIC-W-2015 Rev 7 (NDE Selection)Documento17 pagineSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNessuna valutazione finora

- Saudi Aramco Test ReportDocumento2 pagineSaudi Aramco Test ReportEswari AnandNessuna valutazione finora

- SAIC-W-2085 Pre-Welding Inspection PDFDocumento4 pagineSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNessuna valutazione finora

- Saic LPT 2006Documento12 pagineSaic LPT 2006jerinNessuna valutazione finora

- SAIC-D-2005 Rev 2Documento4 pagineSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- 175 018000 PDFDocumento2 pagine175 018000 PDFAbu Anas M.SalaheldinNessuna valutazione finora

- 175 010300 PDFDocumento2 pagine175 010300 PDFAbu Anas M.SalaheldinNessuna valutazione finora

- 175 030100Documento2 pagine175 030100Abu Anas M.Salaheldin100% (1)

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocumento1 paginaSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNessuna valutazione finora

- RFI (Blank)Documento1 paginaRFI (Blank)SajjadPervaizNessuna valutazione finora

- Satr-W-2010Documento1 paginaSatr-W-2010Joni Carino SuniNessuna valutazione finora

- SAIC-K-4042 Rev 7Documento2 pagineSAIC-K-4042 Rev 7shahzadaNessuna valutazione finora

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocumento5 pagineSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocumento4 pagineSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNessuna valutazione finora

- SAIC-A-1006 - Final Fill InspectionDocumento1 paginaSAIC-A-1006 - Final Fill InspectionwalidNessuna valutazione finora

- Section Subject: Shaybah CPF Expansion ProjectDocumento21 pagineSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- Saic A 2011Documento8 pagineSaic A 2011jerinNessuna valutazione finora

- 175-026600 10312016Documento2 pagine175-026600 10312016Prasanna UmapathyNessuna valutazione finora

- Specification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0Documento13 pagineSpecification and Requisition For Ball Valve: GTF-3-XXXX-XXX-XX-X-0shyamNessuna valutazione finora

- Saep 1105 PDFDocumento7 pagineSaep 1105 PDFbalajiNessuna valutazione finora

- Saic W 2011rev 0Documento4 pagineSaic W 2011rev 0fariboy123Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento13 pagineSaudi Aramco Inspection ChecklistRijwan MohammadNessuna valutazione finora

- Satip F 001 04Documento4 pagineSatip F 001 04Anonymous 4e7GNjzGWNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento2 pagineSaudi Aramco Inspection ChecklistJoni Carino SuniNessuna valutazione finora

- Saic RT 2001Documento24 pagineSaic RT 2001munnaNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento4 pagineSaudi Aramco Inspection ChecklistSajid ShaikhNessuna valutazione finora

- Thermax Limited: Inspection Procedure For GalvanizingDocumento14 pagineThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNessuna valutazione finora

- Satr W 2012Documento1 paginaSatr W 2012Mohammed Hamed BaganNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocumento2 pagineSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNessuna valutazione finora

- Satip e 007 01Documento2 pagineSatip e 007 01Anonymous 4e7GNjzGWNessuna valutazione finora

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocumento3 pagineDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsRAFAEL BRAVONessuna valutazione finora

- Saep 324Documento13 pagineSaep 324Up WeldNessuna valutazione finora

- 175 018200 PDFDocumento2 pagine175 018200 PDFAbu Anas M.SalaheldinNessuna valutazione finora

- SAIC-K-2026 Rev 0Documento2 pagineSAIC-K-2026 Rev 0philipyapNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocumento13 pagineSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- 01 Saip 02Documento6 pagine01 Saip 02malika_00Nessuna valutazione finora

- 175 014301 PDFDocumento2 pagine175 014301 PDFAbu Anas M.SalaheldinNessuna valutazione finora

- Saic W 2003Documento14 pagineSaic W 2003Mohammed IlliasuddinNessuna valutazione finora

- Saep 306Documento15 pagineSaep 306nadeem shaikh100% (1)

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocumento1 paginaSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapNessuna valutazione finora

- Resilent FlooringDocumento7 pagineResilent FlooringphilipyapNessuna valutazione finora

- Fire Protection SysytemDocumento5 pagineFire Protection SysytemphilipyapNessuna valutazione finora

- Bazaar Tent StructureDocumento5 pagineBazaar Tent StructurephilipyapNessuna valutazione finora

- Piping and Ducting SupportDocumento7 paginePiping and Ducting SupportphilipyapNessuna valutazione finora

- DuctworksDocumento7 pagineDuctworksphilipyapNessuna valutazione finora

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDocumento10 pagineSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapNessuna valutazione finora

- Sealant and CaulkingDocumento8 pagineSealant and CaulkingphilipyapNessuna valutazione finora

- Control SystemDocumento21 pagineControl SystemphilipyapNessuna valutazione finora

- Wire, Cable and Low VotageDocumento9 pagineWire, Cable and Low VotagephilipyapNessuna valutazione finora

- Finish CarpentryDocumento17 pagineFinish CarpentryphilipyapNessuna valutazione finora

- Chilled Water PumpDocumento6 pagineChilled Water PumpphilipyapNessuna valutazione finora

- Exterior LightingDocumento8 pagineExterior LightingphilipyapNessuna valutazione finora

- Duct Works & AccessoriesDocumento5 pagineDuct Works & AccessoriesphilipyapNessuna valutazione finora

- Metal FramesDocumento4 pagineMetal FramesphilipyapNessuna valutazione finora

- SignageDocumento4 pagineSignagephilipyapNessuna valutazione finora

- Roof and Deck InsulationDocumento3 pagineRoof and Deck InsulationphilipyapNessuna valutazione finora

- Sheet Membrance Water ProofingDocumento6 pagineSheet Membrance Water ProofingphilipyapNessuna valutazione finora

- Floor MatsDocumento3 pagineFloor MatsphilipyapNessuna valutazione finora

- Handrail RailingDocumento11 pagineHandrail RailingphilipyapNessuna valutazione finora

- Plumbing SpecialitiesDocumento4 paginePlumbing SpecialitiesphilipyapNessuna valutazione finora

- Example 2 - Two Equal Spans: AbutmentDocumento94 pagineExample 2 - Two Equal Spans: AbutmentphilipyapNessuna valutazione finora

- Bridge Superstructure DesignDocumento108 pagineBridge Superstructure Designstefanotomasi123550% (2)

- GeotectilesDocumento2 pagineGeotectilesphilipyapNessuna valutazione finora

- Swimming PoolDocumento4 pagineSwimming PoolphilipyapNessuna valutazione finora

- Glass and GlazingDocumento8 pagineGlass and GlazingphilipyapNessuna valutazione finora

- Sap2000 Analysis Refer ManualDocumento467 pagineSap2000 Analysis Refer ManualphilipyapNessuna valutazione finora

- Example 2 - Option 2: Bent Columns On Capped Piles: AbutmentDocumento178 pagineExample 2 - Option 2: Bent Columns On Capped Piles: AbutmentphilipyapNessuna valutazione finora

- 5) Manual SAP200 - Bridge Seismic Design (Pu)Documento71 pagine5) Manual SAP200 - Bridge Seismic Design (Pu)Alejandro AntezanaNessuna valutazione finora

- Concrete Curb, EdgingDocumento3 pagineConcrete Curb, EdgingphilipyapNessuna valutazione finora

- Monster Energy v. Jing - Counterfeit OpinionDocumento9 pagineMonster Energy v. Jing - Counterfeit OpinionMark JaffeNessuna valutazione finora

- IRDM Assignment-I PDFDocumento4 pagineIRDM Assignment-I PDFPiyush AggarwalNessuna valutazione finora

- The Messenger 190Documento76 pagineThe Messenger 190European Southern ObservatoryNessuna valutazione finora

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Documento90 pagineDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNessuna valutazione finora

- Report On Sonepur MelaDocumento4 pagineReport On Sonepur Melakashtum23Nessuna valutazione finora

- Linberg V MakatiDocumento2 pagineLinberg V MakatiChimney sweepNessuna valutazione finora

- ACCA Strategic Business Reporting (SBR) Workbook 2020Documento840 pagineACCA Strategic Business Reporting (SBR) Workbook 2020Azba Nishath0% (1)

- Contemporary ArtsDocumento16 pagineContemporary Artsantoinette100% (2)

- SOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalDocumento10 pagineSOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalAlba R.Nessuna valutazione finora

- Thesis MaltaDocumento6 pagineThesis Maltaaprilwbndsouthbend100% (2)

- Osssc JR Clerk Odia Paper 2015 - 20171207 - 0001Documento7 pagineOsssc JR Clerk Odia Paper 2015 - 20171207 - 0001songspk100Nessuna valutazione finora

- Entrance 2021: Indira Gandhi Rashtriya Uran AkademiDocumento2 pagineEntrance 2021: Indira Gandhi Rashtriya Uran Akademird meshramNessuna valutazione finora

- Dual Nature of Radiation and MatterDocumento5 pagineDual Nature of Radiation and Mattercopadag753Nessuna valutazione finora

- 2017-Process Tracing in Social SciencesDocumento28 pagine2017-Process Tracing in Social SciencesTudor CherhatNessuna valutazione finora

- Swot Ananlysis of Fintech CompaniesDocumento7 pagineSwot Ananlysis of Fintech CompaniesUyen Le VuNessuna valutazione finora

- TQ Science10 Q3 ST4Documento2 pagineTQ Science10 Q3 ST4mae cudal100% (1)

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDocumento12 pagineBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliNessuna valutazione finora

- Axis Bank - Group 4Documento34 pagineAxis Bank - Group 4Deep Ghose DastidarNessuna valutazione finora

- CHAPTER 5 Ground ImprovementDocumento47 pagineCHAPTER 5 Ground ImprovementBeman EasyNessuna valutazione finora

- Bhakra Nangal Project1Documento3 pagineBhakra Nangal Project1Sonam Pahuja100% (1)

- Debit Note and Credit NoteDocumento2 pagineDebit Note and Credit Noteabdul haseebNessuna valutazione finora

- Coca-Cola BeverageDocumento17 pagineCoca-Cola BeverageMahmood SadiqNessuna valutazione finora

- Thinking Out LoundDocumento2 pagineThinking Out LoundExita ConiaNessuna valutazione finora

- Everyday Life - B1 - ShoppingDocumento7 pagineEveryday Life - B1 - ShoppingAmi BarnesNessuna valutazione finora

- Lotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Documento2 pagineLotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Tayyab KhanNessuna valutazione finora

- Legal NoticeDocumento3 pagineLegal NoticeT Jayant JaisooryaNessuna valutazione finora

- Materials Science and Engineering-Chapter 11Documento3 pagineMaterials Science and Engineering-Chapter 11JurgenNessuna valutazione finora

- WP Seagull Open Source Tool For IMS TestingDocumento7 pagineWP Seagull Open Source Tool For IMS Testingsourchhabs25Nessuna valutazione finora

- Beamer Example: Ethan AltDocumento13 pagineBeamer Example: Ethan AltManh Hoang VanNessuna valutazione finora

- Police Log September 24, 2016Documento14 paginePolice Log September 24, 2016MansfieldMAPoliceNessuna valutazione finora