Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Seed Extraction in Tomato

Caricato da

Dr.Eswara Reddy SiddareddyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Seed Extraction in Tomato

Caricato da

Dr.Eswara Reddy SiddareddyCopyright:

Formati disponibili

SEED EXTRACTION IN TOMATO

S.ESWARA REDDY

Tomato is one of the important vegetable crops of India and Andhra Pradesh. It is the leading crop of Chittoor district. It occupies third position after Potato and sweet potato in its importance. Seed can be extracted from the tomato fruit by one of the following three methods : FERMENTATION METHOD ALKALI TREATMENT METHOD QUICKEST METHOD OR ACID TREATMENT METHOD 1. FERMENTATION METHOD: This method is employed when tomato fruits are generally not very big and they possess a large no. of seeds. The fruits selected for seed are completely lost and nothing can be used as food or otherwise. The selected ripe fruits are harvested from the plants and allowed to ripe further for a day or two in a heap or in an earthen pot. They are then crushed well in an earthen pot by hand or by any mechanical method to make a paste. No fruit juice should be allowed to drain out. Now the entire mass is kept in the vat for a day or two to ferment. It may be complete in one or two or more days according to high or low temperature. Profuse foam formation on the top and no adhering of seed to the tomato flesh on stirring the mass vigorously with a wooden stick or hand, indicates that the fermentation is complete. Now the flesh will float on the top, while the seeds will settle down at the bottom of the vat.

Remove all the fermented mass on the top and then decant off gently all the liquid. The seeds resting on the bottom of the vat are collected and washed 8 10 times with clear water and then they are spread in the sun to become dry. When they are perfectly dry in the sun store them in air tight containers in a cool dry place. It is the simplest method and can be adopted by any layman. They should not be left too long, other wise they may germinate in it. ALKALI TREATMENT METHOD: When fruits are big enough but the no. of seeds is small, method is adopted. Cut the selected ripe fruits into halves and then scoop out the slimy mass containing the seeds into an earthen or porcelain vessel with the help of the handle of a stainless steel, tea spoon or wooden stick. The flesh thus separated can be easily used for eating raw or for any other purpose. Treat the slimy mass with an alkali mixture (150 grams of ordinary washing soda is added to 5 liters of boiling water) in equal volumes.) When the alkali mixture is cooled, allow it to stand overnight in an earthen or porcelain vessel. By next day, all the seeds will settle down at the bottom of the container. Decant off the clear liquid at the top. Seeds thus obtained are washed thoroughly with clear water and allowed to dry in the sun and are preserved . QUICKEST METHOD OR ACID TREATMENT METHOD: This method is followed where seed production is done on large scale. It can also be adopted on the home scale. In this method, too, the flesh of the fruit can be saved. Slimy seed mass is separated as mentioned above and kept in an earthen or a porcelain or glass vessel. This is done by treating with commercial hydrochloric acid in the proportion of 30 ml of fluid per 12kg of the material. The seeds are separated from the slimy mass within 15 30 min., if acid is thoroughly mixed. The acidified liquid is then decanted off and the seeds remaining at the bottom are immediately washed well with clear water and allowed to dry in the sun. They are then preserved . In this method the seeds can be extracted and dried on the same day and any discoloration of seeds, resulting from the fermentation process, is entirely eliminated. There is also no possibility of seed germination during this process. TOMATO SEED EXTRACTOR

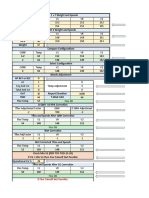

1. Function 2. Specification (a) Overall dimension (b) Capacity (c) Power required 3. General Information

: To extract seed from tomato fruits : : 500 x 450 x 1000 mm : 180 kg of fruit (1.8 kg of seed) per hour. : 1 hp for electric motor and 0.5 hp for pump : The unit consists of a feed hopper, fruit crushing chamber, seed separation unit, water recycling system and seed collecting trough. In the crushing chamber the tomato fruits are crushed and squeezed by the rotating screw auger. In the seed separation unit, water separates the seed from the flesh and collected in a container placed at the bottom of seed separation unit. The water collected in the trough is recycled by means of a pump. The flesh coming out of the seed separation unit is collected separately.

4. 5.

Cost of the unit : Rs. 15,000 Cost of : Rs. 10 per hour

6.

operation Salient features

Seed extraction is faster compared to the manual method Contact address :dr_esreddy@yahoo.co.in Feb 2012

Potrebbero piacerti anche

- Jackfruit: Growing Practices and Nutritional InformationDa EverandJackfruit: Growing Practices and Nutritional InformationNessuna valutazione finora

- Crop Production Technology - Kharif CropsDocumento32 pagineCrop Production Technology - Kharif CropsAKSHAY THOTTUVANessuna valutazione finora

- Intercultural Operations PDFDocumento1 paginaIntercultural Operations PDFsam100% (1)

- Floral Structure, Breeding and Pollination Mechanism During Seed Production in BarleyDocumento23 pagineFloral Structure, Breeding and Pollination Mechanism During Seed Production in BarleyJai Prakash GuptaNessuna valutazione finora

- Production Technology of RiceDocumento3 pagineProduction Technology of RicebutterfilyNessuna valutazione finora

- CpasicumDocumento32 pagineCpasicumNarendhiran VNessuna valutazione finora

- Importance of Nurseries for Raising Strong SeedlingsDocumento4 pagineImportance of Nurseries for Raising Strong SeedlingsWellington KubaraNessuna valutazione finora

- Cultivation and Production of Rice in IndiaDocumento65 pagineCultivation and Production of Rice in IndiarishabhNessuna valutazione finora

- Production Technology of Fruit and Plantatin Crops - Teaching Manual-1Documento133 pagineProduction Technology of Fruit and Plantatin Crops - Teaching Manual-1yogesh yadavNessuna valutazione finora

- Seed Quality: Factors, Importance and ComponentsDocumento17 pagineSeed Quality: Factors, Importance and Componentsdwi cix ndut100% (1)

- FF12 PitayaDocumento2 pagineFF12 Pitayarosnie22Nessuna valutazione finora

- Fundamental of Horticulture-Shobhit MauryaDocumento42 pagineFundamental of Horticulture-Shobhit MauryaOm MauryaNessuna valutazione finora

- 3 Plant Protection II PDFDocumento129 pagine3 Plant Protection II PDFAvijitSinharoyNessuna valutazione finora

- High Density PlantingDocumento8 pagineHigh Density PlantingDr Parag B Jadhav100% (1)

- L7.oil CropsDocumento22 pagineL7.oil CropsMohaajanan AliNessuna valutazione finora

- BulbDocumento4 pagineBulbAdrian MausigNessuna valutazione finora

- Neem Cultivation Techniques and UsesDocumento9 pagineNeem Cultivation Techniques and UsesmandaremNessuna valutazione finora

- Seminar On INFLUENCE OF PRE-HARVEST FACTORS ON POST HARVEST HANDLING OF FLORICULTURAL CROPsDocumento68 pagineSeminar On INFLUENCE OF PRE-HARVEST FACTORS ON POST HARVEST HANDLING OF FLORICULTURAL CROPsAnand Singh RawatNessuna valutazione finora

- Seed Testing Methods For Coated Seed (Or) Pelleted SeedDocumento20 pagineSeed Testing Methods For Coated Seed (Or) Pelleted Seedmanikandan.v100% (1)

- Gardening - Planning The GardenDocumento4 pagineGardening - Planning The Gardencontadino_impazzitoNessuna valutazione finora

- Canopy Mamagement 1Documento30 pagineCanopy Mamagement 1Nitesh PrasadNessuna valutazione finora

- Vegetable Based Cropping SystemDocumento4 pagineVegetable Based Cropping SystemRubi100% (1)

- RAWE Report - KVK Attachment - Submitted To SSUDocumento42 pagineRAWE Report - KVK Attachment - Submitted To SSUSayandeep BandyopadhyayNessuna valutazione finora

- Good Agricultural Practices For Irrigated and Rainfed Lowland Rice in East AfricaDocumento40 pagineGood Agricultural Practices For Irrigated and Rainfed Lowland Rice in East AfricaIRRI_resourcesNessuna valutazione finora

- Nursery Raising of Vegetables CropsDocumento7 pagineNursery Raising of Vegetables Cropsronalit malintad100% (2)

- Citrus Cultivation PDFDocumento13 pagineCitrus Cultivation PDFsohalsingh1Nessuna valutazione finora

- Indian GooseberryDocumento18 pagineIndian GooseberryManish M. Ramani100% (1)

- Banana Production Techniques-EswarDocumento65 pagineBanana Production Techniques-EswarDr.Eswara Reddy Siddareddy100% (1)

- PRACTICAL MANUAL (Crop Production and Mangemnt and Field Crop Production and Management Course)Documento59 paginePRACTICAL MANUAL (Crop Production and Mangemnt and Field Crop Production and Management Course)Tewachew Getahun100% (1)

- Citrus Crops PDFDocumento15 pagineCitrus Crops PDFLucky TraderNessuna valutazione finora

- Introduction To Major Field CropsDocumento217 pagineIntroduction To Major Field CropsRahul SunilNessuna valutazione finora

- Agro-Technology of Barley: (Hordeum Vulgare)Documento21 pagineAgro-Technology of Barley: (Hordeum Vulgare)Precious Prince100% (1)

- Seed Production in Self Pollinated Crops - WheatDocumento18 pagineSeed Production in Self Pollinated Crops - Wheatalemneh bayehNessuna valutazione finora

- Papaya Cultivation 056Documento17 paginePapaya Cultivation 056Sudhangsu Bhaumik100% (1)

- Laboratory Manual: HRT 241 Production Technology For Vegetables and Spices Laboratory (For Private Circulation Only)Documento61 pagineLaboratory Manual: HRT 241 Production Technology For Vegetables and Spices Laboratory (For Private Circulation Only)Ch Dheeraj RaoNessuna valutazione finora

- Organic Banana ProdDocumento9 pagineOrganic Banana ProdFlora May Arenga BillenaNessuna valutazione finora

- MangoCultivation PDFDocumento10 pagineMangoCultivation PDFcacsniteshNessuna valutazione finora

- Insect Pests of Brinjal-By Nanadana Nayana KumaraDocumento45 pagineInsect Pests of Brinjal-By Nanadana Nayana KumaraNandana Nayana KumaraNessuna valutazione finora

- Nursery Raising of Vegetable CropsDocumento31 pagineNursery Raising of Vegetable CropsJobanpreet SinghNessuna valutazione finora

- Introduction of Cerel and PulsesDocumento2 pagineIntroduction of Cerel and Pulsesvikasbnsl1Nessuna valutazione finora

- H. Seed Production, Processing, StorageDocumento77 pagineH. Seed Production, Processing, StoragePETER PAUL ESTILLER100% (1)

- Floral Biology and Fruit Set OF Mango, Citrus and Grape: M.Vijayalaxmi RHM/08-23 M.SC (Hort) 1 YrDocumento52 pagineFloral Biology and Fruit Set OF Mango, Citrus and Grape: M.Vijayalaxmi RHM/08-23 M.SC (Hort) 1 Yrpavani100% (5)

- Maize Production AgronomyDocumento4 pagineMaize Production AgronomySsemwogerere Charles50% (2)

- High Density Planting (HDP) & Ultra High Density Planting (Uhdp)Documento21 pagineHigh Density Planting (HDP) & Ultra High Density Planting (Uhdp)boonyongchira100% (2)

- SEED Study Materiyal-1Documento24 pagineSEED Study Materiyal-1Sridhar Sridhar100% (1)

- Protected Cultivation CourseDocumento23 pagineProtected Cultivation CourseMuhhib AttaullahNessuna valutazione finora

- Biological Pest Control of Plantation CropsDocumento31 pagineBiological Pest Control of Plantation Cropsabhishek padhyNessuna valutazione finora

- Cultivation of Cinnamon - Practices To FollowDocumento4 pagineCultivation of Cinnamon - Practices To FollowDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Seed TechnologyDocumento5 pagineSeed TechnologyNILESH KUMAR SINGH100% (1)

- Growing VegiesDocumento4 pagineGrowing Vegiessleepy_jacksonNessuna valutazione finora

- Plant IdeotypeDocumento20 paginePlant IdeotypeGopi Nath100% (1)

- Papaya Farming: How to Start a Profitable Papaya FarmDocumento12 paginePapaya Farming: How to Start a Profitable Papaya FarmAssefa FikaduNessuna valutazione finora

- Guide: Suggested Cultural Practices For Bitter GourdDocumento5 pagineGuide: Suggested Cultural Practices For Bitter GourdSaurabh NagwekarNessuna valutazione finora

- Pest ManagementDocumento10 paginePest ManagementJohn Fetiza ObispadoNessuna valutazione finora

- Seed Technology 312Documento414 pagineSeed Technology 312shiva kumar goud100% (1)

- Ac681e01 - FAO (2002) - The Lychee Crop in The Asia and PacificDocumento61 pagineAc681e01 - FAO (2002) - The Lychee Crop in The Asia and PacificedysutiarsoNessuna valutazione finora

- Tomato: Growing Practices and Nutritional InformationDa EverandTomato: Growing Practices and Nutritional InformationNessuna valutazione finora

- Precision Agriculture_ Embracing Technology for Efficient Crop ManagementDa EverandPrecision Agriculture_ Embracing Technology for Efficient Crop ManagementNessuna valutazione finora

- Insect Pests of Potato: Global Perspectives on Biology and ManagementDa EverandInsect Pests of Potato: Global Perspectives on Biology and ManagementAndrei AlyokhinNessuna valutazione finora

- A Pedal Operatedpedal Operated Coconut de HuskerDocumento3 pagineA Pedal Operatedpedal Operated Coconut de HuskerDr.Eswara Reddy SiddareddyNessuna valutazione finora

- 40 Amazing Facts About The Human BodyDocumento2 pagine40 Amazing Facts About The Human BodyDr.Eswara Reddy Siddareddy100% (1)

- How To How To Plant A HibiscusDocumento4 pagineHow To How To Plant A HibiscusDr.Eswara Reddy Siddareddy100% (1)

- Importance of Betel VineDocumento3 pagineImportance of Betel VineDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Say No To Sugar, Opt For JaggeryDocumento3 pagineSay No To Sugar, Opt For JaggeryDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Eating Vegetables For Good HealthDocumento11 pagineEating Vegetables For Good HealthDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Banana Fibre ExtractionDocumento41 pagineBanana Fibre ExtractionDr.Eswara Reddy SiddareddyNessuna valutazione finora

- White Roses.Documento27 pagineWhite Roses.Dr.Eswara Reddy SiddareddyNessuna valutazione finora

- Guar Stateplan DataDocumento45 pagineGuar Stateplan DataDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Child LabourDocumento13 pagineChild LabourDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Carnival in Rio de JaineroDocumento16 pagineCarnival in Rio de JaineroDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Efficient Seed Extraction in BrinjalDocumento2 pagineEfficient Seed Extraction in BrinjalDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Influence of Gibberellic Acid On Citrus FuitsDocumento2 pagineInfluence of Gibberellic Acid On Citrus FuitsDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Ten Devil Plants To KnowDocumento6 pagineTen Devil Plants To KnowDr.Eswara Reddy Siddareddy100% (2)

- How Seed Is Extracted in TomatoDocumento4 pagineHow Seed Is Extracted in TomatoDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Golden Words of HitlerDocumento4 pagineGolden Words of HitlerDr.Eswara Reddy SiddareddyNessuna valutazione finora

- List of Stocks in PDSR (Department)Documento19 pagineList of Stocks in PDSR (Department)Dr.Eswara Reddy SiddareddyNessuna valutazione finora

- Flower and Fruit Drop in Litchi (Litchi Chinensis Sonn) .Documento3 pagineFlower and Fruit Drop in Litchi (Litchi Chinensis Sonn) .Dr.Eswara Reddy Siddareddy100% (1)

- Build A Beautiful LifeDocumento38 pagineBuild A Beautiful LifeDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Cold Injury To Fruit PlantsDocumento2 pagineCold Injury To Fruit PlantsDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Solanum Review LiteratureDocumento19 pagineSolanum Review LiteratureDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Sun Burning and Cracking in LitchiDocumento2 pagineSun Burning and Cracking in LitchiDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Water Melon CultivationDocumento5 pagineWater Melon CultivationDr.Eswara Reddy SiddareddyNessuna valutazione finora

- PINEAPPLE-The Sweet Treat That Relieves Arthritis PainDocumento5 paginePINEAPPLE-The Sweet Treat That Relieves Arthritis PainDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Women, Horticlture and EnvironmentDocumento4 pagineWomen, Horticlture and EnvironmentDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Davanam CultivationDocumento4 pagineDavanam CultivationDr.Eswara Reddy SiddareddyNessuna valutazione finora

- What Is HorticultureDocumento9 pagineWhat Is HorticultureDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Mango Garden To House PlotsDocumento17 pagineMango Garden To House PlotsDr.Eswara Reddy SiddareddyNessuna valutazione finora

- Herbal Oil MassageDocumento39 pagineHerbal Oil MassageDr.Eswara Reddy Siddareddy100% (1)

- Indian Foods With SpicesDocumento49 pagineIndian Foods With SpicesDr.Eswara Reddy SiddareddyNessuna valutazione finora

- A320 Flex CalculationDocumento10 pagineA320 Flex CalculationMansour TaoualiNessuna valutazione finora

- Comparison of Unix and Dos: AssignmentDocumento10 pagineComparison of Unix and Dos: AssignmentMohsin ShakoorNessuna valutazione finora

- Ref ModulesDocumento148 pagineRef ModuleshoneyNessuna valutazione finora

- Assumptions of Indifference CurveDocumento12 pagineAssumptions of Indifference CurveAbhishek RavalNessuna valutazione finora

- Fuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DDocumento2 pagineFuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DMar WilkNessuna valutazione finora

- 3 - Big Data CharacteristicsDocumento32 pagine3 - Big Data CharacteristicsWong pi wenNessuna valutazione finora

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDocumento33 pagineKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaNessuna valutazione finora

- GITAM Guidelines For MBA Project Work - 2018Documento6 pagineGITAM Guidelines For MBA Project Work - 2018Telika RamuNessuna valutazione finora

- 08 - Chapter 1 - Waveguide-Transmission Line - Microstrip LinesDocumento76 pagine08 - Chapter 1 - Waveguide-Transmission Line - Microstrip Linesgilberto araujoNessuna valutazione finora

- Steam Technical InfoDocumento2 pagineSteam Technical InfoAnonymous 7z6OzoNessuna valutazione finora

- Adss-Eke 150 (Mm12c) eDocumento7 pagineAdss-Eke 150 (Mm12c) eYuseidy Rguez PaezNessuna valutazione finora

- UniSim Heat Exchangers User Guide PDFDocumento22 pagineUniSim Heat Exchangers User Guide PDFzhangyiliNessuna valutazione finora

- Resultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Documento3 pagineResultados de La Web: GDDS - Traducción Al Español - Ejemplos Inglés - Reverso ..Jo PaterninaNessuna valutazione finora

- Animated Film Techniques for Phrasing Action and DialogueDocumento10 pagineAnimated Film Techniques for Phrasing Action and Dialoguevall-eNessuna valutazione finora

- Nursing ProcessDocumento88 pagineNursing ProcessGerard On LineNessuna valutazione finora

- ISO/TC 46/SC 9/working Group 1Documento4 pagineISO/TC 46/SC 9/working Group 1João Paulo CésarNessuna valutazione finora

- Planets Classification Malefic and BeneficDocumento3 paginePlanets Classification Malefic and Beneficmadhu77Nessuna valutazione finora

- Product Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityDocumento1 paginaProduct Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityKABIR CHOPRANessuna valutazione finora

- Port Ps PDFDocumento2 paginePort Ps PDFluisNessuna valutazione finora

- Elements of TQM: Dr. Sanjay MahalingamDocumento7 pagineElements of TQM: Dr. Sanjay Mahalingamuday saiNessuna valutazione finora

- Calicut University: B. A PhilosophyDocumento6 pagineCalicut University: B. A PhilosophyEjaz KazmiNessuna valutazione finora

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersDocumento153 pagineXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiNessuna valutazione finora

- Ticket SunilDocumento2 pagineTicket SunilDURGA PRASAD TRIPATHYNessuna valutazione finora

- ADV7513 Hardware User GuideDocumento46 pagineADV7513 Hardware User Guide9183290782100% (1)

- SAP PPM 5.0 Certification Exam TopicsDocumento7 pagineSAP PPM 5.0 Certification Exam TopicsongkecanthoNessuna valutazione finora

- Ichiban Ushiro No Daimaou Act 7Documento161 pagineIchiban Ushiro No Daimaou Act 7Haif Al HajrafNessuna valutazione finora

- Public Speaking RulesDocumento12 paginePublic Speaking RulesAnonymous 0ejRGUpmo1Nessuna valutazione finora

- Sheet Metalworking 1 - Chapter 19Documento99 pagineSheet Metalworking 1 - Chapter 19xharpreetxNessuna valutazione finora

- Exp# 1c Exec System Call Aim: CS2257 Operating System LabDocumento3 pagineExp# 1c Exec System Call Aim: CS2257 Operating System LabAbuzar ShNessuna valutazione finora

- Types of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaDocumento7 pagineTypes of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaJimnadominicNessuna valutazione finora